Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Uec PCD PPL PLG 609 p3 G c2

Caricato da

Rob WillestoneTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Uec PCD PPL PLG 609 p3 G c2

Caricato da

Rob WillestoneCopyright:

Formati disponibili

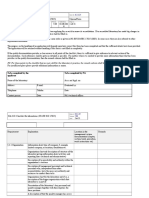

TANAP

TRANS ANATOLIAN NATURAL GAS PIPELINE

PROJECT

Project

Doc.No.

UEC-PCD-PPL-PLG-609

Rev

SAP PO No. P1000202

P3-G

PO No. TNP-TPG-LPPC-CNT-002

VDR Code : NB

Document

Title :

MANUEL ULTRASONIC TEST FOR WELD SEAM PROCEDURE

Equipment

Description

LINE PIPE

Tag Nos.

1.1 1.4 4.1 4.5

Vendor:

UMRAN-EMEK CONSORTIUM

Vendor

Document No.

EMK-PCD-PPL-PLG-009

Rev

Signature

C1- Reviewed & accepted as final & certified.

Manufacture may proceed.

C2 - Reviewed & accepted as marked.

Revise &

resubmit. Manufacture may proceed.

C3- Reviewed & returned.

Correct & resubmit.

Manufacture shall NOT proceed.

C4- Review not required.

Manufacture may proceed

Remarks:-

For information only.

Date

P3-G

MANUEL ULTRASONIC TEST FOR WELD SEAM PROCEDURE

Revision: P3-G

Status:Re-IFR

Date: 19.04.2015

UEC-PCD-PPL-PLG-609

Page : 1of 13

TANAP

TRANS ANATOLIAN NATURAL

GAS

PIPELINE PROJECT

MANUEL ULTRASONIC TEST FOR WELD SEAM PROCEDURE

Rev

Status

Date

P0-A

DIC

05.03.2014

P0-B

IDC

21.03.2014

P0-C

IFR

28.03.2014

P0D

Re-IFR

11.04.2014

P3-A

DIC

18.10.2014

P3-B

IDC

10.11.2014

P3-C

IFR

20.11.2014

P3D

Re-IFR

22.01.2015

P3-E

Re-IFR

22.02.2015

P3-F

Re-IFR

26.03.2015

P3G

Re-IFR

19.04.2015

Document

Status

Description

Discipline Internal

Check

Inter Discipline

Check

First Issued for

Review

Re Issued for

Review

Discipline Internal

Check

Inter Discipline

Check

First Issued for

Review

Re Issued for

Review

Re Issued for

Review

Re Issued for

Review

Re Issued for

Review

Issued

by

Checked

by

Approved

by

KUST

KILE

AKTK

KUST

KILE

AKTK

KUST

KILE

AKTK

KUST

KILE

AKTK

KUST

KILE

AKTK

KUST

KILE

AKTK

KUST

KILE

AKTK

KUST

KILE

AKTK

KUST

KILE

AKTK

KUST

KILE

AKTK

KUST

KILE

AKTK

TANAP

Approval

MANUEL ULTRASONIC TEST FOR WELD SEAM PROCEDURE

Revision: P3-G

Status:Re-IFR

Date: 19.04.2015

UEC-PCD-PPL-PLG-609

Page : 2of 13

DOCUMENT REVISION HISTORY SHEET

Rev.

Revision

Description

Date Issued

Update / Amendment Details

P0-A

DIC

05.03.2014

First issue

P0-B

IDC

21.03.2014

Review of first issue

P0-C

IFR

28.03.2014

First Issued for Review

P0-D

Re-IFR

11.04.2014

Re-issued for review

P3-A

DIC

18.10.2014

First issue

P3-B

IDC

10.11.2014

Review of first issue

P3-C

IFR

20.11.2014

First Issued for Review

P3-D

Re-IFR

22.01.2015

Re Issued for Review

P3-E

Re-IFR

22.01.2015

Re Issued for Review

P3-F

Re-IFR

26.03.2015

P3-G

Re-IFR

19.04.2015

Update of P3-E incorporating comments by

TANAP and EPCM agreed changes from preinspection meeting held on 06.03.2015

Update of P3-F incorporating comments by

TANAP and EPCM agreed changes from MPQT

meeting held on 08.04.2015

HOLDS

No.

Section

Description

Input

From

Planned

Date

MANUEL ULTRASONIC TEST FOR WELD SEAM PROCEDURE

Revision: P3-G

Status:Re-IFR

Date: 19.04.2015

TABLE OF CONTENTS

1.

2.

3.

4.

5.

6.

SCOPE

RESPONSIBILITY

REFERENCE

TESTING PROCEDURE

TEST METHOD

ASSESSMENT OF INDICATORS

7.

ACCEPTANCE

8.

HEALTH AND SAFETY

9.

RESULT

UEC-PCD-PPL-PLG-609

Page : 3of 13

MANUEL ULTRASONIC TEST FOR WELD SEAM PROCEDURE

Revision: P3-G

Status:Re-IFR

Date: 19.04.2015

UEC-PCD-PPL-PLG-609

Page : 4of 13

1. SCOPE

This testing document has been prepared for determination of manual

ultrasonic testing rules and acceptance criteria for weld seams, repair

welding of spiral welded steel pipe.

Suspected regions / indications revealed by automatic UT and the total

area of repair welding shall be inspected by manual UT. Manual UT

coverage shall extend at least 100 mm beyond the ends of the repair

weld that will be carried out in accordance with Project Specifications.

BCH-SPC-PPL-PLG-001, Specification for Submerged Arc Welded Line

Pipe and WRP-SPC-PPL-PLG-025, Addendum to Specification for

Submerged Arc Welded Line Pipe concerning both 1422,4x19,45 mm

API 5L X70M PSL2 and 1219,2 x 16,67 mm API 5L X70M PSL2 pipe

production.

This procedure is applicable at EMEK BORU A.S-Ankara Mill for

inspection to be carried out at mill under Quality Control Department.

2. RESPONSIBILITY

Inspections, calibrations and evaluations are carried out by Level 2

qualified personnel that are certified acc. to SNT TC 1A, ISO 11484 or

ISO 9712. Inspections are performed by Ultrasonic Testing Level 2

qualified person.

3. REFERENCES

BCH-SPC-PPL-PLG-001-Rev-P2-1, Specification for Submerged Arc

Welded Line Pipe

WRP-SPC-PPL-PLG-025-P3-0, Addendum to Specification for

Submerged Arc Welded Line Pipe

UEC-PLN-PPL-PLG-601 Inspection And Test Plan For SAWH Pipe

Project Technical Clarifications, Responses to Clarification Questions

API 5L, 45th Edition, 2012 - Specification for Line Pipe

ISO 10893-11 Automated UT Testing of the Weld Seam of Welded

Steel Tubes for the Detection of Longitudinal and / or Transverse

Imperfections

4. TESTING PROCEDURE

Frequency of Inspection

Each Pipe

Inspection Time

At the production stage and after hydrostatic test

Devices Properties

SONATEST Sitescan D10+:

Test Range: 5mm (0.2in) up to 5,000 mm (200 in.) in steel.

Variable in sequence 10mm or 1mm.

MANUEL ULTRASONIC TEST FOR WELD SEAM PROCEDURE

Revision: P3-G

Status:Re-IFR

Date: 19.04.2015

UEC-PCD-PPL-PLG-609

Page : 5of 13

Velocity: 1000 - 9999 m/s.

Probe Zero: 0 to 999.999 s.

Delay : 0-5,000m at steel velocity in 0.05 steps (0-200 in 0.002 in.

steps)

Gain: 0 to 110dB in 0.5, 1, 2, 6, 10, 14 and 20dB steps.

Test Modes: Pulse echo and transmit/receive.

Gate : Start & Width adjustable over full range. Amplitude 0-100%,

0.5% steps visual and audible alarms. Positive triggering.

SONATEST Sitescan D50:

Test Range: 0-5mm(0.25in)up to 0-10,000mm (400 in.) in steel at

5930m/s (19455f/s)

Velocity :1000 - 10,000 m/s continuously variable.

Probe Zero: 0 to 999.999 s.

Delay: 0-10,000m (400in) in steel at 5930m/s (19455f/s)

Gain:0 to 110dB adjustable in 0.5, 1, 2, 6,10, 14 and 20dB steps.

Test Modes: Pulse echo and transmit/receive.

Gate : Start & Width adjustable over full range. Amplitude 0-100%,

0.5% steps visual and audible alarms. Positive triggering.

Probes :

Krautkramer MWB 60-4(E) -4 MHz

Krautkramer MWB 70-4(E) -4 MHz

SONATEST Gem4-10 TR Probe-4 MHz

SONATEST Gem5-10 TR Probe-4 MHz

SONATEST SMA4-60-4 MHz

SONATEST SMA4-70-4 MHz

SONATEST THM4-10 TR Probe -4 MHz

SONATEST T2DN 4-TR Probe -4 MHz

DOPPLER 4P8X9A60 -4MHz

DOPPLER 4P8X9A70 -4MHz

Inspection Heat

Maximum 40C

Probe Frequency

4 MHz

Wave Type

Transverse wave.

Base Adaption

D>15a

D: Pipe Diameter (1422,4 and 1219,2mm)

a:The length of probe base on inspection direction

D>15x13.7mm

D>205,5 mm

Base adaption is not required

Test Technique: Pulse echo technique

Preparation of Testing Surfaces: Testing surfaces shall be cleansed of

rust, oxide layer, welding splash, indents or grooves.

MANUEL ULTRASONIC TEST FOR WELD SEAM PROCEDURE

Revision: P3-G

Status:Re-IFR

Date: 19.04.2015

UEC-PCD-PPL-PLG-609

Page : 6of 13

Contact Medium: Liquid soap

Coordinate Axes/ Reference Points: q, L, t parameters are as indicated

in FR-164

5. CALIBRATION

Reference standard

One 1.60 mm TDH (located on the center line of the weld seam).

Calibration check and recalibration

The frequency of checking the calibration shall be at least every 4 h,

but also whenever there is an equipment operation team

changeover and at the start and end of the production run.

Calibration Part

The reference tubes or part of pipe shall have the same nominal

diameter and thickness, same surface finish and same heat

treatment delivery condition (e.g. as-rolled, normalized, quenched

and tempered) as the tubes under test, and shall have similar

acoustic properties (e.g. sound velocity and attenuation coefficient).

Distance Calibrations

Probes are reset and verified with echoes coming from 100 mm arc

of K1 block or 25-50 mm arc of K2 block. With using K1 and K2

blocks, angle and index are calculated. Before sensitivity calibration,

distance calibration is performed as given below;

Range=3xd/cos x1.2

d: Wall thickness

Range 3x16.67/cos60x1.2=120mm for 60 probe d=16.67 mm

Range 3x16.67/cos70x1.2=175 mm for 70 probe d=16.67 mm

Range 3x19.45/cos60x1.2=140 mm for 60 probe d=19,45 mm

Range 3x19.45/cos70x1.2=205 mm for 70 probe d=19,45 mm

TEST VOLUME AND SCANNING VOLUME

Testing volume to be covered when scanning for longitudinal and

transverse indications

a

10 mm

Weld and HAZ

10 mm

MANUEL ULTRASONIC TEST FOR WELD SEAM PROCEDURE

Revision: P3-G

Status:Re-IFR

Date: 19.04.2015

A

C

E

UEC-PCD-PPL-PLG-609

Page : 7of 13

B

D

F

Key

a: Scanning Zone

C-D: Longitudinal Indication

A-B-E-F: Transverse Indication

1-2-3: Position

Note: Scanning is done both longitudinally and transversally with

10% overlap from both sides of weld.

Probe pull back dimensions for projection distance(ap)

Calculated for d=16.67 mm 70

ap/2 =(dxtan70)-x ap/2 =(16.67 x tan 70)-12=33.8 mm

ap =(2dxtan70)-x

ap=(2x16.67 x tan 70)-12=79.6 mm

1.5 ap=(3dxtan70)-x 1,5ap=(3x16.67 x tan 70)-12=125.4 mm

Calculated d=16.67 mm 60

ap/2 =(dxtan60)-x ap/2 =(16.67 x tan 60)-12=16.8 mm

ap=(2dxtan60)-x

ap =(2x16.67 x tan60)-12=45.7 mm

1.5 ap=(3dxtan60)-x 1,5ap=(3x16.67 x tan 60)-12=74.6 mm

Calculated for d=19.45 mm 70

ap/2 =(dxtan70)-x ap/2 =(19.45 x tan 70)-12=41.4 mm

ap=(2dxtan70)-x

ap=(2x19.45 x tan 70)-12=94.8 mm

1.5 ap=(3dxtan70)-x 1,5ap=(3x19.45 x tan 70)-12=148.3 mm

Calculated for d=19.45 mm 60

ap/2 =(dxtan60)-x ap/2 =(19.45 x tan 60)-12=21.6 mm

ap=(2dxtan60)-x

ap=(2x19.45 x tan60)-12=55.3 mm

1.5 ap=(3dxtan60)-x 1,5ap =(3x19.45 x tan 60)-12=89.0 mm

MANUEL ULTRASONIC TEST FOR WELD SEAM PROCEDURE

Revision: P3-G

Status:Re-IFR

Date: 19.04.2015

UEC-PCD-PPL-PLG-609

Page : 8of 13

Scanning Speed

Max. 150 mm/s

Calibration Block dimensions

Sensitivity Calibration

Reference reflector:

Calibration shall be performed by 1.6 mm TDH at the center of the

weld.

For gate setting;

4 pcs. N5 notches longitudinal and 2 pcs. N5 notches transversal,

one notch at the inside and another one at the outside.

Definition of DAC

DAC Curve is plotted with using 1,6 mm TDH on a pipe piece and

calculations given below;

MANUEL ULTRASONIC TEST FOR WELD SEAM PROCEDURE

Revision: P3-G

Status:Re-IFR

Date: 19.04.2015

UEC-PCD-PPL-PLG-609

Page : 9of 13

Vv=Dac gain value

v=gain value

VR=record gain value

VR=Vv + v

Note: DAC curve: Obtained by uniting the peak points of

optimum echo heights at varying distances on the amplitude level

where the maximum correction received from reflector at calibration

block is brought to 80% EY.

Sensitivity and range corrections

Characterization and verification of ultrasonic examination equipment

(Combined equipment) shall be checked according to EN 12668-3.

Signal to Noise Ratio: Max. 6 dB

6. ASSESSMENT OF INDICATORS

Suspected regions / indications revealed by automatic UT and the

total area of repair welding shall be inspected by manual UT. Manual

MANUEL ULTRASONIC TEST FOR WELD SEAM PROCEDURE

Revision: P3-G

Status:Re-IFR

Date: 19.04.2015

UEC-PCD-PPL-PLG-609

Page : 10of 13

UT coverage shall extend at least 100 mm beyond the ends of the

repair weld.

Method for Evaluation of Indicators

Comparison block / Comparison curve method (distance-amplitudecorrection (DAC) curve)

Defect length determination method: Transverse and lengthwise

length of indicator shall be determined by half value method.

7. ACCEPTANCE

7.1 Reference level

Distance-amplitude-correction (DAC) curve for TDH with 1.6 mm.

7.2 Record Level

TDH with 1.6 mm;

Reference level -6 dB V= 6 dB

7.3 Disposition of defects:

If the weld seam has inhomogenities exceeding the acceptance

criteria, disposition shall be carried out one of following;

o The section of pipe containing welding defect shall be repair

within the limits of requirements on length.

o The section of pipe containing welding defect shall be cut out

within the limits of requirements on length.

o The pipe shall be rejected.

8. HEALTH AND SAFETY

Throughout the manual ultrasonic inspection, health and safety

precautions shall be undertaken.

9. RESULTS

Record all information that reach assessment level in FR-164 form.

All manual ultrasonic inspection records are kept at least 3 years at

easy accessible location like laboratory. After 3 years all the records

are transferred to archive room. The records that are transferred to

archive room are kept in for 10 years.

MANUEL ULTRASONIC TEST FOR WELD SEAM PROCEDURE

Revision: P3-G

Status:Re-IFR

Date: 19.04.2015

UEC-PCD-PPL-PLG-609

Page : 11of 13

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Ts 16949 Proc Forms MatrixDocumento1 paginaTs 16949 Proc Forms MatrixRob WillestoneNessuna valutazione finora

- Recipe Booklet PRINT VERSIONDocumento40 pagineRecipe Booklet PRINT VERSIONjtsunami815100% (1)

- BS 534 PDFDocumento26 pagineBS 534 PDFRob Willestone50% (2)

- Transaction AnalysisDocumento34 pagineTransaction AnalysisSunil Ramchandani100% (1)

- How To Apply Risk-Based Thinking To Quality ProcessesDocumento58 pagineHow To Apply Risk-Based Thinking To Quality Processesnorlie100% (5)

- Welcome: at TheDocumento32 pagineWelcome: at TheRob WillestoneNessuna valutazione finora

- QEHS ManualDocumento100 pagineQEHS ManualRob WillestoneNessuna valutazione finora

- Apqp FormsDocumento32 pagineApqp FormsAnonymous A2jnZ5MNPxNessuna valutazione finora

- Raymond Lo - The Feng Shui of Swine FluDocumento1 paginaRaymond Lo - The Feng Shui of Swine Fluay2004jan100% (1)

- KPI Assessment FormDocumento2 pagineKPI Assessment FormRob Willestone100% (1)

- Jean-Pierre Wybauw - Fine Chocolates 2 - Great Ganache Experience-Lannoo (2008)Documento209 pagineJean-Pierre Wybauw - Fine Chocolates 2 - Great Ganache Experience-Lannoo (2008)Mi na100% (1)

- Audit ChecklistDocumento21 pagineAudit ChecklistRob WillestoneNessuna valutazione finora

- Pulverizers: By: G. RamachandranDocumento140 paginePulverizers: By: G. Ramachandranshivshankar prajapatiNessuna valutazione finora

- Cqe Sample ExamDocumento17 pagineCqe Sample Examkhelvin4582Nessuna valutazione finora

- Heat Shrink CoatingDocumento5 pagineHeat Shrink CoatingMekhmanNessuna valutazione finora

- MSA Reference Manual 4th EditionDocumento241 pagineMSA Reference Manual 4th EditionMukhammadali Shukuraliev100% (2)

- Soal Post TestDocumento70 pagineSoal Post Testananda96% (25)

- Financial Risk Management (Zain Ullah)Documento12 pagineFinancial Risk Management (Zain Ullah)Afaq AhmadNessuna valutazione finora

- (Clinical Sociology - Research and Practice) Howard M. Rebach, John G. Bruhn (Auth.), Howard M. Rebach, John G. Bruhn (Eds.) - Handbook of Clinical Sociology-Springer US (2001) PDFDocumento441 pagine(Clinical Sociology - Research and Practice) Howard M. Rebach, John G. Bruhn (Auth.), Howard M. Rebach, John G. Bruhn (Eds.) - Handbook of Clinical Sociology-Springer US (2001) PDFMuhammad AliNessuna valutazione finora

- NiCr Test Panels Product Data Sheet EnglishDocumento1 paginaNiCr Test Panels Product Data Sheet EnglishRob WillestoneNessuna valutazione finora

- Pie Field Indicator Product Data Sheet EnglishDocumento1 paginaPie Field Indicator Product Data Sheet EnglishDarwin Zuni RosadoNessuna valutazione finora

- Cqe Sample ExamDocumento1 paginaCqe Sample ExamRob WillestoneNessuna valutazione finora

- Pie Field Indicator Product Data Sheet EnglishDocumento2 paginePie Field Indicator Product Data Sheet EnglishRob Willestone100% (1)

- 40 Hour Retest Training Log: Subject(s) Covered Date TimeDocumento1 pagina40 Hour Retest Training Log: Subject(s) Covered Date Timeervikas34Nessuna valutazione finora

- React (Web Framework) - WikipediaDocumento15 pagineReact (Web Framework) - WikipediaRob WillestoneNessuna valutazione finora

- Magnetic Flux Indicators Product Data Sheet EnglishDocumento1 paginaMagnetic Flux Indicators Product Data Sheet EnglishRob WillestoneNessuna valutazione finora

- Cqe Sample ExamDocumento1 paginaCqe Sample ExamRob WillestoneNessuna valutazione finora

- Shelf Life Magnaflux Chemical Products Oct18Documento1 paginaShelf Life Magnaflux Chemical Products Oct18Rob WillestoneNessuna valutazione finora

- CHA InsertDocumento16 pagineCHA InsertHitendra Nath BarmmaNessuna valutazione finora

- SKL SP2Documento2 pagineSKL SP2Mangalraj MadasamyNessuna valutazione finora

- Sales and Marketing Risks To Consider Yes No N/A Comments / Action RequiredDocumento2 pagineSales and Marketing Risks To Consider Yes No N/A Comments / Action RequiredRob WillestoneNessuna valutazione finora

- 2012 CQT BokDocumento12 pagine2012 CQT BokRob WillestoneNessuna valutazione finora

- Failure Modes and Effects Analysis PaperDocumento22 pagineFailure Modes and Effects Analysis PaperunendratNessuna valutazione finora

- OHSAS18001 Self Ass Checklistrev 2Documento21 pagineOHSAS18001 Self Ass Checklistrev 2sjmpakNessuna valutazione finora

- Wcms 334882 PDFDocumento44 pagineWcms 334882 PDFIrina CălinNessuna valutazione finora

- Management Vs Non Management GuidelinesDocumento1 paginaManagement Vs Non Management GuidelinesRob WillestoneNessuna valutazione finora

- Best Practice Quality Policy StatementsDocumento3 pagineBest Practice Quality Policy StatementsRob WillestoneNessuna valutazione finora

- Laserfiche Records Management FactsheetDocumento2 pagineLaserfiche Records Management FactsheetRob WillestoneNessuna valutazione finora

- SB Management of Native EncryptionDocumento6 pagineSB Management of Native EncryptionRob WillestoneNessuna valutazione finora

- HooksDocumento7 pagineHooksapi-233765416Nessuna valutazione finora

- Switching Power Supply Design: A Concise Practical Handbook: February 2022Documento5 pagineSwitching Power Supply Design: A Concise Practical Handbook: February 2022Juan Gil RocaNessuna valutazione finora

- Bandura Social Cognitive TheoryDocumento93 pagineBandura Social Cognitive TheoryВикторияNessuna valutazione finora

- Laboratory Diagnosis of Parasitic DiseasesDocumento57 pagineLaboratory Diagnosis of Parasitic DiseasesAmanuel MaruNessuna valutazione finora

- Bubba - S Food MS-CDocumento2 pagineBubba - S Food MS-CDũng Trần QuốcNessuna valutazione finora

- Compositional Changes of Crude Oil SARA Fractions Due To Biodegradation and Adsorption Supported On Colloidal Support Such As Clay Susing IatroscanDocumento13 pagineCompositional Changes of Crude Oil SARA Fractions Due To Biodegradation and Adsorption Supported On Colloidal Support Such As Clay Susing IatroscanNatalia KovalovaNessuna valutazione finora

- The Modern Fire Attack - Phil Jose and Dennis LegearDocumento7 pagineThe Modern Fire Attack - Phil Jose and Dennis LegearTomNessuna valutazione finora

- Worksheet 2 - TLC - Updated Summer 2021Documento4 pagineWorksheet 2 - TLC - Updated Summer 2021Bria PopeNessuna valutazione finora

- Seed PrimingDocumento4 pagineSeed PrimingbigbangNessuna valutazione finora

- I. Choose The Meaning of The Underlined Words Using Context CluesDocumento4 pagineI. Choose The Meaning of The Underlined Words Using Context CluesMikko GomezNessuna valutazione finora

- Corp Given To HemaDocumento132 pagineCorp Given To HemaPaceNessuna valutazione finora

- The Effect of Gas Metal Arc Welding (GMAW) Processes On Different Welding Parameters - DoneDocumento5 pagineThe Effect of Gas Metal Arc Welding (GMAW) Processes On Different Welding Parameters - DoneAsim AliNessuna valutazione finora

- WaterproofingDocumento38 pagineWaterproofingPranay GandhiNessuna valutazione finora

- Test Unit 2 Urbanisation L P 12Documento9 pagineTest Unit 2 Urbanisation L P 12Xuân NguyenNessuna valutazione finora

- Commented (JPF1) : - The Latter Accused That Rizal HasDocumento3 pagineCommented (JPF1) : - The Latter Accused That Rizal HasLor100% (1)

- 8291 w13 Ms 22Documento8 pagine8291 w13 Ms 22Caterina De LucaNessuna valutazione finora

- Chapter 2Documento5 pagineChapter 2ERICKA MAE NATONessuna valutazione finora

- International Trade Law: AssignmentDocumento2 pagineInternational Trade Law: AssignmentQuỳnh PhạmmNessuna valutazione finora

- Job Vacancy Kabil - Batam April 2017 RECARE PDFDocumento2 pagineJob Vacancy Kabil - Batam April 2017 RECARE PDFIlham AdeNessuna valutazione finora

- 2.2 WaterDocumento32 pagine2.2 WaterHelena GlanvilleNessuna valutazione finora

- Types of Business OwnershipDocumento2 pagineTypes of Business Ownershipprelovedseller bnNessuna valutazione finora