Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

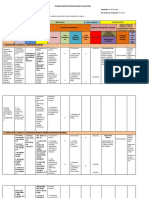

PS Unit 4 Notes

Caricato da

Ashok AmmaiyappanCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

PS Unit 4 Notes

Caricato da

Ashok AmmaiyappanCopyright:

Formati disponibili

WWW.VIDYARTHIPLUS.

COM

UNIT-4

WALLS

1.Write a detailed note on Wall system.

Walls:

Generally classified based on the function as load bearing & non load bearing walls. Eg.

partition wall. They transfer self weight only & they are provided to create barriers that

can be visual, thermal on acoustic.

Stiffening walls:

Provides 3 dimentional stiffness .The load bearing walls which are referred to as

supported walls do not posses foundation o f their own but are either carried by beams or

slabs or directly attached to load bearing walls. The supported walls can form on integral

part of structure or remain as non structural depending on stiffness.

Depending on the orientation of the main beams or load bearing walls relative to long

axis of

the building. Prefabricated wall system are classified as,

Long wall system

Cross wall system

Ring or two way system

Long wall system:

The main beams are load bearing walls are placed parallel to the long axis of building. It

is applied to the building with large prefabricates and is similar to traditional brick work

technique . The longitudinal external walls which carry the floor loads must posses not

only thermal properties but also sufficient load carrying capacity .

The long wall system construction is typical with large blocked structure and special pier

blocks between the windows which carry loads from lintel and the walls above. The

horizontal still blocks are not loaded . In some designs space between the piers is filled

by prefabricated unit consisting of RC window frame complete with window.

The internal wall blocks are normally of full storey height subject to limitations imposed

by lifting equipments available. Both internal and external walls are made of some

materiel.

Cross wall system :

Load bearing walls and beams are placed at right angles to the longitudinal axis of the

building . In this system the floor units are provided with two way structural units which

distributes the to the cross walls and this system is more prominent. The internal walls are

made of ordinary concrete for load bearing walls and the external walls and the external

walls are made of light weight

WWW.VIDYARTHIPLUS.COM

K.BALAJI . ()..,

WWW.VIDYARTHIPLUS.COM

concrete to reduce the weight of the structure. Generally the room size is nearly square in

this system.

Ring system :

Load bearing walls and beams are placed in both ways longitudinally and transversely. In

the building with the ring system of support floor are normally supported on all four

edges and span in two directions. In skeleton construction these floors are placed directly

on columns. In this system, the floor slabs are designed to span in both direction and are

loaded on to the supporting walls. For large load panels cross beams are hidden within

the thickness of the panel.

Curtain wall

All wall systems are required to resist many different forces in the provision of a suitable

separation of indoor and outdoor environments. They are required to:

have sufficient structural strength and rigidity

resist the spread of fire

be durable

control odours

control light

control sound and vibration

control heat flow

control air flow

control water vapour flow

control exterior precipitation

control solar radiation

The term curtain wall was first used to describe the outer wall of medieval

fortifications. Its use in a more contemporary sense is seen in Gothic cathedrals with their

large expanses of lightly framed glass walls between load-bearing buttresses. Today the

term curtain wall is defined in most literature to be any building wall of any material that

is designed to resist lateral loads due to wind or earthquake and its own self weight. In

other words, the curtain wall is a non-load-bearing wall.

WALL TYPES

This category for wall classification includes two generic options. Acomparison between

these two wall types is provided below.

STANDARD

Details and components designed and standardized by manufacturer

Manufacturers sell through a dealer network

WWW.VIDYARTHIPLUS.COM

K.BALAJI . ()..,

WWW.VIDYARTHIPLUS.COM

Manufacturers stock in standard lengths typically 6.5 to 8.2 m (20 to 27 ft.) in length

Standard finishes although custom finishes available

Typical frame width 50 mm (2 inches) or 63.5 mm (2 12 inches) , frame depth 75 to

150 mm (3 to 6 inches)

Manufacturers catalogue information readily available

Standard designation applies only to components not to potential arrangement of

components

CUSTOM

Details and components designed specifically for a single project or group of projects

Materials generally not available on open market but restricted to single supplier or

installer

Minimum size of project required to justify custom extrusions

Allows optimum use of material and flexibility to meet architectural requirements

Component dimensions and cross sections often architecturally distinct.

ERECTION

STICK:

Likely most common wall system especially on low-rise construction and in smaller

population centres

Each component of wall is installed piece by piece in the field. Installed with one- or

two storey mullion lengths and horizontal rails equal in length to width of the infill panels

Field labour intensive and dependent

Often utilize standard system

Minimum requirements for assembly facilities and shipping

Normally short lead time to arrive on-site, but longer erection/close-in time on-site

Difficult to accommodate in-plane movements due to sway or seismic events

UNITIZED:

Most common to large high-rise buildings although found on buildings as low as four

stories. System has grown in popularity since 1980

Large factory assembled framed units complete with spandrel panels and often with

vision lites installed. Panels typically one-storey high by width of infill panels

Panels designed for sequential installation with interlocking split vertical mullions and

nesting horizontal rails at expansion joint

Significant fabrication facility and shipping requirement. More shop labour dependant

and less field dependant than stick system

Normally longer lead time to arrive on-site, but rapid erection with minimum time to

close in building once on-site

Design potential to accommodate in-plane movements due to sway and seismic events

WWW.VIDYARTHIPLUS.COM

K.BALAJI . ()..,

WWW.VIDYARTHIPLUS.COM

Mullion and panel

Consists of grid work similar to stick system and prefabricated framed panels installed

between. Popular through the 1970s but rarely used today

Combines features of stick and unitized wall Systems

Large panel

Typically consists of steel truss type frame one storey in height by 10 to 15 m (33 to 50

feet) in length. Frame supports all of wall elements

Not as popular due to handling issues. Used on smaller specialized projects

Window wall

Consists of wall system spanning between floor slabs with slab edge cover. Almost

entirely restricted to residential applications

Framing lightweight residential type inside stop glazed. Can utilize either stick or

unitized framing. Often use older technology with inherent reliability problems.

2. What is the classification of precast large panel?

Cross wall system

Longitudinal wall system

Two-way system

3. What are types of Cross wall system?

Longitudinal wall system

Homogeneous walls

Non-Homogeneous walls

4.What is meant by box type construction?

In this system room size units are prefabricated and site. Toilet and kitchen blocks could

also be similarly prefabricated and erected at site. This system derives its stability and

stiffness from the box units which are formed by four adjacent walls. Walls are jointed to

make rigid connections among themselves. The box units rest on plinth foundation which

be of conventional type or precast.

5. Write briefly about Types of Wall Panels?

The single way of classification of precast wall panel is based on their size or the

materials of which they are made. They can be classified. According to size, as small and

large, or as narrow vertical stirrups or as broad horizontal bands. The material that are

used for precast wall panel are bricks, hollow clay blocks, normal density concrete, light

weight metal, gypsum, plastic, and timber.

6.What is the classification of precast concrete walls?

WWW.VIDYARTHIPLUS.COM

K.BALAJI . ()..,

WWW.VIDYARTHIPLUS.COM

Based on size

Based on materials used

Based on function

Based on location

Based on cross section

Based on stressing

7. Define Long Wall System?

The main beam (or) load bearing wall are placed to the long axis of building. It is applied

to the building with large prefabricated and similar to traditional brickwork. The

longitudinal wall crosses the floor load must possess not only thermal.

8. What is ring system?

Load bearing walls and beams are placed in both ways longitudinally and transversely. In

the building with ring system of support floors are normally supported on all four edges

and span is two direction. In skeleton construction these floors are placed directly on

columns.

9. Explain the behaviour of large panel construction with suitable sketches.

Large panel structure

All the main part of a building, including exterior wall and interior wall, floor slab, roofs,

and staircase, may be made up from large panel structure are used in two main design

schemes, frame-panel and panel building. In frame-panel building, all the base loads are

borne by the buildings frame, and as enclosure element. Frameless buildings are

assembled from panels that perform the load bearing and enclosing functions

simultaneously.

Large panel structure for Exterior wall

Large panel structure for Interior wall.

Large panel structure for floor slab

Large panel structure for Roof element.

a) Large panel structure for Exterior wall;

Large panel structure for exterior walls consist of panel one or two stories in

height and one or two rooms in width. The panel may be blind (without openings)

or with window or door openings.

WWW.VIDYARTHIPLUS.COM

K.BALAJI . ()..,

WWW.VIDYARTHIPLUS.COM

In terms of design, the wall panels may be single layer (solid) and multilayer(sand

witch) Solid panels are manufactured from materials that have insulating

properties and at the same time can perform supporting functions for example,

light weight concrete, cellular concrete, and hollow ceramic stone.

Sandwich wall panels are made with two or three layers: their thickness depends

on the climate conditions of the regions and the physic technical properties of the

materials used for the insulating layer and for the exterior layer.

The surface of exterior wall panels is covered with decorative mortar or is faced

with ceramic or other finishing tiles.

After assembly, the joints between panel are filled with mortar or with lightweight

or ordinary concrete and then sealed with packing and special mastics.

b) Large panel structure for Interior walls:

The large panel structure of interior walls may be non load bearing or load

bearing.

In the first case, they are made from gypsum slag concrete or from other materials

that act as enclosures. In the case of load bearing structure, the wall panels, which

combine enclosing and load bearing function, are made from heavy or lightweight,

silicate or cellular concrete, or vibration set brick or ceramic work.

The dimensions of the panels are determined by the dimensions of the rooms (in

apartment houses), their height is equal to the height of a story, the width is equal to the

depth or width of a room, and the thickness of the walls between rooms is usually 10-14

cm(between apartment 14-18 cm)

10. Write briefly about types of wall panels.

Classifications of wall panels:

Based on size:

Large

Small

Based on materials:

Bricks

Hollow clay blocks

Normal density concrete

Light-weight metal

WWW.VIDYARTHIPLUS.COM

K.BALAJI . ()..,

WWW.VIDYARTHIPLUS.COM

Gypsum

Plastic and

Timber

WALL SYSTEMS

The main types of precast concrete wall systems are as faades and interior cross-walls.

Walls can be classified as bearing and non-bearing walls. Bearing walls are used to

support bridging components like floors, roofs or beams

The connections of these systems are:

wall to wall at interior and exterior vertical joints

wall to wall at interior and exterior horizontal joints

wall to base/foundation

Non-bearing walls are normally designed to carry their dead weight, which means that

the connections at horizontal joints need to resist the weight of the wall elements above

this level of the wall. However, as an alternative, non-bearing faade walls might be fixed

to the adjacent load bearing system in such a way that the dead weight of each wall

element is supported by the main system. Prefabricated walls can be used as part of the

WWW.VIDYARTHIPLUS.COM

K.BALAJI . ()..,

WWW.VIDYARTHIPLUS.COM

stabilising system to resist horizontal loads in its own plane. In that case the prefabricated

wall should behave as one structural unit composed of interacting wall elements. This

structural interaction within the wall needs to be secured by structural connections that

resist the required shear forces, tensile forces and compressive forces.

Wall & Floor Panels

1. Thickness of wall panels ranges from 120 mm for interior walls to 300 mm for

exterior walls.

2. Floor panel thickness is 60 mm.

3. Wall panel length is equal to the room length, typically on the order of 2.7 m to

3.6 m.

4. In some cases, there are no exterior wall panels and the faade walls are made of

lightweight concrete.

WWW.VIDYARTHIPLUS.COM

K.BALAJI . ()..,

WWW.VIDYARTHIPLUS.COM

Precast interior wall panel with steel dowels and grooves

Connections for panels

1. Based on their location within a building, these connections can be classified

into vertical and horizontal joints.

2. Vertical joints connect the vertical faces of adjoining wall panels and

primarily resist vertical seismic shear forces.

3. Horizontal joints connect the horizontal faces of the adjoining wall and floor

panels and resist both gravity and seismic loads.

JOINTS AND CONNECTIONS

Joint Sealants

WWW.VIDYARTHIPLUS.COM

K.BALAJI . ()..,

WWW.VIDYARTHIPLUS.COM

Sealants were used many hundreds of years ago. The Tower of Babel was reportedly built

with mortar and tar or pitch as a sealant. Naturally occurring bitumen and asphalt

materials have been widely accepted as sealants for many centuries. 1900's most sealants

evolved from vegetable, animal, or mineral substances. The development of modern

polymeric sealants coincided with the development of the polymer industry itself,

sometime in the early 1930s.Joint sealants are used to seal joints and openings (gaps)

between two or more substrates, and is a critical component for building design and

construction. The main purpose of sealants is to prevent air, water, and other

environmental elements from entering or exiting a structure while permitting limited

movement of the substrates. Specialty sealants are used in special applications, such as

for fire stops, electrical or thermal insulation, and aircraft applications. Sealants are used

for a variety of commercial and residential applications. Common sealants include

silicone, acrylic, urethane, butyl and other polymeric types.

Various formulations have been developed over the years, which meet

performance specifications established by industry standards, as well as for the specific

and unique needs of the end user.

Typical considerations for selecting a sealant type for use in the construction industry are:

Joint Design: The specifics of a joint design must match up with a sealant's

movement capabilities for the installed conditions. The practicality of installation

of the sealant and other joint elements and the desired aesthetic appearance also

need to be considered.

Physical and Chemical Properties: Properties of the sealant such as, modulus of

elasticity, its stress/strain recovery characteristics, tear strength, and fatigue

resistance are all factors that influence sealant performance in a joint. The sealant

polymeric type along with additives such as fillers and plasticizers will affect the

performance of the product.

Durability Properties: The adhesion of a sealant to a specific substrate(s) and its

aging characteristics as they relate to resistance to among others ultra-violet

radiation, moisture, temperature, cyclic joint movement, movement during curing,

and bio-degradation can profoundly influence the service life of the installed

sealant.

WWW.VIDYARTHIPLUS.COM

K.BALAJI . ()..,

WWW.VIDYARTHIPLUS.COM

Application/Installation

Properties:

Important

considerations

include

the

consistency of the sealant (pourable or gunnable), pot life and tooling time, tack

free time, application temperature range, and low temperature "gunnability" (i.e.

ability to be dispensed easily by sealant gun). Sealants used for interior

applications, even in high-rise or light commercial structures, will have properties

and needs different from those used in other applications, such as structural sealant

glazing or exterior building facade seals.

Application

Sealants are used to seal joints and openings in various architectural applications, which

include:

High- and low-rise commercial buildings:

Exterior and interior perimeter of windows

Roofing and flashing penetrations and terminations

Building and material expansion joints

Interior perimeters of doors, baseboards, and moldings

Plazas and parking deck joints in traffic surfaces

Joints between tilt-up concrete exterior panels

Airport runway and apron pavement joints

Bridge and highway pavement joints

Sidewalks, parking lots and flat work joints

Water and wastewater treatment facility joints (including in submerged

environments)

Part of a fire and smoke stop assembly for joints and penetrations

Structural sealant glazing

WWW.VIDYARTHIPLUS.COM

K.BALAJI . ()..,

WWW.VIDYARTHIPLUS.COM

Progressive Collapse:

Concrete building structures whether, insitu or precast, is required to perform in

the event of accidental damage or explosion by meeting the design criteria set out

in BS8110 for progressive collapse.

Within the building structure, ties are incorporated to resist calculated forces determined

by a variety of factors, including:

number of stories

centres of walls / size of spans

total loads carried

These are achieved by the use of the following ties incorporated into the precast cross

wall design:

vertical ties

horizontal ties

peripheral ties

internal ties

Joints between panels are tied together using pre-shuttered insitu-fill to create a robust

joint with minimal finishing required. The joints use wire ties designed to meet the

specific tie-force criteria, but also to allow flexibility in assembly tolerances during

erection.

Peripheral and internal ties use high strength steel strand within the nominal insitu joints

at cross-wall locations and around the perimeter of the building to create a continuous tie

arrangement.

Building design is analysed for structural stability by Precast Structures consultants

who have extensive knowledge in the design stability of cross-wall building structures.

WWW.VIDYARTHIPLUS.COM

K.BALAJI . ()..,

WWW.VIDYARTHIPLUS.COM

11. Explain the use of large panel prefab systems with suitable example

WWW.VIDYARTHIPLUS.COM

K.BALAJI . ()..,

WWW.VIDYARTHIPLUS.COM

WWW.VIDYARTHIPLUS.COM

K.BALAJI . ()..,

Potrebbero piacerti anche

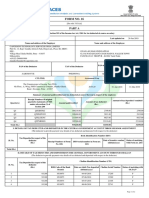

- Sowparnika Indradhanush Phase II Plan SanctionsDocumento1 paginaSowparnika Indradhanush Phase II Plan SanctionsAshok AmmaiyappanNessuna valutazione finora

- Sowparnika Indradhanush Phase II Plan SanctionsDocumento1 paginaSowparnika Indradhanush Phase II Plan SanctionsAshok AmmaiyappanNessuna valutazione finora

- PG - M.B.A Project Management - Project Management - 332 33 Project Formulation and Appraisal - 6119Documento166 paginePG - M.B.A Project Management - Project Management - 332 33 Project Formulation and Appraisal - 6119Ashok AmmaiyappanNessuna valutazione finora

- Otechnical Engg (WWW - Gatenotes.in)Documento183 pagineOtechnical Engg (WWW - Gatenotes.in)Ashok AmmaiyappanNessuna valutazione finora

- Specifications AminitiesDocumento3 pagineSpecifications AminitiesAshok AmmaiyappanNessuna valutazione finora

- Ebrochure JRstrrenclaveDocumento8 pagineEbrochure JRstrrenclaveAshok AmmaiyappanNessuna valutazione finora

- Sowparnika Indradhanush Phase II BrochureDocumento27 pagineSowparnika Indradhanush Phase II BrochureAshok AmmaiyappanNessuna valutazione finora

- Leica Cyclone ENTERPRISE DS 931375 1220 en LRDocumento2 pagineLeica Cyclone ENTERPRISE DS 931375 1220 en LRAshok AmmaiyappanNessuna valutazione finora

- JR STRR Enclave Cost Sheet 2023Documento1 paginaJR STRR Enclave Cost Sheet 2023Ashok AmmaiyappanNessuna valutazione finora

- BIM and QR-codes Interaction On A Construction SitDocumento9 pagineBIM and QR-codes Interaction On A Construction SitAshok AmmaiyappanNessuna valutazione finora

- प्रभाग समिती कDocumento4 pagineप्रभाग समिती कAshok AmmaiyappanNessuna valutazione finora

- Conocarpus English Research PDFDocumento17 pagineConocarpus English Research PDFAshok AmmaiyappanNessuna valutazione finora

- Jennifer SchoolingDocumento22 pagineJennifer SchoolingAshok AmmaiyappanNessuna valutazione finora

- Leica Cyclone Tech Spec 0421 enDocumento10 pagineLeica Cyclone Tech Spec 0421 enAshok AmmaiyappanNessuna valutazione finora

- (GATE NOTES) Steel Structures - Handwritten GATE IES AEE GENCO PSU - Ace Academy Notes - Free Download PDF - CivilEnggForAllDocumento127 pagine(GATE NOTES) Steel Structures - Handwritten GATE IES AEE GENCO PSU - Ace Academy Notes - Free Download PDF - CivilEnggForAllAshok AmmaiyappanNessuna valutazione finora

- Letter of Qualification Sample PDFDocumento3 pagineLetter of Qualification Sample PDFAshok Ammaiyappan100% (1)

- (Gate Ies Psu) Ies Master Steel Structures Study Material For Gate, Psu, Ies, Govt ExamsDocumento154 pagine(Gate Ies Psu) Ies Master Steel Structures Study Material For Gate, Psu, Ies, Govt ExamsAshok AmmaiyappanNessuna valutazione finora

- Pre-Delivery Inspection Checklist: Under Hood - Engine Off On InsideDocumento1 paginaPre-Delivery Inspection Checklist: Under Hood - Engine Off On InsideAshok AmmaiyappanNessuna valutazione finora

- Design of Tall Chimneys by Manohar PDFDocumento297 pagineDesign of Tall Chimneys by Manohar PDFAshok Ammaiyappan100% (4)

- Information Letter Gershwin August 2014 PDFDocumento4 pagineInformation Letter Gershwin August 2014 PDFAshok AmmaiyappanNessuna valutazione finora

- Indian Steel TableDocumento97 pagineIndian Steel Tableshreekant2785% (13)

- Building Construction 1 9 Stairs 1Documento24 pagineBuilding Construction 1 9 Stairs 1Ashok AmmaiyappanNessuna valutazione finora

- Tall Chimneys S N Manohar Part1 PDFDocumento74 pagineTall Chimneys S N Manohar Part1 PDFAshok Ammaiyappan100% (5)

- Tall Chimneys - S N Manohar - Part2Documento74 pagineTall Chimneys - S N Manohar - Part2ksshashidhar100% (2)

- Handbook of Machine Foundations Srinivasulu Vaidyanathan PDFDocumento249 pagineHandbook of Machine Foundations Srinivasulu Vaidyanathan PDFAshok AmmaiyappanNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Sweet Biscuits Snack Bars and Fruit Snacks in MexicoDocumento17 pagineSweet Biscuits Snack Bars and Fruit Snacks in MexicoSantiagoNessuna valutazione finora

- ACIS - Auditing Computer Information SystemDocumento10 pagineACIS - Auditing Computer Information SystemErwin Labayog MedinaNessuna valutazione finora

- SPH4U Assignment - The Wave Nature of LightDocumento2 pagineSPH4U Assignment - The Wave Nature of LightMatthew GreesonNessuna valutazione finora

- Tivoli Performance ViewerDocumento4 pagineTivoli Performance ViewernaveedshakurNessuna valutazione finora

- Simoreg ErrorDocumento30 pagineSimoreg Errorphth411Nessuna valutazione finora

- Everlube 620 CTDSDocumento2 pagineEverlube 620 CTDSchristianNessuna valutazione finora

- Agricultural Economics 1916Documento932 pagineAgricultural Economics 1916OceanNessuna valutazione finora

- TSR KuDocumento16 pagineTSR KuAngsaNessuna valutazione finora

- Mid Term Exam 1Documento2 pagineMid Term Exam 1Anh0% (1)

- SME-Additional Matter As Per Latest Syllabus Implementation WorkshopDocumento14 pagineSME-Additional Matter As Per Latest Syllabus Implementation WorkshopAvijeet BanerjeeNessuna valutazione finora

- Richards Laura - The Golden WindowsDocumento147 pagineRichards Laura - The Golden Windowsmars3942Nessuna valutazione finora

- Form16 2018 2019Documento10 pagineForm16 2018 2019LogeshwaranNessuna valutazione finora

- 30 Creative Activities For KidsDocumento4 pagine30 Creative Activities For KidsLaloGomezNessuna valutazione finora

- The Effectiveness of Risk Management: An Analysis of Project Risk Planning Across Industries and CountriesDocumento13 pagineThe Effectiveness of Risk Management: An Analysis of Project Risk Planning Across Industries and Countriesluisbmwm6Nessuna valutazione finora

- Urun Katalogu 4Documento112 pagineUrun Katalogu 4Jose Luis AcevedoNessuna valutazione finora

- Prachi AgarwalDocumento1 paginaPrachi AgarwalAnees ReddyNessuna valutazione finora

- Microwave Drying of Gelatin Membranes and Dried Product Properties CharacterizationDocumento28 pagineMicrowave Drying of Gelatin Membranes and Dried Product Properties CharacterizationDominico Delven YapinskiNessuna valutazione finora

- RevisionHistory APFIFF33 To V219Documento12 pagineRevisionHistory APFIFF33 To V219younesNessuna valutazione finora

- Oracle Exadata Database Machine X4-2: Features and FactsDocumento17 pagineOracle Exadata Database Machine X4-2: Features and FactsGanesh JNessuna valutazione finora

- Health Insurance in Switzerland ETHDocumento57 pagineHealth Insurance in Switzerland ETHguzman87Nessuna valutazione finora

- 1934 PARIS AIRSHOW REPORT - Part1 PDFDocumento11 pagine1934 PARIS AIRSHOW REPORT - Part1 PDFstarsalingsoul8000Nessuna valutazione finora

- Datasheet Qsfp28 PAMDocumento43 pagineDatasheet Qsfp28 PAMJonny TNessuna valutazione finora

- SBL - The Event - QuestionDocumento9 pagineSBL - The Event - QuestionLucio Indiana WalazaNessuna valutazione finora

- Fidp ResearchDocumento3 pagineFidp ResearchIn SanityNessuna valutazione finora

- The Art of Blues SolosDocumento51 pagineThe Art of Blues SolosEnrique Maldonado100% (8)

- State Immunity Cases With Case DigestsDocumento37 pagineState Immunity Cases With Case DigestsStephanie Dawn Sibi Gok-ong100% (4)

- TAB Procedures From An Engineering FirmDocumento18 pagineTAB Procedures From An Engineering Firmtestuser180Nessuna valutazione finora

- 6 V 6 PlexiDocumento8 pagine6 V 6 PlexiFlyinGaitNessuna valutazione finora

- 4 Bar LinkDocumento4 pagine4 Bar LinkConstance Lynn'da GNessuna valutazione finora

- Job Description For QAQC EngineerDocumento2 pagineJob Description For QAQC EngineerSafriza ZaidiNessuna valutazione finora