Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

02-9 QCS 2014

Caricato da

Raja Ahmed HassanCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

02-9 QCS 2014

Caricato da

Raja Ahmed HassanCopyright:

Formati disponibili

QCS 2014

Section 02: Quality Assurance and Quality Control

Part

09: Nonconformance Monitoring

Page 1

NONCONFORMANCE MONITORING .................................................................... 2

9.1

9.1.1

9.1.2

9.1.3

9.1.4

9.1.5

9.1.6

INTRODUCTION ..................................................................................................... 2

General

2

Review and Disposition of Nonconforming Items

2

Corrective Action

3

Identification of Nonconforming Items

3

Acceptance and Approval of Nonconforming items

4

Nonconformance Records

4

at

ar

on

st

ru

ct

io

Sp

ec

ifi

ca

tio

ns

20

14

QCS 2014

Section 02: Quality Assurance and Quality Control

Part

09: Nonconformance Monitoring

Page 2

NONCONFORMANCE MONITORING

9.1

INTRODUCTION

9.1.1

General

The Contractor shall ensure that product which does not conform to Specification

requirements is identified and controlled to prevent its unintended use or delivery. A

documented procedure shall be established to define the controls and relate responsibilities

and authorities for dealing with nonconforming product:

20

14

by taking action to estimate the detected nonconformity

(b)

by authorizing its use, release or acceptance under concession by the Engineer

(c)

by taking action to preclude its original intended use or application

(d)

by taking action appropriate to the effects, or potential effects, of the nonconformity

when nonconformity product is detected after delivery or use has started .

ca

tio

ns

(a)

When Conforming product is corrected it shall be subject to re-verification to demonstrate

conformity to requirements.

Records of the nature of nonconformities and any subsequent actions taken, including

concessions obtained by the engineer, shall be maintained.

The monitoring system shall apply to material and equipment as well as installation and

construction which fail to conform to the Contract.

A Contractors Quality Nonconformance Template is included in Part 15 Appendix B of this

Section and must be used for recording Nonconformance.

9.1.2

Review and Disposition of Nonconforming Items

The responsibility for review and authority for the disposition of nonconforming items shall be

defined in the Quality Plan.

Nonconforming items shall be reviewed in accordance with documented procedures. A

nonconforming item may be:

ar

on

st

ru

ct

io

Sp

ec

ifi

at

(a)

reworked to meet the specified requirements

(b)

accepted with or without repair if agreed in writing by the Engineer

(c)

re-graded for alternative applications

(d)

rejected or scrapped.

The proposed use or repair of an item which does not conform to the requirements of the

Project Documentation shall be reported to the Engineer.

The description of the

nonconformity and of repairs shall be recorded to denote the actual condition.

Repaired and/or reworked products shall be inspected in accordance with the Quality

Assurance Plan and/or documented procedures

QCS 2014

Section 02: Quality Assurance and Quality Control

Part

09: Nonconformance Monitoring

Page 3

9.1.3

Corrective Action

The Contractor shall take action to eliminate the causes of nonconformities in order to

prevent recurrence. Corrective actions shall be appropriate to the effects of the

nonconformity encountered.

Reviewing nonconformities (including Engineer complaints)

(b)

Determining the causes of nonconformities

(c)

Evaluating the need for action to ensure that conformities do not occur

(d)

Determining and implementing actions needed

(e)

Records of the results of action taken and

(f)

Reviewing the effectiveness of the corrective action taken

ca

tio

ns

20

(a)

14

A documented procedure shall be established to define requirements for:

Any corrective or preventive action taken to eliminate the causes of actual or potential

nonconformities shall be to a degree appropriate to the magnitude of problems and

commensurate with the risks encountered.

The Contractor shall implement and record any changes to the documented procedures for

implementing corrective and preventive action.

The Contractor shall take prompt action to identify the causes of each nonconformance and

the corrective action necessary prevent recurrence. The results of failure and discrepancy

report summaries, Contractor evaluations, and any other pertinent applicable data shall be

used for determining corrective action. Information developed during construction, tests, and

inspections that support the implementation of required improvements and corrections shall

be used to support the adequacy of corrective action taken.

The procedures for preventive action shall include:

determination of the steps needed to deal with any problems requiring preventive

action

ar

(b)

the use of appropriate sources of information such as processes and work operations

which affect product quality, concessions, audit results, quality records and service

reports to detect, analyse and eliminate potential causes of nonconformities

on

(a)

st

ru

ct

io

Sp

ec

ifi

at

(c)

(d)

initiation of preventive action and application of controls to ensure that it is effective

ensuring that relevant information on actions taken is submitted for management

review

9.1.4

Identification of Nonconforming Items

The Contractor shall clearly identify each nonconforming item with a status tag or other

distinguishing mark. The Contractor shall establish procedures for installing, monitoring, and

removing these status tags and identify personnel authorised to remove status tags.

QCS 2014

Section 02: Quality Assurance and Quality Control

Part

09: Nonconformance Monitoring

Page 4

Acceptance and Approval of Nonconforming items

Acceptance of the Contractors proposed disposition of Nonconforming items should be his

obtained in writing from the Engineer prior to the undertaking of any remedial works by the

his Contractor.

Close out of Nonconforming items must be agreed in writing by the Engineer.

9.1.6

Nonconformance Records

The Contractor shall provide the Engineer with the following information for each

nonconformance:

20

(b)

description of nonconformance

(c)

evaluation of nonconformance to establish the cause

(d)

recommended corrective action

(e)

date nonconformance was identified

(f)

date corrective action was completed

(g)

description of final corrective action.

ifi

ec

Sp

The Contractor shall establish and maintain a nonconformance log. The log shall contain the

following information as a minimum:

unique sequential reference number

(b)

date issued

(c)

originator

(d)

description of item deemed to be in nonconformance

(e)

description of nonconformance

(f)

Contractors recommended and final disposition

st

ru

ct

io

(a)

Engineers acceptance of Contractors recommended and final disposition

(g)

date closed

(i)

remarks, as applicable

ar

(h)

at

Q

ns

identification of nonconformance

ca

tio

(a)

on

14

9.1.5

END OF PART

Potrebbero piacerti anche

- 02-7 QCS 2014Documento5 pagine02-7 QCS 2014Raja Ahmed Hassan0% (1)

- 2 QUALITY CONTROL Manual FINALDocumento8 pagine2 QUALITY CONTROL Manual FINALBilisumman Hawwe BeekaNessuna valutazione finora

- 02-2 QCS 2014Documento6 pagine02-2 QCS 2014Raja Ahmed HassanNessuna valutazione finora

- Quality Assurance, Inspection, Testing and Commissioning - MECHDocumento33 pagineQuality Assurance, Inspection, Testing and Commissioning - MECHBriana JenkinsNessuna valutazione finora

- 01.08 - Quality AssuranceDocumento179 pagine01.08 - Quality AssuranceKrishna KishoreNessuna valutazione finora

- Preventive ActionDocumento9 paginePreventive ActionATHMANATHAN SNessuna valutazione finora

- Mumbai Trans Harbour Link Project Non-Conforming Item ProcedureDocumento15 pagineMumbai Trans Harbour Link Project Non-Conforming Item ProcedureDeepak UpadhayayNessuna valutazione finora

- Green Line Underground: Section 02: Quality Assurance and Quality Control 09: Nonconformance MonitoringDocumento4 pagineGreen Line Underground: Section 02: Quality Assurance and Quality Control 09: Nonconformance MonitoringFrancisco M. RamosNessuna valutazione finora

- Nonconformance Monitoring ProcedureDocumento10 pagineNonconformance Monitoring ProcedureAhmed MohamedNessuna valutazione finora

- Control of Non-Conforming Products ProcedureDocumento4 pagineControl of Non-Conforming Products ProcedureAlmario Sagun100% (1)

- 01 40 00 - Quality RequirementsDocumento27 pagine01 40 00 - Quality RequirementsshauhramNessuna valutazione finora

- Quality assurance requirements for ISO 9001 complianceDocumento61 pagineQuality assurance requirements for ISO 9001 complianceSandeep RajurkarNessuna valutazione finora

- PWTP2 - QCP 20160908-ADocumento35 paginePWTP2 - QCP 20160908-AgregNessuna valutazione finora

- At SKTSZZ QA PRO 0008 000 C01 Quality Control InspectionDocumento14 pagineAt SKTSZZ QA PRO 0008 000 C01 Quality Control InspectionAdil HasanovNessuna valutazione finora

- Inspection and Acceptance Precast and Prestressed Concrete Bridge UnitsDocumento14 pagineInspection and Acceptance Precast and Prestressed Concrete Bridge UnitsKaan TekinturhanNessuna valutazione finora

- Quality Assurance Quality Control Manual PDFDocumento18 pagineQuality Assurance Quality Control Manual PDFsaifasadNessuna valutazione finora

- T Proc Notices Notices 050 K Notice Doc 45368 665080217Documento23 pagineT Proc Notices Notices 050 K Notice Doc 45368 665080217ANISNessuna valutazione finora

- Discrepancy Report ProcedureDocumento5 pagineDiscrepancy Report ProcedurePrashansa ShresthaNessuna valutazione finora

- ISO-IEC 17021-2011 Audit Process PDFDocumento62 pagineISO-IEC 17021-2011 Audit Process PDFInatalyNessuna valutazione finora

- Procedure For Corrective ActionDocumento5 pagineProcedure For Corrective Actionndayiragije JMVNessuna valutazione finora

- ISO - Control of Non-Conforming ProductsDocumento5 pagineISO - Control of Non-Conforming ProductsAlmario SagunNessuna valutazione finora

- 02-12 QCS 2014Documento3 pagine02-12 QCS 2014Raja Ahmed HassanNessuna valutazione finora

- Quality Assurance ManualDocumento51 pagineQuality Assurance ManualMadhan RamamoorthyNessuna valutazione finora

- De Beers 'Project Plus' Management SystemDocumento15 pagineDe Beers 'Project Plus' Management Systemkhonzaphi dubeNessuna valutazione finora

- Technical Specification 2Documento2 pagineTechnical Specification 2Buliga MarianNessuna valutazione finora

- Technical Specification 1Documento2 pagineTechnical Specification 1Buliga Marian100% (1)

- Production Inspection Systems Under Type CertificationDocumento6 pagineProduction Inspection Systems Under Type Certificationajrio1785Nessuna valutazione finora

- Section 8 - Quality Assurance/Quality Control PlanDocumento3 pagineSection 8 - Quality Assurance/Quality Control PlanJoemon T JoyNessuna valutazione finora

- Quality Control Program for Solid Concrete MasonryDocumento19 pagineQuality Control Program for Solid Concrete Masonryvelmurug_balaNessuna valutazione finora

- MoDOT Route XX Project Quality Management PlanDocumento17 pagineMoDOT Route XX Project Quality Management PlanKhaled Abdelbaki100% (1)

- Irc SP 47 P 2Documento12 pagineIrc SP 47 P 2RameshNessuna valutazione finora

- Qcs 2010 Part 1.08 Quality AssuranceDocumento179 pagineQcs 2010 Part 1.08 Quality AssuranceRotsapNayrbNessuna valutazione finora

- Standard Operating Procedure: CalibrationDocumento22 pagineStandard Operating Procedure: CalibrationMaryanthony NamyaloNessuna valutazione finora

- Evidence: It Is A Non ConformityDocumento3 pagineEvidence: It Is A Non ConformityReuban SNessuna valutazione finora

- QMS 2015 Manual Rev 3 3.26.19Documento27 pagineQMS 2015 Manual Rev 3 3.26.19Claudio Israel Godinez Somera100% (1)

- AC 21-05 Amdt. 0 - Production Under Type Certification OnlyDocumento7 pagineAC 21-05 Amdt. 0 - Production Under Type Certification OnlyDINAMIKA AVIASINessuna valutazione finora

- Corrective and Preventive ProcedureDocumento9 pagineCorrective and Preventive ProcedureOlakunle AwoniyiNessuna valutazione finora

- AS 9100 Rev D - IAT Question PaperDocumento9 pagineAS 9100 Rev D - IAT Question Paperdaya vashisht100% (1)

- QA QC Manual 2008Documento86 pagineQA QC Manual 2008netomeller100% (2)

- Aerospace Quality Management RequirementsDocumento60 pagineAerospace Quality Management Requirementsramki1980Nessuna valutazione finora

- 1054 Supplier Quality Agreement Rev A 1Documento7 pagine1054 Supplier Quality Agreement Rev A 1imranNessuna valutazione finora

- AC 21-99 Amdt 1Documento9 pagineAC 21-99 Amdt 1Harry NuryantoNessuna valutazione finora

- 02-6 QCS 2014Documento2 pagine02-6 QCS 2014Raja Ahmed HassanNessuna valutazione finora

- QA QC PLAN For CNG..Documento21 pagineQA QC PLAN For CNG..Pugel Yeremias100% (1)

- Vendor and Quality Assurance Implementation Inspection ReportsDocumento65 pagineVendor and Quality Assurance Implementation Inspection ReportsixoteeNessuna valutazione finora

- QCS 2014 S02 - 4Documento231 pagineQCS 2014 S02 - 4Sai Ram NadimuthuNessuna valutazione finora

- Corrective Action Plan Procedure AB-DOC-21-024.0Documento6 pagineCorrective Action Plan Procedure AB-DOC-21-024.0SALES AL ABERNessuna valutazione finora

- Quality Control (QC) Plan SummaryDocumento12 pagineQuality Control (QC) Plan SummaryNarendraNessuna valutazione finora

- Quality ControlDocumento10 pagineQuality ControlSandeep PasumarthiNessuna valutazione finora

- MCS 001 - Issue 1.5 Installer Certification Scheme Requirements 25 Feb 09Documento20 pagineMCS 001 - Issue 1.5 Installer Certification Scheme Requirements 25 Feb 09Christopher PayneNessuna valutazione finora

- 8.5.2-3 Corrective and Preventive ActionDocumento4 pagine8.5.2-3 Corrective and Preventive ActionAhmed HussienNessuna valutazione finora

- Inspection - Rig AcceptanceDocumento40 pagineInspection - Rig AcceptanceSrikanth Bammidi100% (6)

- QS/QC QuestionsDocumento16 pagineQS/QC QuestionsJh Hedra100% (1)

- Corrective Action ProcedureDocumento3 pagineCorrective Action Procedureasderbva100% (1)

- Establishing A CGMP Laboratory Audit System: A Practical GuideDa EverandEstablishing A CGMP Laboratory Audit System: A Practical GuideNessuna valutazione finora

- Practical Guide To Production Planning & Control [Revised Edition]Da EverandPractical Guide To Production Planning & Control [Revised Edition]Valutazione: 1 su 5 stelle1/5 (1)

- The Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Da EverandThe Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Valutazione: 4.5 su 5 stelle4.5/5 (2)

- Turnaround Management for the Oil, Gas, and Process Industries: A Project Management ApproachDa EverandTurnaround Management for the Oil, Gas, and Process Industries: A Project Management ApproachValutazione: 2 su 5 stelle2/5 (1)

- 06-6 QCS 2014Documento30 pagine06-6 QCS 2014Raja Ahmed HassanNessuna valutazione finora

- 06-4 QCS 2014Documento57 pagine06-4 QCS 2014Raja Ahmed Hassan79% (14)

- 05-19 QCS 2014Documento8 pagine05-19 QCS 2014Raja Ahmed HassanNessuna valutazione finora

- 06-3 QCS 2014Documento13 pagine06-3 QCS 2014Raja Ahmed Hassan100% (1)

- 06-2 QCS 2014Documento25 pagine06-2 QCS 2014Raja Ahmed Hassan100% (6)

- 06-1 Road Works General QCS 2014Documento6 pagine06-1 Road Works General QCS 2014VJ Qatar75% (4)

- 06-8 QCS 2014Documento7 pagine06-8 QCS 2014Raja Ahmed HassanNessuna valutazione finora

- 05-15 QCS 2014Documento14 pagine05-15 QCS 2014Raja Ahmed Hassan100% (2)

- 05-5 QCS 2014Documento31 pagine05-5 QCS 2014Raja Ahmed Hassan100% (11)

- 02-15 QCS 2014Documento17 pagine02-15 QCS 2014Raja Ahmed HassanNessuna valutazione finora

- 05-17 QCS 2014Documento8 pagine05-17 QCS 2014Raja Ahmed Hassan100% (2)

- 05-14 QCS 2014Documento7 pagine05-14 QCS 2014Raja Ahmed HassanNessuna valutazione finora

- 05-18 QCS 2014Documento5 pagine05-18 QCS 2014Raja Ahmed HassanNessuna valutazione finora

- 06-1 QCS 2014Documento10 pagine06-1 QCS 2014Raja Ahmed HassanNessuna valutazione finora

- 05-13 QCS 2014Documento15 pagine05-13 QCS 2014Raja Ahmed Hassan33% (3)

- 05-3 QCS 2014Documento5 pagine05-3 QCS 2014Raja Ahmed HassanNessuna valutazione finora

- 05-16 QCS 2014Documento10 pagine05-16 QCS 2014Raja Ahmed HassanNessuna valutazione finora

- 05-8 QCS 2014Documento16 pagine05-8 QCS 2014Raja Ahmed HassanNessuna valutazione finora

- 04-2 QCS 2014Documento5 pagine04-2 QCS 2014Raja Ahmed HassanNessuna valutazione finora

- 05-10 QCS 2014Documento12 pagine05-10 QCS 2014Raja Ahmed HassanNessuna valutazione finora

- 05-12 QCS 2014Documento11 pagine05-12 QCS 2014Raja Ahmed HassanNessuna valutazione finora

- 05-4 QCS 2014Documento5 pagine05-4 QCS 2014Raja Ahmed HassanNessuna valutazione finora

- 05-9 QCS 2014Documento6 pagine05-9 QCS 2014Raja Ahmed HassanNessuna valutazione finora

- 05-6 QCS 2014Documento15 pagine05-6 QCS 2014Raja Ahmed HassanNessuna valutazione finora

- 05-11 QCS 2014Documento8 pagine05-11 QCS 2014Raja Ahmed HassanNessuna valutazione finora

- 05-7 QCS 2014Documento8 pagine05-7 QCS 2014Raja Ahmed HassanNessuna valutazione finora

- 04-1 QCS 2014Documento7 pagine04-1 QCS 2014Raja Ahmed Hassan100% (1)

- 05-1 QCS 2014Documento10 pagine05-1 QCS 2014Raja Ahmed HassanNessuna valutazione finora

- 04-4 QCS 2014Documento13 pagine04-4 QCS 2014Raja Ahmed HassanNessuna valutazione finora

- A Thesis 123Documento77 pagineA Thesis 123Meli SafiraNessuna valutazione finora

- Floor Boxes and Power Supplies OverviewDocumento32 pagineFloor Boxes and Power Supplies OverviewAbdoNessuna valutazione finora

- Introduction to SONET and DWDM Digital Transmission StandardsDocumento35 pagineIntroduction to SONET and DWDM Digital Transmission StandardsOmar Ayoub100% (1)

- MY LIFE VISION, MISSION AND CORE VALUES BMEC 2W 2122Documento4 pagineMY LIFE VISION, MISSION AND CORE VALUES BMEC 2W 2122Nikolai Avery NorthNessuna valutazione finora

- DLL - Mathematics 5 - Q1 - W4Documento9 pagineDLL - Mathematics 5 - Q1 - W4Avelino Coballes IVNessuna valutazione finora

- Update CV KhanDocumento2 pagineUpdate CV KhanqayyukhanNessuna valutazione finora

- Quenching & TemperingDocumento4 pagineQuenching & Temperingkgkganesh8116Nessuna valutazione finora

- PVG 32 BobinasDocumento64 paginePVG 32 BobinasSaul CastañedaNessuna valutazione finora

- QUANTUM TELEPORTATIONDocumento23 pagineQUANTUM TELEPORTATIONalkagabaNessuna valutazione finora

- Core-Core Repulsion Integrals: E (A Z ZJJDocumento1 paginaCore-Core Repulsion Integrals: E (A Z ZJJRaditya D HmNessuna valutazione finora

- Piper Lance II - Turbo Lance II-Maintenance - smv1986Documento568 paginePiper Lance II - Turbo Lance II-Maintenance - smv1986willkobiNessuna valutazione finora

- Speech Language Impairment - Eduu 511Documento15 pagineSpeech Language Impairment - Eduu 511api-549169454Nessuna valutazione finora

- INCaDocumento47 pagineINCaMehdi SoltaniNessuna valutazione finora

- The Monkey's PawThe Lady of The Barge and Others, Part 2. by Jacobs, W. W., 1863-1943Documento20 pagineThe Monkey's PawThe Lady of The Barge and Others, Part 2. by Jacobs, W. W., 1863-1943Gutenberg.orgNessuna valutazione finora

- أسئلة شاملة 1Documento25 pagineأسئلة شاملة 1ibraheemalabsi99Nessuna valutazione finora

- Soil Compaction: A. General PrinciplesDocumento6 pagineSoil Compaction: A. General PrinciplesIcha EstradaNessuna valutazione finora

- Writing Theory DraftDocumento18 pagineWriting Theory Draftapi-488391657Nessuna valutazione finora

- Order Details for Order #10105Documento2 pagineOrder Details for Order #10105Mohamed HarbNessuna valutazione finora

- Suffolk Bus S92 Schedule Effective 5-2712Documento2 pagineSuffolk Bus S92 Schedule Effective 5-2712RiverheadLOCAL67% (6)

- Fractal ForestsDocumento50 pagineFractal ForestsWell Fournier0% (1)

- OCEN 201 Introduction To Ocean & Coastal EngineeringDocumento28 pagineOCEN 201 Introduction To Ocean & Coastal EngineeringbalumaxNessuna valutazione finora

- Stanley I. Sandler: Equations of State For Phase Equilibrium ComputationsDocumento29 pagineStanley I. Sandler: Equations of State For Phase Equilibrium ComputationscsandrasNessuna valutazione finora

- Significant Ships 1993Documento101 pagineSignificant Ships 1993Joe TahirNessuna valutazione finora

- Brochure GM IM Roller Mill Antares MDDR MDDT en LowDocumento8 pagineBrochure GM IM Roller Mill Antares MDDR MDDT en Lowahmed shomanNessuna valutazione finora

- Summary of C: How To Program Sixth Edition by Deitel: Introduction To Computers, The Internet and The WebDocumento15 pagineSummary of C: How To Program Sixth Edition by Deitel: Introduction To Computers, The Internet and The WebFrieda NgaharjoNessuna valutazione finora

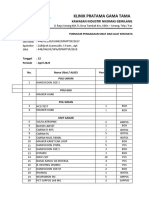

- Pengadaan Obat Dan Alkes TGL 22 April 2021 Klinik PembantuDocumento8 paginePengadaan Obat Dan Alkes TGL 22 April 2021 Klinik PembantuIsma Prasetya WardaniNessuna valutazione finora

- BTech ORB40PT 2014 Study Guide - V3Documento41 pagineBTech ORB40PT 2014 Study Guide - V3Khosi GrootboomNessuna valutazione finora

- Types of EvidenceDocumento13 pagineTypes of EvidenceSteven Jan Sab-itNessuna valutazione finora

- Katalog - Bengkel Print Indonesia PDFDocumento32 pagineKatalog - Bengkel Print Indonesia PDFJoko WaringinNessuna valutazione finora

- Week 5 - Creativity in ResearchDocumento4 pagineWeek 5 - Creativity in ResearchD Barik100% (1)

![Practical Guide To Production Planning & Control [Revised Edition]](https://imgv2-1-f.scribdassets.com/img/word_document/235162742/149x198/2a816df8c8/1709920378?v=1)