Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Study of Characterization of (Peo+kclo4) Polymer Electrolyte System

Caricato da

esatjournalsTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Study of Characterization of (Peo+kclo4) Polymer Electrolyte System

Caricato da

esatjournalsCopyright:

Formati disponibili

IJRET: International Journal of Research in Engineering and Technology

eISSN: 2319-1163 | pISSN: 2321-7308

STUDY OF CHARACTERIZATION OF (PEO+KCLO4) POLYMER

ELECTROLYTE SYSTEM

V. Madhusudhana Reddy1, T. Sreekanth2

1

Associate Professor, Department of Science and Humanities, Malla Reddy College of Engineering and Technology,

Dhullapally, Hyderabad, Andhra Pradesh, India

2

Assistant Professor, Department of Physics, JNTUH College of Engineering, Nachupally (Kondagattu), Karimnagar

District, Andhra Pradesh, India.

Abstract

Solid state polymer electrolytes have been prepared by using poly (ethylene oxide) (PEO) and KClO4 salt in the Wt% ratios of

(90:10), (80:20) and (70:30) by solution casting technique by using methanol (water-free) as solvent. The complexation of pure

PEO with KClO4 salts has been extensively studied using IR studies. In the Differential Scanning Calorimetry (DSC) curves it

observed that, pure PEO melting temperature (Tm) slight shift towards lower temperature is due to the addition of KClO4 salt to the

polymer. XRD data for these films clearly confirm the complexation between the KClO 4 salt and the polymer PEO. The d-values

calculated from the X-ray diffraction of pure PEO and various compositions of KClO4 complexed films are clearly indicate the

complexation of PEO and KClO4.

Keywords: Polymer electrolytes, IR studies, differential scanning calorimetry, X-ray diffraction.

-----------------------------------------------------------------------***----------------------------------------------------------------------1. INTRODUCTION

2. EXPERIMENTAL

Polymer electrolytes are emerging key technology resulting

from the complexation of low-lattice energy salts with

solvating polymers, have generated over the past decade a

widespread and sustained interest with in the scientific

community [1-3]. The solid polymer electrolytes are easy to

fabricate as soft films of only a few microns and their

flexibility permits interfaces with solid electrodes, which

remain intact, when the device is in use. This makes the

application and development of all electrochemical devices

possible. In the present study, our interest is in the preparation

and characterization of polymer films. As per the literature

available, there are various methods to prepare good quality

polymer films. Some excellent reviews [4-7] are available in

the literature on the methods of preparation of good polymer

films.

Poly (ethylene oxide) (PEO) (Aldrich, M.W. 4X10 5) and

various compositions of (PEO+KClO4) polymer electrolytes

were prepared in the Wt% ratios (90:10), (80:20) and (70:30)

by solution casting technique by using methanol (water-free)

as solvent. The solutions were stirred for 15-20 hr, were cast

using polypropylene dishes, and were evaporated slowly at

room temperature. Finally, the films were dried thoroughly at

103 Torr [8]. X-ray diffraction (XRD) analyses of all the

samples were carried out by using a SIEMES / D 5000 X-ray

diffractometer (Cu K radiation = 1.5406 ). The infrared

spectrum of polymer electrolyte films was recorded on a

PERKIN ELMER FTIR spectrophotometer [Model 1605] in

the range of 450-4500 cm-1 with scans 16 cm-1 / sec. DSC (TA

2010 instrument) was used to study the melting temperatures

of the polymer electrolyte films [9].

For the past several years extensive studies have been

performed on the ionic conductivity of certain kinds of ion

containing polymers. These ion-containing polymers show a

relatively high ionic conductivity and have a potential

application as solid electrolytes. Such electrolytes have mainly

been based on the alkali metal salt systems and application to

high batteries, fuel cells etc. therefore, (PEO+KClO4) polymer

electrolytes have been prepared and its characterization has

been studied.

3. RESULTS AND DISCUSSION

3.1 IR Studies

The complexation of pure PEO with various salts has been

extensively studied using vibrational spectroscopic studies

[10].The IR spectra of pure PEO, KClO4 and PEO complexed

with KClO4 are shown in Fig.1 and the vibrational bands

observed in this system are given in the Table - 1. The

following differences in the spectral features have been

observed on comparing the spectra of complexed PEO with

pure PEO and KClO4.

__________________________________________________________________________________________

Volume: 03 Issue: 02 | Feb-2014, Available @ http://www.ijret.org

263

IJRET: International Journal of Research in Engineering and Technology

i) The intensity of the aliphatic C-H stretching

vibrational band observed around 2897.1 cm-1 in PEO

decreases with increasing concentration of KClO4 salt in

the polymer.

ii) The width of the C-O Stretching band observed

around 1095.2 cm-1 in PEO also showed an increase with

an increase of KClO4 in the polymer.

iii) Several new peaks around 4329.6, 4002.0, 2363.4

and 1280.8 cm-1 have been observed in complexed PEO.

eISSN: 2319-1163 | pISSN: 2321-7308

1807.4

1960.0

2167.1

2237.6

2355.1

2872.2

3448.1

4003.4

4329.5

The appearance of new peaks along with changes in existing

peaks (and / or their disappearance) in the IR spectra directly

indicates the complexation of KClO4 with PEO. If the cations

of KClO4 get coordinated with the ether oxygen of PEO, the

spectral changes are expected to be in the COC stretching and

deformation ranges. The decrease in the width of 1095.2 cm -1

band, which is assigned to COC symmetrical and

asymmetrical stretching [11-16], suggests the coordination /

complexation of the salt with the polymer PEO.

3.2 Differential Scanning Calorimetry (DSC)

The Differential Scanning Calorimetry (DSC) curves of pure

PEO and PEO complexed with KClO 4 for various

compositions are shown in Fig.2. An endothermic peak is

observed at 70oC, which corresponding to melting temperature

of pure PEO. The slight shift in the melting point T m, towards

lower temperature is due to the addition of KClO4 salt to the

polymer. Similar result on PEO complexed system has also

been reported by earlier workers [17-19].

Fig 1 IR Spectra (a) Pure PEO, (b) [PEO + KClO4] (80:20),

(c) [PEO + KClO4] (70:30) and (d) KClO4

Table 1 Various vibrational bands observed in the IRSpectra of pure PEO, (PEO+KClO4) Polymer electrolyte and

KClO4 salt.

Pure

PEO

Cm-1

470.6

843.9

9517

1117.7

1237.7

1279.6

1349.3

1464.9

1628.9

PEO+ KClO4

(80:20)

Cm-1

849.6

961.2

1096.4

1231.5

1278.5

1337.3

1469.0

1960.1

PEO+ KClO4

(70:30)

Cm-1

529.1

770.2

839.0

960.2

1108.6

1351.8

1595.9

3471.5

2855.7

KClO4

Cm-1

585.1

949.5

1296.2

1343.2

1396.0

1484.2

1642.8

2355.1

Fig 2 DSC Curves (a) Pure PEO, (b) [PEO + KClO4] (90:10),

(c) [PEO + KClO4] (80:20) and (d) [PEO + KClO4] (70:30)

__________________________________________________________________________________________

Volume: 03 Issue: 02 | Feb-2014, Available @ http://www.ijret.org

264

IJRET: International Journal of Research in Engineering and Technology

eISSN: 2319-1163 | pISSN: 2321-7308

Table 2 Melting temperature of PEO and (PEO+KClO4) polymer electrolyte systems obtained from DSC studies.

Polymer electrolyte

system

Pure PEO

PEO+KCIO4[90:10]

PEO+ KCIO4 [80:20]

PEO+ KCIO4 [70:30]

Melting Temperature

(Tm ) C

70

68

65

63

Table 3 The d-Values calculated from the X-RD Spectra of pure PEO and various compositions of KClO 4 complexed films.

Pure PEO

2

15.092

19.203

23.352

25.258

26.326

26.920

32.497

35.454

36.310

39.735

d

5.8657

4.6181

3.8062

3.5231

3.3825

3.3093

2.7529

2.5291

2.4721

2.2665

PEO+ KClO4 (80:20)

2

13.498

14.981

19.118

21.169

23.359

26.149

26.985

30.986

32.788

35.353

36.163

39.647

45.153

50.027

53.967

d

6.5545

5.9089

4.6385

4.1934

3.8050

3.4050

3.3014

2.8837

2.7291

2.5368

2.4818

2.2714

2.0064

1.8217

1.6976

PEO+ KClO4 (70:30)

2

11.317

14.878

17.081

19.244

21.228

23.428

25.163

26.399

27.116

27.87

35.629

36.326

39.767

45.338

4542

54.006

56.369

d

7.8123

5.9496

5.1867

4.6083

4.1820

3.7940

3.5361

3.3733

3.2858

3.1855

2.5178

2.4711

2.2648

1.9986

1.9110

1.6965

1.6309

KClO4

2

3.135

4.910

14.774

17.610

18.398

19.116

19.943

21.087

22.099

23.314

24.348

26.199

26.982

27.828

31.071

32.552

35.124

36.260

39.689

45.360

47.361

48.646

50.093

54.061

56.175

63.666

d

28.1560

17.9831

5.9910

5.0322

4.8183

4.6390

4.4485

4.2096

4.0190

3.8123

3.6527

3.3986

3.3018

3.2032

2.8759

2.7484

2.5528

2.4754

2.2691

1.9977

1.9178

1.8702

1.8195

1.6949

1.6360

1.4604

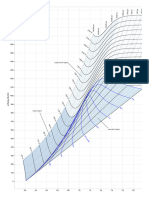

3.3 X-ray Diffraction

PEO complexation with various salts has been extensively

studied using X-ray diffraction and vibrational spectroscopic

studies [11 - 16]. The X-ray diffraction (XRD) pattern of pure

PEO, KClO4 complexed PEO and KClO4 are given in Fig. 3.2.

A comparison of the diffraction spectra of complexed PEO

with that of pure PEO and KClO 4 reveals the following

differences.

__________________________________________________________________________________________

Volume: 03 Issue: 02 | Feb-2014, Available @ http://www.ijret.org

265

IJRET: International Journal of Research in Engineering and Technology

eISSN: 2319-1163 | pISSN: 2321-7308

4. CONCLUSIONS

The IR spectra recorded in these films showed several

vibrational bands at various wave numbers. Several new

bands have appeared and some bands have disappeared in the

IR spectra of complexed films due to the addition of salts to

the polymer. The intensity of certain bands observed in

polymer showed a decrease with an increase in the

concentration of the salts added to the polymer. A decrease in

the width of certain bands has been observed due to the

addition of salts. Due to the addition of salts to the polymer,

several vibrational bands have been found to be shifted from

their positions.

DSC studies in these polymer electrolyte films have shown the

presence of an endothermic peak at 70oC which corresponds to

the melting temperature Tm of the polymer PEO. A slight shift

in the melting point, Tm towards lower temperature has been

observed due to the addition of salt to the polymer.

Fig 3 X-ray diffraction pattern (a) Pure PEO, (b) [PEO +

KClO4] (80:20), (c) [PEO + KClO4] (70:30) and (d) KClO4.

i) The diffraction peaks observed between 2 = 10o and

30o are found to be less intense in complexed PEO films

compared to pure PEO films. This indicates that the

addition of KClO4 salt to the polymer causes a decrease

in the degree of crystallinity of the polymer PEO.

ii) Peaks corresponding to the uncomplexed PEO are also

present together with that of KClO4 in complexed PEO

films showing the simultaneous presence of both

crystalline uncomplexed and complexed PEO. Earlier

workers [20 - 25] have reported similar results on PEO

complexed systems.

iii) Almost no sharp peaks were observed for higher

concentration of the KClO4 salt in the polymer,

indicating the dominant presence of an amorphous phase.

Thus, the XRD data for these films clearly confirm the

complexation between the KClO4 salt and the polymer PEO.

The d-values calculated from the X-ray diffraction of pure

PEO and various compositions of KClO4 complexed films are

given in Table - 3, which clearly indicates the complexation.

A comparison of the X-ray diffraction spectra of complexed

PEO films with that of uncomplexed PEO showed a decrease

in the intensity of the diffraction peaks in complexed films.

This is due to a decrease in the degree of crytallinity of the

polymer due to the addition of the salt, indicating the salvation

of the salt with the polymer. Peaks corresponding to the

uncomplexed PEO are also present in complexed films,

showing the simultaneous presence of both crystalline

uncomplexed and complexed PEO. Almost no sharp peaks

have been observed for higher concentrations of the added

salts, showing the dominant presence of an amorphous phase.

Thus, the results of IR, XRD and DSC have confirmed the

polymer-salt complexation.

REFERENCES

[1]. MacCallum J R and Vincent C A (ed)., Polymer

Electrolytes Review-I,2 (1987/1989) (London: Elsevier).

Bruce P G and Vincent C A., J.Chem.Soc.Faraday

Trans.89.(1993),3187.

[2]. Gray F M., Solid Polymer Electrolytes,(1991) (New

York:VCH).

[3]. Skotheim T A (ed)., Electroresponsive Molecular and

Polymeric Systems vol 1(1988) (New York: Dekker). Takeoka

S, Ohno H and Tsushida E., Polym.Adv.Technol.453, (1993).

[4]. Gregov.L.V., Physics of thin films (eds.) Hass.G. and

Thun.R.E., Vol.3(1966)144.

[5]. Jackson.G.H., Thin solid films, 5(1970)209.

[6]. Mana.E.B., and Durow.L.K., Impedance spectroscopy

Emphsizing Solid material and system, Wiley, New York

(1987).

[7]. White.J.B. and Wagner.C. Thin Solid Films18(1973)157.

[8]. B. Scrosti, Solid State Ionic Device, editted by B. V. R.

Chowdari and S. Radhakrishna (World Scientific Publishing

[9]. DSC 2010 Differential Scanning Calorimeter Operations

Manual. PN 925604.001 REWD [Text and binder],

PN925604.002 REW.D [text only], issued June 1997.

__________________________________________________________________________________________

Volume: 03 Issue: 02 | Feb-2014, Available @ http://www.ijret.org

266

IJRET: International Journal of Research in Engineering and Technology

eISSN: 2319-1163 | pISSN: 2321-7308

[10]. Maurya.K.K., Hashmi.S.A., Chandra.S., J. Phys, Jpn.

61(1992)1709.

[11]. Hashmi.S.A., Ajay Kummar, Maurya.K.K., Chandra.S, J.

Phys. D. Appl. Phys. 23 (1990) 1307.

[12]. Pake.B.L., Ratner.M.A., Shriveir.D.F., J. Electrochem.

Soc. 129 (1982) 1434.

[13]. Pake.B.L., Ratner.M.A., Shriveir.D.F., J.Phys. Chem.

Solids 42 (1981) 493.

[14]. Sreekanth.T., Jaipal Reddy.M., Subramanyam.S., Subba

Rao.U.V., Materials Science & Engineering B. 64 (1999) 107112.

[15]. Jaipal Reddy.M., Sreekanth,T., Subba Rao,U.V., Soild

State Ionics126 (1999) 55-63.

[16]. Sreekanth.T., Jaipal Reddy.M., Ramalibgaiah.S., Subba

Rao.U.V.,J. Of Power Sources 79 (1999) 105

[17]. Jian.W. and Zhiquan SHEN Polymer Journal. Vol.22

No.3 (1990) 283.

[18]. Yang.H., Huq.R. and Farrington.G.C. Sold State Ionics

40/41(1990) 663.

[19]. Yoshiki KATo, Masayoshi WATANABE, Kohci SANUI

and Naoya OGTA. Solid Statr Ionics 40/41 (1990) 632.

[20]. Prasanth Raghavan, Xiaohui Zhao, Jae-Kwang Kim,

James Manuel, Ghanshyam S.Chuhan, Jou-Hyeon Ahn,

Changwoon Nah, Electrochemica Acta 54(2008) 228.

[21]. Shahzada Ahmed, S.A.Agnihotry, Current Applied

Physics 9(2009) 110.

[22]. Sreepathi Rao.S., Jaipal Reddy.M., Laxmi Naraiah.E.

and Subba Rao. U.V., Mat. Sci & Engg. B. 33 (1995) 173.

[23]. Sreepathi Rao.S., Rao.K.V.S., Shareefyddin.MD., Subba

Rao.U.V., and Chandra .S., Solid State Ionics. 67 (1994) 331.

[24]. Maurya.K.K., Srivastava.G.C., Hashmi.S.A., and

Chandra.S., J. Mater, Sci.27(1992) 6357.

[25]. Chandra.S., Hashmi.S.A., Prasad.G.; Solid State Ionics

40/41(1999) 651.

BIOGRAPHIES

First author Dr V Madhusudhana Reddy is

working as Associate Professor in the

department of Science and Humanities at

Malla Reddy College of Engineering and

Techonology, Dhullapally, Hyderabad,

Andhra

Pradesh,

India.

(e-mail:

v.madhusudhanareddy@gmail.com)

Second author Dr T Sreekanth is working as

Assistant Professor in the department of

Physics at JNTUH College of Engineering,

Nachupally (Kondagattu), Karimnagar Dist.,

Andhra Pradesh, India.

(e-mail: srikanth2t@gmail.com)

__________________________________________________________________________________________

Volume: 03 Issue: 02 | Feb-2014, Available @ http://www.ijret.org

267

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- S406 Specifications For The Supply of Stone PDFDocumento6 pagineS406 Specifications For The Supply of Stone PDFMfanelo MbanjwaNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Ugc Model Curriculum Statistics: Submitted To The University Grants Commission in April 2001Documento101 pagineUgc Model Curriculum Statistics: Submitted To The University Grants Commission in April 2001Alok ThakkarNessuna valutazione finora

- Solution Manual For Investment Science by David LuenbergerDocumento94 pagineSolution Manual For Investment Science by David Luenbergerkoenajax96% (28)

- Analysis of Cylindrical Shell Structure With Varying Parameters PDFDocumento6 pagineAnalysis of Cylindrical Shell Structure With Varying Parameters PDFesatjournalsNessuna valutazione finora

- Analysis and Design of A Multi Compartment Central Cone Cement Storing Silo PDFDocumento7 pagineAnalysis and Design of A Multi Compartment Central Cone Cement Storing Silo PDFesatjournalsNessuna valutazione finora

- PTE 3 Week Study ScheduleDocumento3 paginePTE 3 Week Study ScheduleesatjournalsNessuna valutazione finora

- Hungr Et Al 2005 - Landslide Travel DistanceDocumento30 pagineHungr Et Al 2005 - Landslide Travel DistanceJosé Ignacio RamírezNessuna valutazione finora

- Ball Charge ManagementDocumento14 pagineBall Charge ManagementSalud Y SucesosNessuna valutazione finora

- Astm A394 2008 PDFDocumento6 pagineAstm A394 2008 PDFJavier Ricardo Romero BohorquezNessuna valutazione finora

- Analysis and Optimization of Electrodes For Improving The Performance of Ring Laser Gyro PDFDocumento4 pagineAnalysis and Optimization of Electrodes For Improving The Performance of Ring Laser Gyro PDFesatjournalsNessuna valutazione finora

- Analysis and Optimization of Sand Casting Defects With The Help of Artificial Neural Network PDFDocumento6 pagineAnalysis and Optimization of Sand Casting Defects With The Help of Artificial Neural Network PDFesatjournalsNessuna valutazione finora

- A Servey On Wireless Mesh Networking ModuleDocumento5 pagineA Servey On Wireless Mesh Networking ModuleesatjournalsNessuna valutazione finora

- A Review Paper On Smart Health Care System Using Internet of ThingsDocumento5 pagineA Review Paper On Smart Health Care System Using Internet of ThingsesatjournalsNessuna valutazione finora

- A Survey On Identification of Ranking Fraud For Mobile ApplicationsDocumento6 pagineA Survey On Identification of Ranking Fraud For Mobile ApplicationsesatjournalsNessuna valutazione finora

- A Review On Fake Biometric Detection System For Various ApplicationsDocumento4 pagineA Review On Fake Biometric Detection System For Various ApplicationsesatjournalsNessuna valutazione finora

- A Study and Survey On Various Progressive Duplicate Detection MechanismsDocumento3 pagineA Study and Survey On Various Progressive Duplicate Detection MechanismsesatjournalsNessuna valutazione finora

- A Three-Level Disposal Site Selection Criteria System For Toxic and Hazardous Wastes in The PhilippinesDocumento9 pagineA Three-Level Disposal Site Selection Criteria System For Toxic and Hazardous Wastes in The PhilippinesesatjournalsNessuna valutazione finora

- A Women Secure Mobile App For Emergency Usage (Go Safe App)Documento3 pagineA Women Secure Mobile App For Emergency Usage (Go Safe App)esatjournalsNessuna valutazione finora

- A Research On Significance of Kalman Filter-Approach As Applied in Electrical Power SystemDocumento8 pagineA Research On Significance of Kalman Filter-Approach As Applied in Electrical Power SystemesatjournalsNessuna valutazione finora

- Lab Manual of Hydraulics PDFDocumento40 pagineLab Manual of Hydraulics PDFJULIUS CESAR G. CADAONessuna valutazione finora

- A334 Carino, Patricia Andrea Assignment On ForecastingDocumento3 pagineA334 Carino, Patricia Andrea Assignment On ForecastingPatricia Andrea CariñoNessuna valutazione finora

- Permutation PolynomialsDocumento64 paginePermutation Polynomialsmestrado unbNessuna valutazione finora

- Teaching and Learning Plan (TLP) : S. P. Mandali'S Prin L. N. Welingkar Institute of Management Development & ResearchDocumento6 pagineTeaching and Learning Plan (TLP) : S. P. Mandali'S Prin L. N. Welingkar Institute of Management Development & ResearchBhagath VarenyaNessuna valutazione finora

- Ace Om 230Documento3 pagineAce Om 230michaelliu123456Nessuna valutazione finora

- Glpi Developer DocumentationDocumento112 pagineGlpi Developer Documentationvictorlage7Nessuna valutazione finora

- PLX7100A Digital Mobile C-Arm X-Ray Machine: 1. Technical SpecificationDocumento3 paginePLX7100A Digital Mobile C-Arm X-Ray Machine: 1. Technical SpecificationAbdalhakeem AlturkyNessuna valutazione finora

- Geared Motors Power Distribution: V V V VDocumento2 pagineGeared Motors Power Distribution: V V V VShamim Ahsan ParvezNessuna valutazione finora

- 23AE23 DS enDocumento4 pagine23AE23 DS enBhageerathi SahuNessuna valutazione finora

- Research and Development at The BENSON Test RigDocumento20 pagineResearch and Development at The BENSON Test RigsbktceNessuna valutazione finora

- Gauss Method - Nisan 15Documento1 paginaGauss Method - Nisan 15Otis ArmsNessuna valutazione finora

- Rr410209 High Voltage EngineeringDocumento7 pagineRr410209 High Voltage EngineeringSrinivasa Rao GNessuna valutazione finora

- Histograms - 2Documento6 pagineHistograms - 2Sonia HalepotaNessuna valutazione finora

- Numerical ModelDocumento61 pagineNumerical ModelAlbert AguileraNessuna valutazione finora

- Mollier Enthalpy Entropy Chart For Steam - US UnitsDocumento1 paginaMollier Enthalpy Entropy Chart For Steam - US Unitslin tongNessuna valutazione finora

- UNIT 10 (Using Modifiers To Describe Hobbies and Interests)Documento2 pagineUNIT 10 (Using Modifiers To Describe Hobbies and Interests)Julian Jaramillo Angel50% (2)

- Coding Assignment 18-WPS OfficeDocumento9 pagineCoding Assignment 18-WPS Officetamj tamjNessuna valutazione finora

- Mohamad Fakhari Mehrjardi - 1Documento18 pagineMohamad Fakhari Mehrjardi - 1Hilmi SanusiNessuna valutazione finora

- Instructor Guide For IntroductionDocumento174 pagineInstructor Guide For IntroductionNIRANJANNessuna valutazione finora

- 5-Canal Irrigation SystemDocumento23 pagine5-Canal Irrigation Systemwajid malikNessuna valutazione finora

- 8 Coil PWM Drivers PDFDocumento4 pagine8 Coil PWM Drivers PDFDuzng Hoang TriNessuna valutazione finora

- 新型重油催化裂化催化剂RCC 1的研究开发Documento5 pagine新型重油催化裂化催化剂RCC 1的研究开发Anca DumitruNessuna valutazione finora

- Executive Incentives and The Horizon Problem An - 1991 - Journal of AccountingDocumento39 pagineExecutive Incentives and The Horizon Problem An - 1991 - Journal of AccountingYuhan JiNessuna valutazione finora

- Full U-Band Rectangular Waveguide-to-Microstrip Transition Using E-Plane ProbeDocumento4 pagineFull U-Band Rectangular Waveguide-to-Microstrip Transition Using E-Plane ProbeSanjib MandalNessuna valutazione finora