Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

4895-w2 Standard For Purchase of Forged Flanges and Fittings

Caricato da

LorenaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

4895-w2 Standard For Purchase of Forged Flanges and Fittings

Caricato da

LorenaCopyright:

Formati disponibili

Engineering Standards

Standard

4895

Page

1 of 3

STANDARD FOR PURCHASE OF

FORGED FLANGES, FITTINGS AND

REINFORCEMENT SADDLES

Issue Date

Rev. No.

Date

12/87

2

01/92

1.

SCOPE

This standard covers requirements for the design and manufacture of forged steel flanges, fittings and

reinforcement saddles for piping 48" in diameter and less. In this standard, "fittings" does not include flanges or

non-pressure containing reinforcments such as weld saddles.

2.

CODES AND STANDARDS

Flanges, fittings and saddles shall be designed and manufactured in accordance with the latest approved edition of

the following as applicable and as modified by this standard. Each item shall be marked in accordance with the

governing manufacturing specification and that marking shall be described in detail in purchase documents for

verification upon receipt of the items.

American National Standards Institute (ANSI), B16.5, B16.9, B16.11

American Society for Testing and Materials (ASTM), A234, A420, A707

Engineering Standard 4900, "Standard for Purchase of High Test, Wrought, Welding Fittings"

Manufacturers Standardization Society (MSS) SP-44, SP-75

2.1

Flanges shall meet the requirements of ANSI B16.5, material group 1.1, or MSS SP-44, whichever is

applicable. When "low temperature design (-50F)" is specified as an option, the flanges shall also meet

the requirements in Section 4 of this standard.

2.2

Fittings having socket weld or threaded end connections shall meet the requirements of ANSI B16.11.

When "low temperature design (-50F)" is specified as an option, such fittings shall also meet the

requirements of ASTM A420, grade WPL6.

2.3

B-grade, butt weld fittings having a specified minimum yield strength (SMYS) of 35,000 psi shall meet

the requirements of ANSI B16.9 and ASTM A234, grade WPB. When "low temperature design (-50F)"

is specified as an option, such fittings shall meet the requirements of ASTM A420, grade WPL6, rather

than ASTM A234, grade WPB.

2.4

Y-grade, butt weld fittings having a specified minimum yield strength over 35,000 psig shall also meet the

requirements of Engineering Standard 4900.

2.5

B-grade saddles shall be in accordance with ASTM A234 WPB. Saddles having a specified minimum

yield strength (SMYS) greater than 35,000 psig shall be in accordance with MSS SP-75.

3.

SUPPLEMENTAL REQUIREMENTS FOR FLANGES & FITTINGS FOR SOUR GAS SERVICE

3.1

These supplemental requirements shall apply to flanges and fittings when sour gas is specified as the

service fluid.

* Indicates revised paragraph, this Rev. No.

Engineering Standards

Standard

4895

Page

2 of 3

STANDARD FOR PURCHASE OF

FORGED FLANGES, FITTINGS AND

REINFORCEMENT SADDLES

Issue Date

Rev. No.

Date

3.2

12/87

2

01/92

The carbon equivalent computed by the following equation shall not exceed 0.40% based on check

chemical analysis.

CE = %C + %Mn + %Cr + %Mo + %V + %Ni + %Cu

6

5

15

4.

3.3

The maximum design yield strength shall be 60,000 psi and the maximum acceptable actual tensile

strength shall be 90,000 psi.

3.4

The hardness shall not exceed 90 HRB (183 BHN) except that 22 HRC (235 BHN) is acceptable for

carbon and low alloy steels provided they contain less than 1% nickel.

3.5

The manufacturer shall provide test results and certification of compliance in accordance with ASTM

A234, Section 16; ASTM A420, Section 16; or Engineering Standard 4900, whichever is applicable.

SUPPLEMENTAL REQUIREMENTS FOR FLANGES FOR LOW TEMPERATURE SERVICE (-50F)

4.1

When "low temperature design (-50F)" is specified as an option, these requirements shall apply.

4.2

Flanges shall meet the requirements of ASTM A707, grade L3, Class 1, 2, or 3, as applicable, in addition

to ANSI B16.5 or MSS SP-44, whichever is applicable, and this standard, whichever are the more

stringent.

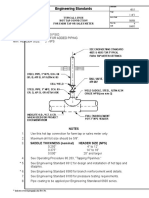

4.3

The following supplementary requirements of ASTM A707 shall also apply:

4.3.1

S1, "Ultrasonic Examination," of 100% of the area within two inches of the welding end on

flanges of all sizes.

4.3.2

Either S3, "Magnetic Particle Examination," or S4, "Liquid Penetrant Examination," shall be

performed at the manufacturer's option except that such examination may be limited to 100

percent of the end bevels after final machining. Any bevel face indication with a dimension in

excess of 1/4" shall be removed. Bevel face indications having dimensions between 1/4" and

1/16" which are not separated by 50 times the length of the longer indication shall also be

removed.

4.3.3

S7, "Notch Toughness, 50% Shear, FATT Minimum," shall be measured and reported as part

of the required Charpy V-notch testing.

4.4

A check analysis shall be furnished for each heat of steel from which flanges are manufactured.

4.5

The specified minimum yield strength of the hub shall not be less than 80 percent of the specified

minimum yield strength of the matching pipe as indicated on the specification sheet. The yield strength of

the hub shall not exceed the specified minimum yield strength by more than 15,000 psi.

4.6

Manufacturer shall provide certification and test results in accordance with ASTM A707, Section 21.

* Indicates revised paragraph, this Rev. No.

Standard

Engineering Standards

4895

Page

3 of 3

STANDARD FOR PURCHASE OF

FORGED FLANGES, FITTINGS AND

REINFORCEMENT SADDLES

Issue Date

12/87

2

01/92

Rev. No.

Date

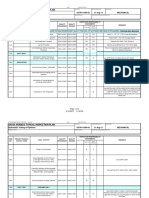

SPECIFICATION SHEET

Location:

Project:

Prepared By:

Date:

Purchase Order No.

Requisition No.

Project No.

Approved By:

Revision:

Revised Date:

P.O. Date:

SERVICE REQUIREMENTS

Item Number

Tag Number

Quantity

Service Fluid

Low Temp. Design (-50F) Req'd

ANSI Pressure Class

Design Pressure (psig)

Design Temperature Range (F)

Design Factor (% stress)

SMYS (psi)

Added Wall for Corrosion (in.)

Field Test Pressure (psig max.)

DESIGN REQUIREMENTS

]Y [ ]N

[ ]Y [ ]N

]Y [

]N

CONFIGURATION REQUIREMENTS

Type (flange, fitting, saddle)

Size, O.D. (in.)

Internal Diameter, Min. (in.)

Flange Face (flat/raised/RTJ)

Matching Pipe or Fitting

Inlet Conn. (BW/SW/NPT)

Size, O.D. (in.)

Wall Thickness (in.)

SMYS (psi)

Outlet Conn. (BW/SW/NPT)

Size, O.D. (in.)

Wall Thickness (in.)

SMYS (psi)

Branch Conn. (BW/SW/NPT)

Size, O.D. (in.)

Wall Thickness (in.)

SMYS (psi)

ADDITIONAL REQUIREMENTS

(1) Fittings having a specified minimum yield strength greater than 35,000 psi shall meet the requirements of

Engineering Standard 4900 in addition to this standard.

(2) See Section 3, this standard, if service fluid is specified "sour gas".

(3) See additional/alternate requirements in this standard for "low temp. design".

* Indicates revised paragraph, this Rev. No.

]Y [

]N

Potrebbero piacerti anche

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Life Cycle of A Ship - ShippipediaDocumento3 pagineLife Cycle of A Ship - ShippipediaarvindkaushikNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- 01 ASME Sec VIII Div 1 - GEN PresentationDocumento112 pagine01 ASME Sec VIII Div 1 - GEN Presentationinatt101Nessuna valutazione finora

- Bolt Identification MarkingsDocumento4 pagineBolt Identification MarkingsAbhishekNessuna valutazione finora

- Codes Standards For On Site Testing LaboratoryDocumento7 pagineCodes Standards For On Site Testing LaboratoryVipin Kumar ParasharNessuna valutazione finora

- DirectoryBulk DrugsDocumento48 pagineDirectoryBulk DrugsPrashantsuthar100% (1)

- Management ScienceDocumento6 pagineManagement ScienceDalia Joy ChanNessuna valutazione finora

- Barilla Spa Case Analysis of JITD ImplementationDocumento11 pagineBarilla Spa Case Analysis of JITD ImplementationRameen KhanNessuna valutazione finora

- Flare System PDFDocumento41 pagineFlare System PDFAzar Deen100% (1)

- Selecting and Designing Branch ConnectionsDocumento8 pagineSelecting and Designing Branch ConnectionsLorenaNessuna valutazione finora

- Supply Chain Improvement - Supply Chain Operations Reference (SCOR) ModelDocumento45 pagineSupply Chain Improvement - Supply Chain Operations Reference (SCOR) ModelRakib HassanNessuna valutazione finora

- Satip A 004 03Documento3 pagineSatip A 004 03Anonymous 4e7GNjzGW100% (1)

- Fire protection system philosophy for Collie Urea PlantDocumento60 pagineFire protection system philosophy for Collie Urea PlantLorena Dávila100% (1)

- Trusting JesusDocumento1 paginaTrusting JesusLorenaNessuna valutazione finora

- Tower of BabelDocumento5 pagineTower of BabelLorenaNessuna valutazione finora

- Good Cooling Tower PractiseDocumento59 pagineGood Cooling Tower Practiseamahmoud3Nessuna valutazione finora

- 2813 HXGN Live 2813 MccombDocumento19 pagine2813 HXGN Live 2813 MccombLorenaNessuna valutazione finora

- Onshore and Offshore: Echnical PresentationDocumento66 pagineOnshore and Offshore: Echnical PresentationAnonymous 4MwmDaNbNessuna valutazione finora

- Fluidos Termicos y Circuitos de CalentamientoDocumento38 pagineFluidos Termicos y Circuitos de CalentamientoClaudio Antonio Figueroa PulgarNessuna valutazione finora

- What's New - CADWorx 2016Documento5 pagineWhat's New - CADWorx 2016LorenaNessuna valutazione finora

- 4940-w3 Standard For Purchase of Valves For Critical Gas ServiceDocumento8 pagine4940-w3 Standard For Purchase of Valves For Critical Gas ServiceLorena DávilaNessuna valutazione finora

- Report DesignerDocumento255 pagineReport Designerdgrant775Nessuna valutazione finora

- Series 1500 Cooling Tower SpecificationDocumento9 pagineSeries 1500 Cooling Tower SpecificationLorenaNessuna valutazione finora

- Good Cooling Tower PractiseDocumento59 pagineGood Cooling Tower Practiseamahmoud3Nessuna valutazione finora

- Demonstration of Hydrogen Air-Assisted FlaDocumento18 pagineDemonstration of Hydrogen Air-Assisted Flahk168Nessuna valutazione finora

- 4890 Guide Bar Installation For Weld TeesDocumento2 pagine4890 Guide Bar Installation For Weld TeesLorena DávilaNessuna valutazione finora

- 4907-w0 Standard For Purchase of Line Pipe For Low Temperature Service (Supplement To ASTM A333)Documento3 pagine4907-w0 Standard For Purchase of Line Pipe For Low Temperature Service (Supplement To ASTM A333)LorenaNessuna valutazione finora

- 4815 Typical 1 Hot Tap Connection For Farm Tap or Sales MeterDocumento1 pagina4815 Typical 1 Hot Tap Connection For Farm Tap or Sales MeterLorenaNessuna valutazione finora

- 4910-w1 Engineering Guideline For Flexible Metal HoseDocumento1 pagina4910-w1 Engineering Guideline For Flexible Metal HoseLorenaNessuna valutazione finora

- 4802-w2 Concrete Anchor Block - Installation DetailsDocumento2 pagine4802-w2 Concrete Anchor Block - Installation DetailsLorenaNessuna valutazione finora

- 4762-w0 Typical Canal Undercrossing, Lined or UnlinedDocumento1 pagina4762-w0 Typical Canal Undercrossing, Lined or UnlinedLorenaNessuna valutazione finora

- 4764-n1 Typical Pipeline Bolt On Type Concrete Weight For 42 O.D. PipelineDocumento1 pagina4764-n1 Typical Pipeline Bolt On Type Concrete Weight For 42 O.D. PipelineLorenaNessuna valutazione finora

- 4758-w0 Restoration of TerracesDocumento1 pagina4758-w0 Restoration of TerracesLorenaNessuna valutazione finora

- Enron Gas Pipeline Engineering Standards for Concrete Pipeline WeightsDocumento2 pagineEnron Gas Pipeline Engineering Standards for Concrete Pipeline WeightsLorenaNessuna valutazione finora

- 4760-w0 Typical Stream or Ditch Pipeline UndercrossingDocumento1 pagina4760-w0 Typical Stream or Ditch Pipeline UndercrossingLorena100% (1)

- 4747-w2 Typical Natural Gas Pipeline and Pipeline Insulator Installation For Cased Highway UndercrossingDocumento1 pagina4747-w2 Typical Natural Gas Pipeline and Pipeline Insulator Installation For Cased Highway UndercrossingLorenaNessuna valutazione finora

- 4763-w2 Yard Applied Concrete Pipe CoatingDocumento7 pagine4763-w2 Yard Applied Concrete Pipe CoatingLorena DávilaNessuna valutazione finora

- 4752-w2 Typical Natural Gas Pipeline and Pipeline Insulator Installation For Railroad UndercrossingDocumento1 pagina4752-w2 Typical Natural Gas Pipeline and Pipeline Insulator Installation For Railroad UndercrossingLorenaNessuna valutazione finora

- 4748-w0 Typical Pipeline and Casing Support at Cased UndercrossingsDocumento1 pagina4748-w0 Typical Pipeline and Casing Support at Cased UndercrossingsLorenaNessuna valutazione finora

- CPP103 CNC Steel Plate Marking and Punching MachineDocumento7 pagineCPP103 CNC Steel Plate Marking and Punching MachineReza MuhammadNessuna valutazione finora

- Chapter 1Documento94 pagineChapter 1rethinamkNessuna valutazione finora

- Effect of Powder Mixed Electric Discharge Machining (PMEDM) On Various Materials With Different Powders: A ReviewDocumento6 pagineEffect of Powder Mixed Electric Discharge Machining (PMEDM) On Various Materials With Different Powders: A ReviewIJIRSTNessuna valutazione finora

- GLASS Industry of The FutureDocumento108 pagineGLASS Industry of The FuturebooksengineerNessuna valutazione finora

- Automation FMSDocumento164 pagineAutomation FMSSudhakar FormworkNessuna valutazione finora

- Shoring and UnderpinningDocumento16 pagineShoring and UnderpinningudithaireshaNessuna valutazione finora

- Storeman DetailsDocumento2 pagineStoreman DetailsPaul SimonNessuna valutazione finora

- Week 1 HW SolutionDocumento2 pagineWeek 1 HW Solutiontucker jacobsNessuna valutazione finora

- Solid Waste Management Transformation and Future Challenges of Source Separation and Recycling Practice in MalaysiaDocumento14 pagineSolid Waste Management Transformation and Future Challenges of Source Separation and Recycling Practice in MalaysiaRed Jagung FishNessuna valutazione finora

- NORSOK M-601 Annex C Weld Inspection GuideDocumento1 paginaNORSOK M-601 Annex C Weld Inspection Guidehalim abas100% (1)

- Marzoli Vouk: Draw FramesDocumento22 pagineMarzoli Vouk: Draw FramesHameedullah AnsariNessuna valutazione finora

- Sa 29 PDFDocumento26 pagineSa 29 PDFRaju SkNessuna valutazione finora

- Oxidative WearDocumento17 pagineOxidative WearManish Kumar SinghNessuna valutazione finora

- Flat Type+epoxy+floor+coatingDocumento3 pagineFlat Type+epoxy+floor+coatingRuano Andreola StumpfNessuna valutazione finora

- Inventory: Question 1 (20 Marks)Documento2 pagineInventory: Question 1 (20 Marks)nur athirahNessuna valutazione finora

- Oil Industry Safety Standards and GuidelinesDocumento6 pagineOil Industry Safety Standards and GuidelinesKrupal PatelNessuna valutazione finora

- RadoviDocumento7 pagineRadoviMihajlo PopovicNessuna valutazione finora

- Electrical Discharge MachiningDocumento16 pagineElectrical Discharge MachiningRizwan MrnNessuna valutazione finora

- 2 ProductivityDocumento14 pagine2 ProductivityMohd Nazri SalimNessuna valutazione finora

- 1 - Autodesk Advanced Manufacturing Solutions Brochure (Digital)Documento12 pagine1 - Autodesk Advanced Manufacturing Solutions Brochure (Digital)AhmedBrahamNessuna valutazione finora