Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Lathe Machine

Caricato da

Hermilih SiregarCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Lathe Machine

Caricato da

Hermilih SiregarCopyright:

Formati disponibili

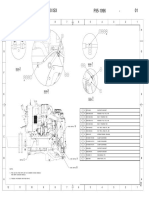

LATHE MACHINE

Powerful easy to operate rigidity high efficiency

BENCH L AT H E

*Picture shown with optional accessories

Description

Swing Over Bed

General Capacity

UoM

C0636D x 1000

mm

360

Swing Over Cross Slide

mm

224

Swing Over Gap

mm

502

Length in Gap

mm

210

Width of Bed

mm

187

Distance Between Centers

mm

1000

Cross Slide Travel

mm

170

Compound Rest Travel

mm

95

Cutting Tool Max Section

mm

16 16

Taper of Spindle

Diameter Of Spindle Bore

Main Spindle

MT#5

mm

40

rpm

70-2000

Metric Pitch Threads

mm

0.1-7 (44 kinds)

Threads Imperial Pitches

TPI

4-112 (42 kinds )

Threads Metric Pitches

mm

0.1-7 (44 kinds)

Threads Diametral Pitches

DP

16-112 (25 kinds)

Number of Spindle Speeds

Range of Spindle Speeds

Spindle Nose

Threading

Threads Module Pitches

Feeding

Leadscrew

MP

0.1-1.75 (34 kinds)

Range of Longitudinal Feeds

mm/rev

0.046-3.249 (24 kinds)

Range of Cross Feeds

mm/rev

0.01-0.703 (24 kinds)

mm

19

TPI/mm

8/3

mm

100

Diameter of Leadscrew

Pitch Threads of Leadscrew

Travel of Tailstock Quill

Tailstock

Taper Hole of Tailstock Quill

MT#3

Quill Diameter

mm

42

Main Motor Power

kW

1.5

Overall Size of Lathe(LWH)

mm

1930 760 1530

Net / Gross Weight

kg

540 / 645

Power

D1-4 or D1-5

Features:

No change gear in tool box.

The thread category complete, not only cutting metric

thread and imperial thread, but also cutting diametral

thread and module thread.

Minimum Cross feed 0.01mm/rev, Minimum

Longitudinal feed 0.046mm/rev.

Standard Accessories:

Three Jaw Chuck

Four Jaw Chuck

Face Plate

Steady Rest

Follow Rest

Foot Brake

Work Light

Dead Center MT3#

Coolant System

Reduction Sleeve 5/3#

Splash Guard

Chip Tray

Metric Changing Gear

Thread Chasing Dial

Tool Box & Tools

Optional Accessories:

Driving Plate

Quick Change Tool Post

Taper Turning Attachment

Chuck Cover

BENCH L AT H E

*Picture shown with optional accessories

Description

General Capacity

UoM

C6236 x 1000

Swing Over Bed

mm

356

Swing Over Cross Slide

mm

220

Swing Over Gap

mm

506

Length in Gap

mm

145

Width of Bed

mm

206

Distance Between Centers

mm

1000

Cross Slide Travel

mm

180

Compound Rest Travel

mm

95

Cutting Tool Max Section

mm

16 x 16

Taper of Spindle

Diameter of Spindle Bore

Main Spindle

MT#5

mm

38

rpm

45-1800

mm

0.4-7 (22 Kinds)

Number of Spindle Speeds

Range of Spindle Speeds

16

Spindle Nose

Threading

Feeding

Leadscrew

Metric Pitch Threads

Threads Imperial Pitches

D1-4

TPI

4-56(44 Kinds)

Range of Longitudinal Feeds

mm/rev

0.043-0.653

Range of Cross Feeds

mm/rev

0.027-0.413

Diameter of Leadscrew

Pitch Threads of Leadscrew

Travel of Tailstock Quill

mm

22

TPI/mm

8/4

mm

Standard Accessories:

Three Jaw Chuck

Four Jaw Chuck

Face Plate

Steady Rest

Follow Rest

Foot Brake

Work Light

Dead Center MT3#

Live Center

Reduction Sleeve 5/3#

Coolant System

Splash Guard

Chip Tray

Metric Changing Gear

Thread Chasing Dial

Tool Box & Tools

Optional Accessories:

Driving Plate

Quick Change Tool Post

Taper Turning Attachment

Chuck Cover

120

Tailstock

Taper Hole of Tailstock Quill

Quill Diameter

mm

45

Power

Main Motor Power

kW

1.5/ 2.4

Overall Size of Lathe(LWH)

mm

1820 x 740 x 1250

Net / Gross Weight

kg

730 / 860

MT#3

GAP BED LATHE

*Picture shown with optional accessories

Description

General Capacity

UoM

C6240B x 1000

Swing Over Bed

mm

400

Swing Over Cross Slide

mm

240

Swing Over Gap

mm

630

Length in Gap

mm

280

Width of Bed

mm

330

Distance Between Centers

mm

1000

Cross Slide Travel

mm

255

Compound Rest Travel

mm

130

Cutting Tool Max Section

mm

25 x 25

Taper of Spindle

Diameter of Spindle Bore

Main Spindle

MT#6

mm

52

rpm

19-1800

Metric Pitch Threads

mm

0.45 - 20

Threads Imperial Pitches

TPI

80 - 1 3/4

Threads Diametral Pitches

DP

160 - 3 1/2

Number of Spindle Speeds

Range of Spindle Speeds

16

Spindle Nose

Threading

Threads Module Pitches

Feeding

Leadscrew

MP

0.25 - 6

Range of Longitudinal Feeds

mm/rev

0.05 - 3.91

Range of Cross Feeds

mm/rev

0.25 - 1.95

mm

32

Diameter of Leadscrew

Pitch Threads of Leadscrew

Travel of Tailstock Quill

Tailstock

TPI/mm

mm

120

Taper Hole of Tailstock Quill

MT#4

Quill Diameter

mm

50

Main Motor Power

kW

4/5.5

Overall Size of Lathe (LWH)

mm

2400 x 1120 x 1560

Net / Gross Weight

kg

2000 / 2200

Power

D1-6

Features:

Hypercoustic quenched and accurate grinded bedway

and dovetail of saddle

52 mm spindle bore

One piece cast iron base, with well rigidity

Main drive gears are hyperacoustic quenched and

accurate grinded, have low working noise

Convenient to cut thread without changing wheels

Foot brake giving rapid braking

Standard Accessories:

Three Jaw Chuck

Four Jaw Chuck

Face Plate

Steady Rest

Follow Rest

Center

Center Sleeve

Work Lamp

Splash Guard

Foot Brake

Coolant System

Live Center

Anchor Bolt

Leveling Pads

Optional Accessories:

Digital Read Out

Tool Post Guard

Taper Turning Attachment

Quick Change Toolpost

Chuck Guard

GAP BED LATHE

*Picture shown with optional accessories

Description

General Capacity

UoM

GH 1660 x 1500

Swing Over Bed

mm

400

Swing Over Cross Slide

mm

222

Swing Over Gap

mm

650

Length in Gap

mm

320

Width of Bed

mm

340

Distance Between Centers

mm

1500

Cross Slide Travel

mm

220

Compound Rest Travel

mm

120

Cutting Tool Max Section

mm

25 x 25

Taper of Spindle

Diameter of Spindle Bore

Main Spindle

MT#6

mm

80

rpm

40 - 1600

Metric Pitch Threads

mm

0.1 - 144 (41 kinds)

Threads Imperial Pitches

TPI

2 - 112 (60 kinds)

Threads Diametral Pitches

DP

4 - 112 (50 kinds)

Threads Module Pitches

MP

0.1 - 7 ( 34 kinds)

Number of Spindle Speeds

Range of Spindle Speeds

12

Spindle Nose

Threading

Feeding

Leadscrew

Range of Longitudinal Feeds

mm/rev

0.0325 - 1.76

Range of Cross Feeds

mm/rev

0.014 - 0.736

mm

36

Diameter of Leadscrew

Pitch Threads of Leadscrew

Travel of Tailstock Quill

Tailstock

D-8

TPI/mm

mm

130

Taper Hole of Tailstock Quill

MT#4

Quill Diameter

mm

70

Main Motor Power

kW

5.5

Overall Size of Lathe (LWH)

mm

1970 x 800 x 1460

Net / Gross Weight

kg

2400 / 2600

Power

Features:

Hypercoustic quenched and accurate grinded bedway

and dovetail of saddle

80 mm spindle bore

One piece cast iron base, with well rigidity

Hypercoustic quenched and accurate grinded main

drive gear

Forced lubrication of headstock by oil pump

Clutch assembled in apron for avoiding overload

automatic feed

Demountable gapped bed is convenient to manufactur

major diameter workpieces

Convenient to cut thread without changing wheels

Five position self feed stop

Foot brake giving rapid braking

Standard Accessories:

Three Jaw Chuck

Four Jaw Chuck

Face Plate

Steady Rest

Follow Rest

Center

Center Sleeve

Work Lamp

Splash Guard

Foot Brake

Coolant System

Live Center

Anchor Bolt

Leveling Pads

Optional Accessories:

Digital Read Out

Tool Post Guard

Taper Turning Attachment

Quick Change Toolpost

Chuck Guard

GAP BED LATHE

*Picture shown with optional accessories

Description

General Capacity

UoM

GH 2060 x 1500

Swing Over Bed

mm

500

Swing Over Cross Slide

mm

330

Swing Over Gap

mm

746

Length in Gap

mm

320

Width of Bed

mm

400

Distance Between Centers

mm

1500

Cross Slide Travel

mm

220

Compound Rest Travel

mm

120

Cutting Tool Max Section

mm

25 x 25

Taper of Spindle

Diameter of Spindle Bore

Main Spindle

MT#6

mm

80

rpm

40 - 1600

Number of Spindle Speeds

Range of Spindle Speeds

12

Spindle Nose

Threading

Feeding

Leadscrew

Metric Pitch Threads

mm

0.1 - 144 (41 kinds)

Threads Imperial Pitches

TPI

2 - 112 (60 kinds)

Threads Diametral Pitches

DP

4 - 112 (50 kinds)

Threads Module Pitches

MP

0.1 - 7 ( 34 kinds)

Range of Longitudinal Feeds

mm/rev

0.0325 - 1.76

Range of Cross Feeds

mm/rev

0.014 - 0.736

mm

36

TPI/mm

Diameter of Leadscrew

Pitch Threads of Leadscrew

Travel of Tailstock Quill

D-8

mm

130

Tailstock

Taper Hole of Tailstock Quill

Quill Diameter

mm

70

Power

Main Motor Power

kW

5.5

Overall Size of Lathe (LWH)

mm

3420 x 1140 x 1700

Net / Gross Weight

kg

3500 / 4060

MT#4

Features:

Hypercoustic quenched and accurate grinded bedway

and dovetail of saddle

80 mm spindle bore

One piece cast iron base, with well rigidity

Hypercoustic quenched and accurate grinded main

drive gear

Forced lubrication of headstock by oil pump

Clutch assembled in apron for avoiding overload

automatic feed

Demountable gapped bed is convenient to manufactur

major diameter workpieces

Convenient to cut thread without changing wheels

Five position self feed stop

Foot brake giving rapid braking

Standard Accessories:

Three Jaw Chuck

Four Jaw Chuck

Face Plate

Steady Rest

Follow Rest

Center

Center Sleeve

Work Lamp

Splash Guard

Foot Brake

Coolant System

Live Center

Anchor Bolt

Leveling Pads

Optional Accessories:

Digital Read Out

Tool Post Guard

Taper Turning Attachment

Quick Change Toolpost

Chuck Guard

GAP BED LATHE

*Picture shown with optional accessories

Description

General

Capacity

Main Spindle

Threading

Feeding

Swing Over Bed

Swing Over Cross Slide

Swing Over Gap

Length in Gap

Width of Bed

Distance Between Centers

Cross Slide Travel

Compound Rest Travel

Cutting Tool Max Section

Taper of Spindle

Diameter of Spindle Bore

Number of Spindle Speeds

Range of Spindle Speeds

Spindle Nose

Metric Pitch Threads

Threads Imperial Pitches

Threads Diametral Pitches

Threads Module Pitches

Range of Longitudinal Feeds

mm

TPI

DP

MP

mm/rev

C6266BD x 2200

660

420

880

280

300

2200

360

130

25 x 25

MT#6

80

16

18 - 1800

D1 - 6

0.1 - 144 (41 steps)

2 - 112 (60 steps)

4 - 112 (50 steps)

0.1 - 7 (34 steps)

0.0325 - 1.76

Range of Cross Feeds

mm/rev

0.014 - 0.736

mm

TPI/mm

mm

36

6

130

MT#4

55

5.5

3600 x 1345 x 1675

2600 / 2800

Diameter of Leadscrew

Leadscrew

Pitch Threads of Leadscrew

Travel of Tailstock Quill

Tailstock

Taper Hole of Tailstock Quill

Quill Diameter

Power

Main Motor Power

Overall Size of Lathe (LWH)

Net / Gross Weight

UoM

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

rpm

mm

kW

mm

kg

Features:

Hypercoustic quenched and accurate grinded bedway and

dovetail of saddle

52 or 80 mm spindle bore

Hypercoustic quenched and accurate grinded main drive gear

Clutch assembled in apron for avoiding overload automatic feed

Convenient to cut thread without changing wheels

Five position self feed stop

Foot brake giving rapid braking

Standard Accessories:

Three Jaw Chuck

Four Jaw Chuck

Face Plate

Steady Rest

Follow Rest

Center

Center Sleeve

Work Lamp

Splash Guard

Foot Brake

Coolant System

Live Center

Anchor Bolt

Leveling Pads

Drive Plate

Optional Accessories:

Digital Read Out

Tool Post Guard

Taper Turning Attachment

Quick Change Toolpost

Chuck Guard

GAP BED LATHE

*Picture shown with optional accessories

Description

UoM

CW6280E x 3000

Swing Over Bed

mm

800

Swing Over Cross Slide

mm

520

Swing Over Gap

mm

1000

Length in Gap

mm

320

General Capacity Width of Bed

mm

320

Distance Between Centers

mm

3000

Cross Slide Travel

mm

493

Compound Rest Travel

mm

200

Cutting Tool Max Section

mm

30 x 30

Taper of Spindle

Main Spindle

Threading

Feeding

Leadscrew

Diameter of Spindle Bore

MT#5

mm

Number of Spindle Speeds

105

18

Range of Spindle Speeds

rpm

7.5 - 1000

Metric Pitch Threads

mm

1 - 240 (39)

Threads Imperial Pitches

TPI

14 - 1 (26)

Threads Diametral Pitches

DP

28-1 (24)

Threads Module Pitches

MP

0.5-120 (53)

Range of Longitudinal Feeds mm/rev

0.1 - 24.3

Range of Cross Feeds

mm/rev

0.05 - 12.15

Pitch Threads of Leadscrew

TPI/mm

2 TPI (12 mm)

Travel of Tailstock Quill

Tailstock

Taper Hole of Tailstock Quill

Power

Main Motor Power

mm

250

MT#6

kW

11

Overall Size of Lathe (L W H)

mm

5200 x 1400 x 1900

Net / Gross weight

kg

4300 / 4900

Features:

Big spindle bore

One piece casting lathe bed

Hardened and ground guide way

High spindle torque

Head stock with hydraulic clutch

Standard accessories:

3 - Jaw chuck

4 - Jaw chuck

Center sleeve

Center

Face plates

Driving plate

Steady rest

Coolant system with delivery pipe

Following rest

Work lamp

Operation manual and part list book

Optional accessories:

Full lenght splash guard

Taper turning attachment

Tool post guard

Quick change toolpost

Rolling center

Digital display unit

Chuck guard

Foot brake

GAP BED LATHE

*Picture shown with optional accessories

Description

General Capacity

Main Spindle

UoM

DY - 410 G

DY - 510 G

DY - 560 G

Swing Over Bed

mm

410

510

560

Swing Over Cross Slide

mm

230

320

310

Swing Over Gap

mm

660

760

800

Width of Bed

mm

330

330

410

Distance Between Centers

mm

1100

1600

3000

Cross Slide Travel

mm

260

260

380

Compound Rest Travel

mm

127

127

255

Cutting Tool Max Section

mm

25 x 25

25 x 25

25 x 25

Diameter of Spindle Bore

mm

63

80

104

12

12

12

rpm

36 - 2000

36 - 2000

25 - 1250

D1-6

D1-6

D1-8

Metric Pitch Threads

mm

0.2 - 14 (45

kinds)

0.2 - 14 (45

kinds)

0.8-14

Threads Imperial Pitches

TPI

2-72 (45 Kinds) 2-72 (45 Kinds)

2-28

Threads Diametral Pitches

DP

8 - 44 (41 Kinds) 8 - 44 (41 Kinds)

4 -56

Number of Spindle Speeds

Range of Spindle Speeds

Spindle Nose

Threading

MP

0.3 - 3.5 (18

kinds)

0.3 - 3.5 (18

kinds)

0.5 - 7

Range of Longitudinal Feeds

mm/rev

0.04 - 1

0.04 - 1

0.05-0.07

Range of Cross Feeds

mm/rev

0.02-0.5

0.02-0.5

0.025 - 0.35

mm

35

35

45

Threads Module Pitches

Feeding

Leadscrew

Diameter of Leadscrew

Pitch Threads of Leadscrew

Travel of Tailstock Quill

Tailstock

Power

Taper Hole of Tailstock Quill

by :

130

130

180

MT#4

MT#4

MT#5

65

75

75

Quill Diameter

mm

Main Motor Power

kW

5.5

5.5

7.5

mm

2370 x 1100 x

1700

2880 x 1100 x

1700

4800 x 1400 x

1630

kg

2000 / 2200

2300 / 2500

3700 / 3900

Overall Size of Lathe (L W H)

Net / Gross Weight

4T.P.I or 6 pitch 4T.P.I or 6 pitch 4T.P.I or 6 pitch

mm

Standard Accessories:

Coolant pump

Halogen work lamp

Tailstock

Auto lubrication sytem

Toolbox

Manual tool post

Center & center sleeve

3 - Jaw scroll chuck 10 *

4 - Jaw chuck 20 *

Face plates 20 *

Rolling center (for DY560G only) *

Steady rest *

Follow rest *

Rear splash guard *

Optional Accessories:

Soft jaw for 3-jaw strong

chuck

Collet chuck 3 - 25mm

Fixed tool post (Quick

change type)

Rear tool post

Larger spindle bore

DRO 2 axis

Chuck guard

CE standard includes rear

splash, tool post, chuck,

lead screw guard, CE electrical equipment.

2 speed tailstock

Rapid traverse X/Z axis

Taper attachment

Grinder

Notes : * Optional Accessories which include for unit stock

GAP BED LATHE

*Picture shown with optional accessories

Description

General Capacity

UoM

GH-1640ZX

GH-1860ZX

GH-2080ZH

Swing Over Bed

mm

406

460

500

Swing Over Cross Slide

mm

254

280

310

Swing Over Gap

mm

657

698

720

Length in Gap

mm

310

310

210

Width of Bed

mm

340

340

405

Distance Between Centers

mm

1015

1524

2030

Cross Slide Travel

mm

228

228

310

Compound Rest Travel

mm

130

130

145

Cutting Tool Max Section

mm

Taper of Spindle

Diameter of Spindle Bore

Main Spindle

mm

Number of Spindle Speeds

Range of Spindle Speeds

rpm

Spindle Nose

Threading

Feeding

Tailstock

Power

10

25 x 25

25 x 25

25 x 25

MT#7 (MT#5)

MT#7 (MT#5)

MT#7

80

80

80

12

12

24

25 - 1800

25 - 1800

9 - 1600

D1-8

D1-8

D1-8

Metric Pitch Threads

mm

0.5 - 20

0.5 - 20

0.5 - 112

Threads Imperial Pitches

TPI

72 - 1 5/8

72 - 1 5/8

28 - 1/8

Threads Diametral Pitches

DP

963 1/4

963 1/4

564

Threads Module Pitches

MP

0,2510

0,2510

0,5112

Range of Longitudinal Feeds mm/rev

0.038 - 2.3

0.038 - 2.3

0.063 - 6.43

Range of Cross Feeds

mm/rev

0.015 - 0.9

0.015 - 0.9

0.027 - 2.73

mm

124

124

150

MT#4

MT#5

MT#5

8.8

8.8

12

Travel of Tailstock Quill

Taper Hole of Tailstock Quill

Main Motor Power

kW

Overall Size of Lathe (L W H)

mm

Net/Gross Weight

kg

2462 x 1016 x 2960 x 1016 x 3480 x 1280 x

1220

1241

1410

2200 / 2400

2700 / 2900

3300 / 3500

Features:

Induction-hardened and ground

cast iron gantry bed

Pull-out bed gap section

Permanently lubricated main, feed

and apron gear

Hardened and ground gears in

headstock and gear box

Guides adjustable without play via

V-ledges

Carriage guide Turcite-B coated

Central lubrication for carriage

Adjustable feed clutch

Transversal adjustment of tailstock

for taper cuts

Tailstock sleeve and hand wheel

with adjustable precision scale

Standard accessories:

3-axis digital readout

Robust cast iron machine stand

3-jaw chuck with basic and reversing jaws

4-jaw chuck

Face plate

4-way tool post with indexing function

Live center point MT-5

Fixed center point MT-5

MT-7/ MT-5 reducing sleeve

Steady rest and follow rest

Splash guard

Foot brake with limit switch

Complete coolant system

Halogen machine light

Stop shaft with 5 adjustable cams

(switch-off of the longitudinal feed)

Longitudinal stop

Chuck guard with limit switch

Levelling elements

Operating tools in tool box

CNC LATHE MACHINE

*Picture shown with optional accessories

Standard accessories:

3 - Jaw Chuck

Tailstock

Work Light

Coolant System

4 - Way Tool Post

Full Enclosure

Fanuc CNC System

Manual Lubrication Pump

Optional accessories:

6 - Way Tool Post

Hydraulic Chuck

Hydraulic Tailstock

Auto - Lubrication Pump

Description

UoM

CNC System

General Capacity

CK6140H

CK6145H

Fanuc Oi-mate

Fanuc Oi-mate

Swing Over Bed

mm

400

460

Swing Over Cross Slide

mm

200

200

Width Of Bed

mm

330

400

Distance Between Centers

mm

750

1000

Diameter Of Spindle Bore

mm

52

80

Main Spindle

Range Of Spindle Speeds

rpm

200-2500

24-1500

D6

D6

Z-Axis

Rapid Movement Speed

m/min

5-8

5-8

X-Axis

Rapid Movement Speed

m/min

3-5

3-5

Travel Of Tailstock Quill

mm

Spindle Nose

Tailstock

Taper Hole Of Tailstock Quill

120

150

MT#4

MT#5

Quill Diameter

mm

55

70

Main Motor Power

kW

5.5

5.5

Overall Size Of Lathe(LWH)

mm

2250 x 1200 x 1700

2550 x 1400 x 1800

Net / Gross Weight

kg

1500 / 1700

1500 / 1700

Power

11

ACCESSORIES

4-Jaw Chuck

Follow Rest

Steady Rest

DRO

Center

Live Center

Chuck Guard

Taper

Attachment

Drive Plate

Face Plate

Quick Change

Toolpost

kls/p&a.241/2k/gut.5/boy.uni/11-14

3-Jaw Chuck

12

Potrebbero piacerti anche

- Get Started with Affinity Photo's Essential Editing ToolsDocumento17 pagineGet Started with Affinity Photo's Essential Editing ToolsHermilih SiregarNessuna valutazione finora

- Electrical Load ComputationDocumento4 pagineElectrical Load ComputationAllen Velasquez Mangaoil87% (15)

- EMC ActuatorsDocumento80 pagineEMC ActuatorsnageshNessuna valutazione finora

- Lathe and Milling Machine GuideDocumento28 pagineLathe and Milling Machine GuideSamantha Ashman100% (2)

- Acoustic Tractor Beam: 35 Steps (With Pictures) PDFDocumento38 pagineAcoustic Tractor Beam: 35 Steps (With Pictures) PDFAmirNessuna valutazione finora

- (Metalworking) Welding and MachiningDocumento1.767 pagine(Metalworking) Welding and MachiningEugeneNessuna valutazione finora

- Dayton Tech BalllockDocumento12 pagineDayton Tech BalllockNaukowyDrpNessuna valutazione finora

- Lathe Part IDocumento151 pagineLathe Part Ishiva100% (1)

- Arc Welding Process PDFDocumento12 pagineArc Welding Process PDFBiswanath RoulNessuna valutazione finora

- Transfer Case Disassembly GuideDocumento12 pagineTransfer Case Disassembly GuideJuan Carlos GlauserNessuna valutazione finora

- How Do I Set Up My TIG Welder?: Owner's ManualDocumento2 pagineHow Do I Set Up My TIG Welder?: Owner's ManualenricoNessuna valutazione finora

- Workshop Technology: Lecture#5 By: Waleed AslamDocumento41 pagineWorkshop Technology: Lecture#5 By: Waleed AslamMuhammad ZeerakNessuna valutazione finora

- Power TrainDocumento168 paginePower TrainJuan RodriguezNessuna valutazione finora

- Pipe JigsDocumento26 paginePipe Jigsarvind565Nessuna valutazione finora

- Miter Gauge PDFDocumento8 pagineMiter Gauge PDFJesus MachadoNessuna valutazione finora

- Machining specifications for VG 4 150 discDocumento1 paginaMachining specifications for VG 4 150 disctauasi_1Nessuna valutazione finora

- Report On Heat Treatment of Plain Carbon Steel Kuet MeDocumento11 pagineReport On Heat Treatment of Plain Carbon Steel Kuet MeAhmed JishanNessuna valutazione finora

- RF 45Documento48 pagineRF 45Daniel Lara100% (1)

- Installation of Electrical Lighting System On Auxiliary Outlet & Lighting FixturesDocumento81 pagineInstallation of Electrical Lighting System On Auxiliary Outlet & Lighting FixturesRex Chambers LadaoNessuna valutazione finora

- Tug Fenders Form - Fill inDocumento2 pagineTug Fenders Form - Fill inaNessuna valutazione finora

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonDa EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNessuna valutazione finora

- HMT Mandrel Bending 101Documento80 pagineHMT Mandrel Bending 101zaiofracassadoNessuna valutazione finora

- Clamping ToolsDocumento190 pagineClamping ToolsИван РадивојевићNessuna valutazione finora

- Dowelingjig Plans Cut TempDocumento9 pagineDowelingjig Plans Cut TempKeith WesleyNessuna valutazione finora

- Construction: Lathes Machining Metals Plastics Jargon Machine Tools Rotating Linear Tool Bits Drill BitsDocumento8 pagineConstruction: Lathes Machining Metals Plastics Jargon Machine Tools Rotating Linear Tool Bits Drill Bitsviruz2_09Nessuna valutazione finora

- Hard Part Turning Fundamentals PDFDocumento26 pagineHard Part Turning Fundamentals PDFPrashant TalnikarNessuna valutazione finora

- JAM003MQN400 pulley specificationsDocumento1 paginaJAM003MQN400 pulley specificationsSebastian Davila hernandezNessuna valutazione finora

- Drilling Machine Types GuideDocumento42 pagineDrilling Machine Types GuideSomenath RahaNessuna valutazione finora

- Mini Mill Users GuideDocumento28 pagineMini Mill Users Guidechriswood_gmailNessuna valutazione finora

- Modular Multi Cat 1205 Product SheetDocumento2 pagineModular Multi Cat 1205 Product SheetAnonymous hlPPOmxXB7Nessuna valutazione finora

- Jam003mqn400 409Documento1 paginaJam003mqn400 409Sebastian Davila hernandezNessuna valutazione finora

- Tig and Plasma Welding: Process Techniques, Recommended Practices and ApplicationsDa EverandTig and Plasma Welding: Process Techniques, Recommended Practices and ApplicationsValutazione: 5 su 5 stelle5/5 (1)

- Epp 5 ToolsDocumento10 pagineEpp 5 Toolsjonathan mosqueraNessuna valutazione finora

- No.2 Wugang Road, Industrial Park, Botou City Hebei Province, China 062150 TEL: 86-317-8222761 8293066 8319026 FAX: 86-317-8319058Documento160 pagineNo.2 Wugang Road, Industrial Park, Botou City Hebei Province, China 062150 TEL: 86-317-8222761 8293066 8319026 FAX: 86-317-8319058boris velastegui sanchezNessuna valutazione finora

- 2009 Amada Press Brake ToolingDocumento48 pagine2009 Amada Press Brake Toolingdissymmetry100% (1)

- JJ104 Workshop Technology Chapter4 Twist DrillDocumento52 pagineJJ104 Workshop Technology Chapter4 Twist DrillAh TiangNessuna valutazione finora

- Belt Vulcanize 1112Documento13 pagineBelt Vulcanize 1112Hermilih SiregarNessuna valutazione finora

- Multi NX R32 Data Engineering - EDAVN121718Documento896 pagineMulti NX R32 Data Engineering - EDAVN121718Hung Tran88% (17)

- YAMAHA - Crypton 110 T110 E - 2005 A 2006Documento57 pagineYAMAHA - Crypton 110 T110 E - 2005 A 2006MiguelAmaya100% (2)

- Gas Tungsten Arc Welding ProcessDocumento9 pagineGas Tungsten Arc Welding ProcessJacques Sau100% (1)

- TIG Welding Amp ChartsDocumento3 pagineTIG Welding Amp ChartsHikmet ParakNessuna valutazione finora

- Machine Shop Guide to Lathe Parts and OperationsDocumento17 pagineMachine Shop Guide to Lathe Parts and OperationsJohn Borja100% (1)

- 43 - Hofmann - Portable Machine Tools Brochure - A4Documento2 pagine43 - Hofmann - Portable Machine Tools Brochure - A4Jorge VillalobosNessuna valutazione finora

- Shaping Machine Operations GuideDocumento25 pagineShaping Machine Operations Guidekatakamharish100% (1)

- CES Business PresentationDocumento50 pagineCES Business PresentationGary David CrowhurstNessuna valutazione finora

- Horizontal Balancing Machine Technical RequirementsDocumento7 pagineHorizontal Balancing Machine Technical RequirementsNguyễn Quốc PhượngNessuna valutazione finora

- Scientific Calculator Operation Guide PDFDocumento75 pagineScientific Calculator Operation Guide PDFArevalo ErolesNessuna valutazione finora

- Lathe DesignDocumento11 pagineLathe DesignShiyas Basheer0% (1)

- Shaper MachineDocumento81 pagineShaper Machinesam clastineNessuna valutazione finora

- Production Engineering Lab VIII SemDocumento24 pagineProduction Engineering Lab VIII Semsunil kumawatNessuna valutazione finora

- Vibro InfigatorDocumento2 pagineVibro InfigatorDanielGabrielBaleaNessuna valutazione finora

- Manufacturing of Spur Gear: Aim of The ExperimentDocumento5 pagineManufacturing of Spur Gear: Aim of The ExperimentParameshwara MeenaNessuna valutazione finora

- TB Welding-English PDFDocumento20 pagineTB Welding-English PDFdanghpNessuna valutazione finora

- Pneumatic Auto Feed Sheet Cutting MachineDocumento5 paginePneumatic Auto Feed Sheet Cutting MachineVigneshwaran Srinivasan100% (1)

- Gas Tungsten Arc Welding - WikipediaDocumento10 pagineGas Tungsten Arc Welding - WikipediadevinfNessuna valutazione finora

- 2010 PBT e InternetDocumento20 pagine2010 PBT e InternetMohammed RiyazNessuna valutazione finora

- Production & Special Purpose LathesDocumento38 pagineProduction & Special Purpose LathesShubham Shekhar100% (1)

- Lathe OperationsDocumento29 pagineLathe OperationsWaqas AhmadNessuna valutazione finora

- Slotting MachineDocumento30 pagineSlotting MachineUsman Zubair100% (1)

- Mechanism of RollingDocumento4 pagineMechanism of RollingGanesh Kotipalli100% (1)

- Automated Machine ToolsDocumento29 pagineAutomated Machine ToolsSyafawati OsmanNessuna valutazione finora

- Toolmakers Microscope MeasurementsDocumento7 pagineToolmakers Microscope MeasurementsskumarNessuna valutazione finora

- Gas Tungsten Arc WeldingDocumento13 pagineGas Tungsten Arc WeldingEmad A.AhmadNessuna valutazione finora

- Sample Cert. NPTELDocumento22 pagineSample Cert. NPTELAbid YusufNessuna valutazione finora

- Wear Analysis of Hard Faced Agricultural Equipment - Doc FFDocumento15 pagineWear Analysis of Hard Faced Agricultural Equipment - Doc FFSunil BasavarajuNessuna valutazione finora

- Chapter 2 - Metal Cutting LatheDocumento165 pagineChapter 2 - Metal Cutting LathebmdbmdbmdNessuna valutazione finora

- Lathe - LVDocumento23 pagineLathe - LVakshaygiitmNessuna valutazione finora

- MD Design ConsiderationDocumento18 pagineMD Design ConsiderationjhpatelNessuna valutazione finora

- Lecture 1 - Intro To Single Point Cutting Tool GeometryDocumento16 pagineLecture 1 - Intro To Single Point Cutting Tool GeometryMuhammad Umar IqtidarNessuna valutazione finora

- Zakf O2 Psa GenDocumento6 pagineZakf O2 Psa GenHermilih SiregarNessuna valutazione finora

- 20l Oxygen Generator NewDocumento6 pagine20l Oxygen Generator NewHermilih SiregarNessuna valutazione finora

- 5.2. Clean Up A Well's DiscussionDocumento16 pagine5.2. Clean Up A Well's DiscussionHermilih SiregarNessuna valutazione finora

- Comprokls PDFDocumento28 pagineComprokls PDFHermilih SiregarNessuna valutazione finora

- Artify More DDocumento6 pagineArtify More DSamo AbdalaNessuna valutazione finora

- X10 LWM1Documento36 pagineX10 LWM1philaskNessuna valutazione finora

- Manual Transaxle ComponentsDocumento3 pagineManual Transaxle ComponentsJuan LoNessuna valutazione finora

- Kunalsinh's Lecture on Lathe MachinesDocumento20 pagineKunalsinh's Lecture on Lathe MachinesKunalsinh88Nessuna valutazione finora

- Directorate of Technical Education Board Examinations - Apr 2018Documento2 pagineDirectorate of Technical Education Board Examinations - Apr 2018skptcaeNessuna valutazione finora

- Classification and Characteristics of Rolling BearingsDocumento5 pagineClassification and Characteristics of Rolling BearingsMahimmay paulNessuna valutazione finora

- Husqvarna 343 345 Brushcutter & Clearing Saw Workshop ManualDocumento63 pagineHusqvarna 343 345 Brushcutter & Clearing Saw Workshop ManualjunglemistNessuna valutazione finora

- Magic Light User GuideDocumento8 pagineMagic Light User GuideBrad JacksonNessuna valutazione finora

- General Catalogue 2020 21 MSGDocumento155 pagineGeneral Catalogue 2020 21 MSGNYA StudioNessuna valutazione finora

- Hot Capillary Thermostats: 800-257-3526 Contact UsDocumento5 pagineHot Capillary Thermostats: 800-257-3526 Contact Usjimmyboy111Nessuna valutazione finora

- Routing - HVAC 2007 T660 ISX F95-1096 - 01: DWG SizeDocumento3 pagineRouting - HVAC 2007 T660 ISX F95-1096 - 01: DWG SizeMiguel CardenasNessuna valutazione finora

- Esp Calculation Sheet - m1Documento7 pagineEsp Calculation Sheet - m1Buraq Aircondition Cont & Gen Maint LLC BuraqNessuna valutazione finora

- 2004 Corolla AC AutoDocumento1 pagina2004 Corolla AC AutoZM OhnNessuna valutazione finora

- PVC Orange: Water Supplies Add Hardware & Construction SupplyDocumento4 paginePVC Orange: Water Supplies Add Hardware & Construction SupplyHaron Delon CENessuna valutazione finora

- SKF spherical roller bearings guideDocumento23 pagineSKF spherical roller bearings guidefilkeNessuna valutazione finora

- Power Shift Transmission Testing and AdjustingDocumento15 paginePower Shift Transmission Testing and AdjustingAnonymous Hd32bhqNessuna valutazione finora

- 0852 Drive-In 4P With PLC: Assembly and Operating Instructions E-Rtg / RTG Electrification SystemDocumento9 pagine0852 Drive-In 4P With PLC: Assembly and Operating Instructions E-Rtg / RTG Electrification SystemAbd Elrahman ElserafyNessuna valutazione finora

- Volume Boosters: Vital Components: Auxiliary EquipmentDocumento2 pagineVolume Boosters: Vital Components: Auxiliary EquipmentAsad NaeemNessuna valutazione finora

- 500sp Loop Fusing UnitDocumento24 pagine500sp Loop Fusing UnitMuhammad AkramNessuna valutazione finora

- HwCompat V4 Device ID ListDocumento423 pagineHwCompat V4 Device ID ListrewNessuna valutazione finora

- Installation Instructions For 10400 Universal Wiring HarnessDocumento16 pagineInstallation Instructions For 10400 Universal Wiring HarnessGasdiesel MechanicNessuna valutazione finora

- How to Make a Skyward Sword Hylian ShieldDocumento25 pagineHow to Make a Skyward Sword Hylian ShieldHugo RodriguesNessuna valutazione finora