Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

ASSAB Tool Steel Performance Comparison Chart

Caricato da

Nugroho Faris SudrajatCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

ASSAB Tool Steel Performance Comparison Chart

Caricato da

Nugroho Faris SudrajatCopyright:

Formati disponibili

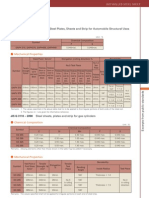

ASSAB Tool Steel Performance Comparison Chart

Reference Standard

WNr.

JIS

Chemical Composition %

Si Mn Cr Mo W V Others

Hardness

Supplied

SKS 3

HB 190

0.95

0.3

1.1

0.5

0.5 0.1

(1.2436)

(SKD 2)

HB 240

2.05

0.3

0.8 12.7

1.1

A2

1.2363

SKD 12

HB 215

1.0

0.3

0.6

1.1

D2

1.2379

SKD 11

HB 210

1.55

0.3

0.4 11.3 0.8

HB 200

0.6

0.35 0.8

4.5

VIKING / CHIPPER

HB 225

(max)

0.5

1.0

0.5

CALDIE

CALDIE

HB 215

(max)

0.7

0.2

ASSAB 88

SLEIPNER

HB 235

0.9

ASSAB Grade

Uddeholm Grade

ASSAB DF-3

ARNE

O1

1.2510

ASSAB XW-5

SVERKER 3

D6 (D3)

ASSAB XW-10

RIGOR

ASSAB XW-42

SVERKER 21

CALMAX

CALMAX

VIKING

AISI

Austenising

Temp. oC

Range of

Hardness

790-850

56-62

General purpose oil hardening tool steel with good surface hardness and

wear resistance.

Cutting : blanking, punching, shearing, trimming.

Forming : bending, drawing, rim rolling, spinning, flow forming.

Gauges and measuring tools.

920-1000

56-62

A 12% Cr, high carbon tool steel with excellent abrasive wear resistance.

Blanking, punching, cropping, shearing, trimming and clipping.

0.2

925-970

56-62

Good hardenability, wear resistance and excellent size stability for

medium runs.

Blanking, punching, piercing, cropping, shearing, trimming and moulds for

abrasive plastics.

0.8

990-1080

58-63

A 12% Cr tool steel with high wear resistance and strength.

Blanking, fine blanking, punching, cropping, shearing, trimming and clipping.

0.5

0.2

950-970

52-59

for the production of electrical components. Typical for blanking

A general steel with high toughness, good wear resistance and polishability. Moulds

dies with high demands on toughness.

8.0

1.5

0.5

980-1050

52-59

Versatile with an excellent combination of toughness and wear resistance

required for chipper-knives, heavy duty blanking and forming.

Suitable for chipper-knives, heavy duty blanking, forming and also abrasive

plastic parts.

0.5

5.0

2.3

0.5

1000-1050

56-61

Very good chipping and cracking resistance with high compressive

strength. Suitable for PVD coating to maximise wear resistance.

Cold forging, forming dies, fine blanking and heavy duty blanking, thread

rolling dies and coining dies. Suitable for AHSS automotive parts.

0.9

0.5

7.8

2.5

0.5

950-1080

58-64

Mixed-abrasive profile, good resistance to chipping, good machining and

WEDM properties.

Blanking, fine blanking, shearing, forming, coining, cold forging, cold

extrusion, thread rolling, drawing, deep drawing and powder pressing.

1.4

2.0

Characteristics

Applications

Cold Work

1.2358

5.3

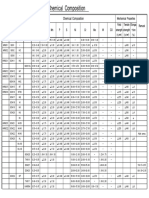

Plastic Mould

ASSAB 618 HH

(P20)

1.2738

HB 340-380

0.37

0.3

0.2

Ni 1.0

Pre-hardened, no hardening is needed.

moulds and extrusion dies for thermoplastics, blow moulds,

Pre-hardened plastic mould steel with good polishability and machinability. Injection

forming tools, machine components, structural components and shafts.

ASSAB 618 T

(P20)

(1.2738)

HB 310-355

0.26

0.1 1.45 1.25 0.6

0.12

Ni 1.05

Pre-hardened, no hardening is needed.

Pre-hardened mould steel with exceptional through hardening properties,

Suitable for large and very large moulds where there is high demand on

good polishability and etching properties combined with good machinability. surface finish.

(P20)

1.2738

HB 340-380

0.37

0.3

1.4

2.0

0.2

Ni 1.0

Pre-hardened, no hardening is needed.

Pre-hardened plastic mould steel with very good polishability.

HB 360-400

0.1

0.3

2.5

3.0

0.3

Ni 1.0

Pre-hardened, no hardening is needed.

Pre-hardened mould steel with best toughness, good machinability and

very good polishability.

Pre-hardened, no hardening is needed.

Pre-hardened corrosion-resistant mould steel. It has very good

machinability, toughness and polishing properties.

Mould for plastic injection (e.g. packaging containers, automotive interior

parts, reflectors, panels and handles for appliances), holder material for

forging, diecasting dies, cutting tools, hot runner manifolds and structural

components.

Injection moulds and blow moulding for corrosive plastics. Plastic

moulding of high surface finish parts (e.g. Bezels and casings for LED/LCD).

PET bottles and construction parts.

Injection moulds and extrusion dies for thermoplastics, blow moulds,

forming tools, machine components, structural components and shafts.

ASSAB 718 HH

IMPAX HH

NIMAX

NIMAX

MIRRAX 40

MIRRAX 40

(420)

HB 360-400

0.21

0.9 0.45 13.5 0.2

0.25

Ni 0.6

+N

MIRRAX ESR

MIRRAX ESR

(420)

HB 250

0.25

0.3

0.5 13.3 0.3

0.3

Ni 1.3

+N

1000-1025

44-52

Stainless mould steel with a unique combination of toughness, corrosion

resistance and through-hardening properties.

For all types of moulds, especially suited for larger tools where corrosion

in production is unacceptable and where high surface finish is required.

STAVAX ESR

STAVAX ESR

(420)

HB 190

0.38

0.9

0.5 13.6

0.3

1000-1050

44-52

Stainless plastic mould steel with excellent polishability and corrosion

resistance.

VIDAR 1 ESR

VIDAR 1 ESR

H11

HB 185

0.38

1.0

0.4

5.0

1.3

0.4

990-1010

44-52

Suitable for both hot work and plastic mould applications, especially large

plastic moulds that require good toughness in combination with high

surface finish obtained by polishing or texturing.

Injection moulds for highly polished parts and for moulding corrosive

plastics.

For general hot work and plastic moulds. Specifically used where high

toughess and high surface requirements are needed in large plastic

moulds, such as lens, extension and reflector moulds for Automotive

lighting systems.

UNIMAX

UNIMAX

HB 185

0.5

0.2

0.5

5.0

2.3

0.5

1000-1025

52-58

High hardness and very good toughness. ESR for excellent polishability.

Suitable for coating and nitriding.

Plastic moulds for abrasive plastics. Suitable for heavy blanking, powder

compacting as well as for warm forging.

ROYALLOY

ROYALLOY

(420 F)

HB 290-330

0.05

0.4

1.2 12.6

S 0.12

+N

+Cu

Stainless steel for holder blocks with excellent machinability and

corrosion resistance.

Holders/bolsters for plastic moulds, plastic and rubber moulds with

low requirements on polishability, dies for plastic extrusion and for

constructional parts.

POLMAX

POLMAX

(420)

HB 200

0.38

0.9

0.5 13.6

0.3

46-52

Excellent polishability, good machinability and good resistance to

corrosion and wear.

Recommended where extreme surface finishes are required, such as lens

moulds and CD moulds.

CORRAX

CORRAX

HRC 34

0.03

0.3

0.3 12.0 1.4

Ni 9.2

Al 1.6

Age hardening to HRC 40-51

Age hardening stainless steel with superior corrosion resistance.

Injection moulds for corrosive plastics, rubber, medical and food industry,

extrusion dies, and engineering parts.

(1.2083) (SUS 420J2)

1.2343

SKD 6

(1.2083) (SUS 420J2)

ASSAB MM40

HRC 40

Pre-hardened, no hardening is required.

1000-1050

beryllium copper mould alloy supplied at approx. 40 HRC,

Pre-hardened, do not have a solid solution High-strength

suitable where a combination of high thermal conductivity, corrosion

and aging treatment

resistance and polishablity is needed.

Be 1.9 (Co+Ni) 0.25 Cu Bal.

Blow moulds : pinch offs, neck rings and handle inserts.

Injection moulds : moulds, cores and inserts.

Injection nozzles and manifolds for hot runner systems.

Hot Work

DIEVAR

ASSAB 8407

SUPREME

ASSAB 8407 2M

DIEVAR

ORVAR

SUPREME

ORVAR 2M

H13

Premium

H13

1.2344

SKD 61

HB 180

0.39

1.0

0.4

5.2

1.4

0.9

1020-1050

44-52

1.2344

SKD 61

HB 185

0.39

1.0

0.4

5.3

1.3

0.9

1020-1050

42-52

High performance hot work tool steel with very good resistance to heat

checking, gross cracking, hot wear and plastic deformation.

Meets and exceeds NADCA 207-2011 specification for premium die

casting materials.

Hot work tool steel with overall good ductility, toughness, wear

resistance, hardenability and machinability.

HB 180

0.38

0.3

0.8

2.6

2.3

0.9

1020-1050

42-52

Highest temperature strength and very good thermal fatigue resistance.

Die casting dies and associated tooling, extrusion dies and extrusion

tooling, forging dies, esp. for copper and brass and hot stamping dies.

HB 230

(max)

0.35

0.2

0.5

5.0

2.3

0.6

1000-1030

44-52

Good temper resistance and higher temperature strength than H13 type

steel.

Tools for hot forging and extrusion.

(SKH 53)

HB 260

(max)

1.28

4.2

5.0 6.4 3.1

1050-1180

60-65

Powder high speed steel with excellent wear resistance and toughness.

Suitable for very long runs.

Blanking of medium to high carbon steel, blanking of harder materials.

Moulds for very abrasive plastics and IC moulds.

SKH 40

HB 300

(max)

1.28

4.2

5.0 6.4 3.1

Co 8.5

1050-1180

60-66

Powder high speed steel for cutting tools with excellent wear resistance,

toughness and good hot hardness.

Suitable for chip forming multi-edge cutting tools, single-edge cutting

tools, cold work applications with high demands on wear resistance and

IC moulds.

HB 340

(max)

2.3

4.2

7.0 6.5 6..5

Co 10.5

1100-1180

60-68

Powder high speed steel for cutting tools with excellent wear resistance,

toughness and excellent hot hardness.

Suitable for chip forming multi-edge cutting tools, single-edge cutting tools

and cold work applications with high demands on wear resistance.

HB 230

1.4

0.4

0.4

4.7

3.5

3.7

950-1150

58-64

Powder tool steel for long run tooling, where high demands on adhesive

wear and chipping resistance is required.

Blanking, fine blanking, forming of thicker work material, esp. austenitic

stainless steel. mild carbon steel, AHSS, copper and aluminium.

HB 270

2.3

0.4

0.4

4.8

3.8

8.0

1020-1080

58-64

Powder tool steel for very long run tooling ,where abrasive wear

resistance and good toughness is required.

Blanking, forming, fine blanking, deep drawing, cold forging and powder

compacting,

HB 300

1.1

0.5

0.4

4.5

3.2 3.7 8.5

N 1.8

950-1150

58-65

A nitrided powder tool steel for the very best resistance to galling and

adhesive wear. Normally no coating is necessary.

Blanking, fine blanking, deep drawing, bending powder compacting of soft

and adhesive metals.

HB 280

1.7

0.8

0.3 18.0 1.0

1050-1100

56-60

Powder tool steel and stainless plastic mould steel with high wear and

corrosion resistance.

Electronics industry: connectors, plugs, switches, resistors and integrated

circuits.

QRO 90 SUPREME QRO 90 SUPREME

FORMVAR

FORMVAR

HB 160

0.35

0.2

0.5

5.0

2.3

0.6

1000-1030

44-52

Excellent choice for die casting of aluminium and magnesium, hot stamping,

forging, and aluminium extrusion.

Suitable for high pressure die casting, hot extrusion, press forging tools

and moulds for plastics.

Tools for extrusion, hot forging and pressing and moulds for plastics.

Powder Metallurgy

ASSAB PM 23

VANADIS 23

(M3:2)

1.3395

SUPERCLEAN

SUPERCLEAN

ASSAB PM 30

VANADIS 30

(M3:2 + Co) 1.3294

SUPERCLEAN

SUPERCLEAN

ASSAB PM 60

VANADIS 60

(1.3292)

SUPERCLEAN

SUPERCLEAN

VANADIS 4 EXTRA VANADIS 4 EXTRA

SUPERCLEAN

SUPERCLEAN

VANADIS 8

VANADIS 8

SUPERCLEAN

SUPERCLEAN

VANCRON 40

VANCRON 40

SUPERCLEAN

SUPERCLEAN

ELMAX

ELMAX

SUPERCLEAN

SUPERCLEAN

( ) - modified grade

3.0

This information is based on our present state of knowledge and is intended to provide general notes on our products and their uses. It should not therefore be construed as a warranty of specific properties of the products described or a warranty for fitness for a particular purpose.

Edition 1600826

Potrebbero piacerti anche

- Aluminium Alloys Aluminium 5754 Properties Fabrication and Applications Supplier Data by AalcoDocumento6 pagineAluminium Alloys Aluminium 5754 Properties Fabrication and Applications Supplier Data by AalcoacwindNessuna valutazione finora

- ASSAB Tool Steel Performance Comparison Chart PDFDocumento1 paginaASSAB Tool Steel Performance Comparison Chart PDFSophian Hakim WirajayaNessuna valutazione finora

- Risers Design Unit-IDocumento24 pagineRisers Design Unit-IQUAZI ADYAN AHMAD 160419736049Nessuna valutazione finora

- SKD61-Forged Hot Work Tool SteelDocumento1 paginaSKD61-Forged Hot Work Tool SteelAgustine SetiawanNessuna valutazione finora

- Tool Steel Grade and Standard DesignationDocumento7 pagineTool Steel Grade and Standard DesignationMustafa SevimliNessuna valutazione finora

- Forging, Rolling, Extrusion and Drawing ProcessesDocumento45 pagineForging, Rolling, Extrusion and Drawing ProcessesHarshan Arumugam100% (1)

- Mikromekanik KompositDocumento24 pagineMikromekanik KompositAri P KusumaNessuna valutazione finora

- A2 Tool Steel: CompositionDocumento1 paginaA2 Tool Steel: CompositionSama Umate100% (1)

- Saph 440Documento1 paginaSaph 440rinkumax2003100% (1)

- JIS Standard For Casting MaterialDocumento4 pagineJIS Standard For Casting MaterialalliceyewNessuna valutazione finora

- Introduction of Heat and Surface Treatment PDFDocumento45 pagineIntroduction of Heat and Surface Treatment PDFScott BakerNessuna valutazione finora

- Datasheet For Metals ST 90 PCDocumento2 pagineDatasheet For Metals ST 90 PCGalNessuna valutazione finora

- Solidification and Crystalline Imperfection Part 1Documento25 pagineSolidification and Crystalline Imperfection Part 1Aiman MutallidNessuna valutazione finora

- Centrifugal CastingDocumento12 pagineCentrifugal Castingsamurai7_77100% (1)

- Welding MetallurgyDocumento1 paginaWelding MetallurgyRavi Ranjan100% (1)

- Chapter - 3 Part 2 - Casting - Processes Types PDFDocumento73 pagineChapter - 3 Part 2 - Casting - Processes Types PDFMohammad TahaNessuna valutazione finora

- MSI DC 01 FosecoDocumento4 pagineMSI DC 01 FosecoVivek Shrivastava100% (1)

- Heat Resistant Alloy Chemical CompositionDocumento2 pagineHeat Resistant Alloy Chemical Compositionsusisaravanan100% (1)

- Welding Design and Process SelectionDocumento36 pagineWelding Design and Process SelectionponcoNessuna valutazione finora

- ZCAST Brochure WebDocumento8 pagineZCAST Brochure WebSrashmiNessuna valutazione finora

- Nisshin Steel Cold Rolled Special Steel StripDocumento28 pagineNisshin Steel Cold Rolled Special Steel StripekopujiantoeNessuna valutazione finora

- Tool Steel SelectionDocumento11 pagineTool Steel SelectionSelvaraj BalasundramNessuna valutazione finora

- Aisi 5160 Alloy Steel (Uns g51600)Documento3 pagineAisi 5160 Alloy Steel (Uns g51600)Felipe Salinas EspinozaNessuna valutazione finora

- Introduction in Alloys and Influence of Elements: Alloys and Melting 01 - Alloys - and - Melting - EN - Docx 1/13Documento13 pagineIntroduction in Alloys and Influence of Elements: Alloys and Melting 01 - Alloys - and - Melting - EN - Docx 1/13luisA1923Nessuna valutazione finora

- Magmahpdc Gating Geometry Optimization: Committed To Casting ExcellenceDocumento8 pagineMagmahpdc Gating Geometry Optimization: Committed To Casting ExcellencemaniacraghuNessuna valutazione finora

- Properties s45cDocumento3 pagineProperties s45ctomas duranNessuna valutazione finora

- 50 Casting DefectsDocumento49 pagine50 Casting DefectsmohammadNessuna valutazione finora

- Materials For Forming ToolsDocumento40 pagineMaterials For Forming Toolssav33Nessuna valutazione finora

- Steel Comp A Ration TableDocumento1 paginaSteel Comp A Ration TablekazdoelahNessuna valutazione finora

- DIN 17100 ST 37-2 SteelDocumento1 paginaDIN 17100 ST 37-2 Steelisaaa100% (1)

- Riser DesignDocumento4 pagineRiser DesignJiggy Jick100% (1)

- Extrusion For ClassDocumento49 pagineExtrusion For ClassNABIL HUSSAINNessuna valutazione finora

- Tabel VCDocumento1 paginaTabel VCgame downloadNessuna valutazione finora

- Metal Casting Dies: Thoguluva Raghavan VijayaramDocumento4 pagineMetal Casting Dies: Thoguluva Raghavan VijayaramcombinationcoffeeNessuna valutazione finora

- Feeding Steel and Ductile Iron CastingDocumento22 pagineFeeding Steel and Ductile Iron Castingjosemiguelzu100% (1)

- Vacuum Oxygen DecarburizationDocumento11 pagineVacuum Oxygen DecarburizationSradha Suman100% (1)

- Fundamentals of Metal CastingDocumento45 pagineFundamentals of Metal CastingsuntharNessuna valutazione finora

- Surface FinishesDocumento8 pagineSurface FinishesasritaipNessuna valutazione finora

- NADCA-High Temp DieDocumento12 pagineNADCA-High Temp DiejalilemadiNessuna valutazione finora

- Gating Ratio: Choke EffectDocumento9 pagineGating Ratio: Choke EffectSiddhant SharmaNessuna valutazione finora

- 111th Metalcasting Congress NadcaDocumento12 pagine111th Metalcasting Congress NadcaMehwishYasmenNessuna valutazione finora

- Tool Steels E28093 Molybdenum High Speed SteelsDocumento5 pagineTool Steels E28093 Molybdenum High Speed Steelswulfgang66Nessuna valutazione finora

- Heat Treatment Grossmann Hardenability PDFDocumento11 pagineHeat Treatment Grossmann Hardenability PDFsivajirao70100% (2)

- Agarwal Fastners Pvt. Ltd.Documento1 paginaAgarwal Fastners Pvt. Ltd.satyam nagaichNessuna valutazione finora

- Casting: "Net Shape" or "Near-Net Shape" Process AdvantagesDocumento27 pagineCasting: "Net Shape" or "Near-Net Shape" Process AdvantagesnsbaruaoleNessuna valutazione finora

- 14 Material and Heat Treatment of Jigs &Documento18 pagine14 Material and Heat Treatment of Jigs &GV RagunathanNessuna valutazione finora

- SPCCDocumento10 pagineSPCCDeepak JainNessuna valutazione finora

- Low Pressure Die CastingDocumento4 pagineLow Pressure Die Castingyang2012100% (1)

- Fabricating of Hastelloy Corrosion Resistant Alloys of HaynesDocumento40 pagineFabricating of Hastelloy Corrosion Resistant Alloys of HayneszuudeeNessuna valutazione finora

- Alloy Steel ASTM A217 GRADE WC6Documento2 pagineAlloy Steel ASTM A217 GRADE WC6Dika Wahyu WijayaNessuna valutazione finora

- Gating-Risering Sec2Documento35 pagineGating-Risering Sec2jagan_4u100% (1)

- Data Table For Grades Tool Die Steels SKD-11Documento3 pagineData Table For Grades Tool Die Steels SKD-11Adhi candra irawanNessuna valutazione finora

- Final Welding of Ti Alloys and MG AlloysDocumento32 pagineFinal Welding of Ti Alloys and MG AlloysArjyajyoti GoswamiNessuna valutazione finora

- Stellite 21 DatasheetDocumento2 pagineStellite 21 Datasheetapply19842371100% (3)

- Assab TableDocumento8 pagineAssab TableIhfan MohdNessuna valutazione finora

- LKM Steel For Mould Base and Special Material Eng 12-2012Documento1 paginaLKM Steel For Mould Base and Special Material Eng 12-2012NazriNessuna valutazione finora

- Grade AssabDocumento3 pagineGrade AssabAshishNessuna valutazione finora

- Aspac Royalloy enDocumento7 pagineAspac Royalloy enNugroho Faris SudrajatNessuna valutazione finora

- Technical Data: ApplicationsDocumento3 pagineTechnical Data: ApplicationssushmaxNessuna valutazione finora

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkDa EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkNessuna valutazione finora

- Assab Royalloy: Prehardened Free Machining Stainless Holder SteelDocumento7 pagineAssab Royalloy: Prehardened Free Machining Stainless Holder SteelNugroho Faris SudrajatNessuna valutazione finora

- Aluminum AssociationDocumento38 pagineAluminum AssociationVJ QatarNessuna valutazione finora

- Assab Royalloy: Prehardened Free Machining Stainless Holder SteelDocumento7 pagineAssab Royalloy: Prehardened Free Machining Stainless Holder SteelNugroho Faris SudrajatNessuna valutazione finora

- Aspac Royalloy enDocumento7 pagineAspac Royalloy enNugroho Faris SudrajatNessuna valutazione finora

- Polymer PropertiesDocumento23 paginePolymer PropertiesNugroho Faris SudrajatNessuna valutazione finora

- Group 4 Project ReportDocumento83 pagineGroup 4 Project ReportAmin MemonNessuna valutazione finora

- SIP - Warehouse Flow ChartDocumento10 pagineSIP - Warehouse Flow ChartkrishnatejanitdgpNessuna valutazione finora

- Logistics and Supply Chain Managementv4 - Part - 1Documento65 pagineLogistics and Supply Chain Managementv4 - Part - 1Soham Savjani100% (3)

- Unit Rate Comparision For DBST: AverageDocumento34 pagineUnit Rate Comparision For DBST: AverageTewodros TadesseNessuna valutazione finora

- Assessment Task 1Documento15 pagineAssessment Task 1rishiNessuna valutazione finora

- Detailed Estimation Report - High Rise at GurgaonDocumento15 pagineDetailed Estimation Report - High Rise at GurgaonJackson ChristianNessuna valutazione finora

- Introduction To Operation ManagementDocumento48 pagineIntroduction To Operation ManagementSwati KatariaNessuna valutazione finora

- Research Paper 2Documento9 pagineResearch Paper 2AL-AMIN AHMED MOBIN 1801015Nessuna valutazione finora

- Ceiling Plan Level 01 Zone 7-Mep Offices Area PDFDocumento1 paginaCeiling Plan Level 01 Zone 7-Mep Offices Area PDFyasir_tecton2076Nessuna valutazione finora

- 4-Channel ManagementDocumento41 pagine4-Channel ManagementArunKumarNessuna valutazione finora

- Ej Pier: Elevated 35 Pier Type Y-1, Span 41.0 + 41.0 M WW/SKDocumento8 pagineEj Pier: Elevated 35 Pier Type Y-1, Span 41.0 + 41.0 M WW/SKgarysootetNessuna valutazione finora

- s001 General Notes Sheet 1 Rev.c4Documento1 paginas001 General Notes Sheet 1 Rev.c4xây dựng 123Nessuna valutazione finora

- Heydar Aliyev Cultural Center: Structu Ral Buil Ding Ma TerialsDocumento3 pagineHeydar Aliyev Cultural Center: Structu Ral Buil Ding Ma TerialsJasmin AzizNessuna valutazione finora

- Udall SystemDocumento6 pagineUdall SystemPaulo BurceNessuna valutazione finora

- Beam To Column Connection1Documento5 pagineBeam To Column Connection1Sudhakar Krishnamurthy50% (2)

- Guide To Pedestrian BridgesDocumento4 pagineGuide To Pedestrian BridgesJuan AlayoNessuna valutazione finora

- E Magazine LIPP Liquid Storage TanksDocumento3 pagineE Magazine LIPP Liquid Storage TanksWibowo ArieNessuna valutazione finora

- History of Architecture 2 History of Architecture 2 Ar. Diane A. Jose Ar. Diane A. JoseDocumento28 pagineHistory of Architecture 2 History of Architecture 2 Ar. Diane A. Jose Ar. Diane A. JoseJohn Roldan BuhayNessuna valutazione finora

- AutoCAD Plant 3D - IV (3D)Documento11 pagineAutoCAD Plant 3D - IV (3D)SivaramanNessuna valutazione finora

- Smart, Eco-Friendly, Money-Saving Home Tips by Kevin ReganDocumento1 paginaSmart, Eco-Friendly, Money-Saving Home Tips by Kevin ReganKathy Irene ReganNessuna valutazione finora

- 2021 Schedule of Finishes MAPLE ModelDocumento1 pagina2021 Schedule of Finishes MAPLE ModelKamille Anne GabaynoNessuna valutazione finora

- BRAC Tower A Mixed Use Multistorey DhakaDocumento58 pagineBRAC Tower A Mixed Use Multistorey Dhakamayuresh barbarwarNessuna valutazione finora

- Plot No - C-98 SEC-NSG FINAL-ModelDocumento1 paginaPlot No - C-98 SEC-NSG FINAL-ModelSAKET TYAGINessuna valutazione finora

- Accomplshment ReportDocumento5 pagineAccomplshment ReportJan Chrispian MirasolNessuna valutazione finora

- Masonry PDFDocumento76 pagineMasonry PDFKian Inductivo0% (1)

- Selectrode: Manufacturers of Custom Welding Lines For Resale Handi-Jig Heat Resistant PuttyDocumento2 pagineSelectrode: Manufacturers of Custom Welding Lines For Resale Handi-Jig Heat Resistant Puttymohamed AdelNessuna valutazione finora

- Basic Cost Terms and ConceptsDocumento8 pagineBasic Cost Terms and Conceptstegegn mogessieNessuna valutazione finora

- Building With Precast Concrete Elements:: HalfenDocumento48 pagineBuilding With Precast Concrete Elements:: HalfenMelanie CabforoNessuna valutazione finora

- Name of Construction Equipment For Oil Gas ProjectsDocumento6 pagineName of Construction Equipment For Oil Gas Projectsrahul nagareNessuna valutazione finora

- Heat LoadDocumento37 pagineHeat LoadRohan Kuldhar100% (1)