Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Potato Cold Storage Load Calculations

Caricato da

SamiYousifCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Potato Cold Storage Load Calculations

Caricato da

SamiYousifCopyright:

Formati disponibili

Potatoes moving on a

conveyor in a cold storage

Potato Cold Storage Load Calculations

per NHB Standard 01:2010

By Ramesh Paranjpey

Technical Advisor & Consultant, Pune

Introduction

NHB Standard 01:2010 gives a summary of cooling load

calculation (on page 40) for

1. 5-A: Loading and temperature pull down to 150C per chamber.

2. 5-B: During pull down to +30C at the rate of 0.50C per day fully

loaded per chamber.

3. 5-C: During holding period at +30C fully loaded per chamber.

Pages 38 and 39 of the Standard give the assumptions for a

5000MT potato cold storage and suggest typical chamber layout.

The refrigeration load is maximum during loading and pull

down to 150C for 1000 bags/day of potatoes, each weighing 50

kg, totaling 50 tons/day per chamber (4% of 1250 tons), and

the cooling load indicated is 85.32 kW or 24.37 TR per chamber.

Detailed calculations arriving at these values are not given in the

Standard.

The subsidy format given on page 29 of the Standard demands

the load calculation summary during pull down and holding

period for each new cold storage planned, and the customer or

contractor needs to engage a refrigeration consultant to calculate

cooling loads in order to fill up the form.

This article has, therefore, been prepared giving detailed

load calculations to make it easy for the contractor or end user to

calculate the cooling load himself. This would also help to calculate

the refrigeration load for any other commodity with different

conditions and parameters like room size, storage capacity and

insulation type for positive temperature cold storages.

For presenting the load calculations, the assumptions

m e n t i o n e d o n p a g e 3 8 o f t h e S t a n d a rd h ave b e e n

considered.

Assumptions

1. Product: Potatoes

2. Location: Uttar Pradesh

3. Outside temperature: +45 0 C maximum DB, +30 0 C WB

(1130F/860F)

4. Product loading temperature: 200C-250C maximum

5. Weight of each bag: 50 kg (110 lbs)

6. Total storage capacity: 5000 metric ton

7. Each room storage: 1250 ton (1250x3.4 = 4250m3)

8. Chamber size (each): 21m Lx16m Wx13.7m H (volume = 4603

m3, floor area = 226 sq m)

9. Loading rate: 4% of total capacity/day = 1250x0.4 = 50 ton or

50000 kg/day

10. Pull down time: 150C in 24 hrs

11. Compressor running hours: 20 hrs/day during pull down

12. Ventilation requirements: 2 to 6 air changes per day (page 4-2-h)

About the Author

Ramesh Paranjpey is a mechanical engineer with an M.Tech in refrigeration

from IIT Bombay with over 35 years experience. He has worked in

very senior positions starting with Kirloskar Pneumatic in Pune, Carrier

Transicold in Bangalore and Singapore as well as Voltas-Air International Pune.

Presently, he works for himself as a technical advisor and consultant. He is

an ASHRAE Fellow, past president ASHRAE W.I. chapter and past president

ISHRAE Pune chapter. He can be contacted at ramesh.paranjpey@gmail.com

Cold Chain d November - December 2014C21

21

Potato Cold Storage Load Calculations per NHB Standard 01:2010

13. Insulation: PUF (32 kg/m3 density, K value = 0.023 W/m.0K =

0.16 Btu.in/h.ft2.0F (ASHRAE Refrigeration Handbook 2014,

page 24.1, Table 1). (Though the Standard mentions PUF

density of 32 kg/cm2, it is recomended that a minimum of 38

kg/cm2 be used.)

14. Thickness (walls, roof, floor): 100 mm (NHB Standard 01:2010,

page 10)

15. Specific heat of potato above freezing: 3.433 kJ/kg.K (NHB

Standard 01: 2010, page 51)

16. Heat of respiration: 18mW/kg (ASHRAE Refrigeration

Handbook 2014, page 19.22) or 18kW/ton (NHB Standard

01:2010, page 51)

17. Loading density: 3.4 m 3/metric ton = 120 cu ft/ton (NHB

Standard 01:2010, page 44)

18. Safety factor of 10% has been considered, whereas diversity

factor has not been considered

Load Calculations

For positive temperature cold storages, the major heat load

contributors are:

Heat gain through walls, roof and flooring

Product load comprising of load due to the difference in

product loading temperature and storage temperature

Respiration load, as the product continues to breathe during

storage for a considerable period

Outside air load due to ventilation requirements and infiltration

Equipment load such as air cooler fan heat gain and forklifts

Loads contributed by human beings operating inside the room

Lighting load

We shall now consider each factor for this typical NHB presented

data on page 40, and how the values have been arrived at.

Transmission Load through Walls/Roof/Floor per day

Q = U x A X TD

= 0.023/0.1 x 2 x (21x16+2x21x13.7+16x13.7) x (45-15)

= 0.23 x1663.4x30

= 11477.46 W, say 11.5 kW

Where U is overall heat transfer coefficient in W/m2.K = K/x,

K is thermal conductivity of insulation used in W/m.K and x is

insulation thickness in m,

A is the external area of each room in m2 (for the sake of

simplicity, no partition wall has been considered and each room

is treated as a separate cold room),

TD is the temperature difference between ambient condition

and cold room temperature in K,

The correct method is to calculate individual wall loads

depending on the direction each wall is facing w.r.t. the sun, and

separate temperatures for roof and flooring. However, to simplify

the calculations, we assume that all the six surfaces are exposed to

TD. This would not make much difference to the load calculation,

as the insulation has a greater influence compared to other factors.

Product Load

= 4% of 1250 ton x sp.ht. x TD

= 50000 x 3.433 kJ/kg.K x (25-15)

=1716500 (24x3600) = 19.87 kW

C22Cold Chain d

22

November - December 2014

It is assumed that the product is loaded at 250C and cooled to

15 C in 24 hours.

Respiration Load

Assuming that the remaining (1250-50 = 1200 ton or 1200000

kg) potatoes are already in store, and refrigeration load on the last

day of loading is considered, the respiration load would be:

Respiration load = 1200000x0.018 = 21600W = 21.6 kW

Total product load would be 19.87+21.6 = 41.47 kW, say 42 kW

Infiltration Load

Based on 4 air changes/day, outside enthalpy 99.173kJ/

kg at 450C DB and 300C WB, inside enthalpy 13.62 kJ/kg at 30C

and 90% RH, h = 85.553. (These values have been taken from

Psychrometric property tables for moist air.)

Amount of ventilation air for 4603 (volume of room, m3) x 4 air

changes (24x3.6) = 213 litre/second.

And using the standard formula for total heat load as 1.2 x l/s

x (h),

= 1.2x213x85.53/1000 = 21.86 kW. With 70% recovery, it would

be 15.3 kW

Internal Load due to Fan Motors

Assuming 4 coolers per room, each with 2 fans of 0.75 kW, total

motor power is 6 kW. Power contributed to heat load at the rate of

993W per motor = 8x0.933 = 7.94 kW

Lighting Load

At 10 W/sq m during loading = 336 sq ft floor area x10 W/1000

= 3.6 kW

Occupancy Load

Assuming 4 persons working inside the cold room during

loading, each person would be contributing 250 W. Total

occupancy load = 250 Wx4 = 1 kW

Total Internal Load = 7.94+ 3.6 + 1 = 12.54 kW

Total Load = Transmission+ product + infiltration + fan motor

+ lighting + occupancy

= 11.5+42+15.3+12.54 = 81.34 kW x 1.1 safety factor = 89.474

kW per chamber

0

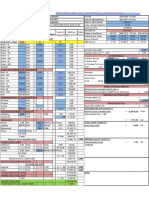

Table 1: Refrigeration load summary per chamber, each of 1250 ton storage capacity

S.

No.

1

2

3

Description

Transmission load

Product load

Internal load

Infiltration and

ventilation air load

Equipment load

Total load

Refrigeration Load, kW/24

hr as Per NHB Standard

01:2010, pg 40

12.12

43.16

5.25

Calculated as Above

11.5

42

4.6

16.14

15.3

8.65

7.94

81.34x1.1 safety

factor = 89.474 kW

85.32 (24.37 TR)

Considering the compressor running time of 20 hours, the

total capacity required would be 89.474x24/20 = 107.36 kW per

room. The Standard is for 5000 tons with 4 rooms. Hence, total

plant capacity required during loading is 429.47 kW.

Refrigeration system capacity recommended in NHB Standard

01:2010 at +20C SST and 380C SCT is 234.85x2 = 469.7 kW (page 42-6-ii).

Since it is a normal practice in India to hold potatoes for

considerable duration in storage, and the holding load

mentioned in the Standard (page 41) is 32.93kWx4 = 131.72

kW, I recommend selecting one compressor to meet the holding

load and a second compressor to meet the initial loading and

pull down load of 297.75 kW (429.47-131.72 = 297.75) instead of

selecting two compressors of equal capacity. Running one base

compressor at full load and the second with variable capacity

depending on the load, with capacity control arrangement

of either cylinder unloading or VFD, would give better power

savings compared to two compressors of equal capacity.

Conclusion

Depending upon individual requirements, the assumptions

to carry out heat load calculations would change, but the

methodology and formulae would remain the same. The user

would now be confident to carry out heat load calculations. It is,

however, recommended that the person using the above formulas

is reasonably competent and familiar with the basics of refrigeration.

The temptation to present calculations in a ready to use excel

format has been purposely avoided as it is my experience that the

use of software is dangerous unless one knows the methodology of calculating with formulae. Once this is mastered, in order

to reduce the calculation time one may use software or an excel

spreadsheet. Not knowing the basics and using ready to use tools

can lead to serious errors, which the user would remain ignorant

v

of till a problem occurs.

Post-Harvest Ripening of Banana and Other Fruits

continued from page 14

Table 1: Fruit pulp temperature (C)

Ripening Schedule

4 days

5 days

6 days

7 days

8 days

First

18 ethylene

16.5 ethylene

16.5 ethylene

15.5 ethylene

14.5 ethylene

Second

18

16.5

16.5

15.5

14.5

Third

16.5

16.5

15.5

15.5

14.5

Days in the ripening room

Fourth

Fifth

Sixth

15.5

Store at 14.5

16.5

16.5

Store at 14.5

15.5

15.5

14.5

15.5

15.5

14.5

14.5

14.5

14.5

determined visually or with a pair of calipers. Individual fingers

should be between light three-quarter and full three-quarter

size. Over-sized fruit ripens rapidly and should be handled with

great care because the peel can easily split during handling, while

under-sized fruit will not ripen normally.

After determining the maturity, pallets are placed in the

ripening room and the air circulation system turned on. The

fruit is heated or cooled to the desired ripening temperature

(14C-18C; do not exceed 20C pulp temperature during the

ripening cycle). Temperature controls the rate of ripening and

high temperatures will result in green ripening, i.e. softening

of the pulp without de-greening of the peel. As soon as the

pulp has reached the set temperature, ethylene is introduced

into the ripening room with an ethylene generator or bottled

ethylene to maintain the levels at 100 ppm for a duration of 24

hours. After ethylene treatment, the room should be vented to

get rid of excess ethylene and CO2. Thereafter, the rooms should

be vented at least twice per day for 20 minutes or continuously

with exhaust fans to keep the CO2 levels below 1%. CO2 levels

above 1% will inhibit the ripening process.

The fruit should be kept at the required temperature until

it has reached the desired stage of ripeness (firmness). Pulp

temperatures must be recorded throughout the room on a

daily basis and the relative humidity should be kept at 90-95%

throughout the ripening cycle. Once the fruit has reached the

desired ripeness, it should be cooled down to 14C to slow down

ripening, and placed in a cold store at 14C. Ripened fruit are

less prone to chilling injury than unripe fruit. Further ripening

after storage can be controlled by time and temperature. The

Seventh

Eighth

Ninth

Store at 14.5

14.5

14.5

Store at 14.5

14.5

14.5

higher the pulp temperature, the shorter is the time required

to reach eat ripeness. The pulp temperature should never be

allowed to rise above 20C during ripening. Please see Table 1.

Uneven Ripening

Uneven ripening in a box, pallet or load is a common

problem encountered in fruit that is ripened after harvesting.

The most common causes of uneven ripening are improper

ripening techniques, insufficient ethylene levels, incorrect

exposure time, incorrect ripening temperature, RH below

90%, temperatures above 21C during ripening, improper air

circulation, excessive holding periods before the start of the

ripening cycle, variable fruit age, variable fruit maturity, wide

variations in pulp temperature upon arrival at the ripening

room, exposure to temperatures below 12C prior to ripening

and exposure to extreme high temperatures prior to ripening

(heat damage).

Conclusion

Fruit ripening chambers are proliferating throughout

the country as the fruit handler community has realized the

importance of deploying a scientific method for ripening in a

cold room, exercising control over temperature, RH and gas

levels of ethylene, CO2 and oxygen. A revolution has taken place

in this sector during last the five years, as ripening chambers

have reached even the smallest villages and farms. Refrigeration

engineers play an important role in setting up these facilities.

This sector has a vast potential for rural employment

generation. National Horticulture Board (NHB) offers handsome

incentives for setting up ripening and cold preservation chambers

v

for all fruits and vegetables and other agricultural produce.

Cold Chain d November - December 2014C23

23

Potrebbero piacerti anche

- Cold Room Heat Load CalculationDocumento10 pagineCold Room Heat Load CalculationCd LictawaNessuna valutazione finora

- Refrigeration Heat Load EstimatingDocumento17 pagineRefrigeration Heat Load EstimatingAnonymous 1gbsuaafddNessuna valutazione finora

- Heat Load CalculationDocumento7 pagineHeat Load CalculationAnthony MacalindongNessuna valutazione finora

- Cold StorageDocumento13 pagineCold StorageChandresh Chaudhari100% (1)

- Design of Cold Storage Structure For Thousand PDFDocumento8 pagineDesign of Cold Storage Structure For Thousand PDFzhyhhNessuna valutazione finora

- Cooling Load CalculationDocumento14 pagineCooling Load CalculationVũ Hằng PhươngNessuna valutazione finora

- Cold StorageDocumento28 pagineCold StorageparasuramanNessuna valutazione finora

- DR ApichitDocumento139 pagineDR ApichitMuh. Yousuf KhanNessuna valutazione finora

- Dehumidification 1Documento24 pagineDehumidification 1Praveenkumar KashyabNessuna valutazione finora

- Product Heat Load CalculatorDocumento7 pagineProduct Heat Load CalculatorNafiz JaberNessuna valutazione finora

- Design and Fabrication of An Ice Cube Making MachineDocumento7 pagineDesign and Fabrication of An Ice Cube Making MachineJunjun AguirreNessuna valutazione finora

- Cold Storage DesignDocumento30 pagineCold Storage DesignMarjohn Lucidos100% (1)

- Absorption Chiller Energy CalculationsDocumento2 pagineAbsorption Chiller Energy CalculationsSarah SamuelNessuna valutazione finora

- Cooltech Prsentation - May 2016Documento12 pagineCooltech Prsentation - May 2016Cooltech ApplicationsNessuna valutazione finora

- Hybrid Cooling TowerDocumento12 pagineHybrid Cooling TowerANIMESH JAINNessuna valutazione finora

- Cooling Load Calculation DetailDocumento2 pagineCooling Load Calculation DetailNikita SinhaNessuna valutazione finora

- Design Calculation Sheet: Laundry AreaDocumento4 pagineDesign Calculation Sheet: Laundry AreaAbdelfatah NewishyNessuna valutazione finora

- An Assignment of Principles of Food Preservation and Processing Submitted by - Roll No.Documento17 pagineAn Assignment of Principles of Food Preservation and Processing Submitted by - Roll No.Keshav SharmaNessuna valutazione finora

- Ice Plant ProductionDocumento8 pagineIce Plant ProductionTristan Paul Guerra Orodio100% (1)

- Cold StoreDocumento33 pagineCold StorehanyassawyNessuna valutazione finora

- Ice Plant ComputationDocumento6 pagineIce Plant ComputationGerk100% (1)

- ASHRAE KITCHEN HOOD DESIGNDocumento24 pagineASHRAE KITCHEN HOOD DESIGNDesigner ForeverNessuna valutazione finora

- Heat Load Cold StoreDocumento17 pagineHeat Load Cold StorevishyachuNessuna valutazione finora

- Design of Cold Storage For Food Products Construction AND Equipment SelectionDocumento16 pagineDesign of Cold Storage For Food Products Construction AND Equipment SelectionervaishaliNessuna valutazione finora

- Solar Powered Ice Making Plant for Low Cost ProductionDocumento9 pagineSolar Powered Ice Making Plant for Low Cost ProductionTarani AttorneyNessuna valutazione finora

- Glass Unit V Air-Conditioning Load CalculationDocumento26 pagineGlass Unit V Air-Conditioning Load CalculationASWIN KUMAR N SNessuna valutazione finora

- Hematra Cooling TowerDocumento4 pagineHematra Cooling Towerjc CincoNessuna valutazione finora

- OMT 2T Tube Ice Machine 201224 PDFDocumento10 pagineOMT 2T Tube Ice Machine 201224 PDFARISNessuna valutazione finora

- Indoor Pool Application Examples - Load CalculationDocumento4 pagineIndoor Pool Application Examples - Load CalculationfireoniceNessuna valutazione finora

- Watts Regulator Potable Water Expansion Tank Sizing ProgramDocumento5 pagineWatts Regulator Potable Water Expansion Tank Sizing ProgramJohn ANessuna valutazione finora

- Cold Storage SheetDocumento15 pagineCold Storage SheetamitbslpawarNessuna valutazione finora

- Calculating cooling load for a battery roomDocumento2 pagineCalculating cooling load for a battery roomMohammed IqbalNessuna valutazione finora

- Design For A Cold Storage and Ice Plant 1907 PDFDocumento30 pagineDesign For A Cold Storage and Ice Plant 1907 PDFMark PamularNessuna valutazione finora

- Abstract Design of VRF SystemDocumento3 pagineAbstract Design of VRF Systemlevaka_vinay463Nessuna valutazione finora

- Hvac Rpoblems NewDocumento20 pagineHvac Rpoblems NewGrace Joy CariNessuna valutazione finora

- Basic Data SheetDocumento15 pagineBasic Data Sheeterkamlakar2234Nessuna valutazione finora

- Cooling TowersDocumento10 pagineCooling TowersAvipsita DasNessuna valutazione finora

- Tube Ice Machine TB30TDocumento5 pagineTube Ice Machine TB30TWisermenNessuna valutazione finora

- Technical Data Sheet R32 ENGLISHDocumento6 pagineTechnical Data Sheet R32 ENGLISHreddy PrasadNessuna valutazione finora

- Swiming Pool HeatingDocumento3 pagineSwiming Pool HeatingCharitha RanwalaNessuna valutazione finora

- HVAC Long Year Maintenance Plan - Status - 12 March 2013Documento12 pagineHVAC Long Year Maintenance Plan - Status - 12 March 2013haskenNessuna valutazione finora

- Experiment No. 1Documento4 pagineExperiment No. 1subhamgupta7495100% (1)

- Diesel Generator Tank CapacityDocumento1 paginaDiesel Generator Tank CapacityHamdy AdelNessuna valutazione finora

- Refridgeration and AC SystemsDocumento22 pagineRefridgeration and AC SystemsApurva ArniNessuna valutazione finora

- Proposed Design of a 30-Ton Ice PlantDocumento8 pagineProposed Design of a 30-Ton Ice Planteafz111Nessuna valutazione finora

- Quality of Refrigerant ThermodynamicsDocumento8 pagineQuality of Refrigerant ThermodynamicsPokemon BhalooNessuna valutazione finora

- Chap 4 - REFRIGERATION CYCLE - Oct 2015Documento58 pagineChap 4 - REFRIGERATION CYCLE - Oct 2015FaizMuhamadZain50% (2)

- Stand Alone Restaurant's Kitchen Ventilation PDFDocumento1 paginaStand Alone Restaurant's Kitchen Ventilation PDFSudhir KulkarniNessuna valutazione finora

- 03-2 PSME Code On Fire ProtectionDocumento23 pagine03-2 PSME Code On Fire ProtectionDessa GuditoNessuna valutazione finora

- Cooling Load Pasig GymnasiumDocumento62 pagineCooling Load Pasig GymnasiumHenry San PedroNessuna valutazione finora

- Project For Cold Storage UnitsDocumento26 pagineProject For Cold Storage Unitsniteen_mulmule485Nessuna valutazione finora

- Questions STPDocumento22 pagineQuestions STPRabindra SinghNessuna valutazione finora

- Liquid Overfeed Systems by R. P. ParanjpeyDocumento15 pagineLiquid Overfeed Systems by R. P. Paranjpeyurp30234Nessuna valutazione finora

- BDB Dimension DetailsDocumento1 paginaBDB Dimension DetailsMohsin ShaikhNessuna valutazione finora

- Additional Formula For Machine DesignDocumento3 pagineAdditional Formula For Machine Designuserako21Nessuna valutazione finora

- Heat Load CalculationsDocumento35 pagineHeat Load CalculationsAbiodun Ilori100% (1)

- Me 162Documento48 pagineMe 162Bill Cipher100% (1)

- Psychrometric Problems Air Conditioning System DesignDocumento11 paginePsychrometric Problems Air Conditioning System DesignSaurabh SharmaNessuna valutazione finora

- Potato Cold Storage Load Calculations PDFDocumento3 paginePotato Cold Storage Load Calculations PDFShort Term CourseNessuna valutazione finora

- TFP110 08 2018Documento6 pagineTFP110 08 2018SamiYousifNessuna valutazione finora

- BoosterPump IS6060 PDFDocumento12 pagineBoosterPump IS6060 PDFSamiYousifNessuna valutazione finora

- 052104Documento6 pagine052104SamiYousifNessuna valutazione finora

- TFP Fire Products Catalog 02 19Documento6 pagineTFP Fire Products Catalog 02 19SamiYousifNessuna valutazione finora

- Turf Irrigation DesignDocumento7 pagineTurf Irrigation DesignSamiYousifNessuna valutazione finora

- Five Topmost Over-Engineered Building ComponentsDocumento15 pagineFive Topmost Over-Engineered Building ComponentsSneha PatilNessuna valutazione finora

- Most Over Engineered Building ComponentsDocumento4 pagineMost Over Engineered Building ComponentsSamiYousifNessuna valutazione finora

- Sta-Rite Intelliboost R Series: Multi-Stage Variable Frequency Drive Booster PumpDocumento2 pagineSta-Rite Intelliboost R Series: Multi-Stage Variable Frequency Drive Booster PumpSamiYousifNessuna valutazione finora

- TFP Fire Products Catalog - 02 19 PDFDocumento112 pagineTFP Fire Products Catalog - 02 19 PDFSamiYousifNessuna valutazione finora

- Sizing Pressure Tank - FinalDocumento5 pagineSizing Pressure Tank - Finalvineeth8624Nessuna valutazione finora

- FP SpecsDocumento37 pagineFP SpecsSamiYousifNessuna valutazione finora

- BoosterPump IS6060 PDFDocumento12 pagineBoosterPump IS6060 PDFSamiYousifNessuna valutazione finora

- Ger 4200 Eco Tech Considerations For CC Performance EnhancementDocumento34 pagineGer 4200 Eco Tech Considerations For CC Performance EnhancementSamiYousifNessuna valutazione finora

- MC4310!03!18 PressuriserBrochureDocumento4 pagineMC4310!03!18 PressuriserBrochureSamiYousifNessuna valutazione finora

- تكنولوجيا الإتصال قضايا معاصرةDocumento7 pagineتكنولوجيا الإتصال قضايا معاصرةSamiYousifNessuna valutazione finora

- Pipe Hangers and SupportsDocumento334 paginePipe Hangers and Supportsandreiasbd100% (2)

- Sta-Rite Intelliboost R Series: Multi-Stage Variable Frequency Drive Booster PumpDocumento2 pagineSta-Rite Intelliboost R Series: Multi-Stage Variable Frequency Drive Booster PumpSamiYousifNessuna valutazione finora

- 45Documento13 pagine45SamiYousifNessuna valutazione finora

- 英文版 PDFDocumento13 pagine英文版 PDFSeverina MallariNessuna valutazione finora

- Fire, Smoke and Control Dampers: Manual - Maintenance, Testing and Inspection RecommendationsDocumento8 pagineFire, Smoke and Control Dampers: Manual - Maintenance, Testing and Inspection RecommendationsSamiYousifNessuna valutazione finora

- مصادر الإسلام ـ جون سي بلرDocumento140 pagineمصادر الإسلام ـ جون سي بلرSamiYousifNessuna valutazione finora

- Ae06900 PDFDocumento7 pagineAe06900 PDFSamiYousifNessuna valutazione finora

- Indg 398Documento7 pagineIndg 398Rajesh MohananNessuna valutazione finora

- Inletair QualityDocumento17 pagineInletair Qualityprashant_mahitkar4532Nessuna valutazione finora

- 40 2013 Lendelova RAEDocumento7 pagine40 2013 Lendelova RAESamiYousifNessuna valutazione finora

- Rules and Rules of Thumb For Duct SystemsDocumento1 paginaRules and Rules of Thumb For Duct SystemssauroNessuna valutazione finora

- Snappy Ductwork Installation GuideDocumento24 pagineSnappy Ductwork Installation Guide63ragtopNessuna valutazione finora

- 10 1 1 483 4669Documento172 pagine10 1 1 483 4669SamiYousifNessuna valutazione finora

- ManualDocumento28 pagineManualSamiYousifNessuna valutazione finora

- F12 Walls CLTD.340134020Documento8 pagineF12 Walls CLTD.340134020Zubair Ahmad DarNessuna valutazione finora

- CAPE Chemistry Data BookletDocumento5 pagineCAPE Chemistry Data BookletAnvitha PanyamNessuna valutazione finora

- LeadGuitar Method 2 PDFDocumento69 pagineLeadGuitar Method 2 PDFsjlerman100% (2)

- WeatheringDocumento9 pagineWeatheringpaul machariaNessuna valutazione finora

- Exrusion 1Documento41 pagineExrusion 1UsMan ZaFarNessuna valutazione finora

- The Standard Model of Particle PhysicsDocumento95 pagineThe Standard Model of Particle PhysicsaliakouNessuna valutazione finora

- Civil Engineering 7000 MCQs - Civil Engineering QuizDocumento26 pagineCivil Engineering 7000 MCQs - Civil Engineering QuizvishalNessuna valutazione finora

- 21” Bass Reflex Cabinet Construction GuideDocumento18 pagine21” Bass Reflex Cabinet Construction GuideZaid Denie100% (1)

- BILL OF QUANTITIES FOR DABHOI-BODELI ROAD WIDENINGDocumento61 pagineBILL OF QUANTITIES FOR DABHOI-BODELI ROAD WIDENINGayman alnossaryNessuna valutazione finora

- User Guide For Auto-WEKA Version 2.2: Lars Kotthoff, Chris Thornton, Frank HutterDocumento15 pagineUser Guide For Auto-WEKA Version 2.2: Lars Kotthoff, Chris Thornton, Frank HutterS M IbrahimNessuna valutazione finora

- 320F Diagrama Hidraulico PDFDocumento2 pagine320F Diagrama Hidraulico PDFRICHARD100% (1)

- Abstract Algebra - Wikipedia PDFDocumento5 pagineAbstract Algebra - Wikipedia PDFjflksdfjlkaNessuna valutazione finora

- PGCRSM-01-BLOCK-03 Research Design ExperimentalDocumento29 paginePGCRSM-01-BLOCK-03 Research Design ExperimentalVijilan Parayil VijayanNessuna valutazione finora

- Basic Blueprint ReadingDocumento219 pagineBasic Blueprint ReadingJShearer93% (15)

- Equotip Piccolo Bambino 2 - Operating Instructions - English - HighDocumento32 pagineEquotip Piccolo Bambino 2 - Operating Instructions - English - HighRicardo Cezar VolertNessuna valutazione finora

- Indore Indira School of Career Studies: Sub: Unix Operating System By: Prof. Marie FernandesDocumento49 pagineIndore Indira School of Career Studies: Sub: Unix Operating System By: Prof. Marie FernandesMarieFernandesNessuna valutazione finora

- Mass BalanceDocumento20 pagineMass BalanceBhaskar BethiNessuna valutazione finora

- Page No 9 1-5 To 7-5-2012Documento1 paginaPage No 9 1-5 To 7-5-2012Gulam Rabbani FidaNessuna valutazione finora

- Cavendish Experiment Determines Universal Gravitational Constant GDocumento4 pagineCavendish Experiment Determines Universal Gravitational Constant GSuraj PatelNessuna valutazione finora

- Sri Mittapalli College of EngineeringDocumento41 pagineSri Mittapalli College of EngineeringbrsreddyNessuna valutazione finora

- Analyzing Java OutOfMemory Problems With IBM Heapdump FacilityDocumento10 pagineAnalyzing Java OutOfMemory Problems With IBM Heapdump FacilityNarendra ChoudaryNessuna valutazione finora

- Virtual Memory I OverviewDocumento46 pagineVirtual Memory I OverviewCao HùngNessuna valutazione finora

- Brosur Cnoptec B204Documento3 pagineBrosur Cnoptec B204Gorengan 27Nessuna valutazione finora

- (Etienne Guyon, Jean-Pierre Hulin, Luc Petit) Hydr (B-Ok - Xyz)Documento17 pagine(Etienne Guyon, Jean-Pierre Hulin, Luc Petit) Hydr (B-Ok - Xyz)Anonymous RjqSfKmINessuna valutazione finora

- Design Assumption of Relaxation Losses in Prestressing TendonsDocumento13 pagineDesign Assumption of Relaxation Losses in Prestressing Tendonsimre78_s3069Nessuna valutazione finora

- LCA Lec20-21 Thevenin-Norton 082010Documento19 pagineLCA Lec20-21 Thevenin-Norton 082010Kainat KhalidNessuna valutazione finora

- FM GPSCDocumento13 pagineFM GPSCVishal DhandhukiyaNessuna valutazione finora

- Thyristors, Triacs, DiacsDocumento5 pagineThyristors, Triacs, DiacsAnonymous n50GmJNessuna valutazione finora

- Describe How Light, Sound, and Heat Travel. Describe How The Path of Light TravelsDocumento3 pagineDescribe How Light, Sound, and Heat Travel. Describe How The Path of Light TravelsGemma Ito100% (2)

- Admmodule s1112ps Iiic 15Documento12 pagineAdmmodule s1112ps Iiic 15Lebz RicaramNessuna valutazione finora

- Stga High Resolution Strain Gauge Extensometers: FeaturesDocumento2 pagineStga High Resolution Strain Gauge Extensometers: FeaturesSoup PongsakornNessuna valutazione finora