Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

1987 J Food Engineering v6, p1 32

Caricato da

Joaquim ReisTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

1987 J Food Engineering v6, p1 32

Caricato da

Joaquim ReisCopyright:

Formati disponibili

Journalof Food Engineering6 (1987) l-32

Food Particle Technology. Part I: Properties of Particles

and Particulate Food Systems

H. Schubert

Institute for Food Engineering, Federal Research Centre for Nutrition, Engesserstr. 20.

D-7500 Karlsruhe, Federal Republic of Germany

(Received 3 September

1985; revised version received 20 January 1986; accepted 25

February 1986)

ABSTRACT

In Part I the properties and the characterization of individual particles

and particulate systems are reviewed, special emphasis being given to

particle size and shape, particle size distribution, interparticle adhesion,

porosiy, capillary action in porous media, instantand flow properties of

powders. The p~cu~~ar~ties

of particulatefoodstu~s, which become evident

through the use of special techniques for measuring these fundamental

characteristics,are considered in detail.

1.

INTRODUCTION

In the past 20 years, particle technology has changed from a largely

empirical to a structured discipline, involving scientific research in many

parts of the world. Decisive contributions to this development

were

made by Rumpf (1975). Particle technology is that branch of process

engineering concerned with the production, processing, analysis and use

of particles.

The differences between integral and particulate matter occur mainly

when the particles are small, i.e. of the order of micrometres to millimetres. This part of the field is known as fine particle technology or

powder technology. This paper is concerned predominantly with fine

solid particles, the largest sector of particle technology.

Advances in this field have so far received little attention in food technology, although foods are frequently in the form of fine particles during

processing or when used by the consumer. The chemical, pharmaceutical

and other process industries are now using the results of research into

Journal of Food Engineering

Publishers Ltd, England,

0260-8774/87/$03.50

1987. Printed in Great Britain

- 0

Elsevier

Applied

Science

H. Schubert

particle behaviour extensively. The benefits to be obtained also deserve

the attention of food technologists although, in view of the special

characteristics of foods, additional research is necessary if the advances

in particle technology are to be applied successfully to food products.

It is the purpose of this paper to describe some important aspects of

particle technology and to illustrate them by examples from food technology.

2.

PROPERTIES

OF INDIVIDUAL

PARTICLES

PARTICULATE

SYSTEMS

AND OF

The properties of particulate systems differ from those of the integral

form of the solids of which the particles are composed. Many such

properties depend on the particle size. Figure 1 shows qualitatively some

selected individual particle and particle system properties. The figures

indicate only a general tendency as deviations from this general

behaviour may sometimes be observed. Some properties of individual

particles will be considered first (Fig. l(a)). The fracture resistance, a,,

increases with decreasing particle size (as there are then fewer flaws in

each particle and a greater proportion of the particle deformations are

plastic): size reduction therefore requires increasingly more energy if fine

particles are to be produced. This is also one reason for the existence of

a grinding limit, i.e. the particle size below which grinders are not capable

of producing smaller particles. With decreasing size the homogeneity of

the particles also generally increases. This property is used, for instance,

traditionally in cereal grain milling to separate the different components

after comminution.

The terminal settling rate Us,illustrated here by a flour particle in air,

first increases rapidly as a function of increasing particle size ( ug CCx2)

and then more slowly ( I+ a Jx). Small particles settle very slowly. Wheat

flour particles of 1 pm size take more than 6 h to fall a distance of 1 m in

still air. Of special importance is the ratio, S,, surface area per unit

volume of particle, which is inversely proportional to particle size. Small

particles accordingly have a large S, value. If a lump material of 1 cm3 in

volume is subdivided into equal spheres of 1 ,um diameter, the surface

area obtained is more than 3 m2. The surface per unit volume is particularly important in heat and mass transfer, the rates of which for small

particles (x < lo-100 pm) are proportional

to S,. Extremely small

particles can dissolve very rapidly and may be dried within a fraction of a

second, but also may cause violent dust explosions. Because of their

large surface per unit volume, microorganisms are capable of exchanging

metabolites and nutrients solely by diffusion at their external surface.

Food particle technology - Part 1

10-l

10-l

10

lo2

PARTICLE

SIZE

10

PARTICLE

lo2

SIZE

lo3 Pm

loL

IO3 pm

I

loL

Fig. 1 Qualitative dependence of some individual particle and some system properties

on particle size. D is particle deposition in fibrous filters, F is adhesion force, His homogeneity of a particle, S, is surface per unit volume, W is weight of a particle, vg is terminal

settling rate, a, is particle fracture resistance.

The properties of particles do not always increase or decrease regularly with increasing particle size. An example of this is particle deposition, D, in fibrous filters. Particles of x = 1 pm are the most difficult to

collect. The deposition of small particles is promoted by diffusion, that

of larger ones by inertial, gravitational and electrostatic forces (Loffler,

1983).

Most important in particle technology is interparticle adhesion. This

usually increases in proportion to the particle size but the ratio of

particle adhesion, F, to particle weight, W, is of primary importance: this

ratio is inversely proportional

to the square of the particle size. For

particles of 1 ,um, for example, F/W is larger by a factor of lo6 than for

particles of 1 mm diameter. This fact explains why small particles adhere

much more strongly to each other and to surfaces than large particles do.

Adhesion forces are also largely responsible for the cohesive strength

of powders which, at constant porosity, is approximately inversely pro-

H. Schubert

portional to the particle size: thus fine powders show a tendency towards

agglomeration or to form lumps. Hence, the flowability of powders

increases with increasing particle size. A similar behaviour is also

observed in their wettability and dispersibility. These properties are of

importance in instant food powders.

The magnitude of interparticle adhesion forces, as compared to other

competing forces such as gravity, accounts for the difference between

cohesive and non-cohesive powders. In non-cohesive powders, interparticle forces are negligible but in cohesive powders they are significant.

The majority of dry food powders are non-cohesive (and thus freeflowing) only when the particle size exceeds about 100 pm. In wet

powders considerably

stronger adhesion forces appear and the

boundary between the cohesive and non-cohesive

occurs at larger

particle size. Since the adhesion forces may be varied over a wide range,

many powder properties may be influenced as desired.

Interparticle adhesion also influences many bulk properties. Three

examples are shown in Fig. l(b). The porosity (the void fraction of the

total volume) increases with decreasing particle size because the interparticle adhesion allows a looser structure. Very fine particles such as

flow conditioners (anticaking or free-flowing agents, dry lubricants) of a

size below lym can attain porosities of more than 95%. If they are

poured into a container of volume 20 litres, the mass of its contents may

be less than 1 kg although the density of the solid is over 2 kg/litre.

Many other properties such as mixability, colour, water-vapour sorption, flavour, etc, depend upon particle properties. Nowadays many of

these properties can be described quantitatively. Considerable advances

have also been made in the description of fluidized solid flow (Molerus,

1982) in particle transport equipment and in fluidized beds.

3.

CHARACTERIZATION

OF PARTICULATE

SYSTEMS

3.1 Characterization of individual particles

3.1.1 Particle size analysis

Particle size is the most important physical particle characteristic. In the

case of simple shapes such as the sphere or cylinder, the size is explicitly

determined by one or several dimensions. In the majority of cases, however, particles are of irregular shape so that a large number of dimensions would be required to describe the size and shape. Since this is not

practicable, essential characteristics must be defined which, depending

on the circumstances, provide adequate description. Because of the

measuring problems involved, particularly in the case of very fine

Food particle technology - Part I

particles, the choice of suitable characteristics defining the particle size is

sometimes tied to particular measuring methods.

To determine the particle size, in principle, any measurable physical

property which correlates with characteristic geometric dimensions or

equivalent dimensions can be used. Equivalent dimensions are dimensions of an imaginary regular particle with the same physical property as

that of the irregularly-shaped

particle being measured. The equivalent

settling rate diameter, for instance, is frequently used; it is the diameter of

a sphere of the same density as the irregularly-shaped particle which in

the same fluid has the same settling rate. In the viscous flow regime, i.e.

for Reynolds number ReSO-25, this equivalent settling rate diameter is

obtained from

x;=

18qv,

g(p, - P)

where Re = (,q, v,x,)/q, r] is coefficient of dynamic viscosity of the fluid,

V~is terminal settling rate of the particle, g is acceleration due to gravity,

pP, ,on are density of the particles and of the fluid, respectively. Equation

(1) applies, for instance, to cereal flour particles in the ranges of X, < 50

pm for sedimentation

in air and x, < 100 pm for sedimentation

in

ethanol.

The attributes usually used to characterize particle size may be classified as follows:

(1) geometrical

characteristics

(such as linear

volumes);

mass;

i:; settling rate in a fluid;

(4) field interferences such as electrical

scattering or diffraction.

dimensions,

field interferences,

areas,

light

Today many devices are available commercially employing one or

other of these attributes from which the particle size or the equivalent

diameter can be determined. However, not all particles of a powder are of

the same size. It .is therefore necessary to measure a great many particles

and produce a particle size distribution. An example is shown in Fig. 2.

The cumulative distribution QAx) as well as the frequency distribution

q,(x) may be measured. Either can be converted into the other, since

q,(x) is the first derivative of Q,(X); x represents the particle size,

frequently an equivalent diameter. Subscript r indicates whether the

distribution is according to number (r= 0), length (r= l), area (r = 2) OI

volume (Y= 3) (see, for example, Leschonski et al., 1974). The cumulative distribution function Q,(X) indicates, for instance, the volume

proportion of particles between x,,,~and x (see Fig. 2).

H. Schubert

0.5

Xmin

X50

Particle

Fig. 2

Cumulative

size

X max

x -

and frequency distribution

of particle size.

This mode of description is advantageous mainly because it allows

several characteristic distribution values to be calculated and converted.

Of special importance in this respect are the various mean values, such

as the weighted mean particle size of the area frequency distribution

%(X)

%lla

x1,2

-w(x

1 dx

(2)

%I,

which is inversely proportional to the surface per unit volume of all

particles of the distribution. A very simple and frequently used mean

particle size is the median value xsOwhich is obtained from the cumulative distribution at Q, = 0.5 or 50% (see Fig. 2).

Before measuring a particle size distribution, a representative sample

must be withdrawn from the powder. To minimize sampling errors a

special sampling technique (Sommer, 1979) is necessary, which includes

sample splitting to provide the necessary quantity for each particle-sizedistribution measurement.

The characterization of individual particles in a collection is possible

only if the particles are separable from each other. Because of the strong

adhesion forces in relation to particle weight, fine particles in particular

require careful dispersion,

otherwise agglomerates

are measured.

Food particle technology - Part I

Depending on the particle measuring method used, the particles are dispersed in gases (Zahradnicek, 1976) or in liquids (Koglin, 1974). Dispersion in gases is satisfactory for particles larger than 2-5 pm; finer

particles have to be dispersed in liquids by means of dispersing agents to

overcome the adhesion forces by repulsion forces. The choice of dispersing liquid is especially important for food powders since the

particles must not swell or otherwise dissolve in or react with the fluid.

After extensive experiment at the authors institute, Hoffmann has established a list of suitable dispersing liquids for all the common food

powders, in which it is still necessary to differentiate between the different particle-size measuring methods. A selection of dispersion liquids is

shown in Table 1.

TABLE 1

Dispersing Liquids Suitable for Use in Particle Size Analysis of Food Powders

Wheat flours

Defatted soya flour

Milk powder

Pea-protein concentrate

Protein concentrate from brewers

spent grain

Microcrystalline cellulose

Wet sieving

refraction or

scattering of

light

Sedimentation

Electrical

impedance

of particles

( Coulter

counter)

1,273

3,8, 10

12,13

2,3, 10, 11

1,1+4,3,5

3,8,11

2,13

2,3, 10, 12

6+7,8+9

8+9,10

8+9,10,14

8+9

12

12,15

2, 12

12,15

10

lo,16

0Dispersant: 1, ethanol, 2, isobutanol; 3, benzene; 4, diethyl phthalate; 5, cyclohexane; 6,

methanol; 7, 5% aqueous lithium chloride; 8, isopropanol; 9, 5% aqueous ammonium

thiocyanate; 10, Isotone (Coulter Electronics); 11, butanol; 12, distilled water + Triton

X lOO@ (Coulter Electronics);

13, octanol; 14, 2% aqueous sodium hydroxide; 15,

acetone; 16, 1% aqueous sodium chloride.

The numerous measuring methods and devices for particle size

analysis will not be discussed here in detail. In recent years, rapid

methods have been developed which usually require expensive equipment. A survey of on-line measurement of particle size distribution in

gases and liquids was published by Leschonski (1978). It should be

noted, however, that not all methods are suitable for foods, even if they

are well proven for other substances such as minerals. For instance, the

densities of foods are in general not very different from those of liquids.

H. Schubert

In the majority of cases experience

methods to be suitable for foods:

has shown the following measuring

(a) analysis of photographic

images including scanning electron

micrographs;

(b) dry (x 2 40 pm) and wet (x 2 5 pm) sieving;

(c) electrical impedance of particles; for example, Coulter Counter

TA II (0.6 pm I x I 800 pm), Elzone Counter (0.25 pm I x I 1020

pm);

(d) evaluation of laser diffraction patterns; for example, Malvern

( 1 ,uml x I 1800 pm), Cilas ( 1 pm< x I 192 pm), Leeds and

Northrup (0.1 ,umlxl20

pm or 2 ~m1x<lOOO pm).

Because of the time taken in sample preparation, method (a) is timeconsuming despite automatic image evaluation. Method (b) is also timeconsuming but indispensable

for many purposes including quality

control. Methods (c) and (d) are rapid methods using automatic measuring equipment suitable for on-line measurements. Whereas with method

(c) the particles can be measured only in an electrically-conducting

liquid, it is possible with method (d) to measure particle-size distribution

in liquids and gases. Particularly because of their rapidity, diffraction

counters working according to method (d), using the Fraunhofer diffraction pattern of particles, have been increasingly used in recent years

(Polke and Bieger, 1979). Figure 3 shows a comparison of methods (c)

and (d) for pea flour. The particle size x is the equivalent volume diameter (method (c)) or the equivalent diameter of a sphere showing the

same characteristics of Fraunhofer diffraction (method (d)). The differences between the measurements on particles dispersed in air and in

liquid demonstrate that the fines were not completely dispersed in air.

Particle size analysis has been developed to a comprehensive discipline requiring special knowledge and experience taught in special

courses (Leschonski, 1982) which deal in detail with measurement of

other properties such as surface per unit volume and particle shape. The

measurement of particle shape (Scarlett, 1979), for which new methods

have been developed (Weichert and Huller, 1979) has gained increasing

importance for food particle technology (Davis and Hawkins, 1979).

3.1.2 Particle adhesion

Particle adhesion in a gaseous environment is an important property in

characterizing individual particles but, apart from a few exceptions, it

has not been possible so far to calculate the adhesion forces between

real particles with sufficient accuracy. Models were therefore developed

to enable adhesion forces to be estimated: in the majority of cases, these

models are based on the assumption of ideally smooth, rigid spheres.

Food particle technology - Part I

Fig. 3

Cumulative

10

20

Particle

particle size distributions

size x

50

-

100

200

IJm

of particle-size milled pea flour.

Even if surface roughness and deformation of the contact areas inevitable in real particles are responsible for deviations between model calculations and measured values, the calculations still provide useful

information as to how the different variables influence adhesion.

Adhesion mechanisms with and without material bridges can be

distinguished.

The most important

adhesion forces between food

particles are shown in Fig. 4. Solid bridges may be formed by sintering,

by chemical bonds and/or by crystallization. The crystallization of amor-

with

material

bridges

chemical

5

slnter

bondi-

,vithout matenal

bndges

van der

Waals

bldge

9

bonding

by

crystolllsed

soiute

liquid bridge

electrostatic

(conductor

VISCOUS bondmg

Fig. 4

Adhesion

mechanisms

between solid particles and a solid plate in a gaseous

environment.

10

H. Schubert

phous constituents frequently causes an undesirable stickiness to occur

in food powders. These processes have been studied in detail for sucrose

and lactose (Niediek, 1982) and also measured as a function of temperature and water content (Downton et al., 1982). Crystallization of solutes

at contact points between particles during drying frequently leads to

strong particle adhesion.

Liquid bridges represent the dominating adhesion mechanism in

nearly all those cases where sufficient moisture is present, but liquid

bridges may also arise from capillary condensation

in moist atmospheres. Adhesion forces due to liquid bridges can be calculated. The

results of such calculations are available for many particle geometries as

diagrams using dimensionless numbers (Schubert, 1982). Figure 5 shows

a simple example of adhesion forces between two equal spheres. The

distance, a, between the surfaces of the spheres as shown in the figure

arises in real particles from surface roughness, the significance of which

for adhesion forces will be explained below.

Adhesion without material bridges is primarily due to van der Waals

and electrostatic forces. Van der Waals forces (F&,, ) are always present;

they may be calculated for two spheres of diameters X, and x2 separated

from each other by distance a between the two surfaces from

3.0

2.5

F

=

2.0

1.5

1.0

0.5

r\

lcrl, \;?.1oyo-ypo-3

\\,

I\

0.05

\ %

Y42

-y

010

0.15

I _-I

0.20

Fig. 5 Adhesion force F of a liquid bridge between two equal spheres - related to the

surface tension y of the liquid and the sphere diameter x - as a function of the distance

ratio a/x for complete wetting (contact angle 6 = 0). Parameter is the volume V, of the

liquid bridge related to the volume V, of the sphere.

Food particle technology - Part I

E,x, %

vdW 16;rt(x, +x2) a*

11

(3)

The vander Waalsinteractionenergy

E, is between 10-i and 2 X lo- IxJ.

Van der Waals force is a maximum for particles in contact with each

other; the contact distance is assumed to be a= a,, = O-4 nm (Krupp,

1967). It should be noted that eqn (3) applies only to ideally smooth rigid

spheres, and to a sphere at a plane surface (where x,/x2 -, 0).

Electrostatic adhesion forces occur in cases where particles have

opposing charges. These charges may be already present as excess

charges or arise only when the particles come into contact due to differences in the values of the electron work function (contact potential).

Electrically non-conducting

particles frequently have excess charge up

to a maximum per surface of around s,,, = 100 e/pm* (elementary

charge e = 1.6 x lo- I9 As). For ideal electrical insulators the adhesion

forces F,,,i can be calculated from Coulombs law,

2

JG~l~2~1~2

Fei,i=

E,E(xI+x2+2a)

(4)

Equation (4) applies to spheres of diameters x1 and x2 where si, s2 are

electric charge per unit surface area of the corresponding spheres, E*, t

are relative and absolute dielectric constants of the surrounding medium.

a is distance of separation between the spheres. Equation (4) also applies

to the sphere-plate system when x,/x2 -+0.

With electrically conducting particles, electrostatic adhesion arises

only after the particles have made contact and is due to the contact

potential which is frequently between U= 0.1 and 0.7 V. The adhesion

force due to a contact potential between two spheres or between sphere

and plate (x1/x2 -, 0) can be stated by:

Fe,,,=

m,&tiX1X2

2(x1

+ ~2)

(5)

A comparison between the adhesion forces represented by eqns

(3)-(5) is shown in Fig. 6. As mentioned before, however, for particle

adhesion the ratio F/W between adhesion force and particle weight is

more important than the absolute value of the adhesion force. In Fig. 6,

therefore, the ratio F/W for two equal spheres is plotted against sphere

diameter. The distance between the two surfaces in contact is assumed to

be a, = O-4 nm, the particle solid density pS = 1.5 g cme3. As Table 2

shows, this is a reasonable mean density value for many food particles,

but since F/W= ps , a conversion of the values shown in Fig. 6 for other

solid densities is very simple.

H. Schubert

12

F= theor. ddhesion f&ce~~~,

W=weight of one sphere

_ <X

1

Sphere

\

\\,

(9 = 1.5 g/cm31

I

10

lo2 Pm

diameter

lo3

Fig. 6 Calculated adhesion force F between two equal spheres (as a fraction of the

weight W of one sphere) for various interparticle adhesion mechanisms vs. sphere

diameter.

TABLE 2

Densities and Bulk Densities of Some Food Powders

Food

Wheat flour

Rye flour

Corn flour

Corn starch

Potato starch

Rice, polished

Cocoa powder (10% or 22% fat content)

Sucrose

Instant dried whole milk

Instant dried skimmed milk

Solid derlsityp,

g cm --;

1.45-1.40

I.45

I.54

1.62

1.65

1.37- 1.39

1.45 or 1.42

1.60

1.3(-1.45)

1.2(-1.4)

Bulk density p,,

g cm --.<

0.55-0.65 (0.4-0.75)

0.45-0.7

0.5-0.7

0.55

0.65

0.7-0.8

0.35-0.4 or 0.4-0.55

0+x5- 1.05

0.45-0.55

0.25-0.55

Figure 6 shows on a log scale that all adhesion forces related to the

particle weight are inversely proportional to the square of the particle

diameter (F/WCCX-*), except for the electrostatic adhesion of insulators

). Particle

adhesion decreases in the order: liquid bridge

lFel,il

WCC

x-1

Food particle technology - Part I

13

forces: van der Waals forces: electrostatic forces. The strong adhesion

between small particles is remarkable. The interparticle force between

spheres of 10 pm diameter, for instance, is in the case of a liquid bridge

2.6 x lo5 greater than the particle weight.

The dependence

of adhesion. forces upon the distance between

particles is important. Large volume liquid bridges - as Fig. 5 shows are little influenced by the distance between particles, whereas small

volume bridges formed by capillary condensation,

for instance, are

strongly affected. As eqns (3)-( 5) show, van der Waals forces decrease

rapidly with separation distance ( FvdW~ a-), whereas the decrease in

electrostatic forces with separation distance is less in the case of electrical conductors (F,,i 0~a - *) and negligible (sphere/sphere) or even zero

(sphere/plate) in the case of electrical insulators. Attraction from greater

distances is consequently due only to the electrostatic forces between

charged particles. If the particles are already in contact, the adhesion is

primarily due to solid bridges, liquid bridges and van der Waals forces.

The effect of distance on adhesion forces is of great significance in the

case of real particles in which surface roughness, which is usually

present, increases the separation distance. In the case of van der Waals

forces and very small liquid bridges, adhesion is determined almost

entirely by the size and shape of the roughness peaks. In such cases

adhesion forces between real particles are frequently smaller by more

than an order of magnitude than the values calculated for perfectly

smooth model solids.

This effect can be illustrated by using the model of a very small sphere

which has been placed between two equally large spheres, as shown in

Fig. 7. Such finely divided solids are added to food powders, for

instance, as flow conditioners to reduce interparticle adhesion and hence

improve flowability (Hollenbach and Peleg, 1983). However, the interstitial sphere may also be regarded as a model for a roughness peak.

Figure 7 shows the ratio of adhesion force F between two spheres of

diameter x2 = 10 ,um and the weight W of one of these spheres (p, = l-5 g

cm-) vs. the diameter x, of the interstitial sphere. According to eqn (3),

the van der Waals force between the two spheres of diameter xx is

Here a, is the distance between the interstitial sphere and the large

sphere in contact, again assumed to be 0.4 nm. For a given x2, the

adhesion force FvdWpasses a minimum at

x: = $x,a$

- 2U

(7)

14

3

Fig. 7

lo5

3

0.1

3 1o-2

Diameter x1 of the interstitiat

pm

sphere

adhesion force F between two equal spheres (as a fraction of the

weight W of one sphere) VS.diameter x, of an interstitiai sphere.

Calculated

For the sphere diameter xz = 10 pm as selected in Fig. 7 the minimum

adhesion force appears at X: = O-01 1 pm. A compa~son with Fig. 6

reveals that this van der Waals force is smaller by a factor of cu. 300 than

the adhesion force between a pair of perfectly smooth spheres. In case of

electrostatic attraction between electrical conductors (not shown in Fig.

7), the adhesion force takes a similar course to that of the van der Waals

force.

The adhesion of the electrical insulator, on the other hand, is independent of x1 and thus also of roughness. Large liquid bridges are also

little influenced by roughness. This is illustrated in Fig. 7, for example,

where the course of the related liquid bridge force is shown for a ratio of

liquid bridge volume Vi, to sphere volume IS,of I,,/ r/, = 0.0 1; this corresponds to a bridge angle of /!I= 20-27, depending on the size of xl_ Very

small liquid bridges resulting from capillary condensation from the moist

atmosphere behave quite differently. Figure 7 shows two examples for

relative air hu~dities of 50 and 80%, which correspond to water activi-

Food particle technology - Part I

15

ties a, = 0.5 and 0.8. The related adhesion force decreases rapidly with

increasing diameter x1 of the interstitial sphere until finally the liquid

bridge becomes unstable (Schubert, 1982) and breaks (dotted line in Fig.

7). Thereafter the related adhesion force increases with increasing

diameter x1 proportionally to x1 and practically independently of a,; in

this case liquid bridges have formed between the sphere of diameter

x2 = 10 ,um and the small sphere (x1).

The liquid bridge forces caused by capillary condensation hence may

decrease by a factor of more than 1000 (cf. Fig. 7) as compared to

perfectly smooth particles without the interstitial sphere. This illustrates

the effect of flow conditioners on powders which are stored in moist

atmospheres (see also Schlitz and Schubert, 1980).

Since the size and shape of actual roughnesses, in contrast to the

model considerations in Fig. 7, are largely unknown, it is necessary to

measure the adhesion forces between real particles if quantitative information is required. Such measurements generally yield adhesion force

distributions over a wide range even with equal-size particles. This is due

to roughnesses of different size which are irregularly spread over the surfaces. Hence, depending on the random contact, the geometry of the

contact area changes in the micro-range. Adhesion force distributions

often range over more than one order of magnitude even for monosize

particles (Schlitz, 1979).

In addition to the above influences there are many other factors to be

taken into account such as adhesion force enhancement due to inelastic

deformation

of the contact areas of the adherents. Interactions of

particles in liquids where repulsive and attractive forces frequently compete with each other also belong to the field of interparticle adhesion.

Review papers provide a survey of the entire field (Schubert, 198 1 a, c). A

research project at present attracting much attention is the adhesion of

microorganisms

to solid surfaces (Ellwood, 1979; Notermans and

Kampelmacher,

1983). Much of classical particle adhesion knowledge

may be used in this field. The same applies to particle adhesion involved

in surface fouling in food processing (Hallstrom et al., 1981).

3.2 Characterization

of powders

3.2.1 Porosity bulk density

Porosity E has been defined as the ratio of void volume V, to total volume

I, of the powder:

H. Schubert

16

In eqn (S), V>is the solid volume. If the particles themselves are porous

(particle porosity EJ then

Fl

-(I -Ep)(l -&J

(9)

where the bulk porosity E,, is the ratio of void volume between particles

to the total volume. The bulk density of a powder is also frequently used:

Ph=(I-&p)(l-&b)Pu=(l-&)P,

(IO)

where p, is the solid density. Table 2 lists the bulk densities of some food

powders. In the case of bulk material made up of closely sized, nonporous particles, if adhesion forces may be neglected, i.e. if the particles

are sufficiently large, the porosity is about E = 0.4. If interparticle

adhesion is significant, porosity increases. Especially in wet powders, or

upon exceeding the relative humidity (RH) at which capillary condensation may take place (frequently at RH > 0.6-0.7) porosity increases, or

the bulk density decreases as compared to the dry condition. Scoville

and Peleg (1981) and Moreyra and Peleg (198 1) studied and quantified

these effects in model substances and various food powders.

Bulk density is of importance because consumers expect that the mass

indicated on the package corresponds to a volume filling the package

almost completely. This frequently presents difficulties in food processing. In many cases producers wish to offer powders combining a large

volume with a small mass. As may be recognized from eqn (lo), this can

be accomplished by producing porous particles. In practice, porous

particles may be produced as hollow spheres or by instantizing fine

particles to larger agglomerates of the desired porosity sp. The following

example demonstrates the wide range of variability in bulk density. A

beverage powder (sugar-cocoa mix) which is sold direct to consumers is

usually expected to show a bulk density of p,=O.30-0.35

g cmm3. A

powder of the same composition intended for use in vending machines,

however, is required to have a bulk density of pb = 0.5-0.6 g cmm3 (Kniel,

1980).

3.2.2 Capillar?, action in powders, pore size distribution

Many food powders are obtained from the wet phase and have to be

dried, frequently after mechanical dewatering. Prior to consumption, or

in the course of further processing, most of the powders have to be

rewetted. Both dewatering and reconstitution - mostly with water are governed by capillary behaviour. It is therefore necessary to characterize powders with regard to their capillary properties. For this reason

capillary pressure curves (Schubert, 1982) have been established which

indicate the capillary pressure p, in a porous medium as a function of the

liquid saturation S; S is the ratio of liquid volume to void volume of the

porous solid system. The capillary pressure curve indicates a distribution

comparable to the particle size distribution. The measuring methods are

explained in detail elsewhere (Schubert, 1982).

Figure 8 shows a typical capillary pressure curve. Starting from the

porous system filled with liquid (S= 1) the capillary drainage curve D,

applies until finally at S= S, only isolated liquid remains. If liquid is

admitted to the pores in the state S = S,, the capillary imbibition curve I

applies until finally at S = 0.8 1 the capillary pressure p, = 0 prevails. Subsequent dewatering leads to curve D. The capillary pressure curve

accordingly shows a hysteresis which may be explained by the existence

of narrow pore necks followed by larger cavities, and by the contact

angle hysteresis (receding contact angle (r, < advancing contact angle 6,,

see drawing in Fig. 8). A frequently used characteristic capillary pressure

is the entry suction p, which is obtained approximately, for complete

wetting (6, = 0), from

PC=:

w -- 4 Y

(11)

&X1,2

-0 i,

0.2

Ok

Liquid

0.6

saturation

0.8

Fig. 8 Capillary pressure of a bulk material (glass spheres, weighted mean diameter

.*11.2

= 79 ym, porosity E = 0.38) vs. degree of liquid saturation (p,(S) = capillary pressure

curve).

18

H. Schubert

(y = surface tension of the liquid; X,,z see eqn (2)). The constant was

found to be b = 6-8 (Schubert, 1972). According to eqn (1 l), the capillary pressure increases with decreasing particle size.

Although the capillary pressure curve holds a key position for the

understanding of the capillary action in porous systems, and is necessary

also for the quantitative description of wetting and dewatering processes,

it is not sufficient to describe capillary processes completely. In wetting

of powders, a dynamic capillary pressure may play an important role in

addition (Schubert, 1978~). This wetting behaviour is of importance for

instant powders: it is discussed below in section 3.2.3.

The capillary pressure so far has been assumed to be a suction pressure, i.e. liquid is sucked into the pores by capillary action. This is indeed

always correct for sufficiently small contact angles, i.e. powders having

good wettability. Mercury, however, which forms a contact angle of

6 = 140 with most solids, behaves differently. In this case mercury must

be pressed into the pores to overcome the capillary pressure. This effect

is used in the so-called mercury porosimetry to determine the pore size

distribution. Since, because of the lower capillary pressure, large pores

are filled first, followed by finer pores which are subsequently filled

under increasing applied pressure, it is possible to deduce from the capillary pressure curve the pore size distribution. To evaluate the measured

results, pore models are required: usually, a cylindrical model is preferred. The excess pressure which is identical with the capillary pressure

p,, and the pore diameter dare correlated by the equation

4Y

p<.= / cos b

(12)

where y is surface tension of mercury, and b is contact angle. Pore size

analyses to characterize porous systems are gaining in importance. In

addition to mercury porosimetry (measuring range: 5 nm < d < 200 pm),

and adsorption methods (0.2 nm < d < 2 nm), sorption isotherms in the

range of capillary condensation (3 nm < cl < 0.5 pm) and micrographs

(d > 0.1 pm) may also be used to determine pore size distribution. The

pertinent literature is discussed in a review paper by Orr ( 1980).

3.2.3 Irutunt properties of powders

Fine powders are difficult to wet with water or aqueous liquids (for

instance, milk) and tend to form lumps which hinder dispersion. By

agglomeration of fine powders of about 100 pm into particles of up to

several millimetres in size, wetting is improved and lump formation

avoided. The causes of this behaviour have been elucidated (Schubert,

Food particle

technology

Part I

19

1978b, 1982). Materials with poor wetting properties such as fatty

particles, for example, which form a large contact angle with the liquid,

may also be changed in respect of their surface properties by reducing

the contact angle and thus improving wettability; this is often done by

spraying with lecithin. The commercial treatment of powders to improve

their wetting, dispersing and, in the case of soluble particles, their dissolving characteristics is called instantizing. The different instantizing

processes are described in a great many publications but the main principles of these processes have been compiled by the present author in a

previous paper (Schubert, 1980).

If a powder is spread on the surface of a liquid, the following processes take place:

(a) penetration of liquid into the porous sysem due to capillary action

(the ability of the powder to be penetrated by the liquid is called

wettability);

(b) sinking of the particles below the liquid surface (sinkability);

(c) dispersion of the powder with little stirring (dispersibility);

(d) solution of the particles in the liquid, provided the particles are

soluble (solubility).

The properties wettabihty, sinkability, dispersibility and solubility are

all subsumed under the term instant properties. In the case of particulate solids having good instant properties, the processes (a)-(d) are

expected to be completed satisfactorily in a few seconds if the layer

thickness of the powder spread on the surface of the liquid is about 10

mm.

Many objective measuring methods to determine instant properties

are available; they are discussed in a review paper (Schubert, 198 16). In

many cases, the disadvantages and shortcomings of these methods are so

great that they have not achieved practical importance, and subjective

evaluation methods have therefore been preferred. In view of the known

disadvantages of subjective evaluations, however, satisfactory objective

measuring procedures have been developed for the most important

properties, wettability and dispersibility (Schubert, 1980, 198 1 b). The

wetting test has also proved useful for non-food products; the dispersion

test used previously, however, is, because of the technical expense

involved, suitable only for research purposes. Dispersibility is most reliably determined from the change with time in the particle-size distribution during dispersion; this is possible by using modern on-line

particle-size analysers, but is too expensive for works practice. A relatively simple method for the determination

of dispersibility has been

developed for non-food powders (Polke et al., 1979) and has worked

20

H. Schubert

well. However, the method is not suitable for the majority of food

powders. This underlines the fact that it is not always possible to apply

methods of general particle technology directly to foods.

As far as food powders are concerned it is essential that, following a

short dispersing phase, soluble particles be dissolved as completely as

possible and the remaining particles be suspended in the liquid for a

sufficiently long time, i.e. neither deposit on the bottom of the receptacle

nor accumulate at the surface*. In accordance with a measuring method

(Mel, 1978) standardized by the International Dairy Federation (IDF) to

characterize the instant properties of dried milk, the following dispersibility value (which also includes the wetting properties) may be defined:

pc;d

cmt

(13)

where c,,,~ is mass concentration of the dispersed proportion and c,[ is

total mass concentration of the mass of the sample in the total liquid

mass. All dissolved and suspended particles are regarded as dispersed;

the remaining particles, i.e. those deposited and those floating at the surface, mostly non-wetted, accordingly are not dispersed. They form the

residual material, mass concentration c,,.

A dispersibility value may also be defined as:

Q=h

I.

(14)

If the dispersed total sample is divided according to the IDF test into

residual mass and dispersed mass, the following correlation between D,

and D, is obtained:

D

125QU +a

99D,+ 151

(15)

The constants 125,99 and 15 1 are obtained from the standardized division ratio according to IDE

In the IDF method the concentrations

c,,,~ and c,,,~are determined

gravimetrically or from the sample weight. The time required for the

determination

of dispersibility is thus 4-5 h. A rapid photometric

method has now been developed in which the concentration is related to

the loss in light transmission T according to the Lambert-Beer

law:

In TK c,. This law is valid only at sufficiently low concentrations and

*This requirement is not sufficient for the dispersion of certain other particles such as

colour pigments. The dispersion test described here is hence not suitable for all instant

powders, only for food powders.

Food particle technology - Part I

21

only when the particle-size distributions of the residual and dispersed

material are the same. Either condition can be fulfilled by adequate pretreatment. From eqn (14), for the photometric dispersion measure

In Td

Dfr=In T,

(16)

orfromeqn(15)

D

125% 1 + D,r)

99D,,+ 151

(17)

D, and D, are the same within the limits of measuring accuracy.

The equipment shown in Fig. 9 is used to measure photometrically the

dispersibility. In a modified IDF method, the powder is dispersed,

divided into residual and dispersed fractions which are then separately

homogenized and filled into the corresponding loading funnel (Fig. 9).

Each fraction is pumped in turn continuously through a cuvette where

the light transmission T, and Td are measured. The apparatus works

automatically. The data are evaluated by a mini-computer. Dispersibility,

which may fluctuate between 0 and lOO%, is indicated digitally.

Measurements, including sample preparation, take only a few minutes.

transmission

Fig. 9

Instrument

for measuring

the dispersibility

transmission.

of instant food powders by light

The instrument has been tested on nearly all instantized food powders

and has been found useful. Figure 10 shows the results for various commercial instant dried skimmed and whole milk products. Four samples of

each product were measured and the standard deviations determined

(indicated by bar-lines in the figure). The photometrically-determined

22

H. Schubert

(II

2

.-

o instant dried

skimmed milk

T=

33

iii

gO.8-

instant dried

whole milk

-0

+

C

.E

;

,/

0.6.

I

CL 0.2V

0.L

0.2

Gravimetrically

Fig. 10

WJ

I

0.6

determined

I

0.8

dispersibility

1

D,

Comparison

between the photometrically

and gravimetrically

dispersibility of instant dried skimmed and whole milk.

determined

dispersibility, D,, is the same, within the measuring accuracy limits, as

the gravimetrically-measured

IDF value D,. None of the commercial

instant dried whole milk products tested had satisfactory instant properties. According to IDF, D, should be L 85% for instant dried whole milk

and h 90% for instant dried skimmed milk. The rapid method which,

because of its ease in handling, is also suitable for routine measurements,

enables instant properties to be determined with sufficient accuracy; the

measurements

may also be used for product and process control

(Schubert, 1985).

3.2.3 Flow properties ofpowders

To ensure that powders are easily discharged or metered from containers, or fluidized and transported by pneumatic conveyors in the

course of a process without difficulties, they must be sufficiently flowable and even tricklable. Numerous empirical studies have been made

on the flowability of powders. However, none of these enables the flowability characteristics to be described independently of the particular

application. This is because of the complicated flow behaviour of particulate solids which differs basically from the flow behaviour of liquids

and fluidized solids. The pressure in a powder stored in a bin, for

23

Food particle technology - Part I

example, does not increase linearly with height, but tends towards a

maximum value. Only fluidized beds show some similarity to liquids.

Jenike ( 1970) established the fundamentals of powder mechanics,

allowing the flowability of particulate solids to be characterized and bins

and hoppers to be designed reliably. Only a brief explanation will be

given here; for details see the original work by Jenike (1970), the survey

papers by Schwedes (1970) and, with regard to food powders, by Peleg

(1977). To obtain the first reliable data as a basis for statements of

general applicability, Jenike developed a shear cell which is shown diagrammatically in Fig. 1 l(a). After consolidation to a certain porosity E,

or bulk density ,ob, the powder is subjected to different normal loads N

and caused to shear by the force S in the horizontal direction. If N is

plotted vs. S, or the normal stress o = N/A,vs.

the shear stress r = S/A,

an experimental yield locus as shown in Fig. 12 is obtained indicating the

yield point of the powder at a particular porosity E. If the yield point of

the same powder is required at a lower porosity, the experiment is

repeated at a higher consolidation degree. In this case the experimental

yield locus would be above that shown in Fig. 12. There is an individual

termination E to every yield locus; at this point steady-state flow is

reached, i.e. no changes in stress or volume take place.

a) Jetike shear cell

cover

ring

powder

base

b1Annular

shear cell

-loading

ring

powder

shear tr *ough

I-

C-R, -j

Ra

&

Fig. 11

Devices

for measuring

the shear resistance of powders.

Annular shear cell.

(a) Jenike shear cell. (b)

H. Schubert

24

tension

Fig. 12

Experimental

compression

Normal

stress

u ---

yield curve and effective yield locus of a cohesive powder.

The stress condition of each point on the yield locus may be decribed

by Mohr stress circles, Two Mohr stress semi-circles which are characterized by special properties are shown in Fig. 12. The larger semi-circle

characterizes the stress conditions during steady-state flow since it is

passing through point E. This stress circle intersects the axis at the two

principal stresses o1 and 02, O, being the major, or the consolidation

stress, and ~7~the minor principal stress. The smaller semi-circle shown

in Fig. 12 is characterized by the fact that the minor principal stress

becomes zero; the major principal stress, f,, is called the unconfined

yield strength by Jenike. Since the minor principal stress is zero, fc represents the compressive strength of the powder at the particular porosity.

Jenike showed that a powder flows more easily out of a bin the greater

the consolidation stress, o,, relative to the unconfined yield strength f,.

The ratio flC= a,/fc is called the flow function ff,; it characterizes the

flowability of powders, an important property in designing bins and

hoppers. According to Jenike, powders may be classified according to

their flowability, as shown in Table 3.

It should be noted that whilst the flow function 8: is a useful guide to

the flowability of powders, it does not completely describe the flowing

behaviour of particulate solids. A complete description is possible only

by means of the yield loci measured at various porosities.

By using the Jenike shear cell, however, only a certain region of the

yield locus curve can be determined experimentally. This region is indicated in Fig. 12 by a bold line, the remaining curve by a dashed line. The

Food particle technology - Part I

Flowability

fs,<2

2<ff,<4

4<fs,<lO

10 <ffc

TABLE 3

of Powders, Classified According

Flow Function #c = a,/fc

25

to the Jenike

Very cohesive, non-flowing

Cohesive

Cohesive

powders

Easy-flowing

Free-flowing

Non-cohesive

powders

point of intersection with the vertical axis corresponds to the cohesion

C. For non-cohesive powders C= 0. Since C depends not only on the

powder properties, but also very much on the consolidation conditions,

C is less suitable as an index of flowability than the flow function &,

Another property used to describe powders is the tensile strength 0,

which lies in the yield locus at the point of intersection with the horizontal axis. a, can be measured by using special equipment (Schubert,

1975). Since it is sometimes difficult to measure the yield locus in the

region in which the Mohr circle is plotted to determine f,, a, may be used

to interpolate the yield locus and hence to improve the measuring accuracy of f, (Eckhoff et al., 1978). This is of particular importance when

slightly cohesive powders are to be investigated, such as instant food

powders for vending machines.

Figure 12 also shows the tangent to the major stress circle from the

origin. This straight line, as experiments have shown, touches (approximately) the major Mohr circles of all other yield loci of a given particulate solid under different consolidation

conditions, i.e. at different

porosities. This straight line which is called the effectve yield locus

characterizes all steady-state flows of a material. The ratio of the two

principal stresses 0, and B, and the effective angle of friction tir are

correlated by the equation

o1

1 + sin &

a,=l-sin~r

(18)

which is interpreted by Jenike as a general law describing the steadystate flow of powders.

Many food powders tend to consolidate with time under the action of

static pressure. Interparticle adhesion increases with time, and flowability decreases correspondingly.

This effect is of importance for the

discharge of material from bins after intervals of time during which the

material may consolidate. The increase in adhesion force with time is

H. Schubert

26

primarily due to inelastic deformations at the contact points between the

particles and to the formation of solid bridges caused by crystallization

processes, for example. The influence of consolidation with time on the

flow behaviour of powders can be measured by using the Jenike shear

cell, provided that the particulate material is exposed to a normal load

for different periods of time before shearing. Yield loci are obtained

which are shifted towards higher shear stresses than without timedependent consolidation. The flow function fs,, and hence also the flowability, decrease correspondingly.

It is necessary, in all studies of the

influence of time on the flow behaviour of particulate material, that the

external conditions during exposure to normal load are kept constant.

This applies particularly to the relative humidity, RH. Many food

powders tend to consolidate with time only at RH > 0.5-0.6. The temperature during the compression may also be of importance, particularly

in cases where interparticle adhesion is promoted by sintering or crystallization processes.

Jenikes theory and the corresponding

measurements

are applied

primarily to the design of bins and hoppers (ter Borg, 198 1). Mass flow

bins in which the entire bulk material is in motion during the discharge

process (compare Fig. 13(a)) are to be preferred. In plug flow bins, the

base angles of which are less steep and smooth, the powder flows

through an outlet with some powder remaining stationary at the sides

(Fig. 13(b)). For foo d s of limited shelf life plug flow bins should be

avoided since the dead regions retain material for an indeterminate

length of time. By using the Jenike procedure, the critical cone angle BC,

which is a function of the effective friction angle 4, and the friction angle

&, between bulk material and wall, may be taken from diagrams giving

ldk

al

Fig. 13

MASS

FLOW

bl PLUG

FLOW

Mass flow and plug flow from bins.

Food particle technology - Part I

27

When the cone angle 8 5 8,, mass flow occurs. For the particulate

solid flow out of the bin, the outlet must have a minimum diameter

d, otherwise the material forms a stable arch. According to Jenikes

stability criterion, a stable arch is possible only for 0; <f,; a; is the major

principal stress acting at the abutment of an arch and which may be

calculated from the equation (see Jenike, 1970)

(20)

The flow factor fl, as a function of 8, 9, and #w, may be taken from

the diagrams of Jenike ( 1970). The condition ai =f, supplies the

critical stress a,, which acts at the abutment of an arch (see Fig. 14) from

which, by means of equation

(21)

the critical minimum diameter d, of the outlet can be determined. In eqn

(2 1), pb is bulk density, g is acceleration due to gravity; H( 0) is a function

of the geometry of the hopper given by published diagrams (Jenike,

1970). If d > d,, the formation of a stable arch which would prevent the

material from being discharged is avoided. Details of Jenikes theory are

beyond the scope of this paper; the reader is referred to Jenikes original

publication (1970) or to an excellent review paper presented by Arnold

et al. (1979).

In practice it is often difficult to determine the f, curve experimentally

in the presence of low stresses. To determine the point of intersection

with the straight line ai = a,/fl, an extrapolation of the f, curve is neces-

Fig. 14

Graphical

construction

to determine

the critical

explanation

see text).

diameter

of a bin outlet

(for

28

H. Schubert

sary. Molerus (1982) suggested a method of avoiding these difficulties.

Starting from interparticle adhesion he established a relation for the

group of yield loci which in the relevant range may be represented as

straight lines. Peleg (1971) has demonstrated

in experiments that the

yield loci of the majority of food powders may be approximated as

straight lines. The linearized yield loci allow the conclusion that the function SC=f( a,) can also be represented as straight line. Molerus formulated the equation for such straight lines as a function of the bulk

properties,

which can be experimentally

determined

in shear tests

(Molerus, 1982). The practical importance of this method will be discussed in Part II.

The accuracy of results obtained in this way would be increased

further if, for the determination of a,,, reliable shear force measurements could be made at very low normal stress; the Jenike shear cell is

not suitable for such experiments, however (Eckhoff et al., 1978). Shear

force measurements at very low normal stresses are, however, possible

by using an annular shear cell as shown diagrammatically in Fig. 1 l(b).

The powder is contained in a shear trough which rotates at angular

speed w. The torsional moment h4 is measured at the non-rotating loading ring which transmits the normal load N. From M, shear force and

hence shear stress can be derived by means of the equation

3M

=2n(R;-

R;)

(22)

which has been confirmed theoretically and experimentally (Gebhard,

198 1). The radii R, and Ri are explained in Fig. 11 (b). To transfer the

shear stress to the powder, the loading ring is roughened at its surface in

contact with the powder. One advantage of the annular shear cell over

the Jenike device is the shorter time required for a complete measurement, but the greatest is the continuous shear displacement possible with

constant sheared area. In the case of the Jenike device, despite an initial

offset (see Fig. 1 l(a)), the practical shear displacement is so small that

some cohesive food powders such as dried onion with more than 6%

moisture, some soup mixes and citric acid cannot be measured (Peleg,

1977), since neither shear failure nor steady-state flow are reached. The

annular shear cell (Walker, 19671, as further developed by Miinz ( 1976)

and modified by Ehlermann of the authors institute to meet the requirements of foods, is therefore preferred. For this purpose the measuring

accuracy particularly in the range of extremely low normal stresses has

been improved. This device is connected to a computer and thus suitable

for automatic operation.

Food particle technology - Part I

29

However, the annular shear cell is a complicated and expensive

device. For preliminary studies and comparative measurements, simpler

methods and equipment may be preferable which were proposed

especially by Peleg et al. for studies of the influence of moisture (Scoville

and Peleg, 198 1; Moreyra and Peleg, 1981) and of flow conditioners

(Hollenbach et al., 1982; Hollenbach and Peleg, 1983) on the flowability

of different food powders. The compression behaviour of powders in the

low pressure range, for instance, may be used to evaluate cohesion. For

food powders, the equation (see also Peleg, 1977)

at, = ~,,o + b 1% ~1~0

(23)

is well proven, where pb and pbo are the bulk density at pressure p, and

the reference pressure p,, (p, = ambient pressure), respectively; b is a

constant called compressibility. There is a clear correlation between b

and the cohesiveness. Powders showing a high compressibility have poor

flowing properties. The change in loose bulk density may also serve as a

measure of the effectiveness of anticaking agents, for example (Hollenbath et al., 1982). This is explainable physically from the influence of

interparticle adhesion on porosity or bulk density as mentioned above. If

quantitative information

regarding flowability is required, however,

shear tests are necessary.

ACKNOWLEDGEMENT

Many of the results reported in this paper were obtained within the

framework of research projects which were kindly supported by the

Deutsche Forschungsgemeinschaft,

Bonn.

REFERENCES

Arnold, P. C., McLean, A. G. and Roberts, A. W. (1979). Bulk Solids: Storage,

Flow and Handling, TUNRA Ltd, The University of Newcastle, New South

Wales 2308, Australia.

Borg, L. ter (198 1). Erfahrungen aus Scherversuchen

mit Schiittgiitern der

Chemie. Chem.-Ing-Tech., 53 (8), 662-3.

Davis, K. W. and Hawkins, A. E. ( 1979). Harmonic descriptors of particle shape:

their role in discrimination. Proc. PARTEC, 2nd Eur. Symp. on Particle

Characterization, Niirnberg, 582-99.

Downton, G. E., Flores-Luna, J. L. and King, C. J. (1982). Mechanism of stickiness in hygroscopic, amorphous powders. Ind. Eng. Chem. Fundam., 21 (4),

447-51.

30

H. Schubert

Eckhoff, R. K., Leverson, P. G. and Schubert, H. (1978). The combination of

tensile strength data of powders and failure loci from Jenike shear cell tests.

Powder Technology 19,115-18.

Ellwood, D. C. (1979). Adhesion of Microorganisms to Sueaces, Academic

Press, London.

Gebhard, H. (198 1). Comparison of powder shear tests using a Jenike flow

factor tester and a rotational shear apparatus. Institution of Chemical

Engineers Symposium Series No. 63, D3/T2-D3/T

10.

Hallstrom, B., Lund, D. B. and Tragardh, Ch. ( 198 1). Fundamentals and applications of surface phenomena associated with fouling and cleaning in food processing. Proc. from an int. workshop at Tylosand (Sweden), arranged by Div.

Food Eng., Lund University, Alnarp, Sweden, in cooperation with Dep. Food

Sci., University of Wisconsin, Mad., USA, pp. 57-73, 148-67,225-35.

Hollenbach, A. M. and Peleg, M. (1983). Interparticle surface affinity and the

bulk properties of conditioned powders. Powder Technology, 35,5 l-62.

Hollenbach, A. M., Peleg, M. and Rufner, R. (1982). Effect of four anticaking

agents on the bulk characteristics of ground sugar. J. Food Sci., 47 (2).

538-44.

Jenike, A. W. ( 1970). Storage and Flow of Solids, Bulletin No. 123 of the Utah

Engineering Experiment Station, 4th Printing (revised), University of Utah,

Salt Lake City, Utah.

Kniel, K. (1980). Herstellung von kakaohaltigen lnstantpulvern.

Proc. Int.

Seminar Instantisieren LV: Solingen-Grafrath, 19.-2 1.05.1980.

Koglin, B. ( 1974). Systematik der Dispergiermittel. Chem. -Zng.-Tech., 46 ( 17).

720-6.

Krupp, H. (1967). Particle adhesion. Theory and experiment. Advan. Colloid

Znterf Sci., 1 (2), 11l-239.

Leschonski, K. ( 1978). On-line-Messung von Partikelgroflenverteilungen

in

Gasen und Fliissigkeiten. Chem.-Zng.-Tech., 50 (3), 194-203.

Leschonski, K. ( 1982). Grundlagen und moderne Verfahren der Partikelmessung.

Manuskript des Instituts fiir Mechanische Verfahrenstechnik der Universitat

Clausthal, D-3392 Clausthal-Zellerfeld.

Leschonski, K., Alex, W. and Koglin, B. (1974). Teilchengrossenanalyse.

Chem.Ing.-Tech., 46,23-6, 101-6.

Loffler, F. ( 1983). Partikelabscheidung

an Tropfen und Fasern. C/rem. -Ing. 7&h., 55 (3), 171-8.

Mol, J. J. ( 1978). Dispersibility and Wettability of Instant Dried Milk, Progress

report of Group E 2, Int. Dairy Federation, E-Dot. 90, Paris.

Molerus, 0. ( 1982). Fluid-Festoff-Stromungen, Springer-Verlag, Berlin.

Moreyra, R. and Peleg, M. ( 198 1). Effect of equilibrium water activity on the

bulk properties of selected food powders. .I. FoodSci., 46 (6). 1918-22.

Miinz, G. (1976). Entwicklung eines Ringschergerates zur Messung der FlieBeigenschaften von Schiittgiitern und Bestimmung des Einflusses der Teilchengrol3enverteilung auf die FheBeigenschaften kohasiver Kalksteinpulver.

Diss. Universitat Karlsruhe.

Niediek, E. A. (1982). Differences in properties between the crystalline and

amorphous forms of sucrose and lactose. Int. Zeitschrifr Lebensmitteltechnologie und -Verfahrenstechnik, 33 (3). 173-85.

Food particle technology - Part I

31

Notermans, S. and Kampelmacher, E. H. (1983). Haften von Bakterien bei der

Fleischverarbeitung.

Fleischwirtschaft, 63 (l), 83-8.

Orr, C. (1980). Pore size and volume determination. Int. Symp. Fine Particle

Process. AZME, 1,404-4 1.

Peleg, M. ( 197 1). Measurements of cohesiveness and flow properties of food

powders. D.Sc. Thesis. Technion, Israel.

Peleg, M. (1977). Flowabilitv of food powders and methods for its evaluation a review. J. Food Process. Eng., 1 (4), 303-28.

Polke, R. and Rieger, R. (1979). TeilchengrGSenanalyse

mit dem Beugungszahler. Proc. PARTEC, 2nd Eur. Symp. on Particle Characterization,

Niimberg, 645-6 1.

Polke, R., Herrmann, W. and Sommer, K. (1979). Charakterisierung

von

Agglomeraten. Chem.-Zng.-Tech., 51 (4), 283-8.

Rumpf, H. (1975). Mechanische

tirfahrenstechnik,

Carl Hanser Verlag,

Miinchen, Wien.

Scarlett, B. (1979). The mathematical description of particle size and shape.

Proc. PARTEC, 2nd Eur. Symp. on Particle Characterization, Niirnberg,

544-64.

Schubert, H. (1972). Untersuchungen

zur Ermittlung von Kapillardruck und

Zugfestigkeit von feuchten Haufwerken aus kornigen Stoffen. Diss. Universitat Karlsruhe.

Schubert, H. (1975). Tensile strength of agglomerates. Powder Technology, 11,

107-19.

Schubert, H. (1978a). Capillary rise in porous media. In: Fibre- Water Znteractions in Paper-Making, ed. Brit. Paper and Board Ind. Fed., London.

Schubert, H. ( 1978b). Optimierung der GroBe und Porositat von Instantagglomeraten in Bezug auf eine schnelle Durchfeuchtung. Veqahrenstechnik,

12 (5), 296-301.

Schubert, H. (1980). Processing and properties of instant powdered foods. In:

Food Process Engineering, eds. P. Linko, Y. Malkki, J. Olkku and J. Larinkari,

Elsevier Applied Science Publishers Ltd, London, pp. 657-84.

Schubert, H. (1981 a). Principles of agglomeration. ht. Chem. Eng., 21 (3),

363-77.

H. ( 198 1 b). Jnstanteigenschaften

von agglomerierten Stoffen. Proc.

PARTEC, 3rd Znt. Symp. Agglomeration, Niirnberg, Vol. 1. A68-82.

Schubert, H. (1981 c). Particle adhesion to solid surfaces. Proc. from an int.

workshop at Tylosand (Sweden), arranged by Div. Food Eng., Lund UniverSchubert,

sity, Alnarp, Sweden, in cooperation with Dep. Food Sci., University of

Wisconsin, Mad., USA, 57-75.

Schubert, H. ( 1982). Kapillaritiit in poriisen Festoffsystemen. Springer-Verlag,

Berlin, Heidelberg, New York.

Schubert, H. (1985). Eine Schnellmethode

zur Messung der Instanteigenschaften pulverformiger

Stoffe. Znt. Zeitschrifi fiir Lebensmitteltechnologie

und -Ver$ahrenstechnik, 36 (3), 149-52.

Schutz, W. (1979). Haftung von Festoffpartikeln an Festkorperoberflachen

in

gasformiger Umgebung. Diss. Universitat Karlsruhe.

Schiitz, W. and Schubert, H. (1980). EinfluB der Umgebungsfeuchte

auf die

Partikelhaftung. Chem.-Zng. -Tech., 52 (5). 45 l-3.

32

H. Schubert

Schwedes, J. (1970). Flieflverhalten von Schiittgiitern in Bunkern. 1. Nachdruck

der 1. Aujlage von l%S, Verlag Chemie GmbH, Weinheim/Bergst.

Scoville, E. and Peleg, M. (198 1). Evaluation of the effects of liquid bridges on

the bulk properties of model powders. J. Food Sci., 46 (l), 174-7.

Sommer, K. (1979). Probennahrne von Pulvern und Kiirnigen Massengiitern,

Springer-Verlag, Berlin.

Walker, D. M. (1967). A basis for bunker design. Powder Technology, 1,228-36.

Weichert, R. and Huller, D. (1979). Volumenbestimmung und Formerkennung

unregelma0ig geformter Partikeln mittels dreidimensionaler

Bildanalyse.

Proc. PARTEC, 2nd Eul: Symp. on Particle Characterization, Niimberg,

600-15.

Zahradnicek, A. (1976). Untersuchungen zur Dispergierung von Quarz- und

Kalksteinraktionen im Korngrorjenbereich

O,S- 10 pm in stromenden Gasen.

Diss. Universitat Karlsruhe.

Potrebbero piacerti anche

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- BP Business Plan Financial Tables Jun14Documento7 pagineBP Business Plan Financial Tables Jun14ocalmaviliNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- Black IPA PDFDocumento1 paginaBlack IPA PDFJoaquim ReisNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Weibull Analysis in ExcelDocumento2 pagineWeibull Analysis in ExcelJoaquim ReisNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Facts Concerning Dust Air PDFDocumento18 pagineFacts Concerning Dust Air PDFJoaquim ReisNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

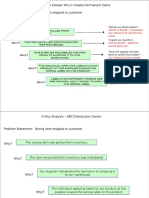

- 3Cs Principle Document Lean ModelDocumento9 pagine3Cs Principle Document Lean ModelJoaquim ReisNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- AnovaDocumento3 pagineAnovaJoaquim ReisNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- 5 WhyDocumento4 pagine5 WhyJoaquim ReisNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Lean Rolling Stock MaintenanceDocumento34 pagineLean Rolling Stock MaintenanceJoaquim Reis100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Lean Maintenance ManagementDocumento42 pagineLean Maintenance ManagementJoaquim ReisNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Cable Size Recommendations 12VdcDocumento2 pagineCable Size Recommendations 12VdcJoaquim ReisNessuna valutazione finora

- Lean MaintenanceDocumento48 pagineLean MaintenanceJoaquim Reis100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Local Exhaust Ventilation LEV Guidance PDFDocumento72 pagineLocal Exhaust Ventilation LEV Guidance PDFJoaquim Reis100% (2)

- E WasteDocumento10 pagineE WasteVarsha RkNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- 05Documento17 pagine05Andreas StathatosNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Chapter 4 - Plasticity of SoilDocumento15 pagineChapter 4 - Plasticity of SoilHussein EssaNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- ExtruderDocumento6 pagineExtruderSamuel AbebawNessuna valutazione finora

- Composite Structures: Shiva Rudraraju, Amit Salvi, Krishna Garikipati, Anthony M. WaasDocumento11 pagineComposite Structures: Shiva Rudraraju, Amit Salvi, Krishna Garikipati, Anthony M. WaasVictor Daniel WaasNessuna valutazione finora

- Dewalt Other Power ToolsDocumento19 pagineDewalt Other Power Toolszexi84Nessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- "The Use of Wood Ash, Pulverized Terracotta, and Hydrated Lime On Making Improvised Bricks" Related StudyDocumento5 pagine"The Use of Wood Ash, Pulverized Terracotta, and Hydrated Lime On Making Improvised Bricks" Related StudyJezreel Clien LapuzNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- EHM Series Slurry Pump: Excellence Pump Industry Co., LTDDocumento6 pagineEHM Series Slurry Pump: Excellence Pump Industry Co., LTDAgung Bakdo TriyonoNessuna valutazione finora

- Plasterboard ImpactchekDocumento3 paginePlasterboard ImpactchekEdwardLuNessuna valutazione finora

- 1,1,6 Precalciner KilnsDocumento39 pagine1,1,6 Precalciner KilnsMohamed Saad100% (1)

- Welding and Allied ProcessesDocumento48 pagineWelding and Allied ProcessesFarazAhmed100% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- GFNDocumento19 pagineGFNAl Amin ZubirNessuna valutazione finora

- M015710 04e PDFDocumento211 pagineM015710 04e PDFTaz UddinNessuna valutazione finora