Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

VX136 105 Pos1 Piggy Back

Caricato da

Cretu DanDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

VX136 105 Pos1 Piggy Back

Caricato da

Cretu DanCopyright:

Formati disponibili

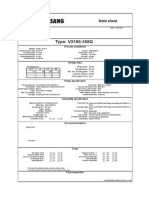

Data sheet

Date: 19.12.2012

Customer:

Project: Tarnaveni wwtp

Project pos. no.: 1 (piggy-back)

Type: VX136-105Q

Process conditions

Medium:

Required volume flow:

Pressure at inlet:

Pressure at discharge:

Differential pressure:

Shaft deflection:

Primary sludge, 20,0 C

25 m/h

0,0 bar

3,0 bar

3,0 bar

0,083 mm

Density:

Temperature:

Viscosity:

pH value:

Dry matter content:

1000,0 kg/m

20,0 C

1,0 mPas

neutral

5%

Design data

Operating points:

m/h

Hz

25

min-1

50

Starting torque: 145 Nm

Operating torque: 132 Nm

kW

281

Max. requ. operating power: 3,9 kW

3,9

Volumetric efficiency: 75,23%

NPSHR (water, 20C): 2,00

Pump specification

Housing segments:

Wear plates:

Shaft pump chamber:

Lobes:

Max. free passage :

Seal type:

Grey cast iron 250

HVSS High wear resistant special steel

60 mm

NBR / HiFlo / 4 Wings

40 mm

Blockring SS 304 Cr2O3/Duronit

Seal carrier:

Pressure disc/strain screw:

O-rings in touch with medium:

Buffer chamber medium:

Buffer chamber options:

Shaft deflection/bar:

Mild steel, nitrated

Mild steel

NBR

Oil

Buffer fluid tank, pressurised

0,028 mm

Assembly specification

Connector left:

Motor manufacturer:

Motor type: M132/MX6-955

Drehzahl (min-1): 955 min-1

Connector right:

Power: 5,5 kW

Connector material:

Voltage: 400/690 V

Base:

Frequency: 50 Hz

Type of drive:

Isolation class: F

Coupling or belt guard:

Motor efficiency classification:

Yes

No

Total weight:

Thermistor sensor:

Drive is suitable for the enlarged temperature range of -20C to +45C.

90 bend to shaft DN125, With flange according to DIN2633

PN16

90 bend for base, type belt drive 4", With flange according

to ANSI B16.5 150lbs RF

Galvanized

Base, type belt drive bended, galvanized

Belt drive (i=3,4)

Belt guard, galvanized

Approx. 310 kg

Accessories/option

Accessories: -lablassleitung

Remarks:

Tests

Idle torque check

Synchronization check

Pressure test buffer chamber

Performance test**

Hydrostatic test**

Yes

Yes

Yes

Yes

Yes

Alignment check* ***

Noise level at 1 m

General visual inspection

Final inscpection

Customer inspection

No

No

No

No

No

Yes

Yes

Yes

Yes

Yes

No

No

No

No

No

* Test only for complete pump units incl. drive motor.

** test only for complete units incl. drive motor and known operating mode.

Final inspection

Created withCAPSpro Version 3.12.05

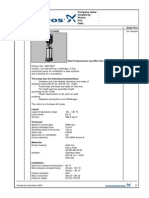

Space required for maintenance work:

Recommended anchor bolts:

W = 700 mm required, 1000 mm recommended

Size: M 16 / Length min 60 mm

Flange data

L

R

ANSI

Standard DIN

DN DN125

D 250 mm

k 210 mm

d 18 mm

Hole number 8

L

H

L1

L2

L3

L4

L5

h

u

v

x

mm

578

1071

453

572,5

480

0

133

320

500

430

50

y

y2

y3

z

250

0

0

18

4"

9"

7 1/2"

3/4"

8

Vogelsang data:

Allowable horizontal forces: 700N

Customer:

Allowable vertical forces: 700N

Quote no.:

Allowable moments: 200Nm

Order no.:

Position no.:

a

b

c

d

Not an assembly drawing. Concept sketch only!

321

200

231

120

90 bend to shaft

a

b

c

d

407

428

0

120

Pump type VX136-105Q

Motor type M132/MX6-955

Type of drive Belt drive (i=3,4)

Coupling or belt guard Belt guard, galvanized

90 bend for base, type belt drive

Base Base, type belt drive bended, galvanized

Total weight Approx. 310 kg

Dimensions shown in mm

Changes of dimensions reserved

Hugo Vogelsang Maschinenbau GmbH

Holthge 10-14, DE-49632 Essen (Oldenburg)

General tolerances acc. to DIN ISO 2768 rough

Created withCAPSpro Version 3.12.05

www.vogelsang-gmbh.com

Date: 19.12.2012

CAPSpro Version 3.12.05

50,00

20,00

45,00

18,00

40,00

16,00

35,00

14,00

30,00

12,00

25

25,00

10,00

20,00

8,00

15,00

6,00

10,00

4,00

5,00

2,00

0,00

Power in [kW]

Volume flow in [m/h]

Volume flow / speed at const. pressure

VX136-105Q (HiFlo 4 Wings NBR)

0,00

0

50

100

150

200

Speed in [min-1]

250

Theoretical volume flow

New pump

Pump with gap (0,5 mm)

Operating points

Water curve

Operating power

300

350

Medium:

400

Water, 20,0 C

P = 3,0 bar

Potrebbero piacerti anche

- Pompa Namol Secundar - RefDocumento3 paginePompa Namol Secundar - RefCretu DanNessuna valutazione finora

- MIS-M-DS-04045 Closed Drain Drum Data Sheet-BDocumento3 pagineMIS-M-DS-04045 Closed Drain Drum Data Sheet-Bhappale2002Nessuna valutazione finora

- W13018-YT01-GDF-457110 Rev 5-APVDocumento8 pagineW13018-YT01-GDF-457110 Rev 5-APVJosé santanaNessuna valutazione finora

- VPC (Flowserve)Documento5 pagineVPC (Flowserve)Wissam JarmakNessuna valutazione finora

- MIS-M-DS-04053 50m3 Slop Tank Data Sheet-BDocumento2 pagineMIS-M-DS-04053 50m3 Slop Tank Data Sheet-Bhappale2002Nessuna valutazione finora

- SSWP Datasheet Horizontal OptionDocumento2 pagineSSWP Datasheet Horizontal OptionshimrozkhanNessuna valutazione finora

- MIS-M-DS-04052 50m3 Treated Water Tank Data Sheet (T-04320) - CDocumento2 pagineMIS-M-DS-04052 50m3 Treated Water Tank Data Sheet (T-04320) - Chappale2002Nessuna valutazione finora

- Annubar Spec SheetDocumento1 paginaAnnubar Spec SheetmeledathNessuna valutazione finora

- Hoja de Datos Bombas SumergiblesDocumento7 pagineHoja de Datos Bombas SumergiblesRicardo BarrosNessuna valutazione finora

- Amacan PDocumento52 pagineAmacan PGogyNessuna valutazione finora

- Manual Ecoflux en - KrohneDocumento14 pagineManual Ecoflux en - Krohnemmihai_popa2006Nessuna valutazione finora

- Submittal Data: End Suction Stainless Steel PumpsDocumento3 pagineSubmittal Data: End Suction Stainless Steel PumpsGustavo Farelo SuarezNessuna valutazione finora

- FHRDocumento5 pagineFHRJavier Melendez RomanNessuna valutazione finora

- Sensus WP Dynamic Cold Water Meter (DN40-300)Documento4 pagineSensus WP Dynamic Cold Water Meter (DN40-300)Roderikus Rendy MNessuna valutazione finora

- Pompa Dari Embung Ke Bak Sirkulasi / Penjernih: ContentsDocumento11 paginePompa Dari Embung Ke Bak Sirkulasi / Penjernih: ContentsewamihawkNessuna valutazione finora

- Catalogodp Pumps PDFDocumento32 pagineCatalogodp Pumps PDFmanuelarranoNessuna valutazione finora

- US-4406-8000093951 D-HSEF - CurveDocumento6 pagineUS-4406-8000093951 D-HSEF - CurveAdrian DragusinNessuna valutazione finora

- DW PompaDocumento32 pagineDW PompaluxorraNessuna valutazione finora

- Deltaflux Bypass FlowmeterDocumento2 pagineDeltaflux Bypass Flowmeternieav280Nessuna valutazione finora

- 15SV04F0556T: Operating DataDocumento4 pagine15SV04F0556T: Operating DataRoger Quevedo MachucaNessuna valutazione finora

- Pump SpecificationDocumento6 paginePump SpecificationCretu DanNessuna valutazione finora

- Anonymous 1-1en PDFDocumento6 pagineAnonymous 1-1en PDFAlexander BrewerNessuna valutazione finora

- Boiler Feed Water PumpDocumento7 pagineBoiler Feed Water PumphadijawaidNessuna valutazione finora

- Hoja de Datos Bombas RAS PTARDocumento8 pagineHoja de Datos Bombas RAS PTARRicardo BarrosNessuna valutazione finora

- Bermad - Filtro en y 70fDocumento2 pagineBermad - Filtro en y 70fYadir BojacaNessuna valutazione finora

- FlowMon Catalogue 2Documento12 pagineFlowMon Catalogue 2dhanu_aquaNessuna valutazione finora

- MIL Control Valve Specification and Sizing CalculationDocumento34 pagineMIL Control Valve Specification and Sizing CalculationRahulTewari67% (3)

- Datasheet BombaDocumento4 pagineDatasheet BombasaculNessuna valutazione finora

- Wafer Type Butterfly Valve Z 611-A Wafer Type Butterfly Valve Z 611-ADocumento4 pagineWafer Type Butterfly Valve Z 611-A Wafer Type Butterfly Valve Z 611-ARadu GanciuNessuna valutazione finora

- Bomba Desaladora AlternativaDocumento6 pagineBomba Desaladora AlternativawaricateNessuna valutazione finora

- Catalog of Vortex (Tianjin China.)Documento23 pagineCatalog of Vortex (Tianjin China.)Waqas JawaidNessuna valutazione finora

- Non Clogging PumpsDocumento15 pagineNon Clogging PumpsSouvik SingharoyNessuna valutazione finora

- Data Sheet Tag 180-Pu-011eDocumento8 pagineData Sheet Tag 180-Pu-011eSarah PerezNessuna valutazione finora

- 2 and 3 Genesis Series PD Meter SpecificationsDocumento6 pagine2 and 3 Genesis Series PD Meter SpecificationsMechanicalMarwanNessuna valutazione finora

- Motor Siemens 1LG6317-4MA90 L2F DatasheetDocumento1 paginaMotor Siemens 1LG6317-4MA90 L2F DatasheetFrancisco ArauzNessuna valutazione finora

- Min1244a12 - Tag 130-Pu-029Documento7 pagineMin1244a12 - Tag 130-Pu-029Monty MathewsNessuna valutazione finora

- SONDA cONDUTIVÍMETRO PDFDocumento8 pagineSONDA cONDUTIVÍMETRO PDFAngeloNessuna valutazione finora

- Estacion de Rebombeo Ptar-OpcionDocumento3 pagineEstacion de Rebombeo Ptar-OpcionRaul CabanillasNessuna valutazione finora

- MIS-M-DS-04050 1000m3 Fire Water Tank Data Sheet (T-07010) - BDocumento2 pagineMIS-M-DS-04050 1000m3 Fire Water Tank Data Sheet (T-07010) - Bhappale2002Nessuna valutazione finora

- Ed 1 DF 66 DDocumento5 pagineEd 1 DF 66 DSurangaG100% (1)

- XOMOXLinedPlugValvesEMEA TechnicalDataDocumento20 pagineXOMOXLinedPlugValvesEMEA TechnicalDataperoooNessuna valutazione finora

- 14564625Documento2 pagine14564625kisgobeNessuna valutazione finora

- 2 4CRDocumento4 pagine2 4CRNestramiNessuna valutazione finora

- 2009 02 M HD 319 0Documento5 pagine2009 02 M HD 319 0ZoebairNessuna valutazione finora

- 12S Series: High Pressure FiltersDocumento6 pagine12S Series: High Pressure FiltersPartsGopher.comNessuna valutazione finora

- Ds FlowserveDocumento5 pagineDs FlowservejmeleNessuna valutazione finora

- Liquid Turbine Flow Meter: Subject To Change Without NoticeDocumento27 pagineLiquid Turbine Flow Meter: Subject To Change Without Noticenew587Nessuna valutazione finora

- Rotametro ABBDocumento10 pagineRotametro ABBjoticamario123Nessuna valutazione finora

- CR 3-25 A-Fgj-A-E Hqqe: Position Qty. Description Single PriceDocumento7 pagineCR 3-25 A-Fgj-A-E Hqqe: Position Qty. Description Single PriceYanuar ZulkarnainNessuna valutazione finora

- HRD Hot Water Pump P001Documento6 pagineHRD Hot Water Pump P001nguyenquoc1988Nessuna valutazione finora

- 08 Ehm 3Documento5 pagine08 Ehm 3Javier Melendez RomanNessuna valutazione finora

- DS PE A 10 Product Profile en Us 52381Documento2 pagineDS PE A 10 Product Profile en Us 52381behnamatgNessuna valutazione finora

- Description Value: Printed From Grundfos CAPSDocumento1 paginaDescription Value: Printed From Grundfos CAPSYanuar ZulkarnainNessuna valutazione finora

- Backwash Pumps - Dmf+gacDocumento11 pagineBackwash Pumps - Dmf+gacAlex CătănescuNessuna valutazione finora

- QUOTATION For WINORAC 12 12 23Documento4 pagineQUOTATION For WINORAC 12 12 23Kasarachi AmadiNessuna valutazione finora

- 5-En 4300-A - C1FPDocumento15 pagine5-En 4300-A - C1FPabuzer1981Nessuna valutazione finora

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDa EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsValutazione: 4.5 su 5 stelle4.5/5 (10)

- How to prepare Welding Procedures for Oil & Gas PipelinesDa EverandHow to prepare Welding Procedures for Oil & Gas PipelinesValutazione: 5 su 5 stelle5/5 (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDa EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNessuna valutazione finora

- Sample Collection Means of Protection When Working in The Field of Wastewater Treatment PlantsDocumento34 pagineSample Collection Means of Protection When Working in The Field of Wastewater Treatment PlantsCretu DanNessuna valutazione finora

- Modification Suction BridgeDocumento1 paginaModification Suction BridgeCretu DanNessuna valutazione finora

- 01.r.04 Plan Sapatura Camera de Intrare Si Gratar RarDocumento1 pagina01.r.04 Plan Sapatura Camera de Intrare Si Gratar RarCretu DanNessuna valutazione finora

- Profil Hidraulic Apa, Namol Si Conducte By-PassDocumento1 paginaProfil Hidraulic Apa, Namol Si Conducte By-PassCretu DanNessuna valutazione finora

- Profil Hidraulic Apa, Namol Si Conducte By-PassDocumento1 paginaProfil Hidraulic Apa, Namol Si Conducte By-PassCretu DanNessuna valutazione finora

- Pump SpecificationDocumento6 paginePump SpecificationCretu DanNessuna valutazione finora

- 7 Drawing With Spare Parts List (2e152779)Documento1 pagina7 Drawing With Spare Parts List (2e152779)Cretu DanNessuna valutazione finora

- 7 Drawing With Spare Parts List (2e152779)Documento1 pagina7 Drawing With Spare Parts List (2e152779)Cretu DanNessuna valutazione finora

- SP Influent Armare AnvelopaDocumento1 paginaSP Influent Armare AnvelopaCretu DanNessuna valutazione finora

- Diagrama MasicaDocumento1 paginaDiagrama MasicaCretu DanNessuna valutazione finora

- CV - Spillway Penstocks BidaproDocumento6 pagineCV - Spillway Penstocks BidaproCretu DanNessuna valutazione finora

- 11 - Profile Conducte TemporareDocumento1 pagina11 - Profile Conducte TemporareCretu DanNessuna valutazione finora

- Romania 70 PDFDocumento624 pagineRomania 70 PDFCretu DanNessuna valutazione finora

- Company Name: Created By: Phone: Fax: Date:: Position Count Description Single PriceDocumento7 pagineCompany Name: Created By: Phone: Fax: Date:: Position Count Description Single PriceCretu DanNessuna valutazione finora

- I-8594 de enDocumento34 pagineI-8594 de enCretu DanNessuna valutazione finora

- Water TreatmentDocumento230 pagineWater TreatmentDaisy96% (23)

- Va 72 EngDocumento72 pagineVa 72 EngCretu DanNessuna valutazione finora

- Drinking Water Treatment MethodsDocumento9 pagineDrinking Water Treatment MethodsCretu DanNessuna valutazione finora

- Water Treatment Plant Operator Training USACEDocumento47 pagineWater Treatment Plant Operator Training USACECretu DanNessuna valutazione finora

- Mit Lab 01Documento6 pagineMit Lab 01api-247714257Nessuna valutazione finora

- Bill Invoice #1609616736Documento4 pagineBill Invoice #1609616736Anonymous BqwUQXz50% (2)

- Ranger 2015Documento135 pagineRanger 2015Tecknobites Vallenar100% (3)

- Darktrace Tech AppliancesDocumento2 pagineDarktrace Tech AppliancesnoneNessuna valutazione finora

- Regulador Avc63-4 Basler ElectricDocumento4 pagineRegulador Avc63-4 Basler ElectricJose Manuel Bautista MartinezNessuna valutazione finora

- 2012 ELECTRICAL Connectors and Harnesses - TL PDFDocumento66 pagine2012 ELECTRICAL Connectors and Harnesses - TL PDFsoftallNessuna valutazione finora

- 3G RNP Principles Nokia NSNDocumento31 pagine3G RNP Principles Nokia NSNFahmi YasserNessuna valutazione finora

- Stogra Stepper Motor ControlsDocumento24 pagineStogra Stepper Motor Controlscatalin_constantinescu100% (2)

- Cac+ Rac Submittal-A4848Documento179 pagineCac+ Rac Submittal-A4848MUBASHIRNessuna valutazione finora

- Temperature Controls K57 Series: Features and BenefitsDocumento2 pagineTemperature Controls K57 Series: Features and BenefitsmaresliviuNessuna valutazione finora

- TCM1.0E TCM2.0E: May, 2008Documento69 pagineTCM1.0E TCM2.0E: May, 2008JejeNessuna valutazione finora

- TV Sony Manual Service Kdl26m4000 Kdl32m4000 Kdl37m4000 Kdl40m4000Documento114 pagineTV Sony Manual Service Kdl26m4000 Kdl32m4000 Kdl37m4000 Kdl40m4000reinaldoNessuna valutazione finora

- Chap4 Student VersionDocumento39 pagineChap4 Student VersionAzrif MoskamNessuna valutazione finora

- 568C3 OverviewDocumento15 pagine568C3 OverviewchioutedNessuna valutazione finora

- Final Day PresentationDocumento43 pagineFinal Day Presentationswanichatterjee0Nessuna valutazione finora

- RF Based Dual Mode RobotDocumento17 pagineRF Based Dual Mode Robotshuhaibasharaf100% (2)

- Precision Micropower, Low Dropout Voltage References: Nominal Output Number Voltage (V)Documento24 paginePrecision Micropower, Low Dropout Voltage References: Nominal Output Number Voltage (V)Jorge Centeno RamosNessuna valutazione finora

- Spesifikasi Evis Exera III - Endoscopy SetDocumento3 pagineSpesifikasi Evis Exera III - Endoscopy SetYudhis RamlanNessuna valutazione finora

- Ieee Base CT PT Sizing For Substation Excel Sheet - Google SearchDocumento2 pagineIeee Base CT PT Sizing For Substation Excel Sheet - Google SearchUjjal ChakmaNessuna valutazione finora

- FSP180 60savDocumento1 paginaFSP180 60savlth126Nessuna valutazione finora

- Resume 1 Page RamDocumento1 paginaResume 1 Page RamRamnarayan ShreyasNessuna valutazione finora

- RSL Cbta Plan: (KVB) (Teknologi Elektronik Etn 102)Documento3 pagineRSL Cbta Plan: (KVB) (Teknologi Elektronik Etn 102)Ha Lim HasanNessuna valutazione finora

- ARM7Documento36 pagineARM7Yogesh SutharNessuna valutazione finora

- 171001Documento2 pagine171001vishalsanziraNessuna valutazione finora

- Qualcomm Client Interview Question - Downlaod VLSI FOR ALLDocumento18 pagineQualcomm Client Interview Question - Downlaod VLSI FOR ALLPrajwal SNessuna valutazione finora

- Fuzzy Logic Controller Design and Implementation For Industrial ApplicationsDocumento6 pagineFuzzy Logic Controller Design and Implementation For Industrial ApplicationsBodoShowNessuna valutazione finora

- A Unified Control and Power Management Scheme For PV-Battery-Based Hybrid Microgrids For Both Grid-Connected and Islanded ModesDocumento11 pagineA Unified Control and Power Management Scheme For PV-Battery-Based Hybrid Microgrids For Both Grid-Connected and Islanded ModesBHARADWAJ CHIVUKULANessuna valutazione finora

- Instuments Types With ExamplesDocumento9 pagineInstuments Types With ExamplesAmmar KhalidNessuna valutazione finora

- Review of Modern Field Effect Transistor Technologie1Documento8 pagineReview of Modern Field Effect Transistor Technologie1G ManNessuna valutazione finora

- SR - N O. Option1 Option2 Option3 Option4 Answ ErDocumento17 pagineSR - N O. Option1 Option2 Option3 Option4 Answ ErChhavi ChawlaNessuna valutazione finora