Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

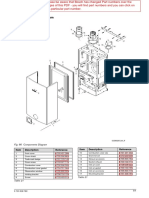

Compressor Section Components

Caricato da

Äbdur RáhmánTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Compressor Section Components

Caricato da

Äbdur RáhmánCopyright:

Formati disponibili

10/24/2015

2.3.COMPRESSORSECTION

Saturday,October24,2015

Home

News

Forum

Careers

Notes

Books

Manuals

IAMBlog

Glossary

IAMSearch

Search

2.3.COMPRESSORSECTION

Like

Share Bethefirstofyourfriendstolikethis.

2.3.1.GENERAL

Description:

The axialflow compressor section consists of the compressor rotor and the inclosing casing. Included within the

compressorcasingaretheinletguidevanes,the17stagesofrotorandstatorblading,andtheexitguidevanes.

Inthecompressor,airisconfinedtothespacebetweentherotorandstatorbladingwhereitiscompressedinstages

byaseriesofalternaterotating(rotor)andstationary(stator)airfoilshapedblades.

Therotorbladessupplytheforceneededtocompresstheairineachstageandthestatorbladesguidetheairsothatit

enters in the following rotor stage at the proper angle. The compressed air exits through the compressor discharge

casingtothecombustionchambers.Airisextractedfromthecompressorforturbinecooling,forbearingsealing,and

duringstartupforpulsationcontrol.

Sinceminimumclearancebetweenrotorandstatorprovidesbestperformanceinacompressor,partshavetobemade

andassembledveryaccurately.

CompressorSection

http://iamechatronics.com/manuals/industrialequipment/gepg9171gasturbine/55723compressorsection

1/13

10/24/2015

2.3.COMPRESSORSECTION

2.3.2.COMPRESSORROTOR

Description:

The compressor rotor is an assembly of 15 individual wheels, two stubshafts, each with an integral wheel, a speed

ring,tiebolts,andthecompressorrotorblades.

Each wheel and the wheel portion of each stubshaft has slots broached around its periphery. The rotor blades and

spacersareinsertedintotheseslotsandareheldinaxialpositionbystakingateachendoftheslot.Thewheelsand

stubshaftsareassembledtoeachotherwith

mating rabbets for concentricity control and are held together with tie bolts. Selective positioning of the wheels is

madeduringassemblytoreducebalancecorrection.Afterassembly,therotorisdynamicallybalancedtoafinelimit.

Theforwardstubshaftismachinedtoprovidetheforwardandaftthrustfacesandthejournalforthen1bearing,as

wellasthesealingsurfacesforthen1bearingoilsealsandthecompressorlowpressureairseals.

CompressorRotorLocation

http://iamechatronics.com/manuals/industrialequipment/gepg9171gasturbine/55723compressorsection

2/13

10/24/2015

2.3.COMPRESSORSECTION

2.3.3.COMPRESSORSTATOR

General:

Thestator(casing)areaofthecompressorsectioniscomposedoffourmajorsections:

inletcasing

forwardcompressorcasing

aftcompressorcasing

compressordischargecasing

Thesesections,inconjunctionwiththeturbineshellandexhaustframeformtheprimarystructureofthegasturbine.

Theysupporttherotoratthebearingpointsandconstitutetheouterwallofthegaspathannulus.

Thecasingboreismaintainedtoclosetoleranceswithrespecttotherotorbladetipsformaximumefficiency.

http://iamechatronics.com/manuals/industrialequipment/gepg9171gasturbine/55723compressorsection

3/13

10/24/2015

2.3.COMPRESSORSECTION

Inletcasing:

Theinletcasingislocatedattheforwardendofthegasturbine.

Its prime function is to uniformly direct air into the compressor. The inlet casing also supports the n 1 bearing

housing,aseparatecastingthatcontainsthen1bearing.Then1bearinghousingissupportedintheinletcasing

on machined surfaces on either side of the inner bellmouth of the lower half casing. To maintain axial and radial

alignmentwiththecompressorrotorshaft,thebearinghousingisshimmed,doweledandboltedinplaceatassembly.

The inner bellmouth is positioned to the outer bellmouth by eight airfoilshaped radial struts that provide structural

integrityfortheinletcasing.Thestrutsarecastintothebellmouthwalls.

http://iamechatronics.com/manuals/industrialequipment/gepg9171gasturbine/55723compressorsection

4/13

10/24/2015

2.3.COMPRESSORSECTION

Variableinletguidevanes:

Variableinletguidevanesarelocatedattheaftendoftheinletcasing.

The position of these vanes has an effect on the quantity of compressor air flow. Movement of these guide vanes is

accomplishedbytheinletguidevanecontrolringthatturnsindividualpiniongearsattachedtotheendofeachvane.

Thecontrolringispositionedbyahydraulic

actuatorandlinkagearmassembly.

http://iamechatronics.com/manuals/industrialequipment/gepg9171gasturbine/55723compressorsection

5/13

10/24/2015

2.3.COMPRESSORSECTION

PINIONGEARSANDCONTROLARRANGEMENTOFTHEV.I.G.V.

http://iamechatronics.com/manuals/industrialequipment/gepg9171gasturbine/55723compressorsection

6/13

10/24/2015

2.3.COMPRESSORSECTION

Forwardcasing:

The forward compressor casing contains the first four compressor stator stages. It also transfers the structural loads

from the adjoining casing to the forward support which is bolted and doweled to this compressor casing's forward

flange.

The forward compressor casing is equipped with two large integrally cast trunnions which are used to lift the gas

turbinewhenitisseparatedfromitsbase.

http://iamechatronics.com/manuals/industrialequipment/gepg9171gasturbine/55723compressorsection

7/13

10/24/2015

2.3.COMPRESSORSECTION

Aftcasing:

The aft compressor casing contains the fifth through tenth compressor stages. Extraction ports in the casing permit

removal of 5th and 11th stage compressor air. This air is used for cooling and sealing functions and is also used for

startingandshutdownpulsationcontrol.

http://iamechatronics.com/manuals/industrialequipment/gepg9171gasturbine/55723compressorsection

8/13

10/24/2015

2.3.COMPRESSORSECTION

Dischargecasing:

The compressor discharge casing is the final portion of the compressor section. It is the longest single casting. It is

situated at the midpoint between the forward and aft supports and is, in effect, the keystone of the gas turbine

structure.

Thefunctionsofthecompressordischargecasingsaretocontainthefinalsevencompressorstages,toformboththe

inner and outer walls of the compressor diffuser and to join the compressor and turbine stators. They also provide

supportforn2bearing,theforwardendofthecombustionwrapper,andtheinnersupportofthefirststageturbine

nozzle.Thecompressordischargecasingconsistsoftwocylinders,onebeingacontinuationofthecompressorcasings

and the other being an inner cylinder that surrounds the compressor rotor. The two cylinders are concentrically

positioned by twelve radial struts. These struts flair out to meet the larger diameter of the turbine shell, and are the

primaryloadbearingmembersinthisportionofthegasturbinestator.

Thesupportingstructureforthen2bearingiscontainedwithintheinnercylinder.Adiffuserisformedbythetapered

annulus between the outer cylinder and inner cylinder of the discharge casing. The diffuser converts some of the

compressorexitvelocityintoaddedpressure.

http://iamechatronics.com/manuals/industrialequipment/gepg9171gasturbine/55723compressorsection

9/13

10/24/2015

2.3.COMPRESSORSECTION

Blading:

The compressor rotor and stator blades are airfoil shaped and designed to compress air efficiently at high blade tip

velocities.Thebladesareattachedtotheirwheelsbydovetailsarrangements.

Thedovetailisverypreciseinsizeandpositionsoastomaintaineachbladeinthedesiredpositionandlocationonthe

wheel.

The compressor stator blades are airfoil shaped and are mounted by similar dovetails into ring segments. The ring

segments are inserted into circumferential grooves in the casing and are held in place with locking keys. The stator

blades of the last nine stages and two exit guide vanes have a square base dovetail that are inserted directly into

circumferentialgroovesinthecasing.Lockingkeysalsoholdtheminplace.

http://iamechatronics.com/manuals/industrialequipment/gepg9171gasturbine/55723compressorsection

10/13

10/24/2015

2.3.COMPRESSORSECTION

http://iamechatronics.com/manuals/industrialequipment/gepg9171gasturbine/55723compressorsection

11/13

10/24/2015

2.3.COMPRESSORSECTION

AboutUs

http://iamechatronics.com/manuals/industrialequipment/gepg9171gasturbine/55723compressorsection

ContactUs

12/13

10/24/2015

Promotions

...more

2.3.COMPRESSORSECTION

PartnerSites

MindanaoStateUniversityIligan

InstituteofTechnology

GasTurbineTutorial

InstrumentationTubingandtheir

Connections

OilandGasProductionHandbook

http://iamechatronics.com/manuals/industrialequipment/gepg9171gasturbine/55723compressorsection

GasTurbineTutorial

Frame9EGasTurbineTutorial

LearnAllenBradleyPLCOnline

Discla

Impor

theirre

derived

Contac

inquirie

exchan

13/13

Potrebbero piacerti anche

- Oral and Practical Review: Reflections on the Part 147 CourseDa EverandOral and Practical Review: Reflections on the Part 147 CourseNessuna valutazione finora

- Ge Frame 9e Comp & Turbine DesignDocumento26 pagineGe Frame 9e Comp & Turbine DesignMuhammad Naveed Akhtar100% (3)

- 1 GT5-8 Comp & Turbine DesignDocumento27 pagine1 GT5-8 Comp & Turbine DesignFazalur Rehman Babar100% (3)

- Comp Amp Turbine COURS 9001EDocumento27 pagineComp Amp Turbine COURS 9001Enabil160874100% (1)

- Ge Frame 9e Comp Turbine DesignDocumento26 pagineGe Frame 9e Comp Turbine Designchakib gueddoumNessuna valutazione finora

- Gas Turbine Cooling and Sealing Air System GuideDocumento2 pagineGas Turbine Cooling and Sealing Air System GuideVignesh SvNessuna valutazione finora

- Gas Turbine Engine - IntroductionDocumento16 pagineGas Turbine Engine - Introductionam_mahmoodNessuna valutazione finora

- Expressor: in Indian Railways, The Trains Normally Work On VacuumDocumento5 pagineExpressor: in Indian Railways, The Trains Normally Work On VacuumManobhiram VenkataNessuna valutazione finora

- Chapter 3 Gas TurbineDocumento120 pagineChapter 3 Gas TurbineGloria Del Carmen Muñoz100% (2)

- Duraflo 596Documento20 pagineDuraflo 596MARIOLARA1980Nessuna valutazione finora

- Gte Components LastDocumento41 pagineGte Components LastTw Carlo BeltranNessuna valutazione finora

- Refrigeration Laboratory Manual 2011Documento19 pagineRefrigeration Laboratory Manual 2011Himanshu Uniyal0% (1)

- Cooling and Sealing Air SystemsDocumento2 pagineCooling and Sealing Air SystemsnayearNessuna valutazione finora

- Ge Frame 9eDocumento22 pagineGe Frame 9eAs C100% (2)

- Compressor ExhausterDocumento4 pagineCompressor ExhausterJeeva RajNessuna valutazione finora

- Cooling & Sealing Air System DescriptionDocumento12 pagineCooling & Sealing Air System DescriptionParmeshwar Nath Tripathi100% (2)

- EX - NO:6 Dismantling of Jet Engine AimDocumento4 pagineEX - NO:6 Dismantling of Jet Engine AimesakkimuthuNessuna valutazione finora

- Screw CompressorDocumento4 pagineScrew Compressordarksun2011100% (2)

- Express orDocumento36 pagineExpress orkr_abhijeet72356587100% (1)

- Compresor Tu Flo 550Documento19 pagineCompresor Tu Flo 550ChrisContrerasNessuna valutazione finora

- CompressorsDocumento51 pagineCompressorsReza RahmanudinNessuna valutazione finora

- Gas Turbine Questions and AnswersDocumento10 pagineGas Turbine Questions and AnswersJêmš Navik100% (1)

- Mini ProjectDocumento37 pagineMini ProjectAmbati ManojNessuna valutazione finora

- UNIT 4 (G) IhpDocumento32 pagineUNIT 4 (G) Ihpsantosh alguleNessuna valutazione finora

- Siemens GT Compressor & TurbineDocumento57 pagineSiemens GT Compressor & Turbinekahar_sani100% (11)

- 4d GP One (Inlet&Comp)Documento16 pagine4d GP One (Inlet&Comp)BookMaggotNessuna valutazione finora

- GE Frame 9E Turbine Stator and Rotor ConstructionDocumento14 pagineGE Frame 9E Turbine Stator and Rotor ConstructionMohammad Ibnul Hossain100% (1)

- 07 TurbineGenDocumento56 pagine07 TurbineGenMariano DianaNessuna valutazione finora

- Screw Compressor Theory 1014Documento3 pagineScrew Compressor Theory 1014free_eagle2009100% (1)

- Gas Turbin Mark VIDocumento42 pagineGas Turbin Mark VIpradeeps2007_1777402100% (3)

- Air Compressor - Notes and QuestionnarieDocumento89 pagineAir Compressor - Notes and QuestionnariedevNessuna valutazione finora

- Compressed AirDocumento14 pagineCompressed Airkstan112233100% (2)

- Aim:-To Study Various Types of Compressors Used For Refrigeration Cycle. TheoryDocumento8 pagineAim:-To Study Various Types of Compressors Used For Refrigeration Cycle. TheoryAamer MohammedNessuna valutazione finora

- Chapter 4 - CompressorDocumento7 pagineChapter 4 - CompressorAparna RNessuna valutazione finora

- Assignment 2: Name: Levitaran A/L Sager MATRICS: A0000623 Lecture: Sir. Azni Bin MonDocumento12 pagineAssignment 2: Name: Levitaran A/L Sager MATRICS: A0000623 Lecture: Sir. Azni Bin MonlevitranNessuna valutazione finora

- Cooling and Sealing AirDocumento3 pagineCooling and Sealing AirKrishna VachaNessuna valutazione finora

- Compressore Tu-Flo 501Documento21 pagineCompressore Tu-Flo 501Sauro GordiniNessuna valutazione finora

- CLASSIFICATION of AIR COMPRESSORS An Air Compressor May Be Classified According To PressureDocumento2 pagineCLASSIFICATION of AIR COMPRESSORS An Air Compressor May Be Classified According To PressureRohit Kumar Kushwaha0% (1)

- Bendix BX 2150Documento36 pagineBendix BX 2150Marcos Valdez100% (1)

- Gas Turbine in Cairo North Power StationDocumento38 pagineGas Turbine in Cairo North Power StationAbdul Moeed Kalson0% (1)

- Scroll Compressor Simulation Model: C. Schein R. RadermacherDocumento9 pagineScroll Compressor Simulation Model: C. Schein R. Radermacherwidi_115Nessuna valutazione finora

- Basic Design: Figure 1. Reciprocating Compressor Cylinder AssemblyDocumento6 pagineBasic Design: Figure 1. Reciprocating Compressor Cylinder AssemblyradhesrikrishnaNessuna valutazione finora

- Training Report CompressoreDocumento6 pagineTraining Report CompressoreEr Raghvendra SinghNessuna valutazione finora

- What is a Centrifugal CompressorDocumento63 pagineWhat is a Centrifugal CompressorRajneesh Patel100% (1)

- Sketch and Describe A Two-Stage Air Compressor Suitable For Marine Use Up To 30 Bar PressureDocumento4 pagineSketch and Describe A Two-Stage Air Compressor Suitable For Marine Use Up To 30 Bar PressureA NNessuna valutazione finora

- Compressor NotesDocumento7 pagineCompressor NotesVibin cvNessuna valutazione finora

- Tu-Flo 501 Compressor: Important! Please ReadDocumento23 pagineTu-Flo 501 Compressor: Important! Please ReadOdai AlsaafinNessuna valutazione finora

- PER micro project compressor typesDocumento14 paginePER micro project compressor typesshirgavepranav6Nessuna valutazione finora

- Aircraft Gas Turbine EngineDocumento11 pagineAircraft Gas Turbine Engineখালিদহাসান100% (1)

- Air Compressors and Pneumatic Control SystemsDocumento7 pagineAir Compressors and Pneumatic Control SystemsBader Shrbaji100% (2)

- BlowerDocumento54 pagineBlowerKristian HutaurukNessuna valutazione finora

- Compressors: Reciprocating Compressors Centrifugal Compressors DrivesDocumento14 pagineCompressors: Reciprocating Compressors Centrifugal Compressors Drivessteepa22Nessuna valutazione finora

- Three Axis Pnumatic Modern TrailDocumento7 pagineThree Axis Pnumatic Modern Trailsuraj dhulannavarNessuna valutazione finora

- Study of Open Type Reciprocating Compressor ManualDocumento4 pagineStudy of Open Type Reciprocating Compressor ManualMohdQasim100% (2)

- Reciprocating: CompressorDocumento12 pagineReciprocating: CompressorAkbar HartawanNessuna valutazione finora

- Air Compressor PresentationDocumento34 pagineAir Compressor PresentationBhupender Ramchandani100% (1)

- Module 2 LecDocumento16 pagineModule 2 LecABDULLA MOHAMED AHMED JASIM ASHOORNessuna valutazione finora

- Chapter No 3 Air CompressorsDocumento59 pagineChapter No 3 Air Compressorsahsan8arshad-4Nessuna valutazione finora

- 1.turbo FundamentalsDocumento35 pagine1.turbo Fundamentalsshubhaastro282750% (2)

- CV RahmanDocumento2 pagineCV RahmanÄbdur RáhmánNessuna valutazione finora

- JD - Mechanical Rotating & Pkgs - Job EngineerDocumento2 pagineJD - Mechanical Rotating & Pkgs - Job EngineerÄbdur RáhmánNessuna valutazione finora

- RECVDocumento5 pagineRECVÄbdur RáhmánNessuna valutazione finora

- Apprenticship Enrolment ProceduresDocumento4 pagineApprenticship Enrolment ProceduresJeya PrakashNessuna valutazione finora

- Mechanical Engineer Resume for Cement Plant ExperienceDocumento3 pagineMechanical Engineer Resume for Cement Plant ExperienceÄbdur RáhmánNessuna valutazione finora

- 20042409Documento13 pagine20042409waleedNessuna valutazione finora

- Maintenance Engineer Sample ResumeDocumento4 pagineMaintenance Engineer Sample ResumeÄbdur Ráhmán100% (1)

- Droop 130523160508 Phpapp01Documento4 pagineDroop 130523160508 Phpapp01Äbdur RáhmánNessuna valutazione finora

- Mechanical Engineer Resume ExampleDocumento2 pagineMechanical Engineer Resume ExampleÄbdur Ráhmán0% (1)

- Shaft Alignment: Nizwa College of TechnologyDocumento15 pagineShaft Alignment: Nizwa College of TechnologyAnonymous ffje1rpaNessuna valutazione finora

- 7c Rules ThumbDocumento5 pagine7c Rules ThumbÄbdur RáhmánNessuna valutazione finora

- Dry Low NOx Combustion For Gas TurbinesDocumento26 pagineDry Low NOx Combustion For Gas Turbinesneo2712100% (2)

- MARK V Speed Control ModeDocumento13 pagineMARK V Speed Control ModeÄbdur RáhmánNessuna valutazione finora

- Gas Turbine in Base Load With Droop Speed ControlDocumento3 pagineGas Turbine in Base Load With Droop Speed ControlÄbdur RáhmánNessuna valutazione finora

- Efficiency of Gas TurbineDocumento10 pagineEfficiency of Gas TurbineÄbdur RáhmánNessuna valutazione finora

- PLC BasicsDocumento30 paginePLC BasicsÄbdur RáhmánNessuna valutazione finora

- Compressor ThrustDocumento6 pagineCompressor ThrustÄbdur RáhmánNessuna valutazione finora

- Turbine 6faDocumento1 paginaTurbine 6faÄbdur RáhmánNessuna valutazione finora

- Turbine 6faDocumento1 paginaTurbine 6faÄbdur RáhmánNessuna valutazione finora

- EW145B Service InformationDocumento373 pagineEW145B Service Informationxzen.urlNessuna valutazione finora

- HardyDocumento3 pagineHardyMarković AlexandarNessuna valutazione finora

- C15 Engine Connecting Rod SpecsDocumento2 pagineC15 Engine Connecting Rod SpecsYubiangel Celeste Perugini Parababith100% (1)

- Air Cylinder: Female Rod End Available As Standard Rod End Styles Suitable For The Application Can Be SelectedDocumento96 pagineAir Cylinder: Female Rod End Available As Standard Rod End Styles Suitable For The Application Can Be SelectedDobos LászlóNessuna valutazione finora

- 2011 ZX-10r Race Kit ManualDocumento79 pagine2011 ZX-10r Race Kit ManualStefaan PhilipsNessuna valutazione finora

- For Intermittent Service: TEEF 3x5 For Well Servicing Performance RatingDocumento2 pagineFor Intermittent Service: TEEF 3x5 For Well Servicing Performance RatingcacaunpsNessuna valutazione finora

- By-Controls 89614 BCXLXDDocumento24 pagineBy-Controls 89614 BCXLXDWADENessuna valutazione finora

- Seal Gas SystemsDocumento2 pagineSeal Gas Systemsdonald sinananNessuna valutazione finora

- 9000 Series Transmissions: M. Neutral Torque Path-CLT 9880 Series and S 9800 Series Models (Figure 2-22)Documento10 pagine9000 Series Transmissions: M. Neutral Torque Path-CLT 9880 Series and S 9800 Series Models (Figure 2-22)amin chaabenNessuna valutazione finora

- 2506d-E15tag2 PN3078 - 1Documento5 pagine2506d-E15tag2 PN3078 - 1Md ShNessuna valutazione finora

- Internal Combustion Engines: Turbo ChargersDocumento15 pagineInternal Combustion Engines: Turbo ChargersMuhammad SaqibNessuna valutazione finora

- 1971 Chevy Overhaul ManualDocumento505 pagine1971 Chevy Overhaul ManualCharlie Moretti100% (1)

- Data TWD1643 GEDocumento17 pagineData TWD1643 GEVolvo Truck100% (3)

- Assenbly EW145BDocumento20 pagineAssenbly EW145Bសុខ ប៊ុនណារ៉ង់Nessuna valutazione finora

- Electrico 416 CDocumento2 pagineElectrico 416 COswaldo Andrade100% (2)

- Catalogue Pièces de Rechange Spare Parts Catalogue: Ref: 15 18 311 0FDocumento17 pagineCatalogue Pièces de Rechange Spare Parts Catalogue: Ref: 15 18 311 0Ffird100% (1)

- ELECTROFRENODocumento56 pagineELECTROFRENOPablo Emilio Arguello AlfaroNessuna valutazione finora

- Hitachi Router M12VC - BD - 9292 PDFDocumento4 pagineHitachi Router M12VC - BD - 9292 PDFjimmyboy111Nessuna valutazione finora

- Toyota 4Y Motor Spec - MotorpowerDocumento1 paginaToyota 4Y Motor Spec - MotorpowerClaudio BustosNessuna valutazione finora

- Price-List Polycab Industrial Flexible CablesDocumento3 paginePrice-List Polycab Industrial Flexible CablesVirendraDwivediNessuna valutazione finora

- Interior Components Diagram and Parts ListDocumento6 pagineInterior Components Diagram and Parts ListSoluciones Tecnicas GastronomicasNessuna valutazione finora

- Bevel and Worm Gear Force AnalysisDocumento3 pagineBevel and Worm Gear Force Analysisangel_granadoNessuna valutazione finora

- Quo GCMDocumento11 pagineQuo GCMcost_engineerNessuna valutazione finora

- Lionrock 45 kVA LRC45X-60HzDocumento4 pagineLionrock 45 kVA LRC45X-60HzMarie Marinas-delos ReyesNessuna valutazione finora

- General MEP (BOQ & COST)Documento21 pagineGeneral MEP (BOQ & COST)Skill IndiaNessuna valutazione finora

- Senco Model L Stapler PartsDocumento4 pagineSenco Model L Stapler Partswcp4570Nessuna valutazione finora

- Posicionador Automax Apex 5000Documento2 paginePosicionador Automax Apex 5000Edwing William Salhuana MendozaNessuna valutazione finora

- M44DDocumento8 pagineM44Dfm.gruianuNessuna valutazione finora

- Operation Manual of Compression Machine 2000 KN CapacityDocumento9 pagineOperation Manual of Compression Machine 2000 KN CapacityFiker Er MarkNessuna valutazione finora

- Introduction to Power System ProtectionDa EverandIntroduction to Power System ProtectionValutazione: 5 su 5 stelle5/5 (1)

- Shorting the Grid: The Hidden Fragility of Our Electric GridDa EverandShorting the Grid: The Hidden Fragility of Our Electric GridValutazione: 4.5 su 5 stelle4.5/5 (2)

- Nuclear Energy in the 21st Century: World Nuclear University PressDa EverandNuclear Energy in the 21st Century: World Nuclear University PressValutazione: 4.5 su 5 stelle4.5/5 (3)

- Introduction to Power System ProtectionDa EverandIntroduction to Power System ProtectionNessuna valutazione finora

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesDa EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesValutazione: 4.5 su 5 stelle4.5/5 (21)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentDa EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentValutazione: 4.5 su 5 stelle4.5/5 (21)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialDa EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNessuna valutazione finora

- OFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyDa EverandOFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyNessuna valutazione finora

- Asset Integrity Management for Offshore and Onshore StructuresDa EverandAsset Integrity Management for Offshore and Onshore StructuresNessuna valutazione finora

- Renewable Energy: A Very Short IntroductionDa EverandRenewable Energy: A Very Short IntroductionValutazione: 4.5 su 5 stelle4.5/5 (12)

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successDa EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successValutazione: 4.5 su 5 stelle4.5/5 (3)

- Build Your Own Electric Vehicle, Third EditionDa EverandBuild Your Own Electric Vehicle, Third EditionValutazione: 4.5 su 5 stelle4.5/5 (3)

- The Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeDa EverandThe Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeValutazione: 4 su 5 stelle4/5 (130)

- The Grid: The Fraying Wires Between Americans and Our Energy FutureDa EverandThe Grid: The Fraying Wires Between Americans and Our Energy FutureValutazione: 3.5 su 5 stelle3.5/5 (48)

- Implementing an Integrated Management System (IMS): The strategic approachDa EverandImplementing an Integrated Management System (IMS): The strategic approachValutazione: 5 su 5 stelle5/5 (2)

- Handbook on Battery Energy Storage SystemDa EverandHandbook on Battery Energy Storage SystemValutazione: 4.5 su 5 stelle4.5/5 (2)

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideDa EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideValutazione: 2 su 5 stelle2/5 (1)

- Industrial Piping and Equipment Estimating ManualDa EverandIndustrial Piping and Equipment Estimating ManualValutazione: 5 su 5 stelle5/5 (7)

- Machine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesDa EverandMachine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesPatrick BangertValutazione: 3 su 5 stelle3/5 (2)

- The Rare Metals War: the dark side of clean energy and digital technologiesDa EverandThe Rare Metals War: the dark side of clean energy and digital technologiesValutazione: 5 su 5 stelle5/5 (2)

- ISO 50001: A strategic guide to establishing an energy management systemDa EverandISO 50001: A strategic guide to establishing an energy management systemNessuna valutazione finora

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsDa EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNessuna valutazione finora

- Pocket Guide to Flanges, Fittings, and Piping DataDa EverandPocket Guide to Flanges, Fittings, and Piping DataValutazione: 3.5 su 5 stelle3.5/5 (22)

- Solar Electricity Basics: Powering Your Home or Office with Solar EnergyDa EverandSolar Electricity Basics: Powering Your Home or Office with Solar EnergyValutazione: 5 su 5 stelle5/5 (3)

- Flow Analysis for Hydrocarbon Pipeline EngineeringDa EverandFlow Analysis for Hydrocarbon Pipeline EngineeringNessuna valutazione finora