Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Aditya Pundhir and Nida Murtaza PDF

Caricato da

Santi WilujengTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Aditya Pundhir and Nida Murtaza PDF

Caricato da

Santi WilujengCopyright:

Formati disponibili

Int.J.Curr.Microbiol.App.

Sci (2015) 4(7): 802-809

ISSN: 2319-7706 Volume 4 Number 7 (2015) pp. 8020-809

http://www.ijcmas.com

Review Article

Hurdle Technology-An Approach towards Food Preservation

Aditya Pundhir1* and Nida Murtaza2

1

Department of Biotechnology, Shobhit University, Meerut, India

2

Centre for Agri-informatics, Shobhit University, Meerut, India

*Corresponding author

ABSTRACT

Keywords

Hurdles, Hurdle

effect, Hurdle

technology,

microbial safety

and stability,

food

preservation

In recent years, food preservation and food security have become an important

factor of concern. In modern era of food processing, the demand for fresh & good

quality food products has led to the emergence of hurdle technology. Hurdle

technology is an efficient technique for improving the quality of food and to

enhance its shelf life.The main objective of this technology is food preservation,

storage of food products and enhancement of their shelf life thereby giving us good

quality products.In the present contribution a brief introduction is given about

hurdle technology, its aspects and widespread applications in different food

products for their efficient preservation.

Introduction

spoilage and poisoning of food materials by

microorganisms is still a major cause for

food spoilage. The microbial safety &

stability of most foods are based on an

application of preservation factors called as

hurdles & the technique applying the

different hurdles is known as hurdle

technology.

Due to the inadequate technologies for post

harvested food preservation more than 50%

of the harvested food is often lost due to

spoilage in developing countries. It has been

reported by FAO of United Nations that one

third of the total harvested food of the world

is lost before it is consumed. The current

consumer demands natural & fresh food

which urges the food manufacturers to

establish a new preservation technique

(Leistner and Gorris, 1995). Statistics shows

that 95% of the investment for agriculture

resources has been allocated for production

while only 5% for the preservation of food.

In the majority of the cases microorganisms

are responsible for the spoilage or

poisoning. Despite the availability of a range

of preservation techniques like freezing,

blanching, pasteurization, canning etc.

Hurdle technology is a concept that was

developed to address the consumer demand

for more natural and fresh foods. (Leistner,

2000) defined hurdle technology as an

intelligent combination of hurdles which

secures the microbial safety and stability as

well as retains the organoleptic, nutritional

quality and economic viability of food

products.

802

Int.J.Curr.Microbiol.App.Sci (2015) 4(7): 802-809

Some of the hurdles such as temperature

(high or low), water activity(aw),

preservatives (nitrite, sorbate), competitive

microorganisms (lactic acid bacteria) and

acidity (pH) have been empirically used for

years to stabilize meat, fish, milk and

vegetables (Leistner, 2000).Various novel

hurdles that are being applied in various

food products includes nano-thermosonication,

ultrahigh

pressure,

photodynamic

inactivation,

modified

atmosphere packaging of both non-respiring

and respiring products, edible coatings,

ethanol, milliard reaction products (Gayn et

al., 2012). The basic concept is to apply

combinations of existing and novel

preservation techniques ("hurdles") in order

to eliminate the growth of micro-organisms.

Therefore, while the aim of effective food

preservation is to control all forms of quality

deterioration, the overriding priority is

always to minimize the potential for the

occurrence and growth of food spoilage and

food poisoning microorganisms.

Homeostasis: It is the process that maintains

the stability of the living cell s internal

environment in response to the changes in

external environment. Some of the examples

of homeostasis in the body are regulation of

temperature and balance between acidity

and alkalinity (pH). These factors are

prerequisite feature of living cells and this

applies to higher organisms as well as

microorganisms (Leistner, 2000). The

concept behind homeostasis is already

known in higher organisms but this

knowledge should be incorporated in

microorganisms important for the poisoning

and spoilage of foods (Leistner, 2000).

Disturbing the homeostasis of the

microorganisms

by

various

hurdles

eventually results in the death of the

spoilage

causing

microbes

thereby

protecting the food product from microbial

spoilage.

Metabolic exhaustion: This aspect of

hurdle technology deals with auto

sterilization of food. This was firstly

observed in the experiment carried out on

liver sausages inoculated with Clostridium

Hurdle technology has been developed to

reduce the usage of preservatives in foods,

and consists of the combined effect of

hurdles to establish an additional

antimicrobial effect, thus improving the

quality of the food (Leistner, 1985).This

modern preservation technology has been

developed for the consumers who demands

healthy and fresh foods that retains its

nutritional and organoleptic properties as

well.

sporogens and stored at 37 C (Leistner et al,

1970). Later this behaviour of some

bacterial spores was regularly observed in

shelf stable meat products during storage

time period (Leistner, 1994b). It has been

observed that the spore counts in hurdle

technology treated food products actually

decreases during storage especially at

ambient temperature. The microbes in the

hurdle treated stable products uses their

energy for homeostasis thereby becoming

metabolically exhausted. This leads to auto

sterilization of food products. Thus, the

microbiologically stable product becomes

safer for storage at normal room

temperatures.

Aspects of hurdle technology

The hurdle technology affects the

physiology and growth of microorganisms

in food. There are mainly 4 major

mechanisms by which hurdle technology

affects the growth of microorganisms in

foods:

803

Int.J.Curr.Microbiol.App.Sci (2015) 4(7): 802-809

Hurdle Technology is a novel concept which

has several applications in the preservation

of various food products such as:

Stress reactions: Some microbes acquire

resistance or may become more virulent

under stress conditions as they synthesize

stress shock proteins. The synthesis of stress

shock protein is affected by several factors

like pH, water activity, ethanol, heat, etc.

The different responses of microbes under

stress conditions might hamper the food

preservation.Exposure to multiple stresses

simultaneously activates the energy utilising

synthesis of several stress shock proteins, in

turn making the microbes metabolically

weak. Therefore, multitarget preservation of

foods could be an efficient approachtowards

reducing the synthesis of stress shock

proteins and in food preservation. (Leistner,

2000).

Dairy products: Hurdle technology has

been applied in many dairy products to

enhance their shelf life. Shelf stable paneer

can be prepared by applying various hurdles

such as pH, aw, preservatives and Modified

Atmosphere Packaging (MAP. The quality

and shelf life of hurdle treated paneer

extended from one to twelvedays at ambient

temperature and six to twenty days at

refrigeration temperature without affecting

its physicochemical and sensory properties

(Thippeswamy et al., 2011).

In another study, the shelf life of paneer

curry was increased using hurdle

technology. The product has been treated

with certain modified control hurdles like

aw, pH and preservatives. The hurdle treated

paneer was found to have better quality than

heat sterilized product (Rao and Patil, 1999).

Multitarget preservation of food: It is a

very important aspect for efficient and

effective preservation of targeted food

material (Lesitner, 1995b). Hurdles applied

in the targeted food material might not just

have effects on microbial stability but they

could

act

synergistically

(Leistner,

1978).Synergistic effect could be achieved

in the targeted food, if the hurdles affects

different targets such as pH, aw, Eh, enzyme

systems simultaneously within the microbial

cell and thus disturb the homeostasis of the

microbes rendering it difficult for the

microbes to synthesise different stress shock

proteins and to maintain their homeostasis

(Leistner, 1995a). Therefore the application

of several hurdles simultaneously would

lead to an optimal microbial stability and

effective food preservation (Leistner,

1994a).

Another product brown peda , a traditional

Indian heat desiccated milk khoa based

product have also been prepared and

preserved through hurdle technology.

(Panjagari et al, 2007) studied the effect of

conventional cardboard boxes, modified

packaging

and

vacuum

packaging

techniques on the sensory, physicochemical,

biochemical,

textural

and

microbiological characteristics of brown

peda during its storage for forty days at 30C

and observed a stable shelf life due to low

moisture content, higher amount of sugar

and severe heat treatment applied during its

preparation. Hurdle treated brown peda

could be best preserved up to forty days at

room temperature (301C) without any

quality loss (Panjagari et al, 2007).

Applications of Hurdle Technology in

different products:

Fruits & Vegetables: Several hurdles are

considered to be important in the

804

Int.J.Curr.Microbiol.App.Sci (2015) 4(7): 802-809

preservation of various vegetables and fruits

like carrot, pineapple, coconut & papaya to

enhance their stability and shelf life.

includes UV light, pulsed light (PL),

ultrasound (US), and high hydrostatic

pressure (HHP) (Gomez et al, 2011).

Shelf-stable grated carrot products are

developed using hurdle technology.

(Vibhakara et al., 2006) used several hurdles

such as antimicrobials, partial dehydration

and packaging in polymeric bags to develop

grated carrotsthat can remain fresh and

microbiologically safe for more than six

months at ambient temperature.

(Sankhla et al., 2012) preserved sugarcane

juice by using several potential hurdles like

heat treatment, preservatives, irradiation and

various

packaging

materials.

The

applicability of these hurdles shows great

enhancement in the level of product safety

and stability and thus it can therefore be

recommended for preservation of all kinds

of food material (Sankhla et al., 2012).

Hurdle technology can also be applied to

develop shelf stable RTE (Ready-To-Eat)

intermediate moisture pineapple with

increased shelf life. Osmotic dehydration,

infrared drying and gamma radiation can

successfully reduce the microbial load in

pineapple slices increasing its shelf life up to

40 days (Saxena et al., 2009).

Hurdle or combined technology is also

applied in the preservation of high moisture

fruit products such as peach, pineapple,

papaya, mango and banana. The technology

is based on the combination of heat

treatment, aw and addition of antimicrobials

(Alzamora et al., 1993).

(Gunathilake,

2005)

applied

hurdle

technology in the preservation of fresh

scrapped coconut. Additives such as

humectants, acidulants and preservatives

were used. The shelf life of hurdle treated

coconut gratings was increased by one

month at ambient temperature and by three

months at refrigerated temperature (5+2 C).

In Meat & Meat products: Hurdle

technology has been applied to a number of

meat products. Thomas et al., 2010 studied

the effect of different hurdles such as (pH,

aw, vacuum packaging and post package

treatment) in pork sausages at refrigerated

temperature. The combined effect of these

hurdles on pork sausages resulted in the

inhibition of the growth of yeast and molds

up to 12 days, while the dipping of sausages

into potassium sorbate solution before

packaging inhibited their growth up to 30

days. Implementation of hurdle technology

into sausages was beneficial as the shelf life

of sausages was increased up to 30 days

while the control untreated samples were

acceptable up to 18 days(Thomas et al.,

2010).

Minimally processed shelf stable high

moisture grated papaya is also prepared by

hurdle technology using different hurdles

like mild heat treatment, aw, pH reduction,

and the addition of preservatives(LpezMalo et al., 1994). This combined methods

technology developed microbiologically

safe and nutritionally intact papaya that is

shelf stable at ambient temperature for more

than five months.

Shelf stable ready to eat pickle type spiced

buffalo meat products was also prepared and

preserved by controlling different hurdles

like pH, water activity, proximate

composition, FFA, Soluble hydroxyproline,

TBA values, nitrite content, protein

Fruit

derived

products:

Several

conventional hurdle strategies are effectively

used along with the novel ones for the

preservation of various fruit products. Some

of the hurdles applied in fruit processing

805

Int.J.Curr.Microbiol.App.Sci (2015) 4(7): 802-809

solubility (Malik and Sharma, 2014). Hurdle

Technology has made it possible to deliver

shelf stable and ready to eat meat products

for space scientists and mountaineers.

Figure.1 Most Common hurdles for food preservation

Figure.2 Basic aspects behind the concept of hurdle technology

806

Int.J.Curr.Microbiol.App.Sci (2015) 4(7): 802-809

Figure.3 Hurdle technology applied in various products

Karthikeyan et al., 2000 applied hurdle

technology for the production of shelf stable

caprine

keema

stable

at

ambient

temperature. The hurdles used by them were

807

Int.J.Curr.Microbiol.App.Sci (2015) 4(7): 802-809

aw, pH vacuum packaging, heat treatment

and preservatives. The hurdle treated keema

was shelf stable and accepted up to the fifth

day unlike the conventionally prepared

keema that is highly perishable and is

accepted only until the first day.

Essential Oils. Food Eng. Rev. 4,

141 148. Doi: 10.1007/S12393-0129055-Y

Karthikeyan, J., Kumar, S., Anjaneyulu,

A.S.R., Rao, K.H., 2000. Application

of Hurdle Technology for the

Development of Caprine Keema and

Its Stability at Ambient Temperature.

Meat

Sci.

54,

9 15.

Doi:

10.1016/S0309-1740(99)00053-4

Leistner, L., 1978. Hurdle effect and energy

saving. In: Downey, W.K. (Ed.),

Food Quality and Nutrition, Applied

Science Publishers, London, UK, pp.

553 557.

Leistner, L., 1985. Hurdle technology

applied to meat products of the shelf

stable product and intermediate

moisture food types. In: Simatos, D.,

Multon, J.L. (Eds.), Properties of

Water inFoods in Relation to Quality

and

Stability,

MartinusNijhoff,

Publishers, Dordrecht, Netherlands,

pp. 309 329.

Leistner, L., 1994a. Further developments in

the utilization of hurdle technology

for food preservation. J Food Eng 22,

421 432.

Leistner, L., 1994b. Food Design by Hurdle

Technology and HACCP, Printed

and distributed by the AdalbertRaps-Foundation,

Kulmbach,

Germany, p. 62

Leistner, L., Gorris, L.G.M., 1995. Food

Preservation by Hurdle Technology.

Trends Food Sci. Technol. 6, 41 46.

Doi: 10.1016/S0924-2244(00)889414

Leistner, L., 1995a. Principles and

applications of hurdle technology.

In: Gould, G.W. (Ed.), New Methods

for Food Preservation, Blackie

Academic and Professional, London,

pp. 1 21

Leistner, L., 1995b. Emerging concepts for

food safety. In: 41st International

Several hurdles such as marination, cooking

and glycerol have been applied in the

production of shelf stable chicken lollipop

(Singh et al., 2014).

With the growing economy there is an

increased demand for fresh and minimally

processed food products. Conventional fruit

preservation methods are based on single

preservation parameter that makes changes

in the sensory and nutritional quality of the

fruit. The hurdle technology makes minimal

sensory and nutritional changes in the

product which makes the product more

valuable and acceptable than obtained by

conventional methods and has become a

boon for the efficient preservation of food

products.

References

Alzamora, S.M., Tapia, M.S., Argaz, A.,

Welli, J., 1993. Application of

Combined Methods Technology in

Minimally Processed Fruits. Food

Res. Int. 26, 125 130. Doi:

10.1016/0963-9969(93)90068-T

Gunathilake K.D.P.P., 2006, Application of

hurdle techniques to preserve fresh

scraped coconut at ambient and

refrigerated storage, J. Natn. Sci.

Foundation Sri Lanka, 33(4), 265-268

Gayn, E., Torres, J.A., Paredes-Sabja, D.,

2012. Hurdle Approach to Increase

the Microbial Inactivation by High

Pressure Processing: Effect of

808

Int.J.Curr.Microbiol.App.Sci (2015) 4(7): 802-809

Congress of Meat Science and

Technology, 20 25 August 1995,

San Antonio, Texas, pp. 321 322.

Leistner, L., 2000. Basic Aspects of Food

Preservation by Hurdle Technology.

Int. J. Food Microbiol. 55, 181 186.

Doi: 10.1016/S0168-1605(00)001616

Lpez-Malo, A., Palou, E., Welti, J., Corte,

P., Argaiz, A., 1994. Shelf-Stable

High Moisture Papaya Minimally

Processed By Combined Methods.

Food Res. Int. 27, 545 553. Doi:

10.1016/0963-9969(94)90140-6

Malik, A.H., Sharma, B.D., 2014. Shelf Life

Study Of Hurdle Treated Ready-ToEat Spiced Buffalo Meat Product

Stored At 30 3 C For 7 Weeks

Under Vacuum And Aerobic

Packaging. J. Food Sci. Technol. 51,

832 844. Doi: 10.1007/S13197-0110592-9

Paula Luisina Gmez, Jorge Welti-Chanes,

and Stella Maris Alzamora, 2011,

Hurdle

Technology in Fruit

Processing,Annual Review of Food

Science and Technology,Vol. 2: 447465. DOI: 10.1146/annurev-food022510-133619

Panjagari, NR., Londhe, GK. , Pal, D., 2007.

Effect of packaging techniques on

self-life of brown peda, a milk based

confection, J. Food Sci and Tech. 47,

117-125

Rao, KJ., Patil, GR., 1999. Development of

ready to eat paneer curry by hurdle

technology. J Food Sci Tech. 36, 3741

Sankhla, S., Chaturvedi, A., Kuna, A.,

Dhanlakshmi, K., 2012. Preservation

of Sugarcane Juice Using Hurdle

Technology. Sugar Tech 14, 26 39.

Doi: 10.1007/S12355-011-0127-8

Saxena, S., Mishra, B.B., Chander, R.,

Sharma, A., 2009. Shelf Stable

Intermediate Moisture Pineapple

(AnanasComosus) Slices Using

Hurdle Technology. LWT - Food

Sci. Technol. 42, 1681 1687.

Doi:10.1016/J.Lwt.2009.05.009

Thippeswamy, L., Venkateshaiah, B.V.,

Patil, S., 2011. Effect of Modified

Atmospheric Packaging on the Shelf

Stability of Paneer Prepared By

Adopting Hurdle Technology. J.

Food Sci. Technol. 48, 230 235.

Doi:10.1007/S13197-010-0155-5

Thomas, R., Anjaneyulu, A.S.R., Kondaiah,

N., 2010. Quality of Hurdle Treated

Pork Sausages during Refrigerated (4

1C) Storage. J. Food Sci.

Technol.

47,

266 272.

Doi:10.1007/S13197-010-0041-1

Veer Pal Singh, Vikas Pathak, Narendra

Kumar Nayak and MeenaGoswami,

2014, Application of hurdle concept

in development and shelf life

enhancement of chicken lollipop,

Int.J.Curr.Microbiol.App.Sci(2014)3

(1): 355-361

Vibhakara,

H.S.J.,

Gupta,

D.K.D.,

Jayaraman, K.S., Mohan, M.S.,

2006. Development of a HighMoisture Shelf-Stable Grated Carrot

Product Using Hurdle Technology. J.

Food Process. Preserv. 30, 134 144.

doi:10.1111/j.17454549.2006.00055.x

809

Potrebbero piacerti anche

- Agricultural Biotechnology and Crop ImprovementDa EverandAgricultural Biotechnology and Crop ImprovementNessuna valutazione finora

- Physical-Chemical Properties of Foods: New Tools for PredictionDa EverandPhysical-Chemical Properties of Foods: New Tools for PredictionNessuna valutazione finora

- Hurdle Technology in Food Preservation: K.Sowjanya, K.Vinay Promod KumarDocumento5 pagineHurdle Technology in Food Preservation: K.Sowjanya, K.Vinay Promod KumarIOSRjournalNessuna valutazione finora

- Leistner 2000 PDFDocumento6 pagineLeistner 2000 PDFProf C.S.PurushothamanNessuna valutazione finora

- Food Chemistry Is The Study of Chemical Processes and Interactions of All Biological and NonDocumento3 pagineFood Chemistry Is The Study of Chemical Processes and Interactions of All Biological and NonshyjenzNessuna valutazione finora

- 2000 Leistner Int J Food Microbio 181ffDocumento6 pagine2000 Leistner Int J Food Microbio 181ffAditya Pratama Edwin RaharjaNessuna valutazione finora

- Unesco - Eolss Sample Chapters: Hurdle TechnologyDocumento0 pagineUnesco - Eolss Sample Chapters: Hurdle TechnologyProf C.S.PurushothamanNessuna valutazione finora

- BiotecnologíaDocumento13 pagineBiotecnologíaEliseo TqNessuna valutazione finora

- Hurdle TechnolgyDocumento25 pagineHurdle TechnolgyCharlene Mae Rabaja DeteraNessuna valutazione finora

- 1.1the Role of Biotechnology in Food Production and ProcessingDocumento12 pagine1.1the Role of Biotechnology in Food Production and ProcessingJavierNessuna valutazione finora

- Food Preservation by Hurdle TechnologyDocumento7 pagineFood Preservation by Hurdle TechnologyProf C.S.PurushothamanNessuna valutazione finora

- Critical Review On Principles and Applications of Hurdle Technology in Food PreservationDocumento7 pagineCritical Review On Principles and Applications of Hurdle Technology in Food PreservationRaselNessuna valutazione finora

- Salam Journal 2Documento13 pagineSalam Journal 2Olasupo VictorNessuna valutazione finora

- Food PreservationDocumento5 pagineFood PreservationMark Christian P. MesinaNessuna valutazione finora

- Further Developmets PDFDocumento12 pagineFurther Developmets PDFLeandro PereiraNessuna valutazione finora

- Review On Methods For Preservation and Natural Preservatives For Extending The Food LongevityDocumento9 pagineReview On Methods For Preservation and Natural Preservatives For Extending The Food LongevitydenNessuna valutazione finora

- 03 Hurdle Technology NotesDocumento11 pagine03 Hurdle Technology NotesProf C.S.PurushothamanNessuna valutazione finora

- Combined Antimicrobial Effect of Bacteriocins With Other Hurdles of Physicochemic and Microbiome To Prolong Shelf Life of FoodDocumento16 pagineCombined Antimicrobial Effect of Bacteriocins With Other Hurdles of Physicochemic and Microbiome To Prolong Shelf Life of Foodhans tafurNessuna valutazione finora

- Effects of Combined Treatments of Irradiation and Antimicrobial CoatingsDocumento5 pagineEffects of Combined Treatments of Irradiation and Antimicrobial CoatingsAna Vitelariu - RaduNessuna valutazione finora

- Term Paper On LaboratoryDocumento5 pagineTerm Paper On LaboratoryJoyce TalasanNessuna valutazione finora

- Hurdle's Technology FINALDocumento16 pagineHurdle's Technology FINALRaghad ZeerNessuna valutazione finora

- Non-Thermal Technologies For Food ProcessingDocumento14 pagineNon-Thermal Technologies For Food ProcessingIgnacioNessuna valutazione finora

- ECNU 15 00850thermalDocumento19 pagineECNU 15 00850thermalFiorent ValenciaNessuna valutazione finora

- QOL 00 4 Ene - 0Documento14 pagineQOL 00 4 Ene - 0Ana BorgesNessuna valutazione finora

- Application of Hurdle Technology in Traditional Indian Dairy ProductsDocumento4 pagineApplication of Hurdle Technology in Traditional Indian Dairy ProductsPravin Zine PatilNessuna valutazione finora

- Conservación Biológica de Alimentos-Review-2018Documento8 pagineConservación Biológica de Alimentos-Review-2018Milade CantilloNessuna valutazione finora

- Bacteriocin-Based Strategies For Food BiopreservationDocumento20 pagineBacteriocin-Based Strategies For Food BiopreservationNurlaila KhairunnisaNessuna valutazione finora

- Role of ProtectiveDocumento8 pagineRole of ProtectiveAgus Prihanto PurnomoNessuna valutazione finora

- Modifikasi Hurdle Technology Dengan Penambahan Ekstrak Kunyit Dan Penyimpanan Suhu Dingin Pada Industri Rumah Tangga Mie BasahDocumento12 pagineModifikasi Hurdle Technology Dengan Penambahan Ekstrak Kunyit Dan Penyimpanan Suhu Dingin Pada Industri Rumah Tangga Mie BasahdindaNessuna valutazione finora

- Shelf Life Enhancement of Functional Doda Burfi (Indian Milk Cake) With Biopreservatives ApplicationDocumento15 pagineShelf Life Enhancement of Functional Doda Burfi (Indian Milk Cake) With Biopreservatives ApplicationHafizh TaufiqNessuna valutazione finora

- Biopreservation by Lactic Acid Bacteria: Michael E. StilesDocumento15 pagineBiopreservation by Lactic Acid Bacteria: Michael E. StilesnevenkanikNessuna valutazione finora

- Relevance of Sterilisation in Food Processing IndustryDocumento9 pagineRelevance of Sterilisation in Food Processing IndustryDainoo BrownNessuna valutazione finora

- 2 HRT 321 Notes PART B 2020Documento41 pagine2 HRT 321 Notes PART B 2020Nisarga T Darya100% (1)

- 2016 Effects of Processing and Storage Preservation Technologies On Nutritional Quality and Biological Activities of Edible Fungi A ReviewDocumento13 pagine2016 Effects of Processing and Storage Preservation Technologies On Nutritional Quality and Biological Activities of Edible Fungi A Reviewsidik marsudiNessuna valutazione finora

- Application of Innovative Technologies For Improved Food Quality and SafetyDocumento83 pagineApplication of Innovative Technologies For Improved Food Quality and SafetyIsha GargNessuna valutazione finora

- The Importance of Science and Food TechnologyDocumento3 pagineThe Importance of Science and Food Technologysha_bee100% (3)

- Innovative Technologies For Creation of Probiotic Foods: E-Mail: Iliana - Nacheva@abv - BGDocumento4 pagineInnovative Technologies For Creation of Probiotic Foods: E-Mail: Iliana - Nacheva@abv - BGFifi Kurnia HidayantiNessuna valutazione finora

- J. Food Eng. 22, 1994, 421-432Documento12 pagineJ. Food Eng. 22, 1994, 421-432Cruz-ClaraNessuna valutazione finora

- TechnicalreportMicrobialdecontamination PDFDocumento10 pagineTechnicalreportMicrobialdecontamination PDFtasyaNessuna valutazione finora

- Food Preservation and MicrobiologyDocumento27 pagineFood Preservation and Microbiologykiran bhardwajNessuna valutazione finora

- Bisulphate FoodDocumento21 pagineBisulphate FoodRock Thakural Jaat100% (1)

- A Review On The Beneficial Aspects of Food ProcessingDocumento33 pagineA Review On The Beneficial Aspects of Food ProcessingJéssica BaumwolleNessuna valutazione finora

- A Comprehensive Review On Preservation of Shiitake Mushroom Lentinus Edodes Techniques Research Advances and Influence On Quality TraitsDocumento35 pagineA Comprehensive Review On Preservation of Shiitake Mushroom Lentinus Edodes Techniques Research Advances and Influence On Quality Traitssheng caoNessuna valutazione finora

- Efeitos de Varios Processo Na Preservacao Antiox de Vegetaisal-Juhaimi2018Documento9 pagineEfeitos de Varios Processo Na Preservacao Antiox de Vegetaisal-Juhaimi2018Elenice Peltz NutricionistaNessuna valutazione finora

- Gao 2007Documento8 pagineGao 2007Florentina BucurNessuna valutazione finora

- Advances in Antimicrobial Food Packaging With Nanotechnology and Natural AntimicrobialsDocumento7 pagineAdvances in Antimicrobial Food Packaging With Nanotechnology and Natural AntimicrobialsIvy NazeerahNessuna valutazione finora

- The Role of Biotechnology in Food Production and ProcessingDocumento6 pagineThe Role of Biotechnology in Food Production and ProcessingkingsleyesedebeNessuna valutazione finora

- Bhupendrasah 1Documento13 pagineBhupendrasah 1UMESH BIKRAM SHAHNessuna valutazione finora

- Olatunde & Benjakul (2018)Documento13 pagineOlatunde & Benjakul (2018)Santiago DangerNessuna valutazione finora

- Shelf Life Extension of CheeseDocumento18 pagineShelf Life Extension of Cheesenils2484100% (1)

- Application of Hurdles For Extending The Shelf Life of Fresh FruitsDocumento18 pagineApplication of Hurdles For Extending The Shelf Life of Fresh FruitsS MishraNessuna valutazione finora

- II. 1. Inovation of Food Processing OK 2022 KULIAH KE 2Documento65 pagineII. 1. Inovation of Food Processing OK 2022 KULIAH KE 2Rofiqoh Nurul HudaNessuna valutazione finora

- Prof Eng 2 Unit 2 Food Processing STD 2020Documento20 pagineProf Eng 2 Unit 2 Food Processing STD 2020Thanh VânNessuna valutazione finora

- Natural Preservatives To Improve Food Quality andDocumento4 pagineNatural Preservatives To Improve Food Quality andEj SeguroNessuna valutazione finora

- Methods For Preservation and Extension of Shelf LifeDocumento14 pagineMethods For Preservation and Extension of Shelf LifedesmadradorNessuna valutazione finora

- Microbiological Evaluation of An Edible Antimicrobial Coating PDFDocumento6 pagineMicrobiological Evaluation of An Edible Antimicrobial Coating PDFLuigi GonzálezNessuna valutazione finora

- 03 t2 Inocuidad AlimentariaDocumento8 pagine03 t2 Inocuidad AlimentariadeiverNessuna valutazione finora

- Food Technology: ObjectivesDocumento194 pagineFood Technology: ObjectivesKishore KumarNessuna valutazione finora

- Alzamora Et Al (1998) - New Strategies For Minimal Processing of Foods. The Role of Multitarget PreservationDocumento10 pagineAlzamora Et Al (1998) - New Strategies For Minimal Processing of Foods. The Role of Multitarget PreservationSebastian DelgadoNessuna valutazione finora

- Review Form2 ID 71ICSkhFE 2018 - Done PDFDocumento2 pagineReview Form2 ID 71ICSkhFE 2018 - Done PDFSanti WilujengNessuna valutazione finora

- AbstractDocumento1 paginaAbstractSanti WilujengNessuna valutazione finora

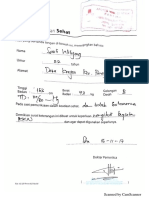

- Surat Keterangan SehatDocumento1 paginaSurat Keterangan SehatSanti WilujengNessuna valutazione finora

- Nurrofi MaretDocumento1 paginaNurrofi MaretSanti WilujengNessuna valutazione finora

- Pencoklatan Ubi Jalar H 1-2Documento9 paginePencoklatan Ubi Jalar H 1-2pashanitaNessuna valutazione finora

- Testing Your Product: Farah Nuraini February 2018Documento27 pagineTesting Your Product: Farah Nuraini February 2018Santi WilujengNessuna valutazione finora

- Jurin1 TonukariDocumento4 pagineJurin1 TonukariSanti WilujengNessuna valutazione finora

- New Doc 2017-11-16 (1) - 2Documento1 paginaNew Doc 2017-11-16 (1) - 2Santi WilujengNessuna valutazione finora

- Benitez PDFDocumento6 pagineBenitez PDFSanti WilujengNessuna valutazione finora

- 1 EARCEE Copyright FormDocumento2 pagine1 EARCEE Copyright FormSanti WilujengNessuna valutazione finora

- Acuan FlakesDocumento27 pagineAcuan FlakesSanti WilujengNessuna valutazione finora

- Fullpaper AasicDocumento3 pagineFullpaper AasicSanti WilujengNessuna valutazione finora

- 234 250Documento26 pagine234 250Freddi CubaNessuna valutazione finora

- Al Qadiri Dkk2007Documento17 pagineAl Qadiri Dkk2007Santi WilujengNessuna valutazione finora

- Acknowledgements We Wish To Thank All The Respondents of The PFS Consumer SurveyDocumento1 paginaAcknowledgements We Wish To Thank All The Respondents of The PFS Consumer SurveySanti WilujengNessuna valutazione finora

- 1 EARCEE Copyright FormDocumento2 pagine1 EARCEE Copyright FormSanti Wilujeng0% (1)

- Aditya Pundhir and Nida MurtazaDocumento8 pagineAditya Pundhir and Nida MurtazaSanti WilujengNessuna valutazione finora

- Refreshing Wasit Juri: Ruang Sidang IDocumento3 pagineRefreshing Wasit Juri: Ruang Sidang ISanti WilujengNessuna valutazione finora

- Form 5 Santi WilujengDocumento1 paginaForm 5 Santi WilujengSanti WilujengNessuna valutazione finora

- P.J. Hansen: Use of A HemacytometerDocumento2 pagineP.J. Hansen: Use of A HemacytometerSanti WilujengNessuna valutazione finora

- Food Security in IndonesiaDocumento2 pagineFood Security in IndonesiaSanti WilujengNessuna valutazione finora

- Fosforilasi OksidatifDocumento82 pagineFosforilasi OksidatifSanti WilujengNessuna valutazione finora

- AcknowledgementsDocumento1 paginaAcknowledgementsSanti WilujengNessuna valutazione finora

- Jurnal BingDocumento10 pagineJurnal BingSanti WilujengNessuna valutazione finora

- International Development Youth Forum 2015Documento3 pagineInternational Development Youth Forum 2015Santi WilujengNessuna valutazione finora

- Material Requirements PlanningDocumento38 pagineMaterial Requirements PlanningElidad SukardiNessuna valutazione finora

- SCH p3Documento8 pagineSCH p3Santi WilujengNessuna valutazione finora

- Flow p3Documento1 paginaFlow p3Santi WilujengNessuna valutazione finora

- Academic and Award Details Information Please Complete Academic and Achievement Information of Study/ OrganizationDocumento2 pagineAcademic and Award Details Information Please Complete Academic and Achievement Information of Study/ OrganizationSanti WilujengNessuna valutazione finora