Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

SAIC-J - 6603 Rev 0 PDF

Caricato da

josediaz141Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

SAIC-J - 6603 Rev 0 PDF

Caricato da

josediaz141Copyright:

Formati disponibili

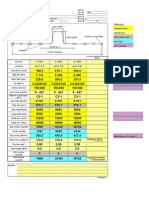

SAUDI ARAMCO ID/PID - 2/19/05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

Instrument Cable-Thermo-Couple Extension Cable-Material

Receiving

PROJECT TITLE

SAIC NUMBER

SAIC-J-6603

WBS / BI / JO NUMBER

EQUIPMENT ID NUMBER(S)

EQUIPMENT DESCRIPTION

LAYOUT DRAWING NUMBER

REV. NO.

SCHEDULED INSPECTION DATE & TIME

ACTUAL INSPECTION DATE & TIME

DATE APPROVED

1-Oct-05

QR NUMBER

INST

CONTRACTOR / SUBCONTRACTOR

EQPT CODE

SYSTEM ID.

PURCHASE ORDER NUMBER

PLANT NO.

EC / PMCC / MCC NO.

QUANTITY INSP.

MH's SPENT

TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER

SAUDI ARAMCO ACTIVITY NUMBER

SAUDI ARAMCO INSPECTION LEVEL

CONTRACTOR INSPECTION LEVEL

ITEM

No.

A.

ACCEPTANCE CRITERIA

REFERENCE

Certification and Third-Party Listing

Schedule Q,

Att, IV, Sec. 3.1.

A1

Review Quality Documentation for Material Receiving.

A2

New and Unused - Instrumentation materials shall be new and unused.

A3

A4

As Designed - Instrumentation materials shall be in accordance with the

Saudi Aramco-approved project-specific design drawings, diagrams,

schedules, lists, databases, and associated documents.

Free of Damage - Instrumentation materials shall be free of damage. All

Incoming material shall be visually inspected for damage and

conformance to all applicable inspection releases with Material Test

Report (MTR).

Schedule "G"

Sec. 4.1

Schedule "G"

Sec. 4.1

Schedule "Q"

Attachment lV

Sec 7.1

A5

QC Before Installation - Instrumentation materials shall conform to all

applicable requirements, standards, and specifications prior to release to

be used as part of the work.

Schedule "Q"

Attachment lV

Sec 7.1

A6

Traceability - Instrumentation materials shall be traceable from the

manufacturer and supplier through delivery, storage, fabrication,

erection, installation, repair, modification and use.

Schedule "Q"

Attachment lV

Sec. 3.3

A7

Verify that the contractor or it's Saudi Aramco approved third party

inspector performed the quality activities at the supplier and sub-supplier

locations as required by the inspection level assigned for the materials

and equipment identified in SAER-1972 Inspection Requirements.

Schedule Q

Attachment llI

Sec 1.2

A8

Cable materials supplied shall be third-party listed as meeting the

requirements of UL

standards ANSI MC 96.1 Temperature measurement Thermocouples

34-SAMSS-913

Sec. 3.2

A9

Inspection Items manufactured to this Specification (34-SAMSS-913) are

subject to the minimum inspection requirements as specified in Saudi

Aramco Inspection Requirements Form 175-347600. 9.2

34-SAMSS-913

Sec. 9.1

A10

Nonmaterial Requirements The supplier shall provide nonmaterial items

as shown on Form NMR-7930.

34-SAMSS-913

Sec. 9.2

A11

Vendor to provide certification that the Thermocouple extension wire is

suitable for the specific type of thermocouple being connected.

Thermocouple extension wire shall meet the requirements of ISA/ANSI

MC96.1 and 34-SAMSS-913 and shall be installed in accordance with

SAES-J-902. Each pair shall be individually twisted and shielded.

SAES-J-400,

Sec.6.3.1

Page 1 of 6

WORK PERMIT REQUIRED?

PASS

FAIL

N/A

RE-INSP DATE

SAUDI ARAMCO ID/PID - 2/19/05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

Instrument Cable-Thermo-Couple Extension Cable-Material

Receiving

PROJECT TITLE

ITEM

No.

SAIC NUMBER

SAIC-J-6603

WBS / BI / JO NUMBER

ACCEPTANCE CRITERIA

REFERENCE

Oil Resistant Cable:Cable intended for applications where it may be

exposed to hydrocarbon oil shall be so designated on Form 8020-913A12

ENG, Line Item 28. The manufacturer shall certify that the cable is

resistant to hydrocarbon oil or as indicated on the specification sheet.

B. Material Requirements

Purchase Order and Instrument specification sheet criteria shall be

confirmed and compared with instrument stainless steel tags / labels

B1

and nameplates, and shipment checked for damage, prior to acceptance

of the shipment

34-SAMSS-913,

Sec. 6.8.2

Schedule Q,

Att IV, Sec. 7.1.

B2

Conductor: Solid thermocouple extension wire per ANSI

MC96.1(Attachment 1& 2)

34-SAMSS-913,

Sec. 6.6.1

B3

Conductor Size: 16 AWG for single pair; 18 AWG for multiple pair; or as

specified on Form 8020-913-ENG, Line Item 13

34-SAMSS-913,

Sec. 6.6.2

B4

B5

Primary Insulation Material: Flame retardant PVC or thermoset

crosslinked polyolefin (XLPO or XLPE), minimum temperature rating

90C.

Primary Insulation Voltage Rating:

300 V

34-SAMSS-913,

Sec. 6.6.3

34-SAMSS-913,

Sec.6.6.4.

B6

Primary Insulation Thickness: 0.38 mm (15 mils) minimum average

thickness

34-SAMSS-913,

Sec. 6.6.5

34-SAMSS-913,

Sec. 6.6.6

34-SAMSS-913,

Sec. 6.6.7

B7

Assembly: Two insulated conductors uniformly twisted into a pair

B8

Lay of Twist: 40 to 60 mm

B9

Color Code: Per ANSI MC.96.1

B10

Number of Pairs or Triads: Refer to Form 8020-913-ENG, line item 12.

Manufacturer's standard products, meeting or exceeding this number is

acceptable upon approval of Buyer

34-SAMSS-913,

Sec. 6.6.9

B11

Pair Identification: Number designation continuously stamped on

conductor (Multiple pair only)

34-SAMSS-913,

Sec. 6.4.10

B12

Cable Assembly: Single grouped assembly, per Manufacturer's standard

34-SAMSS-913,

Sec. 6.4.11

B13

Communication Wire: Not required. If provided, shall be Manufacturer's

standard size; insulation same as primary insulation; orange color

34-SAMSS-913,

Sec. 6.4.12

B14

Individual Shield Material: Aluminum foil bonded to non-hygroscopic

polyester (Mylar) tape, either: foil free-edge or equal-width foil and tape,

per Manufacturer's standard

34-SAMSS-913,

Sec. 6.6.13

B15

Individual Shield Thickness: 0.022 mm (0.85 mil) minimum

34-SAMSS-913,

Sec. 6.6.14

B16

Individual Shield Application: Helical, minimum 25% overlap, to provide

100% coverage and electrical isolation from other shields and

conductors

34-SAMSS-913,

Sec. 6.6.15

B17

Individual Shield Drain Wire Conductor:Solid or stranded (7 strands

minimum), circular tinned copper, per ASTM B33

34-SAMSS-913,

Sec. 6.6.16

B18

Individual Shield Drain Wire Size: Manufacturer's standard, with

minimum size one even gauge size smaller than conductor size

34-SAMSS-913,

Sec. 6.6.17

B19

Individual Shield Drain Wire Application: In continuous contact with

shield foil

34-SAMSS-913,

Sec. 6.6.18

B20

Overall Shield Material: Aluminum foil bonded to non-hygroscopic

polyester (Mylar) tape, either: foil free-edge or equal-width foil and tape,

per Manufacturer's standard

34-SAMSS-913,

Sec. 6.6.19

34-SAMSS-913,

Sec. 6.3.8 & 6.5.8

Page 2 of 6

DATE APPROVED

1-Oct-05

QR NUMBER

INST

CONTRACTOR / SUBCONTRACTOR

PASS

FAIL

N/A

RE-INSP DATE

SAUDI ARAMCO ID/PID - 2/19/05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

Instrument Cable-Thermo-Couple Extension Cable-Material

Receiving

PROJECT TITLE

ITEM

No.

B21

B22

B23

B24

B25

B26

B27

B28

B29

SAIC NUMBER

SAIC-J-6603

WBS / BI / JO NUMBER

ACCEPTANCE CRITERIA

REFERENCE

Overall Shield Thickness: 0.022 mm (0.85 mil) minimum

34-SAMSS-913,

Sec. 6.6.20

Overall Shield Application: Helical, minimum 25% overlap, to provide

100% coverage and electrical isolation from conductors and other

shields

Overall Shield Drain Wire Conductor: Stranded, circular tinned copper,

per ASTM B33, 7 strands minimum

34-SAMSS-913,

Sec. 6.6.22

Overall Shield Drain Wire Size: Manufacturer's standard, with minimum

size one even gauge size smaller than conductor size

34-SAMSS-913,

Sec. 6.6.23

34-SAMSS-913,

Sec. 6.6.21

Overall Shield Drain Wire Application: In continuous contact with shield

34-SAMSS-913,

foil

Sec. 6.6.24

Jacket Material: Flame retardant PVC, minimum temperature rating 90C 34-SAMSS-913,

dry, 75C wet

Sec. 6.6.25

Jacket Thickness:

34-SAMSS-913,

Minimum thickness per UL 13, paragraph 13.1 for Type PLTC

Sec. 6.6.26

34-SAMSS-913,

Jacket Application: Extruded over assembly

Sec. 6.6.27

34-SAMSS-913,

Jacket Color: Per ANSI MC96.1

Sec. 6.6.28

B22

Outer Jacket Marking

The following information shall be clearly marked on the outer jacket of

the cable, in no specific order: a) Manufacturer's name, trade name,

catalog or type number b) Number of pairs/triads c) Conductor size in

mm or AWG d) Voltage rating (300 or 600 V) e) Type of cable (PLTC,

TC or equivalent) f) Approval mark of listing authority (UL, IEC, BS, DIN,

or equivalent) g) "Sunlight resistant" designation, in Manufacturer's

standard nomenclature, for Type TC cable (Optional for Type PLTC

cable) h) "Direct burial" designation, if applicable per UL 13 or UL 1277,

in Manufacturer's standard nomenclature i) "Oil resistant" designation, in

manufacturer's standard nomenclature, for Type TC Cable (preferred for

Types ITC and PLTC Cable)

34-SAMSS-913,

Sec. 7.1

B23

Cable Reel Marking

Each reel shall have a weatherproof (metal or plastic) tag, securely

attached to a flange of the reel and plainly stating:

a) Manufacturer's trade name

b) Date of manufacture

c) Conductor size

d) Cable rating

e) Type of cable

f) Temperature designation

g) Minimum bend radius

h) Maximum pulling tension

i) Shipping length and diameter of cable

j) Saudi Aramco Purchase Order number

34-SAMSS-913,

Sec.7.2

Cables installed in Zone 1 (Class -1, Div.-1) shall be listed as suitable for

that classified area. I

Cables used in other classified areas shall meet the requirements

outlined in NFPA 70 (NEC), articles 501-505. 2.

SAESJ--902,

Note 1

SAESJ--902,

Note 1

B26

. Differences in the manufacturer recommended cable and these

requirements shall be resolved with Instrumentation Unit/PID/P&CSD.

SAESJ--902,

Note 4

B27

Capacitance, Inductance, Resistance, L/R Ratio

Cables for applications which require mutual capacitance, conductor-toground capacitance, resistance and/or L/R (inductance-to-resistance)

ratio to be within specified limits shall comply with the values listed on

Form 8020-913-ENG, Line Items 31 through 36.

B24

B25

Page 3 of 6

34-SAMSS-913,

Sec. 6.8.3

DATE APPROVED

1-Oct-05

QR NUMBER

INST

CONTRACTOR / SUBCONTRACTOR

PASS

FAIL

N/A

RE-INSP DATE

SAUDI ARAMCO ID/PID - 2/19/05 - REV 0 (Standards Cutoff - August 2004)

SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Instrument Cable-Thermo-Couple Extension Cable-Material

Receiving

PROJECT TITLE

ITEM

No.

DATE APPROVED

SAIC-J-6603

WBS / BI / JO NUMBER

ACCEPTANCE CRITERIA

REFERENCE

B28

Thermocouples and extension wires shall meet the requirements as

detailed in table 1-6 ( Aattachment 1-2) to establish uniformity in the

designation of thermocouples and extension wires and to provide, by

means of the color of its insulation, an identification of its type or

composition as well as its polarity when used as part of a thermocouple

system.[ ISA-MC96.1-1982 Sec.1]

SAES-J-400,

Sec.6.1.1

B29

The wire sizes normally used for non-sheathed thermocouples shall

meet the following requirements:

For J, K, and E: 8, 14, 20, 24, and 28 AWG*

For T: 14, 20, 24, and 28 AWG*

For R, S and B: 24 AWG* only[ ISA-MC96.1-1982 Sec. 2.3.1]

SAES-J-400,

Sec.6.1.1

B30

Extension wires shall comply with the following: The wire sizes normally

used for extension wire, either singly or in pairs, are 14, 16, and 20

AWG*. Sixteen (16) gage is most commonly used. Twenty (20) gage and

smaller may be used when bundled and reinforced to provide strength for

pulling. These sizes apply to all types of extension wires.[ISA-MC96.11982 Sec. 2.3.2]

SAES-J-400,

Sec.6.1.1

1-Oct-05

QR NUMBER

INST

CONTRACTOR / SUBCONTRACTOR

PASS

FAIL

N/A

RE-INSP DATE

REMARKS:

REFERENCE DOCUMENTS:

1. Schedule G -- Material, Tools and Equipment (Pro Forma MP-IK-LS Contract), July 1993

2. Schedule Q -- Quality Requirements (Pro Forma Contract), November 2003

3. SAES-J-902, Electrical Systems for Instrumentation, 31 July 2004

4. 34-SAMSS-913 Instrumentation and Thermocouple Cable, 30 June 2002

ATTACHMENTS:

1. Attachment 1 -- Thermo Couple Wire and Extension Wires-Requirements as detailed in ANSI MC96.1-, 1982

2. Attachment 2 -- Symbols For Different Types OF Thermocouple Wire

NOTES:

1. Approved - Acceptable to the authority having jurisdiction (i.e., Saudi Aramco ID).

2. Identified - Recognizable as suitable for the specific application by a qualified testing laboratory (i.e., listing and/or labeling).

3. Listed - Equipment and materials included in a list published by an approved qualified organization concerned with evaluation of products

or services, that maintains periodic inspection of production of listed equipment or materials or periodic evaluation of services, and whose listing

that the equipment, material, or services either meets appropriate designated standards or has been tested and found suitable for a specified

4. Labeled - Equipment or materials to which has been attached a label, symbol, or other identifying mark of an approved qualified organization

with product evaluation, that maintains periodic inspection of production of labeled equipment or materials, and by whose labeling the

indicates compliance with appropriate standards or performance in a specified manner.

Contractor / Third-Party

Saudi Aramco

Construction Representative*

PMT Representative

Work is Complete and Ready for Inspection:

Name, Initials and Date:

T&I Witnessed

QC Record Reviewed

Work Verified

T&I Witnessed

QC Record Reviewed

Work Verified

T&I Witnessed

QC Record Reviewed

Work Verified

Name, Initials and Date:

PID Representative

QC Inspector

Performed Inspection

Work / Rework May Proceed

Name, Initials and Date:

Name, Initials and Date:

QC Supervisor

Proponent and Others

Quality Record Approved:

Name, Sign and Date:

Name, Organization,

Initials and Date:

*Person Responsible for Completion of Quality Work / Test

Y = YES

Page 4 of 6

N = NO F = FAILED

SAUDI ARAMCO ID/PID - 2/19/05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

Instrument Cable-Thermo-Couple Extension Cable-Material

Receiving

SAIC NUMBER

SAIC-J-6603

DATE APPROVED

1-Oct-05

QR NUMBER

INST

Attachment 1 -- Thermo Couple Wire and Extension Wires-Requirements as detailed in ANSI MC96.1-, 1982

Page 5 of 6

SAUDI ARAMCO ID/PID - 2/19/05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

Instrument Cable-Thermo-Couple Extension Cable-Material

Receiving

SAIC NUMBER

SAIC-J-6603

DATE APPROVED

1-Oct-05

Attachment 2 -- SYMBOLS FOR TYPES OF THERMOCOUPLE WIRE

Page 6 of 6

QR NUMBER

INST

Potrebbero piacerti anche

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Functional Safety Practices For OperationsDocumento14 pagineFunctional Safety Practices For OperationsLuc SchramNessuna valutazione finora

- Satr-W-2008 Atyb TRDocumento6 pagineSatr-W-2008 Atyb TRDeo MNessuna valutazione finora

- Variable Speed DrivesDocumento44 pagineVariable Speed Drivesmnt6176100% (2)

- Sprinkler System ComponentsDocumento68 pagineSprinkler System Componentsjosediaz141Nessuna valutazione finora

- Risk Assessment - Group A (GROCERY STORE)Documento12 pagineRisk Assessment - Group A (GROCERY STORE)Eiron UnoNessuna valutazione finora

- Alfred Tuggy y John Stegenga - Concordancia Analítica Greco EspañolaDocumento1.073 pagineAlfred Tuggy y John Stegenga - Concordancia Analítica Greco Españolajosediaz141100% (1)

- Moa-Contract For ServicesDocumento4 pagineMoa-Contract For ServicesJohn Mark Paracad100% (1)

- Pipe Is Under Clamping ForceDocumento7 paginePipe Is Under Clamping Forcejosediaz141Nessuna valutazione finora

- Mitsubishi Case StudyDocumento19 pagineMitsubishi Case StudyAmar KunamNessuna valutazione finora

- Financial Statement and Ratio Analysis of Tata MotorsDocumento120 pagineFinancial Statement and Ratio Analysis of Tata MotorsAMIT K SINGH100% (1)

- 520 L 0541Documento36 pagine520 L 0541eb.silvaNessuna valutazione finora

- Polaroid SX-70 SONAR ManualDocumento41 paginePolaroid SX-70 SONAR ManualRando Personisian100% (1)

- Tyco Channel Design Software Installation InstructionsDocumento5 pagineTyco Channel Design Software Installation Instructionsjosediaz141Nessuna valutazione finora

- SketchDocumento3 pagineSketchjosediaz141Nessuna valutazione finora

- Piping Design InfoDocumento279 paginePiping Design Infojosediaz141Nessuna valutazione finora

- B31 (1) .11 Pipe Thickness CalculationsDocumento2 pagineB31 (1) .11 Pipe Thickness Calculationsjosediaz141Nessuna valutazione finora

- Discharge PR Drop Pipe SizeDocumento12 pagineDischarge PR Drop Pipe Sizejosediaz141Nessuna valutazione finora

- Underground Pipe Stress CheckDocumento9 pagineUnderground Pipe Stress CheckpertmasterNessuna valutazione finora

- Simple Loop1Documento8 pagineSimple Loop1josediaz141Nessuna valutazione finora

- Equipment Design Rubric-WrittenDocumento2 pagineEquipment Design Rubric-WrittenSam Denielle TugaoenNessuna valutazione finora

- IEC Grounding TerminologyDocumento6 pagineIEC Grounding TerminologyjoapmeNessuna valutazione finora

- Fisher Specification Manager SoftwareDocumento4 pagineFisher Specification Manager SoftwarehrtoroNessuna valutazione finora

- QC QaDocumento44 pagineQC Qacabrel TokamNessuna valutazione finora

- Section 'H-H' Section 'J-J' Section 'L-L'Documento1 paginaSection 'H-H' Section 'J-J' Section 'L-L'Rakesh ReddyNessuna valutazione finora

- Royal Petro Energy: Bridging The GapDocumento1 paginaRoyal Petro Energy: Bridging The GapgenebabaNessuna valutazione finora

- Residential Slabs and Footings Workshop 1 DayDocumento1 paginaResidential Slabs and Footings Workshop 1 DayredpuffNessuna valutazione finora

- Value Stream MappingDocumento40 pagineValue Stream Mappingjinyue7302Nessuna valutazione finora

- Introduction To MS ACCESSDocumento27 pagineIntroduction To MS ACCESSMannMann0% (1)

- Phase-Sequence Phase-Loss Relay: K8AB-PH1-LDocumento8 paginePhase-Sequence Phase-Loss Relay: K8AB-PH1-LNguyễn Thanh QuangNessuna valutazione finora

- Resuscitators Blife Coblife Problife W R-Valve Rev3 enDocumento10 pagineResuscitators Blife Coblife Problife W R-Valve Rev3 enraulst1Nessuna valutazione finora

- S-Mart Seal Material and Profile OverviewDocumento8 pagineS-Mart Seal Material and Profile OverviewTimon2005Nessuna valutazione finora

- Modernization of Metal Electroplating With No Mask FixturesDocumento20 pagineModernization of Metal Electroplating With No Mask FixturestonymailinatorNessuna valutazione finora

- Karla CV EnglishDocumento3 pagineKarla CV Englishapi-259644073Nessuna valutazione finora

- Modeling of Composite Tubes Using ANSYSDocumento26 pagineModeling of Composite Tubes Using ANSYSmathewalex18Nessuna valutazione finora

- CCD 0001920Documento2 pagineCCD 0001920Freddy Jose BracamonteNessuna valutazione finora

- C3W Distributor Valve Test DataDocumento10 pagineC3W Distributor Valve Test DataChandra Mohan Rawat0% (1)

- Mmsu Cfat BN 14925 PDFDocumento2 pagineMmsu Cfat BN 14925 PDFJericoNessuna valutazione finora

- 2008 - SeptemberDocumento13 pagine2008 - SeptemberComox Air Force MuseumNessuna valutazione finora

- Tugas Individu Audit IIDocumento4 pagineTugas Individu Audit IIChelsea KambeyNessuna valutazione finora

- Neil Armstrong Interview (1969)Documento8 pagineNeil Armstrong Interview (1969)Aviation/Space History LibraryNessuna valutazione finora