Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Is There Room For Ryan Air

Caricato da

G Jha0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

18 visualizzazioni2 pagineIs There Room for Ryan Air

Titolo originale

Is There Room for Ryan Air

Copyright

© © All Rights Reserved

Formati disponibili

DOCX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoIs There Room for Ryan Air

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

18 visualizzazioni2 pagineIs There Room For Ryan Air

Caricato da

G JhaIs There Room for Ryan Air

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 2

Konway Kola problem

July 2, 2016 Uncategorized

We are a start-up business competing in the carbonated cola market. Our

market includes the states of AR, TX, LA, TN, MO, MS, and OK. Target

customers are food wholesalers, food service companies, vending and

retailers.

Our products are sold in two (2) serving sizes: 12-ounce aluminum cans and

20-ounce plastic bottles. Both stock keeping units (SKUs) are sold to

customers in cases of 24 units. We produce only one flavor, Konway Kola.

No diet products are produced. We pay delivery charges to our customers.

We employ 18 workers; 12 hourly and 6 salaried.

Average hourly pay = $10.80. Annual salaries

average $34,500 per

person.

Our business operations plan is based upon 240

days per year.

Each production shift is scheduled to operate 8

hours.

Annual Sales Forecast :

12-oz. cans = 960,000 cases of 24

20-oz. bottles = 576,000 cases of 24

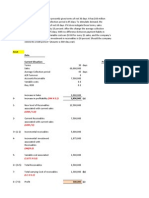

Operating Budget :

Buildings = $1,200,000 purchase, ten (10) year depreciation

Equipment = $600,000 purchase, five (5) year depreciation

Maintenance = $60,000 per year

Energy = $2,000 per shift

Benefits = 40% of total wages and salaries

combined

Marketing = $40,000 per year

Administration & General = $300,000 per

year

Ingredient cost per case = $.72/12 oz.;

$1.20/20 oz.

Packaging cost per case = $.72/12 oz.; $1.10/20

oz.

Warehousing = $180,000 per year

Delivery Charges = $0.325 per case of 12 ounce

cans; $0.490 per case of

20 ounce bottles

Production Schedule :

12 ounce = 8,000 cases per shift

20 ounce = 4,800 cases per shift

Overhead includes : Building and equipment depreciation, employee

benefits, marketing, administration & general, maintenance, energy, and

warehousing ( delivery cost is not included )

Production mix : We plan to pack only one (1) of the two (2) SKUs (either 12

ounce cans or 20 ounce bottles) per 8 hour shift. A total of 240 shifts are

required to produce the annual requirements for both sizes combined.

Questions for you to answer :

1. How many shifts are required to produce the annual sales forecast for

each SKU; 12 ounce and 20 ounce?

2. What is the total cost per case for each SKU? Break down costs into

ingredients, packaging, overhead and labor. Work your answers out to three

(3) places to the right of the decimal point.

3. What must the KKK selling price be per case (including delivery charges)

for each of the SKUs in order to yield a 25% gross margin on sales dollars?

Round up to next whole penny per case.

4. Assuming a 22% profit margin on the retailers selling prices, what will be

the shelf price for one 12 ounce can and for one 20 ounce bottle? Round up

to next whole penny per can or bottle .

5. How might we increase our production capacity?

6. How might we reduce our costs?

7. Do the retail prices per unit look attractive to you?

Link: https://tutorsof.wordpress.com/2016/07/02/konway-kolaproblem/

Potrebbero piacerti anche

- Logistics Management Assignment 1Documento6 pagineLogistics Management Assignment 1Numan RoxNessuna valutazione finora

- Management Accounting 2Documento3 pagineManagement Accounting 2ROB101512Nessuna valutazione finora

- 2015-16 Student CasebookDocumento171 pagine2015-16 Student CasebookFabricio BozzolaNessuna valutazione finora

- Sales Variance Analysis BreakdownDocumento10 pagineSales Variance Analysis BreakdownsrvmnlNessuna valutazione finora

- Assignment PMDocumento3 pagineAssignment PMSyeda ToobaNessuna valutazione finora

- Assignment PM 1....Documento6 pagineAssignment PM 1....Muhammad Arslan QadirNessuna valutazione finora

- 15 ManagementDocumento69 pagine15 ManagementBelista25% (4)

- Costco AnaylizeDocumento96 pagineCostco AnaylizeFernandoNessuna valutazione finora

- Alejandro Espindola Cola WarsDocumento4 pagineAlejandro Espindola Cola WarsEdwin De la CruzNessuna valutazione finora

- Commercial Negotiation Evidence 1Documento10 pagineCommercial Negotiation Evidence 1ScribdTranslationsNessuna valutazione finora

- Hw1-Group 8Documento7 pagineHw1-Group 8ManhNessuna valutazione finora

- Amercian FuelDocumento8 pagineAmercian FuelAsh KaiNessuna valutazione finora

- Chapter 10 QuizDocumento4 pagineChapter 10 QuizChristian BalanquitNessuna valutazione finora

- CVP Analysis Problems SetDocumento3 pagineCVP Analysis Problems SetAbdul Samad100% (2)

- 404 - WCM ExerciseDocumento9 pagine404 - WCM ExerciseChloe Quirona Policios0% (2)

- Capacity PROBLEMSDocumento3 pagineCapacity PROBLEMSJustNessuna valutazione finora

- SCM Numerical 2011Documento13 pagineSCM Numerical 2011arvindpmNessuna valutazione finora

- Incremental Analysis for Business DecisionsDocumento12 pagineIncremental Analysis for Business Decisionsenter_sas100% (1)

- Activity in Class 02 - Operations II - Linear ProgrammingDocumento3 pagineActivity in Class 02 - Operations II - Linear Programmingandycogo1999Nessuna valutazione finora

- New Zealand All Natural Ice Cream (NAN)Documento16 pagineNew Zealand All Natural Ice Cream (NAN)Ashish MohiteNessuna valutazione finora

- MANACO AssignmentDocumento2 pagineMANACO AssignmentKarl Phillip Ramoran Alcarde0% (1)

- Homework 2 - Econ 4160 - w24Documento3 pagineHomework 2 - Econ 4160 - w24aleksandarzubac7Nessuna valutazione finora

- Assign Winston LP Updated StudentDocumento6 pagineAssign Winston LP Updated StudentBianca TiuNessuna valutazione finora

- Problem Set 1 - Basics of Spreadsheet ModelingDocumento3 pagineProblem Set 1 - Basics of Spreadsheet ModelingAbhijeet singhNessuna valutazione finora

- ABDB Final Exam Revision QuestionsDocumento20 pagineABDB Final Exam Revision Questionsannabelletan3Nessuna valutazione finora

- Quanti Assignment 1Documento2 pagineQuanti Assignment 1Jaypee50% (2)

- Acc 311 - Week4 - 4-1 MyAccountingLab Homework Chapters 6-8Documento12 pagineAcc 311 - Week4 - 4-1 MyAccountingLab Homework Chapters 6-8Lilian LNessuna valutazione finora

- Advance Cost Accounting Joint Products Byproducts SpoilageDocumento14 pagineAdvance Cost Accounting Joint Products Byproducts SpoilageAfrah AzzahiraNessuna valutazione finora

- Seminar Materials: Management Analytics 1 Global MBA Ou Tang October 2014Documento8 pagineSeminar Materials: Management Analytics 1 Global MBA Ou Tang October 2014Vicky SinhaNessuna valutazione finora

- Harvard Casebook 2004 For Case Interview Practice - MasterTheCaseDocumento80 pagineHarvard Casebook 2004 For Case Interview Practice - MasterTheCaseMasterTheCase.com100% (3)

- ADMS 2510 Sample Final ExamDocumento11 pagineADMS 2510 Sample Final ExamGrace 'Queen' IfeyiNessuna valutazione finora

- SSM Microsoft Word - Problem Set 01Documento3 pagineSSM Microsoft Word - Problem Set 01Second FloorNessuna valutazione finora

- BE Practice Questions - Quaker Oats 2012Documento2 pagineBE Practice Questions - Quaker Oats 2012Nisan GeeteeNessuna valutazione finora

- Distribution ExamplesDocumento13 pagineDistribution ExamplesVishwanath VerenkarNessuna valutazione finora

- Problems For PresentationDocumento15 pagineProblems For PresentationNachiketa0% (1)

- PM Sect B Test 1 & 2Documento13 paginePM Sect B Test 1 & 2FarahAin FainNessuna valutazione finora

- CASE 7 BestChipDocumento4 pagineCASE 7 BestChipilham arwaniNessuna valutazione finora

- Glove Co variance analysis and production manager performanceDocumento10 pagineGlove Co variance analysis and production manager performanceNguyễn NgaNessuna valutazione finora

- Itc Final PresentationDocumento21 pagineItc Final PresentationShubham TrivediNessuna valutazione finora

- Inventory Management For Quantity Discount & Trade PromotionDocumento25 pagineInventory Management For Quantity Discount & Trade Promotiondurga100% (2)

- Problems: Operations ManagementDocumento2 pagineProblems: Operations ManagementHammad Ishfaq0% (1)

- BALDWIN Case BarnaliDocumento39 pagineBALDWIN Case BarnaliVinay PottiNessuna valutazione finora

- Short-Term Decision ExercisesDocumento44 pagineShort-Term Decision ExercisesScribdTranslationsNessuna valutazione finora

- Chilled RO Water Plant 20 Liter Jar Water PlantDocumento18 pagineChilled RO Water Plant 20 Liter Jar Water PlantYogesh Dhandharia0% (1)

- Krispy KremeDocumento10 pagineKrispy KremeNeşe RomanNessuna valutazione finora

- Decision Making dan PricingDocumento4 pagineDecision Making dan PricingfauziyahNessuna valutazione finora

- Market Estimation and Business Case QuestionsDocumento13 pagineMarket Estimation and Business Case QuestionsPrateek SinglaNessuna valutazione finora

- Week 10 Ch12 Excel ProblemsDocumento10 pagineWeek 10 Ch12 Excel ProblemsMarcus R Urquhart0% (1)

- Incremental Analysis GuideDocumento4 pagineIncremental Analysis Guidedestinyv07100% (1)

- Engineered Products IncDocumento2 pagineEngineered Products IncSalman Adri100% (3)

- Me CS3 Pes1202202920 PDFDocumento2 pagineMe CS3 Pes1202202920 PDFmohammed yaseenNessuna valutazione finora

- TW2. CVP AnalysisDocumento3 pagineTW2. CVP AnalysissnitchundseekerNessuna valutazione finora

- 20 Liter Jar Water Plant Chilled RO Water PlantDocumento18 pagine20 Liter Jar Water Plant Chilled RO Water PlantYogesh DhandhariaNessuna valutazione finora

- Solved ExercisesDocumento9 pagineSolved ExercisesKyle BroflovskiNessuna valutazione finora

- InventoryDocumento82 pagineInventoryKiran GadmaleNessuna valutazione finora

- Guide to Japan-Born Inventory and Accounts Receivable Freshness Control for Managers 2017 (English Version)Da EverandGuide to Japan-Born Inventory and Accounts Receivable Freshness Control for Managers 2017 (English Version)Nessuna valutazione finora

- Guide to Japan-born Inventory and Accounts Receivable Freshness Control for Managers 2017Da EverandGuide to Japan-born Inventory and Accounts Receivable Freshness Control for Managers 2017Nessuna valutazione finora

- Glass Containers, Domestic World Summary: Market Sector Values & Financials by CountryDa EverandGlass Containers, Domestic World Summary: Market Sector Values & Financials by CountryNessuna valutazione finora

- Guide to Japan-born Inventory and Accounts Receivable Freshness Control for Managers: English versionDa EverandGuide to Japan-born Inventory and Accounts Receivable Freshness Control for Managers: English versionNessuna valutazione finora

- Guide to Japan-born Inventory and Accounts Receivable Freshness Control for managersDa EverandGuide to Japan-born Inventory and Accounts Receivable Freshness Control for managersNessuna valutazione finora

- STR581 Strategic Planning & Implementation - All AssignmentsDocumento13 pagineSTR581 Strategic Planning & Implementation - All AssignmentsG JhaNessuna valutazione finora

- Sophia - Project Management - All MilestonesDocumento9 pagineSophia - Project Management - All MilestonesG JhaNessuna valutazione finora

- Ashworth College Semester Examination QuestionsDocumento139 pagineAshworth College Semester Examination QuestionsG Jha100% (2)

- Ashworth Semester Exam BU450 Leadership SkillsDocumento3 pagineAshworth Semester Exam BU450 Leadership SkillsG JhaNessuna valutazione finora

- ECO561 EconomicsDocumento14 pagineECO561 EconomicsG JhaNessuna valutazione finora

- Sophia - Introduction To Ethics - Milestone 1 Score 100 PERCENTDocumento4 pagineSophia - Introduction To Ethics - Milestone 1 Score 100 PERCENTG JhaNessuna valutazione finora

- FP100T Everyday Economics and FinancesDocumento25 pagineFP100T Everyday Economics and FinancesG JhaNessuna valutazione finora

- STR581 Strategic Planning & Implementation - All AssignmentsDocumento13 pagineSTR581 Strategic Planning & Implementation - All AssignmentsG JhaNessuna valutazione finora

- Sophia - Project Management - All MilestonesDocumento9 pagineSophia - Project Management - All MilestonesG JhaNessuna valutazione finora

- Sophia - Introduction To Psychology Unit 6 Milestone Score 100 PercentDocumento9 pagineSophia - Introduction To Psychology Unit 6 Milestone Score 100 PercentG JhaNessuna valutazione finora

- FIN571 Corporate FinanceDocumento16 pagineFIN571 Corporate FinanceG JhaNessuna valutazione finora

- Ashworth Semester Exam BU450 Leadership SkillsDocumento3 pagineAshworth Semester Exam BU450 Leadership SkillsG JhaNessuna valutazione finora

- ECO372 Principles of MacroeconomicsDocumento74 pagineECO372 Principles of MacroeconomicsG JhaNessuna valutazione finora

- Sophia Project Management Complete CourseDocumento38 pagineSophia Project Management Complete CourseG JhaNessuna valutazione finora

- Sophia - Introduction To Psychology Unit 4 Milestone Score 100 PercentDocumento7 pagineSophia - Introduction To Psychology Unit 4 Milestone Score 100 PercentG JhaNessuna valutazione finora

- BUSN311 Law and Ethics in Business EnvironmentDocumento25 pagineBUSN311 Law and Ethics in Business EnvironmentG JhaNessuna valutazione finora

- Sophia - Introduction To Psychology Unit 5 Milestone Score 100 PercentDocumento8 pagineSophia - Introduction To Psychology Unit 5 Milestone Score 100 PercentG JhaNessuna valutazione finora

- MA610 Managerial AccountingDocumento9 pagineMA610 Managerial AccountingG JhaNessuna valutazione finora

- ECO365 Principles of MicroeconomicsDocumento17 pagineECO365 Principles of MicroeconomicsG JhaNessuna valutazione finora

- MB602 EntrepreneurshipDocumento12 pagineMB602 EntrepreneurshipG JhaNessuna valutazione finora

- ACC201 Financial AccountingDocumento47 pagineACC201 Financial AccountingG JhaNessuna valutazione finora

- ACC561 AccountingDocumento21 pagineACC561 AccountingG JhaNessuna valutazione finora

- A01 Introduction To AccountingDocumento50 pagineA01 Introduction To AccountingG JhaNessuna valutazione finora

- ACC290 Principles of Accounting IDocumento25 pagineACC290 Principles of Accounting IG JhaNessuna valutazione finora

- ACC300 Principles of AccountingDocumento11 pagineACC300 Principles of AccountingG JhaNessuna valutazione finora

- MB609 Capstone Strategic ManagementDocumento16 pagineMB609 Capstone Strategic ManagementG JhaNessuna valutazione finora

- MB601 Strategic ManagementDocumento10 pagineMB601 Strategic ManagementG JhaNessuna valutazione finora

- ACC291 Principles of Accounting IIDocumento40 pagineACC291 Principles of Accounting IIG JhaNessuna valutazione finora

- BU330 Accounting For ManagerDocumento89 pagineBU330 Accounting For ManagerG JhaNessuna valutazione finora

- BU340 Managerial FinanceDocumento50 pagineBU340 Managerial FinanceG JhaNessuna valutazione finora

- Art Appreciation ReviewerDocumento14 pagineArt Appreciation ReviewerRon RealinNessuna valutazione finora

- Lecture Notes on Non-Conventional Energy Sources (18ME651Documento29 pagineLecture Notes on Non-Conventional Energy Sources (18ME651Puneeth hr2Nessuna valutazione finora

- Leopold ManeuverDocumento1 paginaLeopold ManeuverLego BrickheadzNessuna valutazione finora

- Tokyo Mou Detention List June 2019Documento23 pagineTokyo Mou Detention List June 2019Hai Le TranNessuna valutazione finora

- Avator CorporationDocumento4 pagineAvator CorporationFraz AhmadNessuna valutazione finora

- Alzheimer's DiseaseDocumento19 pagineAlzheimer's Diseasesanthiyasandy67% (6)

- EnglishDocumento73 pagineEnglishaaaber6Nessuna valutazione finora

- Descriptive Text Purpose:: ( (: The Use of Adjectives and Compound AdjectivesDocumento3 pagineDescriptive Text Purpose:: ( (: The Use of Adjectives and Compound AdjectivesEka Nur Laela Mar'atus SholikhaNessuna valutazione finora

- D345 PDFDocumento3 pagineD345 PDFHusseinawyNessuna valutazione finora

- The Price: Twisted Sister From The Album "Stay Hungry"Documento10 pagineThe Price: Twisted Sister From The Album "Stay Hungry"johnny tolengoNessuna valutazione finora

- Lexical Expressive Means and Stylistic DevicesDocumento27 pagineLexical Expressive Means and Stylistic DevicesTania ShramNessuna valutazione finora

- Item Analysis MPSDocumento14 pagineItem Analysis MPSRose AspirasNessuna valutazione finora

- 2 Marks QA MOMDocumento11 pagine2 Marks QA MOMvasanthNessuna valutazione finora

- Nanotechnology - Google Scholar MetricsDocumento1 paginaNanotechnology - Google Scholar MetricspalkybdNessuna valutazione finora

- As-Hort 121 PDFDocumento4 pagineAs-Hort 121 PDFTeam MrudgandhNessuna valutazione finora

- PCR COVID Test ReportDocumento1 paginaPCR COVID Test ReportBilly Jean BanucaNessuna valutazione finora

- SAUDI ARAMCO PNEUMATIC TEST CHECKLISTDocumento5 pagineSAUDI ARAMCO PNEUMATIC TEST CHECKLISTkarthi51289Nessuna valutazione finora

- Iso 1182 2020Documento12 pagineIso 1182 2020Alessandro MendonçaNessuna valutazione finora

- Drying Kinetics of Open Sun Drying of FishDocumento5 pagineDrying Kinetics of Open Sun Drying of FishchithuNessuna valutazione finora

- Vigilohm IM10, IM20 User Manual PDFDocumento60 pagineVigilohm IM10, IM20 User Manual PDFTomuta StefanNessuna valutazione finora

- Fanuc 16i 210i Ts AlarmsDocumento109 pagineFanuc 16i 210i Ts AlarmstugskulNessuna valutazione finora

- 1999 Reneker Fong Chun Beaded Nanofibers Formed During ElectrospinningDocumento8 pagine1999 Reneker Fong Chun Beaded Nanofibers Formed During ElectrospinningEub EuNessuna valutazione finora

- OGP Life-Saving RulesDocumento24 pagineOGP Life-Saving RulesInternational Association of Oil and Gas Producers100% (3)

- DC-DC Boost Converter With Constant Output Voltage For Grid Connected Photovoltaic Application SystemDocumento5 pagineDC-DC Boost Converter With Constant Output Voltage For Grid Connected Photovoltaic Application SystemMuhammad Adli RizqullohNessuna valutazione finora

- Types of Foundation 1Documento14 pagineTypes of Foundation 1Olawale AdebesinNessuna valutazione finora

- Nerd Chef: Joshua Davidson's ResumeDocumento2 pagineNerd Chef: Joshua Davidson's ResumejwdavidsonNessuna valutazione finora

- Connective Tissue Slide #1Documento19 pagineConnective Tissue Slide #1Faisal AbbasiNessuna valutazione finora

- 2021-2022 LCM100 eDocumento14 pagine2021-2022 LCM100 eJ. S.Nessuna valutazione finora

- Operating Instructions G: Downloaded From Manuals Search EngineDocumento179 pagineOperating Instructions G: Downloaded From Manuals Search Enginea safaie100% (1)

- Solar Energy - NCS, Mumbai UniversityDocumento28 pagineSolar Energy - NCS, Mumbai UniversityVaibhav Vithoba NaikNessuna valutazione finora