Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

United States Patent (191: Schwabegger Et Al. (11) Patent Number: 5,437,776

Caricato da

Oscar Sobrados0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

24 visualizzazioni4 pagineThe document describes a process for reducing phosphorus content in waste water using electrolysis. Waste water flows through sedimentation basins, an activation basin, and a final sedimentation basin in a water treatment plant. Electrolysis is performed in the activation basin using metal electrodes and a direct electric current. This leads to phosphorus precipitation in an efficient and cost-effective manner, allowing over 90% reduction without adding chemicals. The phosphorus is removed with the excess sludge.

Descrizione originale:

Patente

Titolo originale

Us 5437776

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThe document describes a process for reducing phosphorus content in waste water using electrolysis. Waste water flows through sedimentation basins, an activation basin, and a final sedimentation basin in a water treatment plant. Electrolysis is performed in the activation basin using metal electrodes and a direct electric current. This leads to phosphorus precipitation in an efficient and cost-effective manner, allowing over 90% reduction without adding chemicals. The phosphorus is removed with the excess sludge.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

24 visualizzazioni4 pagineUnited States Patent (191: Schwabegger Et Al. (11) Patent Number: 5,437,776

Caricato da

Oscar SobradosThe document describes a process for reducing phosphorus content in waste water using electrolysis. Waste water flows through sedimentation basins, an activation basin, and a final sedimentation basin in a water treatment plant. Electrolysis is performed in the activation basin using metal electrodes and a direct electric current. This leads to phosphorus precipitation in an efficient and cost-effective manner, allowing over 90% reduction without adding chemicals. The phosphorus is removed with the excess sludge.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 4

US005437776A

United States Patent [191

[11] Patent Number:

[45] Date of Patent:

Schwabegger et al.

[54] PROCESS FOR REDUCING THE

FOREIGN PATENT DOCUMENTS

PHOSPHORUS CONTENT OF WASTE

WATER

52-109757 9/1977 Japan .

57-107289 7/1982 Japan .

63137795 11/1986 Japan .

[76] Inventors: Johann Schwabegger, Friensdorf 24,

Wartberg/Aist, Austria, A-4224;

2011472 7/ 1979 United Kingdom .

Rudolf Lumetzberger, Sandleiten 13,

Pregarten, Austria, A-4230

[21] App1.No.:

Jun. 30, 1993

[86] PCT No.:

PCI/AT93/00110

311 Date:

102(e) Date:

Nov. 1986.

1982.

Feb. 25, 1994

Primary Examiner-John Niebling

Feb. 25, 1994

Assistant ExaminerArun S. Phasge

Attorney, Agent, or FirmBrumbaugh Graves Donohue

& Raymond

[57]

Foreign Application Priority Data

Jun. 30, 1992 [AT]

'

English Language Dialog Abstract of JP 52-109757

Sep. 1977.

English Language Dialog Abstract of JP 57-107289 Jul.

[87] PCT Pub. 190.: wo94/0osss

PCT Pub. Date: Jan. 6, 1994

[30]

OTHER PUBLICATIONS

English Language Dialog Abstract of JP 63-137795

204,139

[22] PCT Filed:

5,437,776

Aug. 1, 1995

ABSTRACT

According to a process for lowering the phosphorus

Austria ............................... .. 1328/92

content of waste water, the waste water ?ows in a puri

?cation circuit through individual conditioning basins,

[51]

Int. Cl.6 ............................................ .. C02F 1/461

[52]

US. Cl. .................................. .. 204/149; 204/ 152;

[58]

Field of Search ...................... .. 204/149, 152, 130

204/130

[56]

References Cited

U.S. PATENT DOCUMENTS

3,971,707

4,204,925

7/ 1976 Deshpande ........................ .. 204/ 149

5/1930 Coll-Palagos ..................... .. 204/152

such as a preliminary sedimentation basin, an activation

basin, ?nal sedimentation basin or the like. In order to

reduce the phosphorus content in a rational, ecological

and ef?cient manner, the waste water is subjected to an

electrolysis in one of the conditioning basins, preferably

in the activation basin, by means of metal electrodes and

of an electric direct voltage.

8 Claims, 1 Drawing Sheet

US. Patent

Aug. 1, 1995

5,437,776

5,437,776

nary sedimentation tank 6 back to the puri?cation cycle,

PROCESS FOR REDUCING THE PHOSPHORUS

CONTENT OF WASTE WATER

The invention relates to a process for reducing the

phosphorus content of waste water, which is conducted

in a puri?cation cycle through individual treatment

tanks, such as preliminary treatment tanks, activation

tanks, ?nal sedimentation tanks, or the like.

The phosphorus and nitrogen content of the waste

water supplies the nutrient basis for an often uncon

trolled algal bloom, so that in any waste water treat

ment great attention has to be paid to reducing the

phosphorus content, since precipitation of the phospho

rus from the waste water provides a practical possibility

to in?uence the formation of algae in the natural water

bodies. So far, phosphorus and phosphates have been

precipitated from the waste water by addition of chemi

cal precipitating agents, such as iron salts or lime, this

process however on the one hand causes high costs for

the chemicals and on the other hand additionally pol

lutes the water with the chemicals.

Therefore it is the objective of the invention to re

and the treated water ?ows from the ?nal sedimentation

tank 8 through the discharge 10 into a draining ditch 11.

In the activation tank 7, metal electrodes 12, which are

connected to a direct current supply terminal 13, im

merse into the waste water, allowing an electric ?eld to

build up.

The waste water fed into the sewage treatment plant

1 reaches, after the mecanical puri?cation by a raking

and sandcatching device 5, the preliminary sedimenta

tion tank 6, where denitri?cation takes place and most

of the suspended matter settles. This primary sludge is

withdrawn together with the excess sludge returned to

the cycle from the ?nal sedimentation tank 8, from the

preliminary sedimentation tank 6 and further treated in

thickeners and digestion towers not represented. The

mecanically puri?ed and denitri?ed waste water ?ows

from the preliminary sedimentation tank 6 into the acti

vation tank 7, where it is subjected to electrolysis via

the direct voltage-carrying metal electrodes 12, which

in a rational and ef?cient way leads to a precipitation of

phosphorus. The residual part of the phosphorus and

organic matter still contained are further reduced by

move these shortcomings and to provide a process of

microorganisms in the activation tank 7, special aeration

the kind mentioned above, which in an economical and 25 devices 14 providing the appropiate oxygen supply.

also especially effective way allows a decisive reduction

The sludge-water mixture discharged from the activa

of the phosphorus content of the waste water, rendering

tion tank 7 is conducted to the ?nal sedimentation tank

super?uous to a great extent the addition of chemicals

8, in which the residual sludge settles, and the waste

for phosphorus precipitation.

water now also biologically puri?ed ?ows from the

The invention achieves this objective by subjecting 30 final sedimentation tank 8 via the discharge 10 into the

the waste water in one of the treatment tanks, prefera

draining ditch 11. The sludge from the final sedimenta

bly in the activation tank, to electrolysis, by means of

tion tank 8 is returned via the return sludge spiral pumps

metal electrodes and an electric direct voltage. The

9 each half to the preliminary sedimentation tank 6 and

building up of an electric ?eld in the waste water leads

the activation tank 7, thus being closed the sludge cycle

to chemical changes due to the electrode reactions and 35 and attained the desired degree of puri?cation. The

ion migration, which involve a surprisingly strong

excess sludge ist withdrawn, as mentioned above, to

phosphorus precipitation, the phosphorus being en

gether with the primary sludge from the preliminary

riched in the sludge and then withdrawn with the excess

sedimentation tank 6.

sludge from the puri?cation cycle. The remaining resid

ual part of the phosphorus is decomposed preferably

biologically by microorganisms in the activation tank,

Electrolysis in the process according to the invention

40 has to be performed only in a single step. Despite of

single step operation, a separation ef?ciency in excess of

so that a reduction of the phosphorus content of the

waste water to a desired extent in a non-polluting way,

90% can be achieved.

and which immerse into the waste water with a mutual

performing the electrolysis in the activation tank, the

It has proven extraordinarily ef?cient to perform

without addition of chemicals, can be guaranteed.

electrolysis in the activation tank. In this tank, there

Thus for example, in a sewage treatment plant for 45 occur simultaneously biological processes which also

about 10,000 population equivalences, electrolysis was

favour a phosphate separation. This embodiment of the

performed in the activation tank by means of two tubu

process according to the invention is based on the find

lar electrodes of stainless steel (V4A) connected to a 24

ing that electrolytical and biological processes for phos

V direct current supplying terminal, which have a

phate separation synergistically in?uence each other,

length of about 180 cm and a diameter of about 15 cm 50 leading to an intensi?ed phosphate separation. When

distance of about 50 cm, providing an approximately

90-95% reduction of the phosphorus content to a level

temperature of the activated sludge should not be too

high, in order not to destroy the bacteria present. It has

clearly below the legally established limits without

shown that the process according to the invention al

addition of precipitating agents, the electrodes having 55 lows precipitations of phosphate in excess of 90% even

to be replaced after an endurance of some weeks.

at ambient temperatures. In this embodiment of the

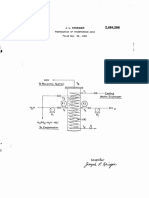

FIG. 1 is a block diagram illustrating an embodiment

process according to the invention it is possible to prac

of the invention.

tice electrolysis with a current density of less than 0,05

In FIG. 1 an embodiment of the invention is illus

A/dm2 of electrode surface at a voltage of about 24

trated in more detail.

volt. Thus the process according to the invention re

In a sewage treatment plant 1, the waste water is

subjected to a puri?cation cycle, being conducted

through an admission 2, a rain tank 3, an admission

quires an extremely low electric power consumption.

The temperature of the activated sludge (mixture of

the discharge from the preliminary sedimentation tank 6

and return sludge from the ?nal sedimentation tank 8) in

spiral pump 4, a raking and sandcatching device 5, a

preliminary sedimentation tank 6, an activation tank 7 65 the activation tank 7 should be below 45 C. External

and a ?nal sedimentation tank 8. A return sludge spiral

heating of the activated sludge in the activation tank 7

pump 9 returns the sludge from the ?nal sedimentation

to temperatures above 40 C is not necessary. Usually

tank 8 partially before and partially after the prelimi

the activated sludge ?ows from the preliminary sedi

5,437,776

mentation tank 6 with a temperature in the range of

about 4 C. (in winter) up to 25 C. (in summer).

It has shown that the phosphorus precipitation ac

cording to the invention works especially well when the

phosphorus present in the waste water is orthophos

waste Water was conducted into the draining ditch.

We claim:

phate.

1. A process for reducing the phosphate content in

waste water, which is conducted in a puri?cation cycle

through individual treatment tanks, selected from the

Another embodiment of the precipitation process

according to the invention consists in providing the

bottom and/or sides of the activation tank electrically

conductive as a cathode, and providing merely the

anode as the only electrode in the activated sludge.

group consisting of preliminary sedimentation tanks,

activation tanks, and ?nal sedimentation tanks compris

ing the steps of:

With the following example, the invention will be

providing microorganisms which decompose phos

described in greater detail:

EXAMPLE

ter mixture from the preliminary sedimentation tank

which ?owed into the activation tank.

The cleared waste water contained 0,5 mg of PO43phosphorus per liter. The COD was 37. The puri?ed

15

phates in one of said treatment tanks; and

simultaneously subjecting the waste water to electrol

ysis in said one treatment tank to precipitate phos

An embodiment of a sewage treatment plant shown in

phates.

the ?gure was used.

2. The process according to claim 1 wherein said one

The admission of liquid to be cleared to the prelimi

treatment tank is an activation tank.

nary sedimentation tank 6 was 33 m3 of waste water per 20

3. The process according to claim 1, wherein the

hour. The waste water had a pH of 7,5, a chemical

electrolysis is performed in a single step.

oxygen demand (COD) of 600 and 8 mg of P043"

4. The process according to claim 1, wherein the

phosphorus per liter. In the preliminary sedimentation

tank 6, denitri?cation took place, and primary sludge

electrolysis is performed by means of metal electrodes

and a direct current voltage.

5. The process according to claim 1 wherein the

generated was withdrawn from the cycle together with

returned excess sludge. From the preliminary sedimen

tation tank 6, sludge water, mixed with return sludge

from the ?nal sedimentation tank 8, ?owed as activated

sludge with a solid content of 5,5 g per liter and with 10

mg of POHr-phosphorus per liter to the activation tank

8. In this activated sludge (25 C.) a cathode and anode

both made of iron having an electrode surface of 0,5 m2

each were immersed. Electrolysis was performed at a

voltage of 24 V and a current intensity of 1,3 A. The 35

sludge/water mixture obtained (electrolytically treated

8. The process according to claim 7, wherein one of

the electrodes is a portion of said one treatment tank

functioning as a cathode and wherein the electrolysis

settling. In the ?nal sedimentation tank, the phosphate

the spiral pump at about 50% to the preliminary sedi

mentation tank and the residual part to the sludge/wa

7. The process according to claim 1, 2, 3, 4, 5, or 6,

wherein the electrolysis is effected by means of a pair of

electrodes and further comprising the step of maintain

ing a current density at the electrodes of less than 0.05

A/dm2 of electrode surface during the electrolysis of

the waste water.

activated sludge) was withdrawn from the activation

tank and conducted to the ?nal sedimentation tank for

containing sludge separated, being mixed afterwards by

temperature of the contents of said one treatment tankis

maintained at less than 45 C.

6. The process according to claim 1, wherein no

chemical agents are added to the contents of said one

treatment tank.

40 comprises subjecting the waste water to electrolysis

between the cathode and the other electrode.

45

55

65

Potrebbero piacerti anche

- Question Paper For DM Sewerage & Drainage Test 2Documento19 pagineQuestion Paper For DM Sewerage & Drainage Test 2Mohamed987100% (3)

- Jean-Louis Cohen - Exhibitionist Revisionism - Exposing Architectural History (September 1999)Documento10 pagineJean-Louis Cohen - Exhibitionist Revisionism - Exposing Architectural History (September 1999)Javier PerezNessuna valutazione finora

- Unit 5-People Should Manage Nature-Ts-Planning Guide-Grade 5Documento1 paginaUnit 5-People Should Manage Nature-Ts-Planning Guide-Grade 5api-457240136Nessuna valutazione finora

- Boiler Water Treatment FundamentalsDocumento8 pagineBoiler Water Treatment FundamentalssauravsinhaaNessuna valutazione finora

- 34P S4hana1909 BPD en UsDocumento18 pagine34P S4hana1909 BPD en UsBiji RoyNessuna valutazione finora

- D2 1 PDFDocumento148 pagineD2 1 PDFsubas khanalNessuna valutazione finora

- MetoxidoDocumento8 pagineMetoxidocessavelinoNessuna valutazione finora

- Ulllted States Patent (10) Patent N0.: US 7,674,380 B2Documento16 pagineUlllted States Patent (10) Patent N0.: US 7,674,380 B2mutazsalihNessuna valutazione finora

- Eletrochemical Phosphate Recovery From Nanofiltration Concentrates PDFDocumento8 pagineEletrochemical Phosphate Recovery From Nanofiltration Concentrates PDFnorfardzeraNessuna valutazione finora

- Method For Preparing Hypophosphorous Acid by Using Electrolytic MethodDocumento5 pagineMethod For Preparing Hypophosphorous Acid by Using Electrolytic MethodsenthilNessuna valutazione finora

- Mitigation of Caustic Stress Corrosion C PDFDocumento9 pagineMitigation of Caustic Stress Corrosion C PDFJean YureNessuna valutazione finora

- Aqua CatDocumento4 pagineAqua Catlonely3Nessuna valutazione finora

- 21 Century Phosphoric Acid Plant Designs (Bigger Is Better) : Page 1 of 8Documento14 pagine21 Century Phosphoric Acid Plant Designs (Bigger Is Better) : Page 1 of 8kaldjdsjkaNessuna valutazione finora

- Copper Lead Zinc Removal - Kashi BanerjeeDocumento11 pagineCopper Lead Zinc Removal - Kashi BanerjeeGeancarlo GutierrezNessuna valutazione finora

- Per Acetic AcidDocumento5 paginePer Acetic AcidMaruthi KNessuna valutazione finora

- Proceeding of The Fertilizer Industry Round TableDocumento32 pagineProceeding of The Fertilizer Industry Round TableKhánh ĐỗNessuna valutazione finora

- C 08 S 09Documento8 pagineC 08 S 09Marnel Roy MayorNessuna valutazione finora

- Phosphoric Acid Flow Sheet of Dihydrate ProcessDocumento3 paginePhosphoric Acid Flow Sheet of Dihydrate ProcessPrakash Mylar100% (1)

- July 20, 1954 J. L. Krieger 2,684,286: InventorDocumento4 pagineJuly 20, 1954 J. L. Krieger 2,684,286: InventorNurhafizah Abd JabarNessuna valutazione finora

- Process For The Production of High Purity Aromatic Carboxylic Acids Using A Benzoic Acid and Water Solvent For Oxidation and PurificationDocumento13 pagineProcess For The Production of High Purity Aromatic Carboxylic Acids Using A Benzoic Acid and Water Solvent For Oxidation and PurificationIsmail VohraNessuna valutazione finora

- Water Treatment BoilerDocumento28 pagineWater Treatment Boilermaharia_22Nessuna valutazione finora

- Calcium Phosphate Scale Formation From Simulated Milk Ultrafiltrate SolutionsDocumento8 pagineCalcium Phosphate Scale Formation From Simulated Milk Ultrafiltrate SolutionssegundosoporteNessuna valutazione finora

- United States Patent (191: (451 July 15,1975Documento6 pagineUnited States Patent (191: (451 July 15,1975ramonik08Nessuna valutazione finora

- Oxidation Ditch PerformanceDocumento15 pagineOxidation Ditch PerformanceLesly RamirezNessuna valutazione finora

- Storage: o - InzoDocumento4 pagineStorage: o - InzoOscar SobradosNessuna valutazione finora

- Calcium Phosphate RO TreatmentDocumento16 pagineCalcium Phosphate RO TreatmentVimal Girnara100% (1)

- III Sem ICTDocumento56 pagineIII Sem ICToctoviancletusNessuna valutazione finora

- Chloride RemovalDocumento12 pagineChloride Removaldilshad kapoor100% (1)

- H3PO4Documento23 pagineH3PO4Leo Edrik Cortez VidalNessuna valutazione finora

- EP0230757B1Documento15 pagineEP0230757B1niteshacharyaNessuna valutazione finora

- TEPZZ 9 9995A - T: European Patent ApplicationDocumento10 pagineTEPZZ 9 9995A - T: European Patent ApplicationAyub riyanNessuna valutazione finora

- Production of Phosphoric Acid by Dry Kiln Process: Aram NasihDocumento8 pagineProduction of Phosphoric Acid by Dry Kiln Process: Aram NasihAram Nasih MuhammadNessuna valutazione finora

- Ip ApplicationDocumento29 pagineIp Applicationjarbas juniorNessuna valutazione finora

- Prediction of Calcium Phosphate Generation and BehDocumento15 paginePrediction of Calcium Phosphate Generation and BehAdib Hossain SijanNessuna valutazione finora

- Ingles CDocumento8 pagineIngles Coscar rodriguezNessuna valutazione finora

- 16.4.1.2 Cooling Tower BlowdownDocumento4 pagine16.4.1.2 Cooling Tower BlowdownIqbalilah RamdaniNessuna valutazione finora

- Phosphate Recovery: Removal of Phosphate From Sewage As Amorphous Calcium Phosphate R.AngelDocumento20 paginePhosphate Recovery: Removal of Phosphate From Sewage As Amorphous Calcium Phosphate R.AngelHector RamírezNessuna valutazione finora

- EP88118571NWA1Documento6 pagineEP88118571NWA1Awat MuhammadNessuna valutazione finora

- US3014784Documento2 pagineUS3014784SatyamSahuNessuna valutazione finora

- Water 12 02834Documento13 pagineWater 12 02834Alvaro Huancachoque AriasNessuna valutazione finora

- Caustic RecoveryDocumento7 pagineCaustic RecoverysivachemtechNessuna valutazione finora

- Utility ManualDocumento95 pagineUtility ManualMuhammad Haris HamayunNessuna valutazione finora

- EP Corrosion PDFDocumento57 pagineEP Corrosion PDFHatem JafouraNessuna valutazione finora

- Feed Water System ComponentsDocumento11 pagineFeed Water System ComponentsBlitz XyrusNessuna valutazione finora

- ANEXO 8 US2436432 A Método para La Fabricación de Ácido Clorhídrico (18 de Mayo 1937)Documento7 pagineANEXO 8 US2436432 A Método para La Fabricación de Ácido Clorhídrico (18 de Mayo 1937)CésarSánchezRosasNessuna valutazione finora

- Salt Chlorination: Nacl, in Solution. Passing A Current Through The Solution Liberates Chlorine Ions, CLDocumento13 pagineSalt Chlorination: Nacl, in Solution. Passing A Current Through The Solution Liberates Chlorine Ions, CLFrank MtetwaNessuna valutazione finora

- JMC PDFDocumento4 pagineJMC PDFnurlianaNessuna valutazione finora

- Us 2509877Documento3 pagineUs 2509877Mary Grace VelitarioNessuna valutazione finora

- Desalination Plant: Let's Explore!Documento33 pagineDesalination Plant: Let's Explore!saqlainNessuna valutazione finora

- US4767543Documento6 pagineUS4767543Baba DookNessuna valutazione finora

- United States Patent 0: '3, l50, l74 ICCDocumento2 pagineUnited States Patent 0: '3, l50, l74 ICCMuhammadAmdadulHoqueNessuna valutazione finora

- Liquid-Liquid Copper Extraction Process Perfected ExperimentsDocumento4 pagineLiquid-Liquid Copper Extraction Process Perfected Experimentscgjp120391Nessuna valutazione finora

- Arease: Nov. 8, 1966 W. Wogt Et Al 3,284,495 Process For The Continuous Manufacture, Purification andDocumento3 pagineArease: Nov. 8, 1966 W. Wogt Et Al 3,284,495 Process For The Continuous Manufacture, Purification andRachmad HermawanNessuna valutazione finora

- Production of Phosphoric Acid by Dry Kiln Process: Prepared By: Revised byDocumento7 pagineProduction of Phosphoric Acid by Dry Kiln Process: Prepared By: Revised byAram Nasih MuhammadNessuna valutazione finora

- V41N05 357 PDFDocumento9 pagineV41N05 357 PDFAjay PatelNessuna valutazione finora

- Superphosphoric Acid by Absorption - of Phosphorus Pentoxide VaporDocumento6 pagineSuperphosphoric Acid by Absorption - of Phosphorus Pentoxide Vaporemerentiana1Nessuna valutazione finora

- Lactic Acid Determination 1Documento24 pagineLactic Acid Determination 1madads25586100% (1)

- 1985年OMI-High speed copper electroplating process and bath thereforDocumento5 pagine1985年OMI-High speed copper electroplating process and bath thereforamicjhcjyNessuna valutazione finora

- Sewage Manual CPEEHO 2Documento314 pagineSewage Manual CPEEHO 2Gokulnath MahalingamNessuna valutazione finora

- March 9, 1965 L. Mavrovic: Filed June 16, 1961Documento6 pagineMarch 9, 1965 L. Mavrovic: Filed June 16, 1961baharuNessuna valutazione finora

- Us 3229777Documento4 pagineUs 3229777Parth AggarwalNessuna valutazione finora

- Scientific American Supplement, No. 446, July 19, 1884Da EverandScientific American Supplement, No. 446, July 19, 1884Nessuna valutazione finora

- Kinetics of Wastewater Treatment: Proceedings of a Post-Conference Seminar Held at the Technical University of Denmark, Copenhagen, 1978Da EverandKinetics of Wastewater Treatment: Proceedings of a Post-Conference Seminar Held at the Technical University of Denmark, Copenhagen, 1978S. H. JenkinsNessuna valutazione finora

- Us 5380445Documento4 pagineUs 5380445Oscar SobradosNessuna valutazione finora

- Conceptual Design of Chemical ProcessesDocumento311 pagineConceptual Design of Chemical ProcessesOscar SobradosNessuna valutazione finora

- Process For Producing Granular Triple Superphosphate: F. DunbarDocumento5 pagineProcess For Producing Granular Triple Superphosphate: F. DunbarOscar SobradosNessuna valutazione finora

- Storage: o - InzoDocumento4 pagineStorage: o - InzoOscar SobradosNessuna valutazione finora

- Case AnalyzerDocumento19 pagineCase AnalyzeranuragNessuna valutazione finora

- SR Cheat Sheets PDFDocumento4 pagineSR Cheat Sheets PDFDevin ZhangNessuna valutazione finora

- Y2V7 Full With SSDocumento294 pagineY2V7 Full With SSAyanokoji KyotakaNessuna valutazione finora

- Catalogue of Palaearctic Coleoptera Vol.4 2007Documento471 pagineCatalogue of Palaearctic Coleoptera Vol.4 2007asmodeus822Nessuna valutazione finora

- Food Product Innovation PDFDocumento35 pagineFood Product Innovation PDFDidik HariadiNessuna valutazione finora

- Mrs. Saba Khan 15 Shahbad Diwan Khana, Bareilly, City, Bareilly, Bareilly, Utt AR PRADESH, 243003,9219172265Documento28 pagineMrs. Saba Khan 15 Shahbad Diwan Khana, Bareilly, City, Bareilly, Bareilly, Utt AR PRADESH, 243003,9219172265amitNessuna valutazione finora

- Sense and NonsenseDocumento263 pagineSense and NonsenseAbdulRehmanKhilji100% (1)

- Exercise On Coordination and ResponseDocumento8 pagineExercise On Coordination and ResponseNorliyana AliNessuna valutazione finora

- Chapter-Communication & NetworkingDocumento70 pagineChapter-Communication & NetworkingAfsar AhmedNessuna valutazione finora

- Lesson 5 Flight of Projectile, Air Resistance Neglected: OverviewDocumento7 pagineLesson 5 Flight of Projectile, Air Resistance Neglected: OverviewNadjer C. AdamNessuna valutazione finora

- GlobalisationDocumento8 pagineGlobalisationdummy12345Nessuna valutazione finora

- Pulsating Heat Pipe ReportDocumento65 paginePulsating Heat Pipe ReportIdul Azharul HoqueNessuna valutazione finora

- Lesson PlansDocumento12 pagineLesson Plansapi-282722668Nessuna valutazione finora

- Engineering Data: Wireway SelectionDocumento3 pagineEngineering Data: Wireway SelectionFidel Castrzzo BaeNessuna valutazione finora

- Small Scale IndustriesDocumento6 pagineSmall Scale IndustriesMangesh KadamNessuna valutazione finora

- Creating Enterprise LeadersDocumento148 pagineCreating Enterprise LeadersValuAidNessuna valutazione finora

- The Impact of Teaching PracticeDocumento14 pagineThe Impact of Teaching PracticemubarakNessuna valutazione finora

- Banana Stem Patty Pre Finale 1Documento16 pagineBanana Stem Patty Pre Finale 1Armel Barayuga86% (7)

- LGDocumento36 pagineLGNanchavisNessuna valutazione finora

- Nonlinear Robust Control of High-Speed Supercavitating Vehicle in The Vertical PlaneDocumento10 pagineNonlinear Robust Control of High-Speed Supercavitating Vehicle in The Vertical Planesamsaptak ghoshNessuna valutazione finora

- Serie10 ElecDocumento75 pagineSerie10 Elecmealier severineNessuna valutazione finora

- Culture-Partners M&A EbookDocumento12 pagineCulture-Partners M&A EbookapachemonoNessuna valutazione finora

- 1778 3557 1 SM PDFDocumento4 pagine1778 3557 1 SM PDFjulio simanjuntakNessuna valutazione finora

- Social Skills Assessments For Children With Autism Spectrum Disorders 2165 7890.1000122Documento9 pagineSocial Skills Assessments For Children With Autism Spectrum Disorders 2165 7890.1000122Shinta SeptiaNessuna valutazione finora

- Japanese Mythology: 2 Kuniumi and KamiumiDocumento12 pagineJapanese Mythology: 2 Kuniumi and KamiumipdekraaijNessuna valutazione finora

- PA SystemDocumento4 paginePA SystemSnehal DambhareNessuna valutazione finora