Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Noverite AD 810G1 PDF

Caricato da

maheshTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Noverite AD 810G1 PDF

Caricato da

maheshCopyright:

Formati disponibili

TECHNICAL DATA SHEET

TDS-854

Edition: June 16, 2016

Original Date of Issue: May 21, 2014

Noverite AD 810G Polymer

A Multifunctional Polymeric Co-Builder for Household and

I&I Applications

Introduction

Noverite AD 810G Polymer is a novel acrylic

terpolymer designed to deliver chelating, antifilming, crystal-growth modification and soil suspension properties to a wide range of applications.

The polymer composition is targeted to deliver

excellent anti-spotting and anti-filming properties in

phosphate-free dishwashing formulations, including

liquid, powder, and unit-dose tablet formats.

Noverite AD 810G polymer can eliminate the need

for other polymers in the formulation and be

combined with sodium citrate and other builders to

deliver high performance solutions which meet

phosphate regulations at a competitive total

formulation cost.

Physical Properties

Typical properties for Noverite AD 810G polymer:

Appearance

Total Activity

Bulk Density (Kg/m3)

Particle Size Range

(400 - 1,000 m)

White to light yellow free

flowing granular

>88 wt% active polymer

(2-12% moisture)

400 - 1,000

Benefits

Noverite AD 810G polymer is a multifunctional

ingredient with the following key benefits:

Typical Use Levels

Application

Auto Dish

Detergents

Unit dose tablet or

sachet

Ecolabel unit dose

tablet or sachet

Enzyme gel

Chlorine gel

Noverite Use

AD 810

Rate

Grade

TS %

Suggested

Co-Builder

Use

Rate

TS %

AD 810G

3-15 Sodium Citrate 10-30

AD 810G

3-4

Sodium Citrate 20-30

AD 810N

AD 810N

3-5

1-5

Sodium Citrate 15-20

N/A

N/A

Note: Glutamic acid diacetic acid (GLDA) may be used as

a partial or whole replace of Sodium Citrate in enzyme gels

formulations. Methylglycinediacetic acid (MGDA) may be

used as a partial or whole replacement of Sodium Citrate in

unit dose or sachets formulations.

Noverite AD 810G polymer is also available in a

liquid form known as Noverite AD 810N polymer.

650 m

Formal product specifications are available upon request.

Application Suggestions

The features and benefits of Noverite AD 810G

polymer make it an ideal candidate for use in

formulating products such as:

Automatic dish detergents

Surface cleaners

Institutional warewashing detergents

Chelating, anti-scaling, and anti-filming

polymeric co-builder

Suitable for use in unit-dose, powder or liquid

formulations

When combined with sodium citrate, provides

cost-effective formulations

For high performance phosphate-free

formulations

Provides excellent replacement for other

polymeric co-builders and builders

Storage and Handling

Packaging: Polyethylene lined, paper bags with a

net weight of 25 kilograms and supersacks

Shelf life: 1 year in a tightly sealed container from

date of manufacture.

Storage temperature: 5-30C (41-86F). Store in

a dry, clean place away from direct heat, light or

sparks.

Keep bags of product sealed until needed.

Keep partially used bags in a humidity controlled

room to prevent moisture uptake.

Consult the product SDS for additional safety and

handling information.

Meets criteria for U.S. Environmental Protection Agency (EPA) Safer Chemical Ingredient under the Safer Choice program

Lubrizol Advanced Materials, Inc. / 9911 Brecksville Road, Cleveland, Ohio 44141-3247 / TEL: 800.379.5389 or 216.447.5000

The information contained herein is being furnished

for informational purposes only, upon the express condition

that the User makes its own assessment of the appropriate

use of such information. While the information contained

herein is believed to be reliable, no representations,

guarantees or warranties of any kind are made as to its

accuracy, suitability for a particular application or the

results to be obtained herefrom.

Lubrizol Advanced

Materials, Inc. ("Lubrizol") cannot guarantee how any

products associated with this information will perform in

combination with other substances or in the Users process.

Due to variations in methods, conditions and equipment

used commercially in processing these materials, no

warranties or guarantees are made as to the suitability of

the information or products for the applications

disclosed. Lubrizol shall not be liable and the User

assumes all risk and responsibility for any use or

handling of any material beyond Lubrizol's direct

control. LUBRIZOL MAKES NO WARRANTIES, EXPRESS

OR IMPLIED, INCLUDING, BUT NOT LIMITED TO,

THE IMPLIED WARRANTIES OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE. It is the

Users sole responsibility to determine if there are any

issues relating to patent infringement of any component or

combination of components relating to the supplied

information. Nothing contained herein is to be

considered as permission, recommendation, nor as an

inducement to practice any patented invention without

permission of the patent owner.

For further information, please visit: www.lubrizol.com/homecare

Lubrizol Advanced Materials, Inc. is a wholly owned subsidiary of The Lubrizol Corporation

All trademarks owned by The Lubrizol Corporation

Copyright 2016 / The Lubrizol Corporation

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Sorez HS 205 Soil Release Polymer Presentation VFDocumento24 pagineSorez HS 205 Soil Release Polymer Presentation VFmaheshNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- FoodContact CERAFLOUR 913 EN PDFDocumento2 pagineFoodContact CERAFLOUR 913 EN PDFmaheshNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Noverite AD 810G PDFDocumento1 paginaNoverite AD 810G PDFmaheshNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Sorez-205 Sell Sheet VF PDFDocumento2 pagineSorez-205 Sell Sheet VF PDFmaheshNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Sensomer CI-50 PDFDocumento2 pagineSensomer CI-50 PDFmaheshNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- TDS Ceraflour 998 Us PDFDocumento2 pagineTDS Ceraflour 998 Us PDFmaheshNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Bindzil PDFDocumento1 paginaBindzil PDFmaheshNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Reach SQ Ceraflour 1000 en PDFDocumento4 pagineReach SQ Ceraflour 1000 en PDFmaheshNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Aquacer 497 en PDFDocumento2 pagineAquacer 497 en PDFmaheshNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Varisoft222LM90-TDS-02 19 09 PDFDocumento2 pagineVarisoft222LM90-TDS-02 19 09 PDFmaheshNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Methocel Coating PolymersDocumento36 pagineMethocel Coating PolymersPradeep BhimaneniNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- SDS CERAFLOUR 1000 US en PDFDocumento10 pagineSDS CERAFLOUR 1000 US en PDFmaheshNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- FoodContact CERAFLOUR 1000 EN PDFDocumento2 pagineFoodContact CERAFLOUR 1000 EN PDFmaheshNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- 0902770182ca660e PDFDocumento22 pagine0902770182ca660e PDFmaheshNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- EHEDG Yearbook 2015 2016Documento180 pagineEHEDG Yearbook 2015 2016mahesh100% (2)

- SANOVO Maxi Bag FillerDocumento1 paginaSANOVO Maxi Bag FillermaheshNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Suchit CVDocumento3 pagineSuchit CVmaheshNessuna valutazione finora

- Masterflow 810 - MSDS - 270212 - SGDocumento9 pagineMasterflow 810 - MSDS - 270212 - SGmidaNessuna valutazione finora

- WD-40 3-In-One Drip Oil MSDSDocumento5 pagineWD-40 3-In-One Drip Oil MSDSHai HaNessuna valutazione finora

- Damar ResinDocumento3 pagineDamar ResinKukuh Satrio WibowoNessuna valutazione finora

- Method Statement & Risk Assessment Installation of VAVDocumento16 pagineMethod Statement & Risk Assessment Installation of VAVAbu Muhammed KhwajaNessuna valutazione finora

- Polymatrix MSDSDocumento4 paginePolymatrix MSDSpallab mukhopadhyayNessuna valutazione finora

- Finish Powerball Quantum Ultimate Pro DishwashingDocumento10 pagineFinish Powerball Quantum Ultimate Pro DishwashingCatalin DonceaNessuna valutazione finora

- Hi-Stick Spray Paint MsdsDocumento6 pagineHi-Stick Spray Paint MsdszayzanNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Carquest Wearever Non Chlorinated Brake Parts Cleaner W7341 PDFDocumento12 pagineCarquest Wearever Non Chlorinated Brake Parts Cleaner W7341 PDFYoutube For EducationNessuna valutazione finora

- Msds OxalatDocumento4 pagineMsds OxalatAnggit PermataNessuna valutazione finora

- fC469.50 (DG-GHS)Documento8 paginefC469.50 (DG-GHS)Mohammed Tanjil Morshed remonNessuna valutazione finora

- Descaler MSDSDocumento5 pagineDescaler MSDSAbdul Malik AnsariNessuna valutazione finora

- Tailing MSDSDocumento2 pagineTailing MSDSZacNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Vol Vi A - Terminal and Tank Farm Odpcp - Donlin Gold Project - August 2012Documento110 pagineVol Vi A - Terminal and Tank Farm Odpcp - Donlin Gold Project - August 2012yeNessuna valutazione finora

- ZenTreat D 201 (SDS)Documento3 pagineZenTreat D 201 (SDS)Abhay BhoirNessuna valutazione finora

- Msds Ethyl AcetateDocumento9 pagineMsds Ethyl AcetateDenis AlifiaNessuna valutazione finora

- Certification Letters For LEED Projects: Donald House Manager of Regulatory Affairs MAPEI CorporationDocumento5 pagineCertification Letters For LEED Projects: Donald House Manager of Regulatory Affairs MAPEI CorporationIgnacio Luis Reig MataixNessuna valutazione finora

- Cl2 Material Safety Data SheetDocumento11 pagineCl2 Material Safety Data SheetChristian CoboNessuna valutazione finora

- Plumbing SafetyDocumento2 paginePlumbing Safetyazizi_fadzli100% (1)

- Royal Ultra 865MDocumento9 pagineRoyal Ultra 865Mjuanfdez42368Nessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Material Safety Data Sheet AvaligDocumento4 pagineMaterial Safety Data Sheet Avaligfs1640Nessuna valutazione finora

- Aircol 266 and 299 PDFDocumento2 pagineAircol 266 and 299 PDFnauta007Nessuna valutazione finora

- Material Safety Data Sheet of Cefixime (Compacted)Documento6 pagineMaterial Safety Data Sheet of Cefixime (Compacted)opd pharmacyNessuna valutazione finora

- Msds-2013 08 e Vrla Type - Long-twn-VnDocumento8 pagineMsds-2013 08 e Vrla Type - Long-twn-Vnthuongle411Nessuna valutazione finora

- Trilon MDocumento21 pagineTrilon MMariaCamilaGomezNessuna valutazione finora

- Toolbox On Drum Handling: Facilitator: Kikile Masomese Henry. Date: 5 August, 2014Documento1 paginaToolbox On Drum Handling: Facilitator: Kikile Masomese Henry. Date: 5 August, 2014Masomese Henry KikileNessuna valutazione finora

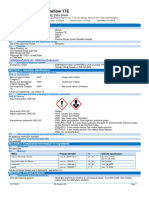

- Sureflow 17E MSDSDocumento6 pagineSureflow 17E MSDSSudhanandh VSNessuna valutazione finora

- Aa 3295-En PDFDocumento3 pagineAa 3295-En PDFDan AyalaNessuna valutazione finora

- Consumables Catalogue Eng PDFDocumento658 pagineConsumables Catalogue Eng PDFnrusydNessuna valutazione finora

- Truck Driver Contract AgreementDocumento17 pagineTruck Driver Contract AgreementMaacahNessuna valutazione finora

- ASTM B705 (2009) - Standard Specification For Nickel-Alloy (UNS N06625, N06219 and N08825) Welded PipeDocumento3 pagineASTM B705 (2009) - Standard Specification For Nickel-Alloy (UNS N06625, N06219 and N08825) Welded PipeanoopNessuna valutazione finora