Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Fe05b PDF

Caricato da

vette512Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Fe05b PDF

Caricato da

vette512Copyright:

Formati disponibili

7

HOME

DTC P0107, P0108

5.21

GENERAL

f1939x9x

MAP Sensor

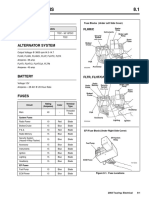

See Figure 5-51. The manifold absolute pressure sensor

(MAP sensor) is supplied 5 volts from the ECM (Pin 14) and

sends a signal back to the ECM (Pin 25). This signal varies in

accordance with engine vacuum and atmospheric barometric

pressure. Changes in barometric pressure are influenced by

weather and altitude.

Table 5-31. Code Description

DTC

LAMP

CODE

P0107

12

MAP sensor open/low

P0108

12

MAP sensor high

DESCRIPTION

MAP Sensor

Figure 5-51. Induction Module (Top View)

Diagnostic Notes

DIAGNOSTICS

1.

These codes will set if the MAP sensor signal is out of

range. Code P0108 can only be detected with the engine

running.

Connect BREAKOUT BOX (Part No. HD-43876)

between wire harness and ECM. See Section 5.7 BREAKOUT BOX: EFI.

2.

Use HARNESS CONNECTOR TEST KIT (Part No. HD41404), gray pin probes and patch cords.

With the MAP sensor disconnected, the ECM and Scanalyzer should recognize a low voltage. If low voltage is

observed, the ECM and harness are not at fault unless

there is a short to ground.

Scanalyzer Notes

Diagnostic Tips

The reference numbers below correlate with the circled numbers on the Test 5.21 flow charts.

Gently place a jumper wire across MAP sensor connector [80B] Terminals B and C using HARNESS CONNECTOR TEST KIT (Part No. HD-41404), gray male probes

and patch cord. With the jumper in place, the ECM and

Scanalyzer should recognize a high voltage.

MAP sensor output check. Using the VACUUM PUMP

(Part No. HD-23738), apply a vacuum to the pressure

port of the MAP sensor. The signal voltage should lower

as the vacuum is applied.

The MAP and TP sensors are connected to the same

reference line (+5V Vref). If the reference line goes to

ground or open, multiple codes will be set (DTC P0107,

P0108, P0122, P0123).

The Scanalyzer icon appears at those points in the flow chart

where the Scanalyzer can be used.

1.

Press F1 key on Scanalyzer to view volts.

2003 Touring: Engine Management (EFI)

5-73

HOME

f1743q9s

MAP

Sensor

25

26

R/W

To TP

Sensor

BK/W

To TP, ET &

IAT Sensors

V/W

A B C

R/W

[80B]

V/W

A B C

BK/W

[80A]

[78B]

[78A]

14

ECM

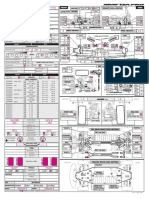

Figure 5-52. MAP Sensor Circuit

Table 5-32. Wire Harness Connectors in Figure 5-52.

DESCRIPTION

NO.

5-74

TYPE

LOCATION

[78]

ECM

36-Place Packard

Under Right Side Cover

[80]

MAP Sensor

3-Place Packard

Top of Induction Module

2003 Touring: Engine Management (EFI)

HOME

Test 5.21 (Part 1 of 2)

MAP SENSOR: DTC P0107, P0108

USING BREAKOUT BOX

USING SCANALYZER

Connect Breakout Box. With ignition ON,

measure voltage between Terminals 25

and 26 on Breakout Box.

With engine running, observe

Scanalyzer MAP voltage values.

1

With key ON, engine OFF, voltage must be

between 3.5 and 5.0 volts.

With key ON, engine running, voltage must

be between 1.5-3.0 volts at hot idle.

Does voltage fit specifications?

YES

NO

Perform 5.8 WIGGLE TEST

to check for intermittents.

Intermittents present?

STOP

Go to Test 5.21 (Part 2 of 2).

YES

NO

To the source of intermittents, start

with box marked by Bold Asterisk

under Test 5.21 (Part 2 of 2). Wiggle

harness while watching DVOM.

Replace MAP sensor. Clear codes if a

Scanalyzer is available and road test. Did

check engine lamp illuminate and set DTC

P0107 or P0108?

7620

YES

NO

Install original MAP sensor.

Replace ECM (reprogram,

relearn) and road test again

to verify.

System

now OK.

7630

7625

At some point in the flow chart you

may be instructed to jump directly

to the box marked by a bold asterisk. Disregard the asterisk (but not

the instruction box) if your normal

progression through the chart

brings you to this location.

Clear codes and confirm proper

operation with no check engine

lamp.

2003 Touring: Engine Management (EFI)

5-75

HOME

Test 5.21 (Part 2 of 2)

MAP SENSOR: DTC P0107, P0108

Continued from

Test 5.21 (Part 1 of 2).

Check the 5 volt reference supply

at Connector [80B]. With

ignition ON, measure voltage between

Sockets C (R/W) and A (BK/W).

Voltage approximately 5.0 volts?

YES

NO.

Greater

than 6V.

Connect Breakout Box to Connector [78B]

leaving ECM disconnected.

OPEN CHECK: Measure resistance

between Socket B of Connector [80B]

and Terminal 25 of Breakout Box.

Resistance less than 1 ohm?

NO.

Less

than 4.5V.

Locate short to 12 volts

on R/W wire. Repair

as necessary.

7635

YES

NO

SHORT CHECK: Measure

resistance between Socket B

of Connector [80B] and

chassis ground. Resistance

greater than 1 megohm?

Locate and repair

open on V/W wire.

7645

YES

NO

Replace

MAP sensor.

Connect Breakout Box to

Connector [78B] leaving ECM

disconnected. Check continuity

between Socket C of Connector [80B]

and Terminal 14 of Breakout Box.

Then measure continuity between

Socket A of Connector [80B] and

Terminal 26 of Breakout Box.

Continuity less than 1 ohm?

Locate and repair

grounded V/W wire.

7650

YES

NO

Check resistance between

Socket C of Connector

[80B] and Terminal 26 of

Breakout Box.

Resistance greater than

1 megohm?

Locate and repair

open wire.

YES

NO

Replace ECM.

Reprogram and learn

password.

Locate and repair

short between

R/W and BK/W

wires.

7640

7655

7641

7642

At some point in the flow chart you

may be instructed to jump directly

to the box marked by a bold asterisk. Disregard the asterisk (but not

the instruction box) if your normal

progression through the chart

brings you to this location.

5-76

2003 Touring: Engine Management (EFI)

Clear codes and confirm proper

operation with no check engine

lamp.

HOME

DTC P0112, P0113

5.22

GENERAL

DIAGNOSTICS

IAT Sensor

Diagnostic Tips

The ECM supplies and monitors a voltage signal (Pin 7) to

one side of the intake air temperature sensor (IAT sensor).

The other side of the IAT sensor is connected to a common

sensor ground, which is also connected to the ECM (Pin 26).

The IAT sensor is a thermistor device, meaning that at a specific temperature, it will have a specific resistance across its

terminals. As this resistance varies, so does the voltage on

Pin 7.

At high temperatures, the resistance of the sensor is very

low, which effectively lowers the signal voltage on Pin 7.

At low temperatures, the resistance is very high, allowing

the voltage to rise close to 5 volts.

The Scanalyzer displays intake air temperature in degrees, or

by pressing the F1 key, in volts. An intermittent may be

caused by a poor connection, rubbed through wire insulation

or a wire broken inside the insulation. Check the following

conditions:

Poor connection: Inspect ECM and harness connector

[78] for backed out terminals, improper mating, broken

locks, improperly formed or damaged terminals, poor terminal-to-wire connection and damaged harness.

See Section 5.8 WIGGLE TEST to locate intermittents: If connections and harness are OK, use the Scanalyzer to check the intake air temperature reading while

moving related connectors and wiring harness. If failure

is induced, the intake air temperature display will change.

Shifted sensor: See Table 5-34. Use table to test the

intake air temperature sensor at various temperature levels in order to evaluate the possibility of a shifted (out-ofcalibration) sensor which can result in driveability problems.

The ECM monitors this voltage to compensate for various

operating conditions.

NOTE

Table 5-33. Code Description

DTC

LAMP

CODE

P0112

15

IAT sensor voltage low

P0113

15

IAT sensor open/high

All voltage and resistance values are approximate (20%).

Measure IAT sensor resistance between ECM Terminal 7 and

system ground (ECM Terminal 26).

DESCRIPTION

Diagnostic Notes

The reference numbers below correlate with the circled numbers on the Test 5.22 flow charts.

Table 5-34. IAT Sensor Table

TEMP C

RESISTANCE

VOLTAGE

TEMP F

-40

100950

4.9

-40

-30

53100

4.8

-22

-20

29121

4.7

-4

-10

16599

4.5

14

9750

4.2

32

10

5970

3.8

50

20

3747

3.3

68

25

3000

3.0

77

30

2417

2.7

86

40

1598

2.2

104

50

1080

1.8

122

60

746

1.4

140

70

526

1.0

158

1.

Connect BREAKOUT BOX (Part No. HD-43876) to EFI

wire harness only (leave ECM disconnected). See Section 5.7 BREAKOUT BOX: EFI.

2.

If the engine has not been operated for 1 hour, the measured resistance should be very close to the measured

resistance across the ET sensor which is Pins 6 and 26

on the Breakout Box. Scanalyzer values (using Data

Monitor Mode) will be approximately the same if code is

historic. Current code will read default value.

3.

Use HARNESS CONNECTOR TEST KIT (Part No. HD41404), gray pin probes and patch cords.

4.

Use HARNESS CONNECTOR TEST KIT (Part No. HD41404), gray socket probes and patch cords.

5.

See INTAKE AIR TEMPERATURE SENSOR, REMOVAL/INSTALLATION, in the 2003 Touring Models Service Manual (Part Number 99483-03).

Scanalyzer Notes

The Scanalyzer icon appears at those points in the flow chart

where the Scanalyzer can be used.

2003 Touring: Engine Management (EFI)

5-77

HOME

f1743r9s

IAT

Sensor

A B

[78B]

[78A]

BK/W

To TP, ET &

MAP Sensors

Lt GN/Y

Lt GN/Y

[89B]

A B

BK/W

[89A]

26

ECM

Figure 5-53. IAT Sensor Circuit

Table 5-35. Wire Harness Connectors in Figure 5-53.

DESCRIPTION

NO.

5-78

TYPE

LOCATION

[78]

ECM

36-Place Packard

Under Right Side Cover

[89]

IAT Sensor

2-Place Packard

Below Fuel Tank (Right Side)

2003 Touring: Engine Management (EFI)

HOME

Test 5.22 (Part 1 of 2)

IAT SENSOR: DTC P0112, P0113

Connect Breakout Box to Connector [78B]

leaving ECM disconnected. With engine at room

temperature (60-90 F or 16-32 C), use a DVOM

to measure resistance across Terminals 7

and 26 on Breakout Box.

Resistance between 1.4k ohms and 6.9k ohms?

1

2

YES

NO

Connect ECM to Breakout Box.

Perform 5.8 WIGGLE TEST to check for

intermittents. Intermittents present?

STOP

Go to Test 5.22 (Part 2 of 2).

YES

NO

While wiggling harness, perform

steps marked by BOLD ASTERISKS under Test 5.22 (Part 2 of 2).

Repair as necessary.

Disconnect Connector [89]. Turn

ignition ON. Using a DVOM,

measure the voltage between

Terminals 7 (positive) and 26

(negative) on Breakout Box.

Voltage approximately 5 volts?

7715

YES

Replace IAT sensor, clear codes if

Scanalyzer is available and road test.

Did check engine lamp illuminate and

set DTC P0112 or P0113?

NO.

Less than

4.7 volts.

NO.

Greater than

5.3 volts.

With IAT sensor disconnected,

disconnect ECM from breakout box.

Measure resistance between

Breakout Box Pin 7 and Pins 10 or 28.

Resistance less than 1 megohm?

Unplug ECM leaving Breakout Box

connected at vehicle harness.

Measure voltage between

Breakout Box Pin 7 and Pins 10 or 28.

Voltage 0 volts?

YES

NO

YES

NO

YES

NO

Install original IAT

sensor. Replace

ECM. Reprogram

and learn password.

Road test.

System

OK.

Locate and repair

short to ground on

Lt GN/Y wire.

Replace ECM.

Reprogram and

learn password.

Replace ECM.

Reprogram and

learn password.

Examine IAT signal wire (Lt GN/Y)

for short to voltage and repair.

7725

7730

7735

7740

7745

7720

Clear codes and confirm proper

operation with no check engine

lamp.

At some point in the flow chart you

may be instructed to jump directly

to the box marked by a bold asterisk. Disregard the asterisk (but not

the instruction box) if your normal

progression through the chart

brings you to this location.

2003 Touring: Engine Management (EFI)

5-79

HOME

Test 5.22 (Part 2 of 2)

IAT SENSOR: DTC P0112, P0113

Continued from

Test 5.22 (Part 1 of 2).

Disconnect Connector [89] and examine

for damage. Connector OK?

YES

NO

Using a DVOM, measure the resistance

between Socket A of Connector [89B]

and Terminal 7 on Breakout Box.

Resistance less than 1.0 ohm?

Repair

connector.

7750

YES

NO

Using a DVOM, measure the resistance

between Socket B of Connector [89B]

and Terminal 26 on Breakout Box.

Resistance less than 1.0 ohm?

Locate and repair open

on Lt GN/Y wire.

YES

NO

Using a DVOM, measure the resistance

between Terminals 7 and 26 on

Breakout Box. Resistance greater

than 1.0 megohm?

Locate and repair

open on BK/W wire.

YES

NO

Using a DVOM, measure the resistance

between Terminal 7 on Breakout Box

and ground. Resistance greater

than 1.0 megohm?

Locate and repair

short between Lt GN/Y

and BK/W wires.

7750

7750

7750

YES

NO

Remove IAT sensor and measure

resistance across Pins in Connector

[89A]. With sensor at room temperature

(60-90 F or 16-32 C), is resistance

between 1.4k ohms and 6.9k ohms?

Locate and repair

short to ground

7750

YES

At some point in the flow chart you

may be instructed to jump directly

to the box marked by a bold asterisk. Disregard the asterisk (but not

the instruction box) if your normal

progression through the chart

brings you to this location.

NO

Perform 5.8 WIGGLE TEST on steps

marked with a BOLD ASTERISK above to

locate intermittents. Repair as necessary.

Replace

IAT sensor.

7760

7755

5-80

2003 Touring: Engine Management (EFI)

Clear codes and confirm proper

operation with no check engine

lamp.

HOME

DTC P0117, P0118

5.23

GENERAL

DIAGNOSTICS

ET Sensor

Diagnostic Tips

The ECM supplies and monitors a voltage signal (Pin 6) to

one side of the engine temperature sensor (ET sensor). The

other side of the ET sensor is connected to a common sensor

ground, which is also connected to the ECM (Pin 26).

The ET sensor is a thermistor device, which means that at a

specific temperature it will have a specific resistance across

its terminals. As this resistance varies, so does the voltage on

Pin 6.

At high temperatures, the resistance of the sensor is very

low, which effectively lowers the signal voltage on Pin 6.

The Scanalyzer displays engine temperature in degrees, or

by pressing the F1 key, in volts. After the engine is started,

the temperature should rise steadily.

An intermittent may be caused by a poor connection, rubbed

through wire insulation or a wire broken inside the insulation.

Check the following conditions:

Poor connection: Inspect ECM and harness connector

[78] for backed out terminals, improper mating, broken

locks, improperly formed or damaged terminals, poor terminal-to-wire connection and damaged harness.

See Section 5.8 WIGGLE TEST to locate intermittents: If connections and harness are OK, use the Scanalyzer to check the intake air temperature reading while

moving related connectors and wiring harness. If failure

is induced, the intake air temperature display will change.

Shifted sensor: See Table 5-37. Use table to test the

engine temperature sensor at various temperature levels

in order to evaluate the possibility of a shifted (out-of-calibration) sensor which can result in driveability problems.

At low temperatures, the resistance is very high, allowing

the voltage to rise close to 5 volts.

The ECM monitors this voltage to compensate for various

operating conditions. The ECM also uses the sensor input as

a reference for determining IAC pintle position.

Table 5-36. Code Description

DTC

LAMP

CODE

P0117

14

ET sensor voltage low

P0118

14

ET sensor open/high

NOTE

All voltage and resistance values are approximate (20%).

Measure ET sensor resistance between ECM Terminal 6 and

system ground (ECM Terminal 26).

DESCRIPTION

Diagnostic Notes

The reference numbers below correlate with the circled numbers on the Test 5.23 flow charts.

Table 5-37. ET Sensor Table

TEMP C

RESISTANCE

VOLTAGE

TEMP F

-10

16599

4.5

14

9750

4.1

32

10

5970

3.8

50

20

3747

3.3

68

25

3000

3.0

77

30

2417

2.7

86

40

1598

2.2

104

50

1080

1.8

122

60

746

1.4

140

70

526

1.0

158

80

377

0.8

176

90

275

0.6

194

100

204

0.5

212

110

153

0.4

230

1.

Connect BREAKOUT BOX (Part No. HD-43876) to EFI

wire harness only (leave ECM disconnected). See Section 5.7 BREAKOUT BOX: EFI.

2.

If engine has not been operated for 1 hour, the measured

resistance should be very close to the measured resistance across the IAT sensor which is Pins 7 and 26 on

the Breakout Box. Scanalyzer values (using Data Monitor Mode) will be approximately the same if code is historic. Current code will read default value.

3.

Use HARNESS CONNECTOR TEST KIT (Part No. HD41404), gray pin probes and patch cords.

4.

Use HARNESS CONNECTOR TEST KIT (Part No. HD41404), gray socket probes and patch cords.

5.

See ENGINE TEMPERATURE SENSOR, REMOVAL/

INSTALLATION, in the 2003 Touring Models Service

Manual (Part Number 99483-03).

Scanalyzer Notes

The Scanalyzer icon appears at those points in the flow chart

where the Scanalyzer can be used.

2003 Touring: Engine Management (EFI)

5-81

HOME

f1743s9s

ET

Sensor

[90B]

A B

PK/Y

A B

BK/W

[90A]

BK/W

[78B]

[78A]

PK/Y

To TP, IAT &

MAP Sensors

26

ECM

Figure 5-54. ET Sensor Circuit

Table 5-38. Wire Harness Connectors in Figure 5-54.

NO.

5-82

DESCRIPTION

TYPE

LOCATION

[78]

ECM

36-Place Packard

Under Right Side Cover

[90]

ET Sensor

2-Place Packard

Back of Front Cylinder (Left Side)

2003 Touring: Engine Management (EFI)

HOME

Test 5.23 (Part 1 of 2)

ET SENSOR: DTC P0117, P0118

1

2

Connect Breakout Box to Connector [78B]

leaving ECM disconnected. With engine at

room temperature (60-90 F or 16-32 C),

use a DVOM to measure resistance across

Terminals 6 and 26 on Breakout Box. Resistance between 1.4k ohms and 6.9k ohms?

YES

NO

Connect ECM to Breakout Box.

Perform 5.8 WIGGLE TEST to check for

intermittents. Intermittents present?

STOP

Go to Test 5.23 (Part 2 of 2).

YES

NO

While wiggling harness, perform

steps marked by BOLD ASTERISKS under Test 5.23 (Part 2 of 2).

Repair as necessary.

Disconnect Connector [90]. Turn

ignition ON. Using a DVOM,

measure the voltage between

Terminals 6 (positive) and

26 (negative) on Breakout Box.

Voltage approximately 5 volts?

7660

YES

Replace ET sensor, clear codes if

Scanalyzer is available and road test.

Did check engine lamp illuminate and

set DTC P0117 or P0118?

YES

NO

Install original

ET sensor and replace

ECM. Reprogram and

learn password.

Road test.

System

OK.

7665

7670

NO.

Less than

4.7 volts.

NO.

Greater than

5.3 volts.

With ET sensor disconnected,

disconnect Connector [78B].

Measure resistance between

Pin 6 and Pins 10 or 28.

Resistance less than 1 megohm?

Unplug ECM leaving Breakout Box

connected at vehicle harness.

Measure voltage between

Pin 6 and Pins 10 or 28.

Voltage 0 volts?

YES

NO

YES

NO

Locate and repair

short to ground

on PK/Y wire.

Replace ECM.

Reprogram and

learn password.

Replace ECM.

Reprogram and

learn password.

Examine ET

signal wire (PK/Y)

for short to voltage

and repair.

7675

7680

7685

7690

Clear codes and confirm proper

operation with no check engine

lamp.

At some point in the flow chart you

may be instructed to jump directly

to the box marked by a bold asterisk. Disregard the asterisk (but not

the instruction box) if your normal

progression through the chart

brings you to this location.

2003 Touring: Engine Management (EFI)

5-83

HOME

Test 5.23 (Part 2 of 2)

ET SENSOR: DTC P0117, P0118

Continued from

Test 5.23 (Part 1 of 2).

Disconnect Connector [90B] and

examine for damage. Connector OK?

YES

NO

Using a DVOM, measure resistance

between Socket A of Connector [90B]

and Terminal 6 on Breakout Box.

Resistance less than 1.0 ohm?

Repair

connector.

7695

YES

NO

Using a DVOM, measure resistance

between Socket B of Connector [90B]

and Terminal 26 on Breakout Box.

Resistance less than 1.0 ohm?

Locate and repair

open on PK/Y wire.

YES

NO

Using a DVOM, measure the resistance

between Terminals 6 and 26 on

Breakout Box. Resistance greater

than 1.0 megohm?

Locate and repair

open on BK/W wire.

YES

NO

Using a DVOM, measure the resistance

between Terminal 6 on Breakout Box

and ground. Resistance greater

than 1.0 megohm?

Locate and repair

short between PK/Y

and BK/W wires.

YES

NO

Remove ET sensor and measure

resistance across Pins of Connector [90B].

With sensor at room temperature (60-90 F

or 16-32 C), is resistance between

1.4k ohms and 6.9k ohms?

Locate and repair

short to ground.

YES

NO

Perform 5.8 WIGGLE TEST on steps

marked with a BOLD ASTERISK above to

locate intermittents. Repair as necessary.

7695

7695

7695

7695

Replace

ET sensor.

7710

7705

5-84

2003 Touring: Engine Management (EFI)

Clear codes and confirm proper

operation with no check engine

lamp.

At some point in the flow chart you

may be instructed to jump directly

to the box marked by a bold asterisk. Disregard the asterisk (but not

the instruction box) if your normal

progression through the chart

brings you to this location.

HOME

DTC P0122, P0123

GENERAL

5.24

Check for the following conditions:

Poor Connection: Inspect ECM and harness connector

[78B] for backed out terminals, improper mating, broken

locks, improperly formed or damaged terminals, poor terminal-to-wire connection and damaged harness.

Perform 5.8 WIGGLE TEST to locate intermittents: If

connections and harness check out OK, monitor TP sensor voltage using a Scanalyzer or DVOM while moving

related connectors and wiring harness. If the failure is

induced, the TP sensor display will also change in data

monitor mode.

TP sensor scaling: Observe the TP sensor voltage display while opening the throttle with engine stopped and

ignition key ON. Display should vary from closed throttle

TP sensor voltage (when throttle is closed) to greater

than 4.5 volts (when throttle is held wide open). As the

throttle is slowly moved, the voltage should change

gradually without spikes or low voltages being observed.

TP Sensor

The ECM supplies a 5 volt signal (Pin 14) to the throttle position sensor (TP sensor). The TP sensor sends a signal back

to the ECM (Pin 24). The returned signal varies in voltage

according to throttle position.

At idle (closed throttle), the signal is typically in the range

of 0.20-0.60 volts.

At wide open throttle, the signal is normally 4.6-4.9 volts.

A code P0122 or P0123 will set if the TP sensor voltage signal does not fall within the acceptable range.

If TPS sensor is greater than 90%, then the system is in

clear flood mode and engine will not start. While spark

will be present, fuel is shut off (injectors disabled). Problem can be mechanical, such as throttle/throttle cables

stuck.

Table 5-39. Code Description

DTC

LAMP

CODE

P0122

11

TP sensor open/low

P0123

11

TP sensor high

DESCRIPTION

Diagnostic Notes

The reference numbers below correlate with the circled numbers on the Test 5.24 flow charts.

1.

DIAGNOSTICS

Diagnostic Tips

The Scanalyzer or DVOM reads throttle position in volts, or by

pressing the F1 key, as a percentage of throttle opening. Voltage should increase at a steady rate as the throttle is moved

from idle to wide open. A short to ground or open on the GY/

V or R/W wires also will result in a DTC P0122. A short to

ground or open on the R/W wire (+5v REF) sets multiple

codes as described below.

NOTE

The MAP and TP sensors are both connected to the same

reference line (+5v Vref). If the line goes to ground or open,

multiple trouble codes will be set, that is, diagnostic trouble

codes P0107, P0108 and P0122 or P0123. Start with the

trouble code having the lowest ranking value.

Connect a BREAKOUT BOX (Part No. HD-43876)

between EFI wire harness and ECM before measuring

voltage. See Section 5.7 BREAKOUT BOX: EFI.

a.

If using a DVOM to measure voltage, take reading

across Pin 24 (positive lead) and Pin 26 (negative

lead) on Breakout Box.

b.

If using Scanalyzer to measure voltage, consult

Data Monitor Mode. See Section 5.5 SCANALYZER: EFI for more information.

2.

See THROTTLE POSITION SENSOR, REMOVAL/

INSTALLATION, in the 2003 Touring Models Service

Manual (Part Number 99483-03).

3.

Use HARNESS CONNECTOR TEST KIT (Part No. HD41404), gray pin probes and patch cords.

Scanalyzer Notes

The Scanalyzer icon appears at those points in the flow chart

where the Scanalyzer can be used.

2003 Touring: Engine Management (EFI)

5-85

HOME

s0452x9x

TP

sensor

A B C

R/W

[88B]

To MAP, ET &

IAT sensors

GY/V

A B C

BK/W

[88A]

GY/V

BK/W

[78B]

[78A]

R/W

To MAP

sensor

14

24

26

ECM

Figure 5-55. TP Sensor Circuit

Table 5-40. Wire Harness Connectors in Figure 5-55.

NO.

5-86

DESCRIPTION

TYPE

LOCATION

[78]

ECM

36-Place Packard

Under Right Side Cover

[88]

TP Sensor

3-Place Packard

Below Fuel Tank (Right Side)

2003 Touring: Engine Management (EFI)

HOME

Test 5.24 (Part 1 of 2)

TP SENSOR: DTC P0122, P0123

With ignition key ON, measure TP sensor voltage while

gradually opening throttle. Does voltage increase steadily

with no spikes or low voltages from 0.2-0.6 volts at idle

(closed throttle) to 4.6-4.9 volts at wide open throttle?

YES

NO.

But voltage is

greater than

4.95 volts.

Check engine lamp ON

continuously and

DTC P0122 or P0123

the only one set?

NO.

Low voltage

or spikes

observed.

Unplug Connector [88B] and

measure voltage between

Sockets B (+) and A (-) with

ignition ON.

Is reading 4.8-5.0 volts?

STOP

Go to Test 5.24 (Part 2 of 2).

YES

NO

YES

NO

Replace ECM.

Reprogram and

learn password.

Perform 5.8 WIGGLE TEST

to check for intermittents.

Intermittents present?

Measure resistance

between Terminal

24 on Breakout Box

and chassis ground.

Greater than 1

megohm?

Measure

resistance between

Socket B of Connector [88B] and Terminal

14 on Breakout Box.

Less than 1.0 ohm?

7555

YES

NO

While wiggling harness,

start with the first step of

Test 5.24 (Part 2 of 2)

(marked by BOLD ASTERISK). Repair as necessary.

Replace TP sensor,

clear codes if Scanalyzer is

available and road test.

Did check engine lamp

illuminate and set

DTC P0122 or P0123?

YES

NO

Replace

TP sensor.

Locate and repair

short to ground

on GY/V signal

wire.

7560

YES

NO

Install original

TP sensor, replace ECM

(reprogram and learn

password) and road test.

System

OK.

7595

7605

YES

NO

Locate and repair

open in

BK/W wire.

Locate and

repair open in

R/W wire.

7610

7570

7615

7565

Clear codes and confirm proper

operation with no check engine

lamp.

At some point in the flow chart you

may be instructed to jump directly

to the box marked by a bold asterisk. Disregard the asterisk (but not

the instruction box) if your normal

progression through the chart

brings you to this location.

2003 Touring: Engine Management (EFI)

5-87

HOME

Test 5.24 (Part 2 of 2)

TP SENSOR: DTC P0122, P0123

Continued from Test 5.24 (Part 1 of 2).

With ignition key OFF, disconnect Connector [78B].

Turn ignition key ON. Voltage greater than 0 volts across

Terminals 24 and 26 on Breakout Box?

YES

NO

Locate and repair

short between

GY/V signal wire

and 12 volts.

Measure resistance between

Terminal 24 on Breakout Box and

Socket C of Connector [88B].

Less than 0.5 ohm?

7575

YES

NO

Measure resistance

between Sockets C and B

on Connector [88B].

Less than 1.0 megohm?

Locate and repair

open on GY/V

signal wire.

YES

NO

Locate and repair

short between R/W

and GY/V signal

wires.

Replace

TP sensor.

7590

7585

Clear codes and confirm proper

operation with no check engine

lamp.

5-88

2003 Touring: Engine Management (EFI)

At some point in the flow chart you

may be instructed to jump directly

to the box marked by a bold asterisk. Disregard the asterisk (but not

the instruction box) if your normal

progression through the chart

brings you to this location.

7580

HOME

DTC P0261, P0262, P0263, P0264

GENERAL

5.25

s0472x9x

Fuel Injectors

The fuel injectors are solenoids that allow pressurized fuel

into the intake tract. The injectors are timed to the engine

cycle and triggered sequentially. The power for the injectors

comes from the system relay. The system relay also provides

power for the fuel pump and the ignition coil. The ECM provides the path to ground to trigger the injectors.

NOTE

ECM power fuse and EFI system relay failures or wiring harness problems will cause 12 volt power to be lost to both

injectors, ignition coils and fuel pump.

Figure 5-56. Fuel Injector Connector

HD34730-2C

Table 5-41. Code Description

DTC

LAMP

CODE

P0261

23

Front injector open/low

P0262

23

Front injector high

P0263

32

Rear injector open/low

P0264

32

Rear injector high

DESCRIPTION

Figure 5-57. Fuel Injector Test Lamp

(Part No. HD-34730-2C)

DIAGNOSTICS

Diagnostic Notes

The reference numbers below correlate with the circled numbers on the Test 5.25 flow charts.

1.

See FUEL INJECTORS, REMOVAL/INSTALLATION, in

the 2003 Touring Models Service Manual (Part Number

99483-03).

2.

Use HARNESS CONNECTOR TEST KIT (Part No. HD41404), purple pin probe and patch cord.

3.

Connect a BREAKOUT BOX (Part No. HD-43876)

between EFI wire harness and ECM. See Section 5.7

BREAKOUT BOX: EFI.

4.

Use HARNESS CONNECTOR TEST KIT (Part No. HD41404), gray socket probe and patch cord.

2003 Touring: Engine Management (EFI)

5-89

HOME

[62B]

f1973k9s

System

relay

[62B]

Y/GN

O/GY

[141B] [141A]

BK

AB

AB

W/BK

Y/BE

BE/O

C D

GY/BE

C D

[85B] [85A]

A B

Y/BE

A B

8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36

Ignition

coil

[83B] [83A]

W/BK

BE/GY

GN/GY

15 amp

ECM fuse

W/Y

GY/BE

BE/O

12

11

10

9

8

7

6

5

4

3

2

1

Battery

R

W/BK

BK

8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36

Y/GN

BE/GY

Coil F

Ion

[84B] [84A]

3 4

Inj. F

W/Y

15 amp

fuel pump

fuse

3 4

Inj. R

Y/GN

GN/O

AB

ECM

Fuel pump

[13A] [13B]

AB

Coil R

30 85 86

GN/O

W/BK

87A

BE/GY

87

Q C P R

[78B]

Y/GN

[78A]

12

11

10

9

8

7

6

5

4

3

2

1

BK

R/BK

BK

I BA

15 amp

IGN fuse

GY

Main circuit

breaker

[33B]

[33A]

Ignition

switch

W/BK

12 11 10 9 8 7 6 5 4 3 2 1

12 11 10 9 8 7 6 5 4 3 2 1

[8B] [8A]

[22A]

[22B]

BK

12-Place on

FLHP-I Only

BK

BK

Engine stop

switch

Figure 5-58. Battery Voltage Circuit Diagram (FLHR/C-I, FLHP-I)

Table 5-42. Wire Harness Connectors in Figure 5-58.

5-90

NO.

DESCRIPTION

TYPE

LOCATION

[8]

Ignition (Main to EFI Harness)

12-Place Deutsch (Gray)

Under Right Side Cover

[22]

Right Handlebar Switches

12-Place Deutsch (Black)

Inside Headlamp Nacelle

[33]

Ignition/Light Key Switch

3-Place Packard

Under Left Side Cover

[78]

ECM

36-Place Packard

Under Right Side Cover

[83]

Ignition Coil

4-Place Packard

Below Fuel Tank (Left Side)

[84]

Front Injector

2-Place Packard

Below Fuel Tank (Left Side)

[85]

Rear Injector

2-Place Packard

Below Fuel Tank (Left Side)

2003 Touring: Engine Management (EFI)

HOME

[62B]

f1973a9s

System relay

BE/GY

GN/O

W/BK

Y/GN

O/GY

[84B] [84A]

15 amp

fuel pump

fuse

W/Y

[141B] [141A]

BK

Y/GN

AB

AB

W/BK

Y/BE

BE/O

C D

GY/BE

C D

[85B] [85A]

A B

Y/BE

A B

Ignition

coil

[83B] [83A]

W/BK

BE/GY

GN/GY

15 amp

ECM fuse

W/Y

BK

GY/BE

BE/GY

BE/O

12

11

10

9

8

7

6

5

4

3

2

1

12

11

10

9

8

7

6

5

4

3

2

1

Battery

R

W/BK

Coil F

Y/GN

GN/O

AB

Ion

Fuel pump

[13A] [13B]

AB

Inj. F

8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36

Inj. R

8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36

ECM

1 2 3 4 5 6 7

1 2 3 4 5 6 7

Coil R

87A

87

30 85 86

[78B]

I Q C P R

Y/GN

[78A]

BK

R/BK

BK

Main circuit

breaker

DCBA

[33B]

[33A]

15 amp

IGN fuse

Ignition

switch

GY

W/BK

12 11 10 9 8 7 6 5 4 3 2 1

BK

BK

[1B]

[1A]

12 11 10 9 8 7 6 5 4 3 2 1

[8B] [8A]

BK

[22A]

[22B]

12 11 10 9 8 7 6 5 4 3 2 1

12 11 10 9 8 7 6 5 4 3 2 1

Engine stop

switch

Figure 5-59. Battery Voltage Circuit Diagram (FLTR-I, FLHTC/U-I)

Table 5-43. Wire Harness Connectors in Figure 5-59.

NO.

DESCRIPTION

TYPE

LOCATION

[1]

Main to Interconnect Harness

12-Place Deutsch (Black)

Inner Fairing (Right Fairing Bracket)

[8]

Main to EFI Harness

12-Place Deutsch (Gray)

Under Right Side Cover

[22]

Right Handlebar Switches

12-Place Deutsch (Black)

Inner Fairing (Right Fairing Support Brace)

[33]

Ignition/Light Key Switch

4-Place Packard

Inner Fairing (Top Fork Bracket)

[78]

ECM

36-Place Packard

Under Right Side Cover

[83]

Ignition Coil

4-Place Packard

Below Fuel Tank (Left Side)

[84]

Front Injector

2-Place Packard

Below Fuel Tank (Left Side)

[85]

Rear Injector

2-Place Packard

Below Fuel Tank (Left Side)

2003 Touring: Engine Management (EFI)

5-91

HOME

Test 5.25 (Part 1 of 3)

FUEL INJECTORS: DTC P0261, P0262, P0263, P0264

Is wire bail on connector securely

attached to the fuel injector?

YES

NO

See Figure 5-57. Using Fuel

Injector Test Lamp, crank

engine. Does lamp flash?

Reconnect.

7785

YES

NO

Recheck connections.

Perform 5.8 WIGGLE TEST

to check for intermittents.

Intermittents present?

Check Socket A (Y/GN wire)

on Connector [84B]/[85B] to

ground. Voltage equivalent to

battery voltage for 2 seconds

after key ON?

YES

NO

Repair

intermittent.

7790

Measure resistance

of suspect injector

across injector

terminals. Is resistance

10-25 ohms?

YES

NO

STOP

Check for 12 volts at Terminal 87

of system relay during first 2

seconds after key ON.

Correct voltage present?

Go to Test 5.25 (Part 2 of 3).

YES

NO

YES

Check for loose

or corroded terminals

in harness.

NO

Replace

injector.

System relay OK. Measure

resistance between Terminal 87 of

system relay and Socket A

(Y/GN wire) of Connector [84B]/[85B].

Resistance less than 0.5 ohm?

7795

7790

YES

NO

Perform 5.8 WIGGLE TEST

to check for intermittents.

Repair as necessary.

Locate and repair

bad connection

or open wire.

7820

STOP

Go to Test 5.25

(Part 3 of 3).

7825

Clear codes and confirm proper

operation with no check engine

lamp.

5-92

2003 Touring: Engine Management (EFI)

HOME

Test 5.25 (Part 2 of 3)

FUEL INJECTORS: DTC P0261, P0262, P0263, P0264

2

3

FRONT INJECTOR: DTC P0261 or P0262.

REAR INJECTOR: DTC P0263 or P0264.

Measure resistance between Socket B of

Connector [84B] and Terminal 21 (W/Y wire)

on Breakout Box.

Measure resistance between Socket B of

Connector [85B] and Terminal 19 (GN/GY wire)

on Breakout Box.

2

3

Resistance

less than 0.5 ohm?

YES

NO

Check for continuity between

Terminal 10 on Breakout Box

and ground.

Locate and repair

open or poor

connection.

7805

Continuity present?

YES

NO

Front injector code: Check for

continuity between Terminals 10 and

21 on Breakout Box.

Rear injector code: Check for

continuity between Terminals 10 and

19 on Breakout Box.

Locate and

repair open.

7808

Continuity present?

YES

NO

Locate and

repair short

to ground.

With key on, check for voltage

to ground (Terminal 10 on

Breakout Box).

7808

Front injector code: Terminal 21

on Breakout Box.

Rear injector code: Terminal 19

on Breakout Box.

Voltage present after two seconds?

Clear codes and confirm proper

operation with no check engine

lamp.

YES

NO

Locate and

repair short

to voltage.

Replace ECM.

Reprogram and

learn password.

7809

7815

2003 Touring: Engine Management (EFI)

5-93

HOME

Test 5.25 (Part 3 of 3)

FUEL INJECTORS: DTC P0261, P0262, P0263, P0264

Continued from Test 5.25 (Part 1 of 3).

Check for 12 volts at Terminal 30 of system relay.

Correct voltage present?

YES

NO

Check for 12 volts at Terminal

86 of system relay.

Correct voltage present?

Locate and repair

open between

fuse and system relay.

7830

YES

NO

Measure resistance between

Terminal 86 of system

relay and Terminal 13 on

Breakout Box.

Resistance less than 0.5 ohm?

See Section 5.13 NO

ECM POWER.

YES

NO

Measure resistance between

Terminal 85 of system relay

and Terminal 4 on Breakout

Box.

Locate and

repair open on

W/BK wire.

7835

YES

NO

Install known good relay.

Does fuel pump run for first

2 seconds after key ON?

Locate and

repair open on

GN/O wire.

7840

YES

NO

Replace

system relay.

Reinstall original relay.

7845

Replace ECM. Reprogram

and learn password.

7850

Clear codes and confirm proper

operation with no check engine

lamp.

5-94

2003 Touring: Engine Management (EFI)

HOME

DTC P0373, P0374

GENERAL

5.26

f1692x8x

CKP Sensor

If the crank position sensor (CKP sensor) signal is weak or

absent, diagnostic trouble codes P0373 or P0374 will be set.

NOTE

If signal is not detected or cannot synchronize (DTC P0374),

engine will not start.

Table 5-44. Code Description

DTC

LAMP

CODE

P0373

41

CKP sensor intermittent

P0374

41

CKP sensor synch error

DESCRIPTION

Figure 5-60. CKP Sensor

f1916x9x

DIAGNOSTICS

Diagnostic Tips

Engine must be cranked for more than five seconds without CKP signal to set code.

With a fully charged battery and vehicle at room temperature, the Scanalyzer should display RPM in Data Monitor Mode while cranking. (A low voltage during cranking

may cause the Scanalyzer to reset). If RPM is present,

problem is intermittent.

Diagnostic Notes

The reference numbers below correlate with the circled numbers on the Test 5.26 flow chart.

1.

Connect BREAKOUT BOX (Part No. HD-43876) to ECM

wire harness only (leave ECM disconnected). See Section 5.7 BREAKOUT BOX: EFI.

2.

One megohm is very high resistance. Some meters will

read , OL, etc.

3.

Use HARNESS CONNECTOR TEST KIT (Part No. HD41404), brown socket probes and patch cords.

4.

For testing purposes, install sensor without running wiring along normal path. Disconnect and route wiring properly if system is now OK.

Crankshaft Position

Sensor [79]

Oil Pressure

Sending Unit [140]

Figure 5-61. CKP Sensor Connector Location

2003 Touring: Engine Management (EFI)

5-95

HOME

s0453x9x

[78B]

[78A]

BK

BK

BK

[79A]

[79B]

BK

CKP

sensor

10

12

28

30

ECM

Figure 5-62. CKP Circuit

Table 5-45. Wire Harness Connectors in Figure 5-62.

NO.

5-96

DESCRIPTION

[78]

ECM

[79]

CKP Sensor

2003 Touring: Engine Management (EFI)

TYPE

LOCATION

36-Place Packard

Under Right Side Cover

2-Place Mini-Deutsch

Under Right Side Cover

HOME

Test 5.26

CKP SENSOR: DTC P0373, P0374

1

2

Connect Breakout Box to harness only

leaving ECM disconnected. Measure resistance

between Terminals 30 and 28 and between

Terminals 12 and 28 on Breakout Box.

Resistance more than 1 megohm?

YES

NO

Check for intermittent connection, pinched

or damaged wires, and loose or missing

CKP sensor fastener. Conditions found?

Disconnect Connector [79]. Leaving

ECM disconnected, measure resistance

between Terminals 12 and 28 and

between Terminals 30 and 28 on Breakout Box. Continuity to ground

(less than 1 megohm resistance)?

YES

NO

Repair as

necessary.

Connect DVOM to Pins 12 and 30

on Breakout Box.

Set DVOM to AC volts and crank engine.

Does DVOM read 1 VAC minimum

during cranking?

7980

YES

YES

NO

Repair short to

ground on R or

BK wire between

Connectors [78B]

and [79B].

Replace

CKP sensor.

NO

With DVOM or Scanalyzer still

connected, check for intermittents

using 5.8 WIGGLE TEST.

Intermittents present?

YES

7981

7980

Connect DVOM at

Pins 1 and 2 of Connector [79A].

Does DVOM read 1 VAC

minimum while cranking?

NO

Repair as

necessary.

7982

Install known good CKP

sensor. Clear codes

and retest. DTC P0373

or P0374 set?

YES

NO

Reinstall original

CKP sensor. Replace

ECM. Reprogram

and learn password.

Replace

CKP sensor.

7983

7984

YES

NO

Check for continuity between

Socket 1 of Connector [79B]

and Terminal 30 on

Breakout Box.

Continuity present?

Replace

CKP sensor.

7985

YES

NO

Repair open on BK wire

between Socket 2 of

Connector [79B] and

Terminal 12 on Breakout Box.

Repair open on R wire

between Socket 1 of

Connector [79B] and

Terminal 30 on Breakout Box.

7986

7987

Clear codes and confirm proper

operation with no check engine

lamp.

2003 Touring: Engine Management (EFI)

5-97

HOME

DTC P0501, P0502

5.27

GENERAL

7951

Vehicle Speed Sensor

See Figure 5-63. The vehicle speed sensor is powered and

monitored by the speedometer. The speedometer sends a

vehicle speed signal (9000 pulses/mile) to the ECM. The

ECM processes the vehicle speed signal and transmits this

signal to the TSM/TSSM through the serial data line.

NOTE

When the vehicle speed signal is greater than 0, the idle

speed control is inhibited.

Table 5-46. Code Description

DTC

LAMP

CODE

P0501

43

VSS sensor low

P0502

43

VSS sensor high

DESCRIPTION

Figure 5-63. Speedometer Speed Sensor

HD41354

DIAGNOSTICS

Diagnostic Notes

The reference numbers below correlate with the circled numbers on the Test 5.27 flow charts.

1.

The speedometer has a built-in diagnostic mode.

a.

To enter diagnostic mode, depress odometer reset

switch and turn ignition switch to IGN.

b.

To clear codes, depress odometer reset switch and

hold for ten seconds.

c.

2.

3.

See Figure 5-64. Check system using SPEEDOMETER

TESTER (Part No. HD-41354). Enter the number 70 to

simulate 3 MPH. If tester is not available, elevate the rear

wheel and spin briskly while looking for a voltage drop.

4.

Use HARNESS CONNECTOR TEST KIT (Part No. HD41404), black pin probe and patch cord.

To return speedometer to normal operating mode,

cycle ignition switch.

Connect BREAKOUT BOX (Part No. HD-43876)

between wire harness and ECM. See Section 5.7 BREAKOUT BOX: EFI.

5-98

Figure 5-64. Speedometer Tester

2003 Touring: Engine Management (EFI)

HOME

f1973c9s

Radio

23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

[2A]

[2B]

12 11 10 9 8 7 6 5 4 3 2 1

Speedometer

[27A]

[27B]

W/GN

12 11 10 9 8 7 6 5 4 3 2 1

[39A]

[39B]

Speedometer

sensor

11

10

C

D

E

F

G

Cruise Control

Module

BK

BK

W/GN

[8A]

[8B]

[17B] [17A]

12 11 10 9 8 7 6 5 4 3 2 1

12 11 10 9 8 7 6 5 4 3 2 1

W/GN

[65A] [65B]

[78B]

[78A]

1 2 3 4 5 6 7

8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36

1 2 3 4 5 6 7

8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36

ECM

Figure 5-65. Vehicle Speed Sensor Circuit (FLTR-I, FLHTC/U-I)

Table 5-47. Wire Harness Connectors in Figure 5-65.

NO.

DESCRIPTION

MODEL

TYPE

LOCATION

[2]

Main to Interconnect Harness

All

12-Place Deutsch

(Gray)

Inner Fairing (Right Radio Support

Bracket)

[8]

Ignition (Main to EFI Harness)

All

12-Place Deutsch

(Gray)

Under Right Side Cover

[17]

Cruise Control Module

All

10-Place Packard

Under Left Side Cover

[27]

Radio

All

23-Place Amp (Black)

Inner Fairing -Back of Radio (Right Side)

[39]

Speedometer

FLTR-I

12-Place Packard

Under Instrument Bezel

(Back of Speedometer)

FLHTC/U-I

12-Place Packard

Inner Fairing (Back of Speedometer)

[65]

Speedometer Speed Sensor

All

3-Place Deutsch

Upper Frame Crossmember

(Under Seat)

[78]

ECM

All

36-Place Packard

Under Right Side Cover

2003 Touring: Engine Management (EFI)

5-99

HOME

f1973b9s

Speedometer

[39A]

[39B]

Speedometer

sensor

12

C

D

E

F

G

H

BK

BK

J

K

W/GN

[8A]

[8B]

12 11 10 9 8 7 6 5 4 3 2 1

[17B] [17A]

12 11 10 9 8 7 6 5 4 3 2 1

W/GN

[65A] [65B]

Cruise Control

Module

[78B]

[78A]

1 2 3 4 5 6 7

8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36

1 2 3 4 5 6 7

8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36

ECM

Figure 5-66. Vehicle Speed Sensor Circuit (FLHR/C-I)

Table 5-48. Wire Harness Connectors in Figure 5-66.

NO.

DESCRIPTION

[8]

Ignition (Main to EFI Harness)

[17]

Cruise Control Module

[39]

Speedometer

[65]

[78]

TYPE

LOCATION

12-Place Deutsch (Gray)

Under Right Side Cover

10-Place Packard

Under Left Side Cover

12-Place Mini-Deutsch

Back of Speedometer (Under Console)

Speedometer Speed Sensor

3-Place Deutsch

Upper Frame Crossmember (Under Seat)

ECM

36-Place Packard

Under Right Side Cover

5-100 2003 Touring: Engine Management (EFI)

HOME

Test 5.27 (Part 1 of 2)

VEHICLE SPEED SENSOR: DTC P0501, P0502

Does speedometer

operate properly?

YES

NO

Place speedometer into diagnostic

mode and clear fault codes. Connect

all circuits and ride motorcycle for

approximately 1 mile (1.6 km). Check

for new logged codes.

Codes present?

See Speedometer Test

2A under Section 2.2

SPEEDOMETER.

YES

NO

See Speedometer Test

2A under Section 2.2

SPEEDOMETER.

2

3

Connect Scanalyzer to Connector [91A].

Place Scanalyzer in Data Monitor Mode.

Jack up rear wheel and rotate faster than 3 MPH.

Is vehicle speed registered on display?

YES

NO

Clear codes. Clear

debris off speedometer

sensor. Retest.

STOP

7954

Clear codes and confirm proper

operation with no check engine

lamp.

Go to Test 5.27 (Part 2 of 2).

At some point in the flow chart you

may be instructed to jump directly

to the box marked by a bold asterisk. Disregard the asterisk (but not

the instruction box) if your normal

progression through the chart

brings you to this location.

2003 Touring: Engine Management (EFI) 5-101

HOME

Test 5.27 (Part 2 of 2)

VEHICLE SPEED SENSOR: DTC P0501, P0502

Continued from Test 5.27 (Part 1 of 2).

Verify that speedometer is connected and ignition switch

is turned to IGNITION. Check for voltage on Terminal 33 of

Breakout Box while rotating tire faster then 3 MPH.

Does voltage match specifications?

Rear wheel rotating: 3-6 volts.

Rear wheel stationary: 9-11 volts.

YES

NO

Disconnect Connector [78]. Inspect

for damaged terminals, terminals

backed out or corrosion. Terminal

problems present?

Disconnect Connector [78]. Inspect

for damaged terminals, terminals

backed out or corrosion. Terminal

problems present?

YES

NO

YES

NO

Repair terminal

damage.

Reconnect. Problem

still exist?

Repair terminal

damage.

Reconnect Connector

[78]. Problem still

exist?

7956

YES

Replace ECM.

Reprogram and learn

password.

7959

NO

YES

NO

Problem

fixed.

Disconnect Connectors

[78] and [39]. Check for continuity

to ground on W/GN wire.

Continuity present?

Problem

fixed.

7958

7957

YES

NO

Locate and repair

short to ground

on W/GN wire.

Check for continuity on W/GN

wire between Connector [39] and

Terminal 33 on Breakout Box.

Continuity present?

7962

YES

NO

Replace

speedometer.

Locate and

repair open.

7963

Clear codes and confirm proper

operation with no check engine

lamp.

5-102 2003 Touring: Engine Management (EFI)

At some point in the flow chart you

may be instructed to jump directly

to the box marked by a bold asterisk. Disregard the asterisk (but not

the instruction box) if your normal

progression through the chart

brings you to this location.

7964

7961

HOME

DTC P0562, P0563

5.28

GENERAL

f2023x9x

Battery Voltage

Battery voltage is constantly monitored by the ECM (Pin 13).

If the battery voltage fails to meet normal operating parameters, a code is set.

Code P0562 is displayed when battery positive voltage is

less than 11.0 volts at 2000 RPM for longer than 5 seconds.

Code P0563 is displayed when battery positive voltage is

greater than 16.0 volts for more than 4 seconds.

NOTES

Warm idle speed will be automatically increased if battery voltage is low at idle.

TSSM problems may also set a code P0562 or P0563.

Table 5-49. Code Description

DTC

LAMP

CODE

P0562

16

Battery voltage low

P0563

16

Battery voltage high

DESCRIPTION

Ignition

Fuse

Figure 5-67. Left Side Cover Removed

(FLTR, FLHT/C)

Diagnostic Notes

The reference numbers below correlate with the circled numbers on the Test 5.28 flow charts.

1.

Low voltage generally indicates a loose wire, corroded

battery connections and/or a charging system problem.

A high voltage condition may be caused by a shorted

stator (check when hot) or faulty voltage regulator.

Yes. Charge battery.

b.

No. See charging system troubleshooting.

Connect BREAKOUT BOX (Part No. HD-43876)

between wire harness and ECM. See Section 5.7 BREAKOUT BOX: EFI.

3.

Use Scanalyzer Data Monitor Mode to check RPM on

vehicles without tachometers.

4.

This checks for voltage drops in the ignition module circuit.

a.

Place (+) probe to battery positive terminal.

b.

Place (-) probe to W/BK terminal on Breakout Box.

5.

Problem is most likely the ground connection at the

frame.

6.

Connect BREAKOUT BOX (Part No. HD-42682) to Connector [22]. FLHR/C-I models will also need HD-42962

adapters.

Scanalyzer Notes

The Scanalyzer icon appears at those points in the flow chart

where the Scanalyzer can be used.

a.

2.

DIAGNOSTICS

Diagnostic Tips

Was battery allowed to discharge? Was battery drawn

down by a starting problem?

2003 Touring: Engine Management (EFI) 5-103

HOME

f1973d9s

[62B]

BE/GY

GN/O

W/BK

BK

W/BK

Main circuit

breaker

15 amp

ECM fuse

Battery

BK

W/BK

BK

8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36

GN/O

BK

1 2 3 4 5 6 7

8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36

System relay

BE/GY

1 2 3 4 5 6 7

ECM

I Q C P R

[78B]

87A

87

30 85 86

Y/GN

[78A]

12

11

10

9

8

7

6

5

4

3

2

1

12

11

10

9

8

7

6

5

4

3

2

1

R/BK

I BA

15 amp

IGN fuse

GY

[33B]

[33A]

Ignition

switch

W/BK

12 11 10 9 8 7 6 5 4 3 2 1

12 11 10 9 8 7 6 5 4 3 2 1

[8B] [8A]

[22A]

[22B]

12-Place on

FLHP-I Only

Engine stop

switch

BK

Figure 5-68. Battery Voltage Circuit Diagram (FLHR/C-I, FLHP-I)

Table 5-50. Wire Harness Connectors in Figure 5-68.

NO.

DESCRIPTION

[8]

Ignition (Main to EFI Harness)

[22]

Right Handlebar Switches

[33]

[78]

TYPE

LOCATION

8-Place Deutsch (Gray)

Under Right Side Cover

12-Place Deutsch (Black)

Inside Headlamp Nacelle

Ignition/Light Key Switch

3-Place Packard

Under Left Side Cover

ECM

36-Place Packard

Under Right Side Cover

5-104 2003 Touring: Engine Management (EFI)

HOME

f1973j9s

[78A]

[78B]

[62B]

87A

8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36

15 amp

ECM fuse

Battery

BK

W/BK

8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36

W/BK

BK

BK

BK

System relay

BE/GY

3 4

30 85 86

3 4

Q C P R

GN/O

ECM

BE/GY

GN/O

W/BK

87

Y/GN

12

11

10

9

8

7

6

5

4

3

2

1

12

11

10

9

8

7

6

5

4

3

2

1

Main circuit

breaker

R/BK

DCBA

[33B]

[33A]

15 amp

IGN fuse

Ignition

switch

GY

W/BK

12 11 10 9 8 7 6 5 4 3 2 1

[8B] [8A]

[1B]

[1A]

12 11 10 9 8 7 6 5 4 3 2 1

[22A]

[22B]

12 11 10 9 8 7 6 5 4 3 2 1

BK

12 11 10 9 8 7 6 5 4 3 2 1

Engine stop

switch

Figure 5-69. Battery Voltage Circuit Diagram (FLTR-I, FLHTC/U-I)

Table 5-51. Wire Harness Connectors in Figure 5-69.

NO.

DESCRIPTION

TYPE

LOCATION

[1]

Main to Interconnect Harness

12-Place Deutsch (Black)

Inner Fairing (Right Fairing Bracket)

[8]

Ignition (Main to EFI Harness)

8-Place Deutsch (Gray)

Under Right Side Cover

[22]

Right Handlebar Switches

12-Place Deutsch (Black)

Inner Fairing (Right Fairing Support Brace)

[33]

Ignition/Light Key Switch

4-Place Packard

Inner Fairing (Top Fork Bracket)

[78]

ECM

36-Place Packard

Under Right Side Cover

2003 Touring: Engine Management (EFI) 5-105

HOME

Test 5.28 (Part 1 of 2)

BATTERY VOLTAGE: DTC P0562, P0563

2

3

Perform charging system tests.

Charging system OK?

YES

NO

Connect Breakout Box. With engine

running at 2000 RPM or higher for 10

seconds or longer, measure voltage

between Terminals 13 and 10 and

between Terminals 13 and 28

on Breakout Box.

Is voltage above 11.0 volts?

Repair charging system.

See Section 1 of this manual.

YES

NO

System

OK.

With ignition ON, measure voltage drop

between battery positive (+) terminal

and Terminal 13 (-) on Breakout Box.

Is voltage drop greater than 0.5 volt?

7770

YES

NO

With ignition ON, measure voltage

drop between battery positive (+)

terminal and Terminal 4 (-) on Breakout Box. Is voltage drop greater

than 0.5 volt?

Measure voltage drop between

battery negative (-) terminal and

Terminal 10 (+) on Breakout Box and

between battery negative (-) terminal

and Terminal 28 on Breakout Box. Is

voltage drop greater than 0.5 volt?

YES

NO

With ignition ON, measure voltage drop

between battery positive (+) terminal

and Terminal 3 (-) on Breakout Box.

Is voltage drop greater than 0.5 volt?

Replace W/BK wire

or terminals between

Connectors [22A]

and [78B].

YES

NO

Locate and repair

bad connection.

Problem is intermittent.

Perform 5.8 WIGGLE

TEST. Locate and

repair bad connection.

7775

7776

7310

YES

STOP

NO

Inspect Connector [22] for

corrosion or loose wires. If

conditions are not present,

replace engine stop switch.

Go to Test 5.28 (Part 2 of 2).

5-106 2003 Touring: Engine Management (EFI)

7781

Clear codes and confirm proper

operation with no check engine

lamp.

HOME

Test 5.28 (Part 2 of 2)

BATTERY VOLTAGE: DTC P0562, P0563

Continued from Test 5.28 (Part 1 of 2).

With ignition ON, measure voltage drop between battery positive (+) terminal and GY terminal of 15 amp

ignition fuse (-). Is voltage drop greater than 0.5 volt?

YES

NO

With ignition ON, measure voltage drop

between battery positive (+) terminal and

R/BK terminal of 15 amp ignition fuse. Is

voltage drop greater than 0.5 volt?

Replace GY wire

or terminals.

YES

NO

With ignition ON, measure voltage drop

between battery positive (+) terminal and

silver post of main circuit breaker (-).

Is voltage drop greater than 0.5 volt?

Replace fuse or

fuse terminals.

YES

NO

With ignition ON, measure voltage drop

between battery positive (+) terminal and

copper post of main circuit breaker (-).

Is voltage drop greater than 0.5 volt?

Replace ignition

switch or terminals.

7780

7782

7783

YES

NO

High resistance between 40 amp

circuit breaker and battery. Replace

wire or terminals.

Replace circuit

breaker.

7779

7784

Clear codes and confirm proper

operation with no check engine

lamp.

2003 Touring: Engine Management (EFI) 5-107

HOME

DTC P0603, P0605

5.29

GENERAL

DIAGNOSTICS

ECM Failure

DTC P0603 Test

See Table 5-52. The codes indicate a failure that requires

replacement of the ECM (Job Time Code 7913). See ELECTRONIC CONTROL MODULE, REMOVAL/INSTALLATION,

in the 2003 Touring Models Service Manual (Part Number

99483-03).

Table 5-52. Code Description

DTC

LAMP

CODE

DESCRIPTION

P0603

54

ECM EEPROM error

P0605

53

ECM flash error

5-108 2003 Touring: Engine Management (EFI)

1.

Power down the vehicle.

2.

Clear codes using Scanalyzer.

3.

Replace ECM if codes reappear.

DTC P0605 Test

1.

Power down the vehicle.

2.

Clear codes using Scanalyzer.

3.

Attempt to reprogram ECM using correct calibration.

4.

Restart vehicle. If code reappears, replace ECM.

5.

Perform password learn and code clearing.

HOME

DTC P1009, P1010

5.30

GENERAL

Data Link

Connector [91A]

Password Problem

The ECM and TSM/TSSM exchange passwords during operation. An incorrect password or missing password will set a

diagnostic code.

NOTE

If the TSM/TSSM is not connected to the wiring harness, the

vehicle will not start.

Table 5-53. Code Description

DTC

LAMP

CODE

P1009

99

Incorrect password

P1010

99

Missing password

DESCRIPTION

f1917x9x

Figure 5-70. Right Side Cover Removed

DIAGNOSTICS

7844

Diagnostic Notes

The reference numbers below correlate with the circled numbers on the Test 5.30 flow charts.

1.

DTC P1009 may be set if a recent ECM or TSM/TSSM

replacement did not follow the correct password assignment procedure. See Section 3.24 TSM/TSSM for

details.

2.

Use HARNESS CONNECTOR TEST KIT (Part No. HD41404), black socket probes and patch cord.

3.

Connect BREAKOUT BOX (Part No. HD-43876)

between wire harness and ECM. See Section 5.7 BREAKOUT BOX: EFI.

4.

See TURN SIGNAL/SECURITY MODULE, REMOVAL/

INSTALLATION, in the 2003 Touring Models Service

Manual (Part Number 99483-03). If necessary, be sure to

reference the Electrical Diagnostic Manual for the password learn routine (Scanalyzer menu refers to this function as module replacement).

Figure 5-71. TSM/TSSM Module

2003 Touring: Engine Management (EFI) 5-109

HOME

GY/Y

f1973e9s

[30B]

[30A]

[8A]

[8B]

1 2 3 4 5 6 7 8 9 10 11 12

1 2 3 4 5 6 7 8 9 10 11 12

TSM/TSSM

Module

1 2 3 4 5 6 7 8 9 10 11 12

1 2 3 4 5 6 7 8 9 10 11 12

Data Link

Connector

1

LtGN/R

BK

LtGN/V

GY

[91A] [91B]

LtGN/R

LtGN/V

12V

[78B]

[78A]

Scanalyzer

ECM

Figure 5-72. ECM and TSM/TSSM Circuit

Table 5-54. Wire Harness Connectors in Figure 5-72.

NO.

DESCRIPTION

TYPE

LOCATION

[8]

Ignition (Main to EFI Harness)

12-Place Deutsch (Gray)

Under Right Side Cover

[30]

TSM/TSSM

12-Place Deutsch

Cavity in Crossmember

at Rear of Battery Box (Under Seat)

[78]

ECM

36-Place Packard

Under Right Side Cover

[91]

Data Link

4-Place Deutsch

Under Right Side Cover

5-110 2003 Touring: Engine Management (EFI)

HOME

Test 5.30

PASSWORD PROBLEM: DTC P1009, P1010

Which diagnostic trouble

code was set?

1

4

DTC P1009.

Bad password.

Reprogram password.

See Section 3.24 TSM/

TSSM.

DTC P1009 still exist?

DTC P1010.

No password.

Are there any

U-codes set?

YES

YES

NO

Replace TSSM and

relearn password.

System OK?

System

OK.

Troubleshoot

lowest U-code.

Remove Connector [78].

Check for continuity to ground at

Pin 3 of Connector [91A].

Continuity present?

6701

YES

NO

System

OK.

NO

Reinstall original TSSM

and replace ECM.

Reprogram and

relearn password.

4

6702

YES

NO

Locate and repair

short to ground.

Check for battery voltage

on Pin 3 of Connector [91A].

Battery voltage present?

6704

6703

YES

NO

Locate and repair

short to voltage.

6705

Check for continuity between

Pin 3 of Connector [91A]

and Terminal 5 on Breakout Box.

Continuity present?

YES

NO

Replace TSM/TSSM and

relearn password.

System OK?

Inspect terminals

for damage or repair

opens as necessary.

6706

YES

NO

System

OK.

6707

Reinstall original TSSM

and replace ECM.

Reprogram and

relearn password.

6708

2003 Touring: Engine Management (EFI) 5-111

HOME

DTC P1351, P1352, P1354, P1355

GENERAL

5.31

7863

Ignition Coil

Ignition coil codes will set if the ignition coil primary voltage is

out of range. This could occur if there is an open coil or loss of

power to the coil. If front and rear codes are set simultaneously, it is likely a coil power failure or a coil failure.

The coil receives power from the system relay at the same

time that the fuel pump and injectors are activated. The system relay is active for the first 2 seconds after the ignition

switch is turned ON and then shuts off until RPM is detected

from the CKP sensor, at which time it is reactivated. The ECM

is responsible for turning on the system relay by providing the

ground to activate the relay, which in turn powers the coil.

Figure 5-73. Ignition Coil Circuit Test

Table 5-55. Code Description

DTC

LAMP

CODE

P1351

24

Front ignition coil open/low

P1352

24

Front ignition coil high/shorted

P1354

25

Rear ignition coil open/low

P1355

25

Rear ignition coil high/shorted

DESCRIPTION

s0475x9x

D

C

B

A

DIAGNOSTICS

Diagnostic Notes

Figure 5-74. Ignition Coil Connector Terminals

The reference numbers below correlate with the circled numbers on the Test 5.31 flow charts.

1.

Use HARNESS CONNECTOR TEST KIT (Part No. HD41404), gray pin probes and patch cord.

2.

See Figure 5-73. Plug IGNITION COIL CIRCUIT TEST

ADAPTER (Part No. HD-44687) and FUEL INJECTOR

TEST LAMP (Part No. HD-34730-2C) into Breakout Box.

Note that cranking the engine with test lamp in place of

the ignition coil can sometimes cause a DTC P1351,

P1352, P1354 or P1355. This condition is normal and

does not by itself indicate a malfunction. Clear codes

afterward.

5-112 2003 Touring: Engine Management (EFI)

3.

Connect BREAKOUT BOX (Part No. HD-43876)

between EFI wire harness and ECM. See Section 5.7

BREAKOUT BOX: EFI.

4.

Use HARNESS CONNECTOR TEST KIT (Part No. HD41404), gray socket probes and patch cord.

HOME

[62B]

f1973k9s

System

relay

[62B]

Y/GN

O/GY

[141B] [141A]

BK

AB

AB

W/BK

Y/BE

BE/O

C D

GY/BE

C D

[85B] [85A]

A B

Y/BE

A B

8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36

Ignition

coil

[83B] [83A]

W/BK

BE/GY

GN/GY

15 amp

ECM fuse

W/Y

GY/BE

BE/O

12

11

10

9

8

7

6

5

4

3

2

1

Battery

R

W/BK

BK

8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36

Y/GN

BE/GY

Coil F

Ion

[84B] [84A]

3 4

Inj. F

W/Y

15 amp

fuel pump

fuse

3 4

Inj. R

Y/GN

GN/O

AB

ECM

Fuel pump

[13A] [13B]

AB

Coil R

30 85 86

GN/O

W/BK

87A

BE/GY

87

Q C P R

[78B]

Y/GN

[78A]

12

11

10

9

8

7

6

5

4

3

2

1

BK

R/BK

BK

I BA

15 amp

IGN fuse

GY

Main circuit

breaker

[33B]

[33A]

Ignition

switch

W/BK

12 11 10 9 8 7 6 5 4 3 2 1

[22A]

[22B]

12 11 10 9 8 7 6 5 4 3 2 1

[8B] [8A]

12-Place on

FLHP-I Only

BK

BK

Engine stop

switch

BK

Figure 5-75. Battery Voltage Circuit Diagram (FLHR/C-I, FLHP-I)

Table 5-56. Wire Harness Connectors in Figure 5-75.

NO.

DESCRIPTION

[8]

Ignition (Main to EFI Harness)

[22]

Right Handlebar Switches

[33]

TYPE

LOCATION

8-Place Deutsch (Gray)

Under Right Side Cover

12-Place Deutsch (Black)

Inside Headlamp Nacelle

Ignition/Light Key Switch

3-Place Packard

Under Left Side Cover

[78]

ECM

36-Place Packard

Under Right Side Cover

[83]

Ignition Coil

4-Place Packard

Below Fuel Tank (Left Side)

[84]

Front Injector

2-Place Packard

Below Fuel Tank (Left Side)

[85]

Rear Injector

2-Place Packard

Below Fuel Tank (Left Side)

2003 Touring: Engine Management (EFI) 5-113

HOME

[62B]

f1973a9s

System relay

BE/GY

GN/O

W/BK

Y/GN

O/GY

[84B] [84A]

15 amp

fuel pump