Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

D 02016 Sub WDFG Co A 003

Caricato da

Rogelio Guerra0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

8 visualizzazioni18 pagineespecificaciones tecnicas

Titolo originale

D-02016-SUB-WDFG-CO-A-003

Copyright

© © All Rights Reserved

Formati disponibili

PDF o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoespecificaciones tecnicas

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

8 visualizzazioni18 pagineD 02016 Sub WDFG Co A 003

Caricato da

Rogelio Guerraespecificaciones tecnicas

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF o leggi online su Scribd

Sei sulla pagina 1di 18

4

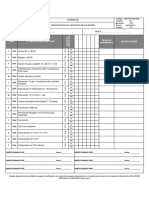

WORLDDUTY ” SUBMITTAL

PROYECTO | “WORLD DUTY FREE GROUP SALIDAS INTERNACCIONALES* SUBMITTAL N*. | D.22016-SUB-WWDFG-CO-A.008

copi6o 02016 REVISION. | 0

SuBPROYECTO | CO ESPECIALIDAD [A FASE aw

| area ESPIGON FECHA TODEENERODE 2016 |

[[CONTRATISTA | BJ CONSTRUCCION E INGENIERIA SRL. CwOFE ING. GERONINO PEREZ

| TPO De SUBMITTAL:

El Espeetficacién Técnica (nueva/modificacién) 1 Plan de Trabajo

I Muestra de materiales i Certificacién de equipos

I Listado de documentos Oi Ficha Técnica

1 ESPECIFICACION DE REFERENCIA: 24863-3PS-09310 N*. PLANO DE REFERENCIA: CO-A-03-806

DESCRIPCION DEL SUBAITTAL:

ACERO INOXIDABLE

Se hace entraga de la especiticacién Técnica cel acero inoxidable y 2 su vez una muestra enfisica que se utlizard en los falss cielos,

‘especificamente en el FC3 de nuestro proyecto en mencién..

Responsable Contratista: N&J CONSTRUCCION € INGENIERIA S.R.L.

Nombre: ALEJANDRA MONTENEGRO HERNANDEZ Firm:

INFORMACION PARA EL CONTRATISTA.

STA PARA EL SUBMITTAL:

Cédigo 1: Proceder con el Trabajo.

Codigo 2 Revisar y reenviar. Proceder con el Trabajo, sujeto a incorporactén de cambios indicados.

1 Cédigo 3: Revisar y reenviar. No proceder con el Trabajo,

(_ Cédigo 4: No requiere revision. Proceder con el Trabajo.

‘COMENTARIO / RESPUESTA TECNICA

(WAI CONSTRUCCION E NGENERLA SH.

RECIBIDO |

02 FEB IM

os}o>/ 6

Respongidb por: Revisado por: | ‘Aprobado\

Sila respuesta det Submittal par parte de LAP ene on impacto on cool eronogram, ex respesabiidad cel Corratsianolfiar ymedatamente 2

trae de una propuesta de eambio. El trabajo realizado st autorzac'on ce LAP sera por cuenta riesgo cel Contratista

PLANCHAS ACERO INOX. ASTM A240

TP 304 / 3041 (UNS $30400/S30403)

[ACERO INOXIDABLE AUSTENITICO AL CROMO~ NIQUEL

**PRE(304/304L) = 17.5

£1304 es el aceroinoxidable mds versétily mas usado en el mercado, usado especlalmente para la Industria alimentcia,

ALEACION:

r% Nise cx n% S% Nx.

175-195 | 20-100 | oosméx | 200m | 075mix | oto max

13041 es una variaci6n del 304 el cual presenta un contenido menor de carbono (0.03% méx), esto ayuda a evitar

'a corrosién intergranular que se puede dar en un proceso de soldadura.

| sumuMisTRO: Formatos 120mm X 240mm, 1500mm x 3000mm, 150mm x6000mm Acabade’ ASTM: 28, NE NP

|

RESISTENCIA A LA CORROSION (APLICACIONES):

| ENV EL MEDIO AMBIENTE URBANO (MEDIO OXIDANTE): Lz resistencia ald Eorrosién del 204°es elicelente en medios

| ambientes urbanos y también cercanos al mar teniendo en cuenta un régimen de limpieza, Puede usarse para la fabricacién

‘de muebles, enchapados en interiores y exterores, ascensores, lineas de cocina, escaleras, barands, marcos estructural,

Uiradores para puerta, cajones, bisagras, tanques, etc

| EN LA INDUSTRIA ALIMENTICIA: Debido al alto contenido de'Cromo y Niguel, laresistencia a la corrosién del 304 en

| procesos de fabricacién de alimentos como la fabricacién de pastas, pulpas, jugos, cerveza, zicar, derivacos de la leche y

| otros es excelente, Asi como en Ia fabricacién de jabones, ceras grasas omestibies. El 304 es el acero inoxidable usado

| por excelencia para estos procesos en general salvo en algunos proces0s que son muy corrosivos en la cual se recomienda

| 21316. (E.Fabricacién de pulpa de tomate y/o manejo de sangre de animales}

EN LA INDUSTRIA QUIMICA: Por el contenido de Niguel que posee, [a resistencia 3 |a corrosion del 204 es muy buen en

clertos procesos quimicos. Para cada caso debe consuitarse con nuestros ejecutvos, teniendo en cuenta, la temperatura, la

concentracién de las sustancias. £1 304 también se_puede usar para fabricar utensilos de cocina, articulos de mesa,

cuchileria,ftros de agua, depsitos Interiores de agua, utensiios para ganado, fruteros, jarrones, tazones.

PROPIEDADES MECANICAS:

Aesitenciaala | UimitedeFluencia | Alsrgamiento

‘rece (Ts) MPa | (8S) MPa Somm x | Durer HON

STD. 515 min 205 min 40 min 201 max.

‘iPIco 650 320 55 2

CONFORMADO (Embuticlén}: Por el contenido alto de Niquel, el 304 tiene una ata capacidad para el conformado como

ala embbuticin, lo cual hace de que et 304 pueda ser usado para embuticiones mediss y profundas.

SOLDABIUIDAD: £1 304 tiene una muy buena Soldabilidad y puede soldarse con todos fos métodos corvencionales usindose

‘elementos de aperte como alambre de soldadura yelectrodos. ELECTRODOS: INOK AW E 3081-36.

‘PRE: ASOSTENCA FQUWALENTE POR PADURAS eu buen nda de reste a cers cuantomayore alr, mayor es rests

ERB

CS304

Technical Data

The material contained in this manual has been designed as a

guide for customers of Columbus Stainless (Pty) Ltd. However,

the material contained herein is not intended as a substitute

for any person's procedures and should not be used or relied upon for

any specific or general application without first obtaining competent

advice. Furthermore, Columbus Stainless (Pty) Ltd disclaims any

responsibility for the suitability of the steel in question for any particular

purpose or for the performance or selection of the steel, unless Columbus

Stainless (Pty) Ltd specifically and expressly authorises the purpose

or selection. The material contained in this manual does not purport

to be a comprehensive or exhaustive statement of all relevant material

applicable to special and general steel products and no representation,

condition or warranty, express or implied, is given by Columbus Stainless

(Pty) Ltd as to the accuracy or completeness of this manual and, so

far as is permitted by law, Columbus Stainless (Pty) Ltd, its members,

staff and consultants disclaim any duty of care in relation to the

preparation of this manual and the information that it contains and

shall not be liable for any direct, indirect or consequential loss, damage

or injury suffered by any person, howsoever caused as a result of

relying on any statement in or omission to this manual and any such

liability is expressly disclaimed, [Columbus Stainless (Pty) Ltd shall not

be liable in the event of a breakdown, malfunction or failure occurring

due to faulty design, material or workmanship of the steel, whether

based on the information contained herein or not, and shall not, under

any circumstances, be liable for any damages, either direct or indirect,

particularly consequential damages, including but not limited to damages

for loss of profits.]

INTRODUCTION

Types CS304, CS304L and CS304H are the most versatile and widely

used of all the stainless steels. Their chemical composition, mechanical

properties, weldability and corrosion/oxidation resistance provide the

best all-round performance stainless steels at relatively low cost.

They have excellent low temperature properties and respond

well to hardening by cold working. The carefully controlled chemical

composition of the CS304 types enables them to be deep drawn

more severely than AISI types 301 and 302, without intermediate

annealing. This has made them dominant in the manufacture of drawn

stainless steel parts such as sinks and saucepans. They are readily

press-braked or roll formed into a variety of shapes for applications

in the industrial, architectural and transportation fields.

‘The CS304 types have good welding characteristics, Post weld annealing

is not normally required to restore the excellent performance of these

grades in a wide range of mildly corrosive conditions. Type CS304L

does not require post weld annealing and finds extensive use in heavy

gauge components where freedom from carbide precipitation is often

required.

Type CS304H, with a higher carbon content, is normally specified

where good mechanical properties at elevated temperatures are

required. The higher carbon content may lead to sensitisation

with a concomitant loss of corrosion resistance in a corrosive

environment. Welding procedures should be selected with care.

Type CS321 is a titanium stabilised version of S304 and Is used in

applications exposed to the temperature range 450°C to 850°C where

there is a high risk of sensitisation. CS321 has higher elevated

temperature properties than C5304. Although having good resistance

to oxidation and sensitisation, C5321 is unsuitable for use in highly

oxidising environments due to possible “knifeline” attack.

Typical applications for CS321 would include furnace parts, after

burners, expansion bellows, compensators, catalytic converters, etc.

RODUCT RANGE

‘The latest revision of the Product Guide should be consulted, as the

product range is subject to change without notice. The Product Guide

is available from the Technical Customer Services Department or can

be found at www.columbusstainless.co.za

‘SPECIFICATIONS & TOLERANCES

Columbus Stainless (Pty) Ltd supplies CS304/CS321 to ASTM A240

(304, 304H, 3041 and 321), EN 10088-2, EN 10028-7

(1.4301, 1.4306, 1.4307 and 1.4541) and EN 10095 (1.4878).

Columbus Stainless (Pty) Ltd normally supplies material to the

following tolerances:

HOT ROLLED.

ASTM A480M

ASME SA480M

EN 10051 and EN 10029 Class 8

COLD ROLLED

ASTM A480M

ASME SA480M

EN ISO 9445

Other tolerances may be available on request. Further information

is available in the Product Guide, which can be obtained from the

Technical Customer Services Department or can be found at

vww.columbusstainless.co.za

'

f

¢

(CHEMICAL COMPOSITION

In accordance with ASTM A240 (304, ,

ENO PE S08, 1.4306, 1.4307 and 1.4541)

EN 10088-2,

and EN 10095

304H, 304L and 32

1

Type

%C

Si

%Mn

%P.

%S.

%N

0.080

2.00

0.045

0.030

304H

0.040

0:100

0.75

2.00

hax

0.045)

0.030

max

304L

0.030

0.75

2.00

0,045

0.030

0.100

ax

0.080

0.75

2.00

0.045

0.030

0.10

0.070

1.00

2.00

0.045

0.015

0.41

max

0.030

inax.

1.00

2.00

max.

0.045,

max

0.015

imax

0.11

mak

MECHANICAL PROPERTIES)

In accordance with ASTM A240 (304, 304H, 304L and 321),

EN 10088-2, EN 10088-7 (1.4301, 1.4306, 1.4307 and 1.4541)

and EN 10095 (1.4878),

0.2% 1.0% _ | Tensile ]

Proauct|Proof Stress| Proof Stress] Strenath| Elongation) Brinel

Type |'Form!| (MPa) | (MPa) | (MPa) | (%) _ |Hardness|

304 eae

304H| All | 205 min _ 515 min| 40 min? | 201 max

304L | All | 170 min 485 min| 40 min? | 201 max:

321 |_All_| 205 min ___|515 min| 40 min? | 217 max

540

C_| 230min | 260 min | _750_|45 minss|

520

1.4301] _H | 210 min | 250 min | 720 | 45 min’s

520

P| 210min | 250 min | _720_| 45 min?

520

c | 220 250 min | 670 | 45 min

1.4306} 520

1.4307|_H_ | 200 min | 240 min | 670_| 45 min?

500

P| 200 min | 240 min | 650 | 45 min?

520

¢_| 220min | 250 min |_720__| 40 mina*

520

1,4541|_H__| 200 min | 240 min | 720 | 40 min? [60 min‘

500

P| 200 min | 240 min | 700_| 40min? '60 mins}

190 min | 230 min |__| 4o.min?+|215 max:

1) C= cold rolled strip, H = hot rolled strip s 8mm, P = hot rolled plate >8mm.

2) Elongation over a gauge length of Somm.

3) Proportional elongation with the gauge length = 5.65VSo

(Sp = cross-sectional area of the test plece).

4) For gauges <3mm, elongation over a gauge length of Somm.

5) For stretcher levelled material, the minimum value Is 5% lower.

6) For gauges >10mm, transverse direction at 20°C.

PROPERTIES AT ELEVATED TEMPERATURES)

‘The properties quoted below are typical of annealed CS304 and CS321

only as strength values for CS304L fall rapidly at temperatures above

425°C. These values are given as a guideline only, and should not

be used for design purposes.

SHORT TIME ELEVATED TEMPERATURE TENSILE PROPERTIES

Temperature (°C)

Property lrypel 100| 300 | 500 | 600 | 700 | 800 | 900 |1 o00|1 100

}

rensie Strength (mPa)| 304510 | 435 | 410 | 360 | 245] 135] 75| 40 20}

321/525 | 405 | 380 | 335 | 265| 175|100| 60 | 25

0.2% Prof Stress (Mpay|304| 220] 145 | 125 [110] 95 | 70

321 | 210] 165 | 140] 130115 | 95 |

Tongation (ein som 204] 52140 [736] (35 | 35i[ 37] 42 | 773 | 9

321] s0[ 43| 37] 37| 48| 68] 62] 62] 987)

MAXIMUM RECOMMENDED SERVICE TEMPERATURE

Operating Conditions ‘Temperature (°C)

[Type _ 8 et

Continuous 830 | 830

Intermittent 800 | 800.

REPRESENTATIVE CREEP RUPTURE PROPERTIES,

Stress (MPa) to Produce 1% Strain

Stress (MPa) to Produce Rupture

10 000 hours |100 000 hours| 1 000 hours | 10 000 hours

304 | 321 | 304 | 321 | 304 | 321 | 30a | 321

160 115 315 | 345 | 225 | 255

110 125 75. 80 | 200 230 145 | 160

75 | 85 | 50] 50 | 130 | 135 | 95 | 105

so | 50 30 | 30 | 85 | 100| 60 | 65

35 |_ 30] 20| 20| 60] 65| 40 | 40

25 20 15 10 | 35 45 _25 | 25

PROPERTIES AT SUB-ZERO TEMPERATURES)

“The properties quoted below are typical of annealed C5304 only

[Temperature (°C) _| 20 o | -10 | -50 | -100 | -140 | -196

HTensle Strength (MPa 616 | ses | 976 | 1101 | 1281 | 1368 | 1609

10.2% ProofStress(MPa)| 255 | 242 | 240 | 236 | 222 | 246 | 231

Elongation (%) wo | 64 | 55 | 50] 42 | ai [36

fimpact Eneray (3) | 217 | 204 | 194 | 194 | 168 | 160 | 168

FATIGUE CONSIDERATIONS

When looking into the fatigue of austenitic stainless steels,

it Is important to note that design and fabrication - not material,

are the major contributors to fatigue failure. Design codes (e.g. ASME

and BS 5500) use data from low-cycle fatigue tests carried out

on machined specimens to produce conservative S-N curves

used with stress concentration factors (kc) or fatigue strength reduction

factors (ky). In essence, the fatigue strength of a welded

joint should be used for design purposes, as the inevitable flaws

(even only those of cross-sectional change) within a weld will

control the overall fatigue performance of the structure.

The curve below shows a typical S-N curve for CS304 stainless steel

(longitudinal).

Maximum Stress, MPa

PHYSICAL PROPERTIES

‘The values given below are for 20°C, unless otherwise specified.

cs304

Density

7 900kg/m*|

Modulus of Elasticity in Tension

193GPa

193GPa

Modulus of Elasticity in Torsion

86GPa

86GPa

Poisson‘s Ratio

0.26

0.24

Specific Heat Capacity

500)/kaK

5003/kgK

‘Thermal Conductivity:

@ 100°C

@ 500°C

16.2W/mK

21.5W/mK

16.1W/mK

22.2W/mk

Electrical Resistivity

720n_m

720n_m

‘Mean Co-efficent of Thermal Expansion: 0 ~ 100°C

0 ~ 315°C)

0 - 540°C:

0 = 700°C:

47.2umymk

17.8umrymk

18.4umymk

18.9um/mk

16.6um/mk.

47.2un/enk.

18.6um/mK

19.0um/mk

Melting Range

400-1 450°¢|

Relative Permeability

1.02

1.02

(Note: this grade is non-magnetic becoming slightly magnetic after cold working)

THERMAL PROCESSING & FABRICATION,

ANNEALING

‘Annealing of types CS304 and CS304L is achieved by heating to between

1010°C and 1 120°C for 90 minutes per 25mm thickness followed by

water or air quenching. The best corrosion resistance is achieved when

the final annealing temperature is above 1 070°C. C5321 should not

be annealed above 1 066°C. Controlled atmospheres are recommended

in order to avoid excessive oxidation of the surface.

STRESS RELIEVING

The lower carbon grade (CS304L) can be stress relieved at

450°C to 600°C for 60 minutes with little danger of sensitisation.

A lower stress relieving temperature of 400°C maximum must

be used with CS304 with longer soaking times. If, however,

stress relieving is to be carried out above 600°C, there is

a serious threat of grain boundary sensitisation occurring

with a concomitant loss in corrosion resistance. In this

instance, a stabilised grade such as CS321 should be used.

HOT WORKING

S304 can be readily forged, upset and hot headed. Uniform heating

of the steel in the range of 1 150°C to 1 250°C Is required. The finishing

temperature should not be below 900°C. Upsetting operations and

forgings require 2 finishing temperature between 930°C and 980°C.

Forgings should be air cooled. All hot working operations should

be followed by annealing and pickling and passivation to

restore the mechanical properties and corrosion resistance.

COLD WORKING

CS304 types, being extremely tough and ductile, can be

readily deep drawn, stamped, headed and upset without

difficulty. Since CS304 types work harden, severe cold forming

operations should be followed by annealing.

MACHINING

Like all the austenitic steels, this alloy group machines with

a rough and stringy swarf. Rigidly supported tools with as

heavy a cut as possible should be used to prevent glazing.

WELDING

€S304 types have good welding characteristics and are suited

to all standard welding methods. Either matching or slightly

over-alloyed filler wires should be used. For maximum corrosion

resistance, the higher carbon type CS304 should be annealed

after welding to dissolve any chromium carbides which may have

precipitated. The weld discolouration should be removed by pickling

and passivation to restore maximum corrosion resistance.

CORROSION RESISTANCE

S304 and CS321 have excellent corrosion resistance in a wide variety

Of corrosive media, including foodstuffs, sterilising solutions, most

organic chemicals and dyes and a wide variety of inorganic

chemicals. Iso-corrosion diagrams for CS304 In sulphuric, nitric,

hydrochloric, phosphoric and acetic acids are shown below.

Iso-corrosion diagrams for CS321 appear overleaf.

SULPHURIC ACID Type cs304] |” Nrtarc AcrD Type C5304)

| 120— s120—|

fe 100—

so—

co—

40

201

weiia vo

Temperature Ce)

PHOSPHORIC ACID Type C5304]

120

100

80

60

40

201

101520 0 20 40 60 60 100

Sf Acid by Weight Se Acid by Walgnt

i

Temperature CO)

‘ACETIC ACID Type C5304]

mils per year mm per year

botin pot cu® <1 <.03

15 03-13

re

a

by Weight,

In service, acid corrosion may be either inhibited or accelerated by

the presence of other chemicals or contaminants. The reaction of a

material to all the possible service variables cannot be fully assessed

in the laboratory. Consequently, tests have been carried out in pure

acid solutions and are intended only to provide a guide to general

uniform corrosion in these media. In-situ testing will provide more

reliable data for material selection.

‘SULPHURIC ACID NITRIC ACID

120 120

100

100

80— 80 —

60.

40—

Temperature Cc)

Temperature Ce)

201

2040 Go 80 100 2040 60 60 100

% Acid by Woight Sf Acid by Weight

e e

£ ie

i z

i i

5 10 15 0 20.40 60 80 100

Acid by Weight Se acid by Weight

Type C5321]

mils per year mm per year

‘ag pla a + a

<.03

03-13

Temperature CC)

13-75

‘a0 60 80 100

>75

by Weight

PITTING CORROSION

Pitting resistance is important, mainly in applications involving

contact with chloride solutions, particularly in the presence of

oxidising media. These conditions may be conducive to localised

penetration of the passive surface film on the steel and a single

deep pit may well be more damaging than a much greater number of

relatively shallow pits. Where pitting corrosion is anticipated, steels

containing molybdenum (such as CS316) should be considered,

The diagram below shows the critical temperature for initiation of

pitting (CPT) at different chloride contents for CS304, C5316 and

52205 types.

a

>

&

5

Critical pitting temperatures (CPT) for C5304, C5316 and CS2205 at

varying concentrations of sodium chloride (potentiostatic determination

at + 300mV SCE). pH = 6.0.

OXIDATION

S304 types have good oxidation resistance in intermittent service up

to 800°C and in continuous service to 830°C. Continuous use of

type 304 in the 450°C to 850°C temperature range is not

recommended due to carbide precipitation but CS304 often performs

well in temperatures fluctuating above and below this range.

‘One should use the “L” variant in these applications.

ATMOSPHERIC CORROSION

The atmospheric corrosion resistance of austenitic stainless steel Is

unequalled by virtually all other uncoated engineering materials.

Stainless steel develops maximum resistance to staining and pitting

with the addition of molybdenum. For this reason, it is common

Practice to use the CS316 molybdenum bearing grade in areas where

the atmosphere is highly polluted with chlorides, sulphur compounds

and solids, either singly or in combination. However, in urban and

rural areas CS304 generally performs satisfactorily.

INTERGRANULAR CORROSION

Sensitisation may occur when the Heat Affected Zones of welds in

some austenitic stainless steels are cooled through the sensitising

temperature range of between 450°C and 850°C. At this

temperature, a compositional change may occur at the grain

boundaries, If a sensitised material is then subjected to a corrosive

environment, intergranular attack may be experienced. This

corrosion takes place preferentially in the heat affected zone away

from and parallel to the weld. Susceptibility to this form of attack,

often termed “weld decay", may be assessed by the following

standard tests:

a) boiling copper sulphate/sulphuric acid test as specified in

ASTM A262-98, Practice E.

b) for non titanium stabilised grades only, boiling nitric acid test as

specified in ASTM A262-98, Practice C.

In the more severe nitric acid test, some weldments in

plates of CS304 may exhibit slight intergranular corrosion. For

service in the as-welded condition in severe chemical

environments, CS304L would be recommended In preference to CS304.

STRESS CORROSION CRACKING

Stress corrosion cracking (SCC) can occur in austenitic stainless

steels when they are stressed in tension in chloride environments at

temperatures in excess of about 60°C. The stress may be applied,

as in a pressure system or it may be residual arising from cold

working operations or welding. Additionally, the chloride ion

concentration need not be very high initially, if locations exist

which concentrations of salt can accumulate, Assessment of these

parameters and accurate prediction of the probability of SCC occurring in

service is therefore dificult

Where there is a likelihood of SCC occurring, a beneficial increase in life can

be easily obtained by a reduction in operating stress and temperature.

‘Alternatively, specially designed alloys, such as duplex stainless steels, will

have to be used where SCC cracking is likely to occur.

300}

200}

Temperature Ce)

cs304 |

cS316t

50]

00003 ~0.008.~=~=C 04 i 70

__c1¢96)

Resistance to Stress Corrosion Cracking (Laboratory results) for CS304L,

CS316L and CS2205.

FOR FURTHER INFORMATION PLEASE CONTACT:

Technical Customer Services

Columbus Stainless (Pty) Ltd

PO Box 133

Middelburg 1050

South Africa

Tel: +27 (13) 247 3343,

Fax: +27 (13) 247 2289

E-mail: technical-help@columbus.co.za

Commercial

Columbus Stainless (Pty) Ltd

PO Box 133

Middelburg 1050

South Africa

Tel: +27 (13) 247 2020

Fax: +27 (13) 247 2771

E-mail: commercial-help@columbus.co.za

Date of Issue: June 2007

Potrebbero piacerti anche

- Protocolo Obras RRSSDocumento21 pagineProtocolo Obras RRSSDaniel Carlos Sotelo MamaniNessuna valutazione finora

- Set - sgc.Pc.002 - Prueba Start Up Acs MscaDocumento4 pagineSet - sgc.Pc.002 - Prueba Start Up Acs MscaRogelio GuerraNessuna valutazione finora

- Tupa 2020 07 01 2020Documento49 pagineTupa 2020 07 01 2020Jesús Serquén EffioNessuna valutazione finora

- Verificación kit de botiquín en basesDocumento2 pagineVerificación kit de botiquín en basesRogelio GuerraNessuna valutazione finora

- Tuberias y Accesorios E.3.1Documento2 pagineTuberias y Accesorios E.3.1Rogelio GuerraNessuna valutazione finora

- SET - SGC.PC.006-F-06 Resistencia de Aisl. Circ. Elect PDFDocumento1 paginaSET - SGC.PC.006-F-06 Resistencia de Aisl. Circ. Elect PDFRogelio GuerraNessuna valutazione finora

- Galvanizado en CalienteDocumento24 pagineGalvanizado en CalienteJavier FloresNessuna valutazione finora

- SET - SGC.PC.003-F-03 Conductores ADI PDFDocumento1 paginaSET - SGC.PC.003-F-03 Conductores ADI PDFRogelio GuerraNessuna valutazione finora

- Manual de Operaciones de Molinete AlvaradoDocumento46 pagineManual de Operaciones de Molinete AlvaradoRogelio GuerraNessuna valutazione finora

- SET - sgc.PC.001-F-01 Registro Inspección de Inst. de Tuberias ConduitDocumento1 paginaSET - sgc.PC.001-F-01 Registro Inspección de Inst. de Tuberias ConduitRogelio GuerraNessuna valutazione finora

- SET - SGC.PC.003-F-03 Conductores ACS MSCA PDFDocumento1 paginaSET - SGC.PC.003-F-03 Conductores ACS MSCA PDFRogelio GuerraNessuna valutazione finora

- SET - SGC.PC.005-F-05 Resistencia de Aisl. Circ. SDI PDFDocumento1 paginaSET - SGC.PC.005-F-05 Resistencia de Aisl. Circ. SDI PDFRogelio GuerraNessuna valutazione finora

- Procedimiento Accidente de TrabajoDocumento8 pagineProcedimiento Accidente de TrabajoRogelio GuerraNessuna valutazione finora

- Sistema de alarma y detección en aeropuertoDocumento1 paginaSistema de alarma y detección en aeropuertoRogelio GuerraNessuna valutazione finora

- ID-M-1 Anexo 2 Identificaciones - Revisión 8Documento67 pagineID-M-1 Anexo 2 Identificaciones - Revisión 8Rogelio GuerraNessuna valutazione finora

- Modelo de SubmittalDocumento25 pagineModelo de SubmittalRogelio Guerra100% (3)

- SET - SGC.PC.004-F-04 Medición Continuidad PDFDocumento1 paginaSET - SGC.PC.004-F-04 Medición Continuidad PDFRogelio GuerraNessuna valutazione finora

- Manual Del Curso de PlataformaDocumento38 pagineManual Del Curso de PlataformaRogelio Guerra100% (1)

- Procedimientos - Ingeniería Lap 6Documento48 pagineProcedimientos - Ingeniería Lap 6Rogelio Guerra0% (1)

- Plan de Calidad - Mejoras en Edificaciones Del AeropuertoDocumento17 paginePlan de Calidad - Mejoras en Edificaciones Del AeropuertoRogelio GuerraNessuna valutazione finora

- Presentacion M&J C. I.Documento39 paginePresentacion M&J C. I.Rogelio GuerraNessuna valutazione finora

- Presentacion M&J SRLDocumento39 paginePresentacion M&J SRLRogelio GuerraNessuna valutazione finora

- IBM SPSS Statistics BaseDocumento341 pagineIBM SPSS Statistics Basedolce19gNessuna valutazione finora

- Formulario Quimica GeneralDocumento4 pagineFormulario Quimica GeneralRogelio GuerraNessuna valutazione finora

- Presentacion M&J SRLDocumento39 paginePresentacion M&J SRLRogelio GuerraNessuna valutazione finora

- 29 PT Reubicacion de Registro InternacionalDocumento9 pagine29 PT Reubicacion de Registro InternacionalRogelio GuerraNessuna valutazione finora

- Acta de Reunià N N°03Documento2 pagineActa de Reunià N N°03Rogelio GuerraNessuna valutazione finora

- Manual de Mantenimiento Paneles Metálicos PRECORDocumento2 pagineManual de Mantenimiento Paneles Metálicos PRECORRogelio Guerra100% (1)

- Matriz de Riesgos Laborales MRL 2Documento3 pagineMatriz de Riesgos Laborales MRL 2Junior MendozaNessuna valutazione finora