Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Wet Scrubber Maintenance and Inspections: Pre-Startup Scrubber Inspection Checklist

Caricato da

Edmund YoongTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Wet Scrubber Maintenance and Inspections: Pre-Startup Scrubber Inspection Checklist

Caricato da

Edmund YoongCopyright:

Formati disponibili

For other compliance tools and resources online, go to www.environmentalcompliancealert.

com

Wet Scrubber Maintenance and Inspections

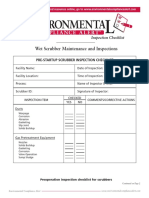

PRE-STARTUP SCRUBBER INSPECTION CHECKLIST

Facility Name:

Date of Inspection:

Facility Location:

Time of Inspection:

Process:

Name of Inspector (Print):

Scrubber ID:

Signature of Inspector:

INSPECTION ITEM

CHECKED

YES

NO

COMMENTS/CORRECTIVE ACTIONS

Ducts

Warpage

Corrosion

Abrasion

Gasketing

Slip Joint

Solids Buildup

Gas Pretreatment Equipment

Nozzles

Solids Buildup

Gasketing

Corrosion

Valve Operation

Sump Sludge

Preoperation inspection checklist for scrubbers

Continued on Page 2

Environmental Compliance Alert

www.environmentalcompliancealert.com

Page 2

INSPECTION ITEM

CHECKED

YES

NO

COMMENTS/CORRECTIVE ACTIONS

Scrubber

Nozzles

Clogging

Wearing

Abrasion

Abrasion

Buildup

Corrosion

Piping

Scaling

Rusting

Riggings

Leakage

Sump Sludge

Mist Eliminator

Nozzles

Clogging

Wearing

Abrasion

Piping

Rusting

Pitting

Leakage

Valve Operation

Corrosion

Mist Eliminator Media

Buildup

Cleaned

Replaced

Liquor Treatment

pH Control

Calibration Check

Probe Buildup

Caustic Hold Tank

Sludge Buildup

Valve Operation

Piping Leakage

Preoperation inspection checklist for scrubbers (continued)

Continued on Page 3

Environmental Compliance Alert

www.environmentalcompliancealert.com

Page 3

DAILY SCRUBBER INSPECTION FORM

Facility Name:

Date of Inspection:

Facility Location:

Time of Inspection:

Process:

Name of Inspector (Print):

Scrubber 10:

Signature of Inspector:

INSPECTION ITEM

COMMENTS/CORRECTIVE ACTIONS

1) Gas pretreatment equipment

(if applicable)

- Leaks

- Abnormal sounds

- Pressure drop normal?

2) Scrubber and mist eliminator

- Leaks

- Abnormal sounds

- Pressure drop normal?

3) Liquor treatment

- Leaks

- Abnormal sounds

Pressures:

Pressure drop across scrubber _____ in. WG

Scrubbing liquid pressure _____ psi

Scrubber liquid flow _____ gpm

Temperatures:

Gas into system _____ F

Quench liquid flow _____ gpm

(if applicable)

Gas into scrubber _____ F

Gas from scrubber _____ F

Liquid from scrubber _____ F

Fan amps _____

Pump amps _____

Opacity _____ %

Daily inspection form example

Continued on Page 4

Environmental Compliance Alert

www.environmentalcompliancealert.com

Page 4

MONTHLY SCRUBBER INSPECTION FORM

Facility Name:

Date of Inspection:

Facility Location:

Time of Inspection:

Process:

Name of Inspector (Print):

Scrubber ID:

Signature of Inspector:

INSPECTION ITEM

COMMENTS/CORRECTIVE ACTIONS

1) Gas pretreatment equipment

Piping Leakage

Valve Operation

Pump/Lub.

2) Scrubber

Piping Leakage

Valve Operation

Level Control

Pump/Lub.

3) Mist Eliminator

Piping Leakage

Valve Operation

Pump/Lub.

4) Liquor Treatment

Piping Leakage

Valve Operation

Level Control

Pump/Lub.

5) Fans. Ducts, Pipes

- Abrasion

- Corrosion

- Solids Buildup

6) Check sensors, alarm systems, and

bypass devices for proper operation

Monthly inspection form example

Continued on Page 5

Environmental Compliance Alert

www.environmentalcompliancealert.com

Page 5

MAINTENANCE REPORT FORM

Department

Unit

System

Originator:

Subsystem

Component

Date:

Assigned to: 1

Mechanical

Priority:

Subcomponent

Time:

Emergency

Unit Status: 1

Normal

Electrical

Same Day

Derated

Instrumentation

Routine

Down

Repairable

Hold for:

Tools

Parts

Outage

Problem Description:

Foreman:

Date:

Job Status:

Cause of Problem:

Work Done:

Supervisor:

Completion Date:

Materials Used:

Labor Requirements:

Maintenance report form example

Environmental Compliance Alert

www.environmentalcompliancealert.com

Potrebbero piacerti anche

- Wet Scrubber Maintenance and Inspections: Pre-Startup Scrubber Inspection ChecklistDocumento5 pagineWet Scrubber Maintenance and Inspections: Pre-Startup Scrubber Inspection ChecklistvanyoNessuna valutazione finora

- WELD SUMMARY TRACKINGDocumento30 pagineWELD SUMMARY TRACKINGThamaraikani Mani100% (1)

- Complete workshop consumables listDocumento3 pagineComplete workshop consumables listDharmendra ChudasmaNessuna valutazione finora

- Intermediate Inspection CriteriaDocumento2 pagineIntermediate Inspection CriteriaKaleem UllahNessuna valutazione finora

- Chemical Dosing Pump SATRDocumento2 pagineChemical Dosing Pump SATRDeshan Sing100% (1)

- VINDAIR SOP.01 Duct Pressure TestDocumento3 pagineVINDAIR SOP.01 Duct Pressure TestRamakrishna Agumbe100% (1)

- Mechanical Commissioning 2Documento66 pagineMechanical Commissioning 2mohamed abd el attyNessuna valutazione finora

- Liquid Penetrant ExaminationDocumento5 pagineLiquid Penetrant ExaminationKevin ThomasNessuna valutazione finora

- Construction of Sewage Treatment PlantDocumento55 pagineConstruction of Sewage Treatment PlantDevendra Sharma100% (5)

- Recall Points CH1 To CH5Documento5 pagineRecall Points CH1 To CH5Chiheb KaanicheNessuna valutazione finora

- PEI UST Inspection ChecklistDocumento6 paginePEI UST Inspection ChecklistdamonfitzNessuna valutazione finora

- E-Book - Leak Testing in The Automotive IndustryDocumento51 pagineE-Book - Leak Testing in The Automotive IndustryKrishna Mohan T.RNessuna valutazione finora

- Inspection Of: Piping Systems (In-Service) 570Documento36 pagineInspection Of: Piping Systems (In-Service) 570g_jeyasankar100% (2)

- Commissioning Methodologies (CM) - MUS-01 Pipework Flushing and Cleaning Method StatementDocumento3 pagineCommissioning Methodologies (CM) - MUS-01 Pipework Flushing and Cleaning Method StatementMohammad OsmanNessuna valutazione finora

- JIEYUAN Project Execution Plan of Chemical Cleaning and Oil Flushing For Cooling Medium SystemDocumento12 pagineJIEYUAN Project Execution Plan of Chemical Cleaning and Oil Flushing For Cooling Medium SystemTao QuNessuna valutazione finora

- ASME CODE Requirements - PipingDocumento6 pagineASME CODE Requirements - PipingJithin FrancizNessuna valutazione finora

- Dye Penetrant Inspection ProcedureDocumento5 pagineDye Penetrant Inspection ProcedureaezeadNessuna valutazione finora

- 2014 CSME LinBussmannTranDocumento6 pagine2014 CSME LinBussmannTranFábio Henrique Lucas da CostaNessuna valutazione finora

- Internal Cleaning of Piping System PDFDocumento6 pagineInternal Cleaning of Piping System PDFNight WatchNessuna valutazione finora

- Leak Testing Basic Principles - Background Information of Leaks and Leak Testing From TQCDocumento3 pagineLeak Testing Basic Principles - Background Information of Leaks and Leak Testing From TQCMirza Safeer Ahmad100% (1)

- Leak Detection Methods: A Comparative Study of Technologies and Techniques Short VersionDocumento24 pagineLeak Detection Methods: A Comparative Study of Technologies and Techniques Short VersionHappy202180% (5)

- Method Statement Sandblasting Rev. 0Documento7 pagineMethod Statement Sandblasting Rev. 0spazzbgt80% (10)

- Agchem Construction Plumbing WorksDocumento39 pagineAgchem Construction Plumbing WorksRegine Dela Fuente100% (1)

- CLEANING VALIDATION PROTOCOLDocumento7 pagineCLEANING VALIDATION PROTOCOLArieTamaNessuna valutazione finora

- Liquid Penetrant Testing (PT) Detects Surface FlawsDocumento7 pagineLiquid Penetrant Testing (PT) Detects Surface Flawsmuthuswamy77Nessuna valutazione finora

- Saudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 30-Oct-17 MechDocumento2 pagineSaudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 30-Oct-17 MechJagdishNessuna valutazione finora

- Parenteral Process ValidationDocumento30 pagineParenteral Process Validationravindra82% (11)

- Parenteral Process Validation (1) DarusazDocumento30 pagineParenteral Process Validation (1) Darusazeshwar_orgNessuna valutazione finora

- Gas Leak TestingDocumento6 pagineGas Leak Testingsudeep_singh1Nessuna valutazione finora

- List of TCVN 2010: Số hiệu Tên tài liệuDocumento244 pagineList of TCVN 2010: Số hiệu Tên tài liệuTcp Vn0% (1)

- Analisa Teknis Pengujian Kekedapan Pengelasan Pada Tangki Tongkang Dengan Membandingkan Metode Chalk Test, Air Pressure Test Dan VacuumDocumento18 pagineAnalisa Teknis Pengujian Kekedapan Pengelasan Pada Tangki Tongkang Dengan Membandingkan Metode Chalk Test, Air Pressure Test Dan VacuumIbnu HajarNessuna valutazione finora

- BLANK RISK ASSESSMENT-Trace Analytics-CSnewDocumento1 paginaBLANK RISK ASSESSMENT-Trace Analytics-CSnewLucero MarinNessuna valutazione finora

- Method Statement For Chemical Cleaning - 1Documento11 pagineMethod Statement For Chemical Cleaning - 1Nguyễn Bá Huy100% (2)

- How to inspect gearboxes for wear and prevent failureDocumento14 pagineHow to inspect gearboxes for wear and prevent failuremahdiNessuna valutazione finora

- Sterility Test Failure Investigation FormDocumento9 pagineSterility Test Failure Investigation FormmishannakNessuna valutazione finora

- How To Inspect Gear BoxDocumento11 pagineHow To Inspect Gear BoxSubbarayan SaravanakumarNessuna valutazione finora

- Non-Destructive Testing Requirements: Welding Procedures ManualDocumento4 pagineNon-Destructive Testing Requirements: Welding Procedures ManualcarlosNessuna valutazione finora

- 007 UTube CleaningDocumento2 pagine007 UTube CleaninggshdavidNessuna valutazione finora

- 1823 Chapter VDocumento10 pagine1823 Chapter VberkahharianNessuna valutazione finora

- SL - No Components Failure Mechanism Possible Root Causes Evaluation Method Observation RecommendationDocumento9 pagineSL - No Components Failure Mechanism Possible Root Causes Evaluation Method Observation RecommendationPrakash WarrierNessuna valutazione finora

- Saudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 24-Jul-18 MechDocumento2 pagineSaudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 24-Jul-18 Mechnadeem0% (1)

- Boiler InspectionDocumento6 pagineBoiler Inspectiondaimahesh100% (1)

- WP-3000 GPD Annual Cleaning OF Double Pass Ro System: Chem Tech ConsultantsDocumento4 pagineWP-3000 GPD Annual Cleaning OF Double Pass Ro System: Chem Tech ConsultantsAbdul SamadNessuna valutazione finora

- How To Inspect A GearboxDocumento12 pagineHow To Inspect A Gearboxivan wijayaNessuna valutazione finora

- Cleanliness of Surfaces: Vacuum-Insulated Piping SystemsDocumento5 pagineCleanliness of Surfaces: Vacuum-Insulated Piping SystemsKreshna Wisnu BrataNessuna valutazione finora

- 18F46-DOMI of Piping System and Valves Level 2Documento5 pagine18F46-DOMI of Piping System and Valves Level 2ehabwardaNessuna valutazione finora

- PIPELINE TESTING PROCEDURESDocumento5 paginePIPELINE TESTING PROCEDURESdương_thành_28Nessuna valutazione finora

- How To Inspect A GearboxDocumento13 pagineHow To Inspect A Gearboxkamal arabNessuna valutazione finora

- AfterCooler Seperators Drains PDFDocumento11 pagineAfterCooler Seperators Drains PDFzamijakaNessuna valutazione finora

- Hydrotest Procedure For PipingDocumento4 pagineHydrotest Procedure For Pipingsuria qaqcNessuna valutazione finora

- Monthly Crane Inspection ChecklistDocumento2 pagineMonthly Crane Inspection Checklistslamet4riadiNessuna valutazione finora

- Satr A 2008Documento2 pagineSatr A 2008Shahzad HussainNessuna valutazione finora

- Leak TestingDocumento5 pagineLeak Testingogie_0513Nessuna valutazione finora

- Flushing Procedure For Chilled Water System Chemical Treatment Method Statement HQDocumento8 pagineFlushing Procedure For Chilled Water System Chemical Treatment Method Statement HQTerrence Gil Pamienta Buenaflor67% (3)

- A Practical Handbook for Drilling Fluids ProcessingDa EverandA Practical Handbook for Drilling Fluids ProcessingNessuna valutazione finora

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryDa EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNessuna valutazione finora

- Abrasive Water Jet Perforation and Multi-Stage FracturingDa EverandAbrasive Water Jet Perforation and Multi-Stage FracturingNessuna valutazione finora

- Storage Tanks Selection, Design, Testing, Inspection, and Maintenance: Emission Management and Environmental Protection: Emission Management and Environmental ProtectionDa EverandStorage Tanks Selection, Design, Testing, Inspection, and Maintenance: Emission Management and Environmental Protection: Emission Management and Environmental ProtectionNessuna valutazione finora

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceDa EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNessuna valutazione finora

- Well Testing Project Management: Onshore and Offshore OperationsDa EverandWell Testing Project Management: Onshore and Offshore OperationsNessuna valutazione finora

- Working With Change Management in Service OutsourcingDocumento20 pagineWorking With Change Management in Service OutsourcingEdmund Yoong100% (1)

- Occupancy-Driven Energy ManagementDocumento6 pagineOccupancy-Driven Energy ManagementEdmund YoongNessuna valutazione finora

- MK SensorDocumento28 pagineMK SensorEdmund YoongNessuna valutazione finora

- Indirect Cost Savings When OutsourcingDocumento20 pagineIndirect Cost Savings When OutsourcingEdmund YoongNessuna valutazione finora

- ISS 2020 Future of Service Management White Book October 2016Documento144 pagineISS 2020 Future of Service Management White Book October 2016Edmund YoongNessuna valutazione finora

- KNX Solutions enDocumento41 pagineKNX Solutions enEdmund Yoong100% (1)

- T3-1 Gain Competitive Insights of Orchestry of SymphonyDocumento109 pagineT3-1 Gain Competitive Insights of Orchestry of SymphonyEdmund YoongNessuna valutazione finora

- HR Issues To Be Considered When Outsourcing ServicesDocumento20 pagineHR Issues To Be Considered When Outsourcing ServicesEdmund YoongNessuna valutazione finora

- Exercise - Word Match .: Words AnswerDocumento2 pagineExercise - Word Match .: Words AnswerEdmund YoongNessuna valutazione finora

- Iso 9001 2008 Checklist Sample Rev 2-20-09usDocumento8 pagineIso 9001 2008 Checklist Sample Rev 2-20-09usRonaldSincheNessuna valutazione finora

- Jciinternalauditchecklist 160510164212Documento14 pagineJciinternalauditchecklist 160510164212Edmund Yoong75% (4)

- ISS 2020 Vision - Future of Outsourcing and Perspectives For Facility ManagementDocumento106 pagineISS 2020 Vision - Future of Outsourcing and Perspectives For Facility ManagementEdmund YoongNessuna valutazione finora

- Sustainability PDFDocumento24 pagineSustainability PDFEdmund YoongNessuna valutazione finora

- Defining Service Excellence in Facility ManagementDocumento16 pagineDefining Service Excellence in Facility ManagementEdmund YoongNessuna valutazione finora

- ISS 2020 Vision - Future of Outsourcing and Perspectives For Facility ManagementDocumento106 pagineISS 2020 Vision - Future of Outsourcing and Perspectives For Facility ManagementEdmund YoongNessuna valutazione finora

- Code For Environmental Sustainability of BuildingsDocumento136 pagineCode For Environmental Sustainability of BuildingsJosé Manuel M. S. SousaNessuna valutazione finora

- ISS 2020 VisionDocumento88 pagineISS 2020 VisionEdmund YoongNessuna valutazione finora

- Creating A Security Request For ProposalDocumento16 pagineCreating A Security Request For ProposalEdmund YoongNessuna valutazione finora

- Sensors Used in Power Sources For IoEDocumento33 pagineSensors Used in Power Sources For IoEKiran KirruNessuna valutazione finora

- T3-1 Gain Competitive Insights of Orchestry of SymphonyDocumento109 pagineT3-1 Gain Competitive Insights of Orchestry of SymphonyEdmund YoongNessuna valutazione finora

- Detect Occupancy Using Smart Meter DataDocumento14 pagineDetect Occupancy Using Smart Meter DataEdmund YoongNessuna valutazione finora

- Benchmarking For Facility Professionals Ifma Foundation Whitepaper SmallDocumento102 pagineBenchmarking For Facility Professionals Ifma Foundation Whitepaper SmallEdmund YoongNessuna valutazione finora

- Low-Cost Coarse AirborneDocumento6 pagineLow-Cost Coarse AirborneEdmund YoongNessuna valutazione finora

- Household Occupancy Monitoring Using Electricity MetersDocumento12 pagineHousehold Occupancy Monitoring Using Electricity MetersEdmund YoongNessuna valutazione finora

- KNX Solutions enDocumento41 pagineKNX Solutions enEdmund Yoong100% (1)

- Energy Efficient HVAC System With Distributed Sensing and ControlDocumento10 pagineEnergy Efficient HVAC System With Distributed Sensing and ControlEdmund YoongNessuna valutazione finora

- MK SensorDocumento28 pagineMK SensorEdmund YoongNessuna valutazione finora

- CV Seshan SrirangarajanDocumento6 pagineCV Seshan SrirangarajanEdmund YoongNessuna valutazione finora

- Energy Efficiency in LaboratoriesDocumento9 pagineEnergy Efficiency in LaboratoriesEdmund YoongNessuna valutazione finora

- CRE SustainabilityDocumento28 pagineCRE SustainabilityEdmund YoongNessuna valutazione finora

- Satellite 2755dvdDocumento2 pagineSatellite 2755dvdeduinnNessuna valutazione finora

- Indoor Multi-Wall Path Loss Model at 1.93 GHZDocumento6 pagineIndoor Multi-Wall Path Loss Model at 1.93 GHZadonniniNessuna valutazione finora

- Management GurusDocumento44 pagineManagement GurusRouben ParmanumNessuna valutazione finora

- Accuret-A20: Electrical SpecificationsDocumento2 pagineAccuret-A20: Electrical SpecificationsClaudio CalabreseNessuna valutazione finora

- IES 2012 Exam Civil Engineering Paper II Solved With Answer KeyDocumento21 pagineIES 2012 Exam Civil Engineering Paper II Solved With Answer KeyPratik Nayak0% (2)

- SEP2 MeterViewDocumento23 pagineSEP2 MeterViewmarcofffmota3196Nessuna valutazione finora

- Instruction Manual - Digital Drybath - ENDocumento19 pagineInstruction Manual - Digital Drybath - ENAlain ManceraNessuna valutazione finora

- RK-2001 Operation ManualDocumento11 pagineRK-2001 Operation Manuale-ComfortUSANessuna valutazione finora

- AF09-30-01-13 100-250V50/60HZ-DC Contactor: Product-DetailsDocumento5 pagineAF09-30-01-13 100-250V50/60HZ-DC Contactor: Product-DetailsTheo Pozo JNessuna valutazione finora

- Blueendo MorcellatorDocumento7 pagineBlueendo MorcellatorLia GuslianiNessuna valutazione finora

- Astm C109-16Documento10 pagineAstm C109-16Travis TwaddellNessuna valutazione finora

- Hydraulic Cylinder Seal Kits: Quality With Value GuaranteedDocumento16 pagineHydraulic Cylinder Seal Kits: Quality With Value GuaranteedHenry GamboaNessuna valutazione finora

- SY155WDocumento4 pagineSY155WLutfi DstrNessuna valutazione finora

- 1000100en Image LD DidacticDocumento12 pagine1000100en Image LD DidacticUditha MuthumalaNessuna valutazione finora

- Adaptive Cruise Control: Current Flow DiagramDocumento5 pagineAdaptive Cruise Control: Current Flow DiagramHany ElsehrawyNessuna valutazione finora

- Hospital Management SystemDocumento63 pagineHospital Management Systemsanjay yadavNessuna valutazione finora

- Seller DashboardDocumento8 pagineSeller DashboardAditya KumarNessuna valutazione finora

- Ducha EmpotradaDocumento1 paginaDucha Empotradagilmar melendresNessuna valutazione finora

- Design Diesel-Photovoltaic Hybrid Power PlantDocumento93 pagineDesign Diesel-Photovoltaic Hybrid Power PlantDaniel Okere100% (1)

- Installation & Maintenance Instructions Pressure Regulator With Integral Pilot Regulator R18Documento2 pagineInstallation & Maintenance Instructions Pressure Regulator With Integral Pilot Regulator R18luis ivanNessuna valutazione finora

- Canon Ir3245 Series-PcDocumento154 pagineCanon Ir3245 Series-PcPetrescu CezarNessuna valutazione finora

- NACA Report 184 The Aerodynamic Forces On Airship HullsDocumento16 pagineNACA Report 184 The Aerodynamic Forces On Airship Hullsshatal16Nessuna valutazione finora

- Quiz 12Documento3 pagineQuiz 12mwende faiyuuNessuna valutazione finora

- Advance Diploma For CivilDocumento4 pagineAdvance Diploma For CivilAung Naing Latt AungNessuna valutazione finora

- Advanced MICS Platform with 28 ModulationsDocumento4 pagineAdvanced MICS Platform with 28 ModulationsKIRAN SONICSNessuna valutazione finora

- Technical Spec & BOQ Screw ConveyorDocumento7 pagineTechnical Spec & BOQ Screw ConveyorjhsudhsdhwuNessuna valutazione finora

- High-Temperature Quad 2-Inputs OR Gate DatasheetDocumento6 pagineHigh-Temperature Quad 2-Inputs OR Gate DatasheetSalim Abdul Rahman Sa'dyNessuna valutazione finora

- Catalogo General KOBA 1000 - e - 2012revDocumento21 pagineCatalogo General KOBA 1000 - e - 2012revTECNIMETALNessuna valutazione finora

- Ewsd BSNL PDFDocumento2 pagineEwsd BSNL PDFAdamNessuna valutazione finora

- CD 74 HCT 164 MDocumento16 pagineCD 74 HCT 164 MfabriziocasNessuna valutazione finora