Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Apa80 1049

Caricato da

RupeshRaoTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Apa80 1049

Caricato da

RupeshRaoCopyright:

Formati disponibili

Appl. Phys.

A 80, 10491051 (2005)

Applied Physics A

DOI: 10.1007/s00339-004-3044-9

Materials Science & Processing

t.-w. kim1,,u

t. kawazoe1

s. yamazaki2

m. ohtsu1,2,

Low-temperature synthesis

and room temperature ultraviolet lasing

of nanocrystalline ZnO films

1 Japan

Science and Technology Corporation, 687-1, Tsuruma, Machida, Tokyo, 194-0004, Japan

Graduate School of Science and Engineering, Tokyo Institute of Technology, Yokohama,

Kanagawa, 226-8502, Japan

2 Interdisciplinary

Received: 4 March 2004/Accepted: 20 September 2004

Published online: 18 November 2004 Springer-Verlag 2004

ABSTRACT Nanocrystalline ZnO films were fabricated via

a simple method involving the oxidation of Zn films at a remarkably low temperature of 380 C. X-ray diffraction study confirmed that the Zn films were completely oxidized even at the

low temperature of 380 C and the ZnO films fabricated were

of polycrystalline wurtzite structure. Room temperature optical pumping using a frequency-quintupled Q-switched Nd:YAG

laser ( = 213 nm) exhibited that sharp peaks at around 3.12 eV

emerged above excitation powers of 7 MW/cm2 , demonstrating lasing in the ZnO films. These results represent that the

process is a simple, promising approach for fabricating ZnO of

sufficient optical performance for use as ultraviolet (UV) light

emitters and an alternative UV laser source; both are key components in short-wavelength photonic devices.

PACS 81.07.Bc; 61.46.+w;

68.55.-a; 78.55.Et; 42.55.Px

ZnO, which has a room temperature bandgap of 3.37 eV and

an exciton binding energy of 60 meV, is a promising wide

bandgap semiconductor for applications with photonic devices in ultraviolet (UV) region [13]. In particular, the high

exciton binding energy is feasible for fabricating the photonic devices emitting UV light or laser at room temperature

(RT) via an exciton recombination process. Few researchers

have report the room temperature observation of UV emission

and/or lasing in epitaxially grown ZnO films fabricated by

using several methods such as pulsed laser deposition [4, 5],

plasma-assisted molecular beam epitaxy [6], and metalorganic vapor phase epitaxy [7]. Recently, it was reported that

UV lasing were demonstrated in ZnO nanowires synthesized

at a relatively high temperature of about 1000 C using a vapor

phase transport process [8].

However, requirements of epitaxial growth of the film or

a high growth temperature might restrict an available substrate

material due to their lattice mismatches and higher endurance

against heat. Therefore, development of a low temperature

u Fax: +81-44-819-2053, E-mail: twkim90@ksp.or.jp

Present address: Kanagawa Academy of Science and Technology

(KAST), 3-2-1, Sakado, Takatsu-ku, Kawasaki, Kanagawa, 213-0012

Japan

Present address: School of Engineering, The University of Tokyo,

7-3-1 Hongo, Bunkyo-ku, Tokyo 113-8656, Japan

process for preparing high-quality ZnO films with reliable optical performances is strongly required to manufacture a variety of ZnO-based optical devices. In the previous report,

we have showed that ZnO nanocrystallites fabricated by the

same low temperature oxidation of metallic Zn precursors,

exhibited strong UV emission peak around 3.27 eV at room

temperature [9]. In addition, for fabricating a high-quality

ZnO nanodots, we have developed a technique with control

over the size and position, using near-field optical chemical

vapor deposition (NFO-CVD) [10]. Furthermore, the photoluminescence properties of a single ZnO nanodot fabricated

using the method were reported [11]. ZnO nanodots can be

a promising material for a nanophotonic switching device that

is indispensable for the realization of nanophotonic integrated

circuits (ICs) we proposed [12]. In this study, we report the

low temperature growth of nanocrystalline ZnO films and the

observation of UV lasing in the films.

We employed a simple method for fabricating nanocrystalline ZnO films via the oxidation of Zn films at a remarkably

low temperature of 380 C; Zn films with a nominal thickness

of 500 nm were deposited on CaF2 (111) substrate by thermal evaporation of pure metallic Zn powder (99.999%), and

then the sample was placed in a thermal furnace under a constant flow of high-purity oxygen gas. The crystal structure and

morphology of the samples were characterized using X-ray

diffraction (XRD) and scanning electron microscopy (SEM),

respectively. Optical pumping was carried out using a frequency quintupled Q-switched Nd:YAG laser ( = 213 nm,

20 Hz, 4 ns pulse width) at room temperature. The pump beam

was focused to a spot of 0.5 mm diameter on the film with the

45 oblique direction and the emission light were detected in

the normal direction to the film.

Figure 1 shows XRD patterns of as-deposited metallic Zn

films (a) and ZnO (b) obtained by the oxidation at 380 C for

6 h. For the as-deposited Zn thin films, a strong peak is observed at 2 = 36.39 , which corresponds to the (002) diffraction of hexagonal phase Zn (Fig. 1(a)). Annealing the sample

at 380 C transformed the Zn into ZnO, as shown in Fig. 1(b).

Diffraction peaks are observed at 2 = 31.88 , 34.56 , and

36.29 , which correspond to (100), (002), and (101) of ZnO

with wurtzite structure, respectively. Simple estimation of the

lattice constants with the position of each diffraction peak provides lattice constants of a = 0.324 and c = 0.519 nm, which

are in good agreement with those of bulk ZnO. In contrast,

1050

Applied Physics A Materials Science & Processing

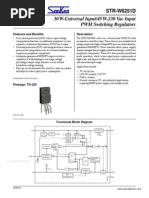

FIGURE 1 XRD patterns of as-prepared Zn films and the ZnO fabricated at 380 C. For the as-prepared Zn films, a strong peak is observed at

2 = 36.39 , which corresponds to the (002) diffraction of hexagonal phase

Zn. After oxidation at 380 C, diffraction peaks are observed at 2 = 31.88 ,

34.56 , and 36.29 , which correspond to (100), (002), and (101) of ZnO with

wurtzite structure, respectively

no peak of Zn was observed for the sample. These indicate

that the Zn films are completely transformed into crystalline

ZnO at a temperature as low as 380 C. We have oxidized

the samples at various temperatures. According to the results, above 420 C single crystalline ZnO nanowires were

obtained instead of polycrystalline ZnO nanocrystallites. We

could not observe the laser action in the samples composed of

nanowires. We think that the result was caused by the thin film

thickness. The detailed experimental results on these were

given in our previous work [13]. In addition, we have also

tried to fully oxidize the sample below 380 C, but the samples oxidized below 380 C for 6 hrs were not fully oxidized.

This fact was confirmed by the XRD and X-ray photoelectron

spectroscopy measurements.

Figure 2 shows typical SEM images of as-prepared Zn

films with a different film thickness (a and b) and ZnO films

(c and d) formed after oxidation at 380 C for 6 h; a nominal

film thickness of 50 nm for a and c, and 500 nm for b and d.

Lots of separated hexagonal Zn plates, of which diameters

range from 100 to 900 nm with thicknesses from 20 to 50 nm,

are seen in Fig. 2a. We believe that the characteristic hexagonal shape is indicative of the formation of single-crystal

pure metal Zn. As the film thickness increases, layer structure

of Zn plates are seen in Fig. 2b. After oxidation, the hexagonal

Zn plates somewhat swelled due to the increase of the cell

volume caused by the incorporation of oxygen (see Fig. 2c,d).

We carried out optical pumping for the sample at room

temperature. Figure 3 shows the emission spectra observed

with the different pulse energies. And the inset illustrates the

measurement configuration. For the pulse energy of 0.022 mJ,

a broad emission peak is observed at around 385 nm, which

is attributed to a spontaneous emission of ZnO. As the excitation energy increases, the emission intensity rapidly increases

and sharp peaks emerge in the spectra, when the excitation

energy exceeded 0.043 mJ, showing the onset of laser action.

The full-width half maximum (FWHM) of the sharp peaks is

less than 0.6 nm, which is much smaller than that of the spontaneous emission peak. Figure 4 shows the integrated emission intensity as a function of incident pump pulse energy.

The threshold intensity for the lasing was determined to be

FIGURE 2 SEM images of asprepared Zn films with a different

film thickness ((a) and (b)) and

the ZnO films ((c) and (d)) formed

after oxidation at 380 C for 6 h;

a nominal film thickness of 50 nm

for (a) and (c), and 500 nm for (b)

and (d)

KIM et al.

Low-temperature synthesis and room temperature ultraviolet lasing of nanocrystalline ZnO films

1051

0.4 MW/cm2 . We believe that lasing in our sample resulted

from the same mechanism. However, it should be noted that

their samples were prepared with pulsed laser deposition at

a relatively high temperature (500 700 C) comparing with

that in our case (380 C). Meanwhile, S. Cho et al. reported the

observation of lasing in ZnO polycrystalline films fabricated

at 1000 C [15]. The threshold intensity of their sample was

9 MW/cm2 . Here, it may be worthy to notice that there is

a difference in the threshold intensities between the samples.

We think that the threshold intensity can be affected by several

parameters such as size of ZnO nanocrystals, film thickness,

and compactness of sample. In our case, the laser action can

be achieved using ZnO films fabricated at a remarkable low

temperature of 380 C.

In conclusion, we have fabricated nanocrystalline ZnO

films via a simple method involving the oxidation of Zn

films at a remarkably low temperature of 380 C. Room

temperature optical pumping using a frequency-quintupled

Q-switched Nd:YAG laser ( = 213 nm) exhibited that sharp

peaks at around 3.12 eV emerged above excitation powers of

7 MW/cm2 , demonstrating lasing in the ZnO films. These

results represent that the process is a simple, promising approach for fabricating ZnO of sufficient optical performance

for use as ultraviolet (UV) light emitters and an alternative UV

laser source; both are key components in short-wavelength

photonic devices.

FIGURE 3 Emission spectra from the nanocrystalline ZnO films when the

pump pulse energy is 0.022, 0.043, and 0.116 mJ (from bottom to top). The

inset illustrates the measurement configuration

ACKNOWLEDGEMENTS

We

gratefully

acknowledge

Dr. T. Yatsui for his useful discussions.

REFERENCES

FIGURE 4 Integrated emission intensity of the ZnO films as a function of

the incident pump pulse energy

7 MW/cm2 . Recently, there were a few reports on the lasing from polycrystalline ZnO film. For instance, H. Cao et al.

investigated the lasing in ZnO polycrystalline films composed

of fine ZnO nanoparticles with sizes of 50 150 nm [14]. According to their report, lasing action can be achieved in polycrystalline ZnO films by self-formed cavities due to strong

optical scattering in the films. And the threshold intensity was

1 R.E. Dietz, J.J. Hopfield, D.G. Thomas: J. Appl. Phys. 32, 2282 (1961)

2 D.M. Bagnall, Y.F. Chen, Z. Zhu, T. Yao, S. Koyama, M.Y. Shen,

T. Goto: Appl. Phys. Lett. 70, 2230 (1997)

3 Z.K. Tang, P. Yu, G.K.L. Wong, M. Kawasaki, A. Ohtomo, H. Koinuma,

Y. Segawa: Solid State Commun. 103, 459 (1997)

4 Z.K. Tang, G.K.L. Wong, P. Yu, M. Kawasaki, A. Ohtomo, H. Koinuma,

Y. Segawa: Appl. Phys. Lett. 72, 3270 (1998)

5 J.F. Muth, R.M. Kolbas, A.K. Sharma, S. Oktyabrsky, J. Narayan:

J. Appl. Phys. 85, 7884 (1999)

6 Y. Chen, N.T. Tuan, Y. Segawa, H-J. Ko, S-K. Hong, T. Yao: Appl. Phys.

Lett. 78, 1469 (2001)

7 S.W. Jung, W.I. Park, H.D. Cheong, Gyu-Chul Yi, Hyun M. Jang,

S. Hong, T. Joo: Appl. Phys. Lett. 80, 1924 (2002)

8 M.H. Huang, S. Mao, H. Feick, H. Yan, Y. Wu, H. Kind, E. Weber,

R. Russo, P. Yang: Science 292, 1897 (2001)

9 T-W. Kim, T. Kawazoe, S. Yamazaki, J. Lim, T. Yatsui, M. Ohtsu: Solid

State Comm. 127, 21 (2003)

10 Y. Yamamoto, M. Kourogi, M. Ohtsu, V. Polonski, G.H. Lee: Appl.

Phys. Lett. 76, 2173 (2000)

11 T. Yatsui, T. Kawazoe, M. Ueda, Y. Yamamoto, M. Kourogi, M. Ohtsu:

Appl. Phys. Lett. 81, 3651 (2002)

12 M. Ohtsu, K. Kobayashi, T. Kawazoe, S. Sangu, T. Yatsui: IEEE J. Sel.

Top. Quantum Electron. 8, 839 (2002)

13 T.-W. Kim, T. Kawazoe, S. Yamazaki, M. Ohtsu: Appl. Phys. Lett 84,

3358 (2004)

14 H. Cao, Y.G. Zhao, H.C. Ong, S.T. Ho, J.Y. Dai, J.Y. Wu, R.P.H. Chang:

Appl. Phys. Lett. 73, 3656 (1998)

15 S. Cho, J. Ma, Y. Kim, Y. Sun, G.K.L. Wong, J.B. Ketterson: Appl. Phys.

Lett. 75, 2761 (1999)

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1091)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Vetco RL Connector Conductor SpecDocumento19 pagineVetco RL Connector Conductor Speccv sabira100% (1)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- UGRD-ECE6205-Signals-Spectra-and-Signal-Processing-legit-not-quizess MidALLDocumento19 pagineUGRD-ECE6205-Signals-Spectra-and-Signal-Processing-legit-not-quizess MidALLJitlee Papa100% (3)

- The Physics of Bowling BallsDocumento34 pagineThe Physics of Bowling Ballskhisham20005389100% (2)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Concise Guide To Quantum Computing: Sergei Kurgalin Sergei BorzunovDocumento129 pagineConcise Guide To Quantum Computing: Sergei Kurgalin Sergei BorzunovVi Kem0% (1)

- As 4678 2002 Earth Retaining Structures CorrectionDocumento6 pagineAs 4678 2002 Earth Retaining Structures CorrectionMacNessuna valutazione finora

- Report Esomeprazole IV Inj (Guide Batch 03)Documento60 pagineReport Esomeprazole IV Inj (Guide Batch 03)Sari Widya Astuti SelianNessuna valutazione finora

- SMSCP Level 1 System Analysis: Analyzing A Mechatronic SystemDocumento25 pagineSMSCP Level 1 System Analysis: Analyzing A Mechatronic SystemIsaac GisoreNessuna valutazione finora

- Li2017 Enhancing Sm3+ Red Emission Via Energy Transfer From Bi3+ Sm3+ Based On Terbium Bridge Mechanism in Ca2Al2SiO7 PhosphorsDocumento7 pagineLi2017 Enhancing Sm3+ Red Emission Via Energy Transfer From Bi3+ Sm3+ Based On Terbium Bridge Mechanism in Ca2Al2SiO7 PhosphorsRupeshRaoNessuna valutazione finora

- Molecular Design On Highly Efficient White Electroluminescence From A Single-Polymer System With Simultaneous Blue, Green, and Red EmissionDocumento5 pagineMolecular Design On Highly Efficient White Electroluminescence From A Single-Polymer System With Simultaneous Blue, Green, and Red EmissionRupeshRaoNessuna valutazione finora

- The Investigation of Photoluminescence Centers in Porous Alumina MembranesDocumento4 pagineThe Investigation of Photoluminescence Centers in Porous Alumina MembranesRupeshRaoNessuna valutazione finora

- Photoluminescence Emissions of Ceramics: A Marker of Production TechnologyDocumento4 paginePhotoluminescence Emissions of Ceramics: A Marker of Production TechnologyRupeshRaoNessuna valutazione finora

- Synthesis and Photoluminescence of Aligned Sio Nanowire ArraysDocumento3 pagineSynthesis and Photoluminescence of Aligned Sio Nanowire ArraysRupeshRaoNessuna valutazione finora

- Structure and Optical Non-Linearity of Pbo.2B203: Acta CrystDocumento6 pagineStructure and Optical Non-Linearity of Pbo.2B203: Acta CrystRupeshRaoNessuna valutazione finora

- Up-Conversion Photoluminescence in Polyfluorene Doped With Metal Octaethyl PorphyrinsDocumento4 pagineUp-Conversion Photoluminescence in Polyfluorene Doped With Metal Octaethyl PorphyrinsRupeshRaoNessuna valutazione finora

- Multifunctional Sodium Lanthanide Silicates: From Blue Emitters and Infrared S-Band Amplifiers To X-Ray PhosphorsDocumento6 pagineMultifunctional Sodium Lanthanide Silicates: From Blue Emitters and Infrared S-Band Amplifiers To X-Ray PhosphorsRupeshRaoNessuna valutazione finora

- Transparent YVO4 FilmsDocumento10 pagineTransparent YVO4 FilmsRupeshRaoNessuna valutazione finora

- The Title Goes Here With Each Initial Letter Capitalized: Author's Name and Author's NameDocumento7 pagineThe Title Goes Here With Each Initial Letter Capitalized: Author's Name and Author's NameRupeshRaoNessuna valutazione finora

- CrystalMaker - Technical SpecificationsDocumento6 pagineCrystalMaker - Technical SpecificationsRupeshRaoNessuna valutazione finora

- Prospect ATR901.RevB Eng PDFDocumento25 pagineProspect ATR901.RevB Eng PDFUntea LiviuNessuna valutazione finora

- Service Menu: Operación de SistemasDocumento8 pagineService Menu: Operación de Sistemasjuan castaedaNessuna valutazione finora

- Jurnal AutorefractometerDocumento11 pagineJurnal AutorefractometerNeida Valeria DanunNessuna valutazione finora

- Serial ATA II: Extensions To Serial ATA 1.0aDocumento110 pagineSerial ATA II: Extensions To Serial ATA 1.0aRaj Shekhar ReddyNessuna valutazione finora

- Thermowax Issues Reparation Autochoke Som fastnat-GCV140-160-190Documento6 pagineThermowax Issues Reparation Autochoke Som fastnat-GCV140-160-190coyote556Nessuna valutazione finora

- Valvoline HTO 32Documento1 paginaValvoline HTO 32octo widodoNessuna valutazione finora

- Sodium Dichloroisocyanurate (Nadcc - Anhydrous and Dihydrate)Documento8 pagineSodium Dichloroisocyanurate (Nadcc - Anhydrous and Dihydrate)Tarek AlmahdyNessuna valutazione finora

- A Syntactic Analysis of Surah Al MasadDocumento14 pagineA Syntactic Analysis of Surah Al MasadLisda Farikhatunnisak100% (1)

- CMDBuild UserManual ENG V250Documento89 pagineCMDBuild UserManual ENG V250Elio ZerpaNessuna valutazione finora

- MATH10 Lesson 5Documento46 pagineMATH10 Lesson 5Bea OroNessuna valutazione finora

- Machine Vision Technology: Past, Present, and FutureDocumento12 pagineMachine Vision Technology: Past, Present, and FutureMekaTronNessuna valutazione finora

- Non Concurrent ForcesDocumento6 pagineNon Concurrent ForcesLeah Rivera0% (1)

- Dart Language SpecificationDocumento111 pagineDart Language SpecificationLiaboNessuna valutazione finora

- A Computer-Based Optimization Method For: Archives FEB 24 1970Documento325 pagineA Computer-Based Optimization Method For: Archives FEB 24 1970Age MaradiagaNessuna valutazione finora

- Datasheet PDFDocumento15 pagineDatasheet PDFperro sNessuna valutazione finora

- Must-On Board Diagnostics II PCED PDFDocumento19 pagineMust-On Board Diagnostics II PCED PDFRopama BraNessuna valutazione finora

- Sample SCJP QuestionsDocumento23 pagineSample SCJP QuestionsManuel GalganaNessuna valutazione finora

- CE 103 Structural AnalysisDocumento80 pagineCE 103 Structural AnalysisasdasNessuna valutazione finora

- Example 3 (Science-Based)Documento75 pagineExample 3 (Science-Based)poppygibson1111Nessuna valutazione finora

- Toshiba VFS15 User ManualDocumento361 pagineToshiba VFS15 User ManualdanyNessuna valutazione finora

- Chapter Two (LPM)Documento18 pagineChapter Two (LPM)Yohannes BelaynehNessuna valutazione finora

- Internal and External Exposure: The Body Is Equally Exposed To Radiation in Both CasesDocumento53 pagineInternal and External Exposure: The Body Is Equally Exposed To Radiation in Both CasesKross OgbeborNessuna valutazione finora

- Service Manual: NX-1200DV, NX-1200D, NX-1200NV, NX-1200N, NX-1300DU, NX-1300D, NX-1300NU, NX-1300NDocumento86 pagineService Manual: NX-1200DV, NX-1200D, NX-1200NV, NX-1200N, NX-1300DU, NX-1300D, NX-1300NU, NX-1300NMarcelo LilloNessuna valutazione finora