Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Usage of Enzymatic Bioprocessing For Raw Linen Fabric Preparing

Caricato da

SEP-PublisherTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Usage of Enzymatic Bioprocessing For Raw Linen Fabric Preparing

Caricato da

SEP-PublisherCopyright:

Formati disponibili

Textiles and Light Industrial Science and Technology (TLIST) Volume 2 Issue 3, July 2013

www.tlist-journal.org

Usage of Enzymatic Bioprocessing for Raw

Linen Fabric Preparing

Aina Bernava *1, Skaidrite Reihmane 2

1,2

Riga Technical University/Institute of Polymer Materials

Azenes St. 14/24, Riga, LV-1048, Latvia

aina.bernava@inbox.lv; 2reihmane@ktf.rtu.lv

Abstract

Enzymatic treatment application in textiles preparing

processes extends due to the offer of new enzyme products,

improvement of processing results and ecology of

technologies. Enzymes are high molecular protein

biocatalysts specific in their action. In presented research,

cellulase and pectinase enzymes are used for preparing raw

linen fabric with emphasis on colour characteristic changes.

Colour coordinates of experimental samples have been

evaluated in RGB system. As well the whiteness of the linen

fabric was measured. Determinated coordinates of colour

vector in a colour space a*, b* and L* and calculated lightness

difference (L*), common colour differences (E), colour

saturation (C), hue (H) shove that enzyme type and

modification method have influence on raw linen colour

parameters and whiteness is insignificant. If the higher

whiteness as 29 % is required, the additional chemical

bleaching is necessary.

Keywords

Linen Fabric; Bioprocessing; Enzymes; Pectinases; Cellulases

Introduction

Classical textiles wet processing contains three stages:

pretreatment (or preparing), coloration (dyeing and/or

printing) and finishing. Any operation for improving

the apperance or usefulness of the fabric is necessary,

but it is well known that the final result is closely

connected

with

pretreatment

processes

and

technologies. One of the oldest techniques applied in

the textiles field (Roy Choudhury A.K.,Wei Q)treatment in aqueous solutions till nowdays stays as

main. The first step before dyeing is raw materials

pretreating for impurities and natural pigments

removal, which differs acordingly in raw material and

requirements.

The enzymes high molecular protein biocatalists can

be safely used in a wide selection of textile processes

such as de-sizing, scouring, bleaching, dyeing and

finishing, where the alternatives are chemicals whose

disposal into the environment causes many problems.

Textile processing with enzymes aims to provide the

textile technologist with an understanding of enzymes

and their use for textile materials (Marek J.).

Enzymes are generally globular proteins with long

linear chains of amino acids that fold to produce threedimensional product, making specific structures with

unique properties. At present, more than 2000 enzymes

have been isolated and characterised, among which 50

have industrial applications. A typical feature of

enzymes is its selectivity. Most of the textile enzymes

catalyze the digestion or hydrolysis of certain large

organic molecules like starch, cellulose and protein

(Shaikh M. A.).

The enzyme products, in general, are easy to use and

treatment can be adapted to run on existing equipment

and at different stages of textile wet processes; in

addition, mild treatment conditions (i.e. temperature

and pH) can be employed. Enzymes completely

biodegradable, fail to accumulate in the environment;

and they save chemicals and energy with the capability

to reduce processing time as well as improve the

surface properties and texture of cellulose-based

fabrics. Furthermore, novel techniques can improve the

characteristics of enzymes, e.g. thermostability of

cellulases (Montazer M.).

Alkaline pectinases are generally produced by bacteria.

Pectinolytic enzymes have been applied for the

degumming of jute, sunn hemp, flax, ramie and

coconut fibers for textile application to remove the

non-cellulosic gummy material of pectin and

hemicellulose. Bioscouring is an alternative and more

environmentally friendly method to remove noncellulosic impurities from raw cellulose fibers by

specific enzymes to make the surface more hydrophilic

(Rasheedha Banu A., Biscaro Pedrolli B.D.). Pectins are

responsible for the hydrophobic properties of raw

cotton and its degradation with pectinolytic enzymes

has been suggested to facilitate the removal of waxes

131

www.tlist-journal.org

Textiles and Light Industrial Science and Technology (TLIST) Volume 2 Issue 3, July 2013

and thus leading to a considerable reduction rate of

water and chemicals consumption. Treatment with

pectin degrading enzymes would not affect the

cellulose backbone and thus avoiding a fiber damage

(Rasheedha Banu A.). Our group first results of

pectinases enzymes used for hemp retting and results

of the obtained fibers colour difference show that

pectinase treatment causes colour characteristics

(Bernava A.).

The cellulases enzyme treatment of jute fabrics resultes

in increase of whiteness index (Kozlowsky R.). The

information about cellulases used in the textile

industry to create a fashionable stonewashed

appearance and biofinishing of linen and other bast

fibres are known (MiettinenOinonen A). One of the

reasons for the wide use of cellulases is their

comparetively low price (MiettinenOinonen A).

was used for experiments.

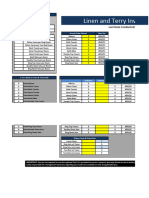

TABLE 1. THE PARAMETERS OF RAW LINEN FABRIC USED FOR

EXPERIMENTS

Parameter

Value

Linear density of warp

50 tex

Linear density of weft

50 tex

Density of warp/10cm

174 yarns

Density of weft/10cm

138 yarns

Weight of fabric

162.8 g/m2

Treatments

The commercially available products pectinase enzyme

Beisol PRO (CHT BEITLICH GmbH, Germany) earlear

used for hemp retting (Bernava A.) and cellulase

enzyme Beizym ENC-SB (CHT BEITLICH GmbH,

Germany) were choosed for investigations.

Methods of Treating

The aim of this research is examination of some

cellulase and pectinase enzymes treatment having

influence on colour characteristics of raw linen fabric.

Conditions of treating and designations of samples are

presented in table 2.

Materials and Methods

Methods of Testing

1) Determination of Testing Samples Changes

Materials

Raw 100% linen plaine weave fabric (characteristic in

Tab.1) produced by the company "Larelini" Ltd, Latvia,

The mass differences of samples after conditioning

were fixed.

TABLE 2. CONDITIONS OF ENZYME TREATMENT AND DESIGNATIONS OF SAMPLES

Enzyme

-

Cellulase Enzyme

Beizym ENC-SB

Pectinase Enzyme

Beisol PRO

Treatment conditions

Designation

Without treatment

No-washed

Washing in water (M 50) at 75C for 15 min. with after treatment

(M 50) in washing agent Felosan NOF 2 g/l water solution at 100C for 60 min with

following rinse in cold/warm water

M 50, concentration of enzyme 1%, at 45-50C, for 60 min, followed by rinse with

cold/warm water

M 50 , concentration of enzyme 2%, at 45-50C, for 60 min, followed by rinse with

cold/warm water

M 50 , concentration of enzyme 1%, at 55C, for 15 min, followed by rinse with

cold/warm water

M 50 , concentration of enzyme 2%, at 55C, for 15 min, followed by rinse with

cold/warm water

2) Colour Testing

The samples representing variations of enzymes

modification were analyzed on 8 points of each side

of sample, using RGB system (CQA Easy Color V3.0

Pocketspec Technologies Inc, USA) which allows

determining coordinates of colour vector a*, b*

and L*-lightness in CIELab- 76 colour space.

Lightness difference (L*), common colour

differences (E), colour saturation (C) and hue (H)

were calculated following common formulas:

132

L* =

Pre-washed

C1

C2

sample

L*s tan dard

sample

a*s tan dard

sample

b*s tan drd

L*

a* = a*

b* = b*

P1

P2

E = (L*) 2 + (a*) 2 + (b*) 2

C = (a*) 2 + (b*) 2

H = arctg (

b*

)

a*

Textiles and Light Industrial Science and Technology (TLIST) Volume 2 Issue 3, July 2013

Linen fabric without washing was used as the

standard.

www.tlist-journal.org

manual (Rhopoint) was performed.

4) Microscopy of Surface

3) Testing of Whiteness

The linen fabric surface investigation with the

image of optical microscopy (microscope Leica

Microsystems GmbH, Germany, magnification 50x)

was used.

Whiteness of the linen fabric surface was

determined with Rhopoint Novo-Shade Duo 45/00

reflectometer (Rhopoint Instrumentation Ltd, UK).

Preparing and testing of samples according to user

TABLE 3. RESULTS OF COLOUR TESTING

Sample

Parameter

a*

No-washed

Pre-washed

C1

C2

P1

P2

4.5

4.7

5.4

5.5

5.1

4.9

b*

3.8

3.7

3.5

3.4

3.6

3.8

L*

59.4

0.2

60.4

60.1

60.1

60.1

0.2

5.2

5.4

4.9

4.7

a*

b*

-0.1

3.6

3.6

3.8

3.9

Lightness difference, L*

57.4

60.2

59.9

59.9

59.9

57.6

60.5

60.2

60.2

60.2

0.9

6.7

6.4

6.2

6.1

-0.6

0.6

0.6

0.7

0.7

Common colour diference, E

Colour saturation, C

5.9

Hue, H

Results and Discussion

colour of samples is slightly redder.

There are practically no changes of mass of linen fabric

after pectinase enzyme treatment; and insignificant

mass lose (0.1- 0.5%) of investigated samples has been

observed in cellulase enzyme treatment case.

Obviously, main masses of impurities are removed in

prewashing process and action of enzymes is

impossible to determine by simple weight method.

The value of coordinate of standard b* is 3.8. Prewashed and both enzyme treated samples parameters

of b* are lower than standard. a* of pre-washed linen

fabric is 0.2, b*-0.1. a* and b* after cellulase

enzyme treatment in all cases are positive; and small

diferences causes used kind of enzyme.

The values of calculated colour parameters are shown

in Table3. The values of a* and b* coordinates (Tab.3)

of all samples are positives. Pre-washed linen fabric a*

parameter is slightly higher in comparison with nowashed (standard). With both enzymes treating a*

coordinate is higher than standard; meaning that

The colour parameters of tested samples are

characterized with common colour difference E

(Fig.1), colour saturation C (Fig.2), hue H (Fig.3) and

lightness difference L* (Fig.4), all of which give

information about colour of fabric. In preparing

processes, most significant parameters are E, L* and

whiteness.

FIG. 1. COMMON COLOUR DIFFERENCE OF PRE-WASHED AND ENZYME TREATED LINEN FABRICS

133

www.tlist-journal.org

Textiles and Light Industrial Science and Technology (TLIST) Volume 2 Issue 3, July 2013

C2

C1

P2

P1

Prewas

6

5

4

3

2

1

0

Nowas

Colour Saturation

Designation of Sample

FIG. 2. COLOUR SATURATION OF NO-WASHED, PRE-WASHED AND ENZYME TREATED LINEN FABRICS

H

0.7

0.5

Hue

0.3

-0.5

-0.7

C2

C1

P2

-0.3

P1

-0.1

Pre-washed

0.1

Designation of Sample

FIG. 3. HUE OF PRE-WASHED AND ENZYME TREATED LINEN FABRICS

Lightness, L*

Whiteness

60

50

40

Value

30

20

10

P2

P1

C2

C1

Prewashe

d

Designation of Sample

FIG. 4. LIGHTNESS DIFFERENCE AND WHITENESS (%) OF INVESTIGATED LINEN FABRICS

Common colour difference (Tab.3, Fig.1) of pre-washed

linen fabric is 57.6. Insignificant increase of E after

enzyme treatment independently of kind and

treatment conditions has been observed.

Colour saturation (Tab.3, Fig.2) of no-washed linen

fabric is 5.9. Saturation decrease is remarkable for prewashed linen fabric (0.9). Colour saturation returns to

134

no-washed sample level after enzyme treatment

independently of enzyme kind and treatment

conditions.

Hue (Tab.3, Fig.3) of pre-washed linen fabric is -0.6.

Values of hue for samples after enzymes treating are

positives, which means that insignificant colour and

colour saturation differences are connected with hue of

Textiles and Light Industrial Science and Technology (TLIST) Volume 2 Issue 3, July 2013

www.tlist-journal.org

linen fabric.

For comparison and explaining the obtained results,

the another index-whiteness of surface was determined

with Rhopoint Novo-Shade Duo 45/00 reflectometer,

designed to assess the shade of any flat surface from

black (0%-no reflectance) to brilliant white (100%-full

reflectance) was used.

The results of experiments together with L*

parameters are shown in fig.4. insignificant growth of

lightness difference L* and whiteness after enzyme

treatment independently of kind and treatment

conditions has been observed. The correlation between

lightness difference L* and whiteness is evident

(fig.4).

The investigation results of microscopy images of

fibres surface (Fig.5-7) show treatment influence on

fabric surface. Enzyme treatment causes some splitting

of the yarns, and the effect is more remarkable in the

case of cellulase enzyme.

FIG. 7 MICROSCOPY OF SURFACE OF CELLULASE (C2)

TREATED LINEN FABRIC

Conclusions

Enzyme type and modification method having

influence on raw linen colour parameters and

whiteness are insignificant, meaning that enzyme dont

act on natural pigments responsible for colour

characteristics of natural fibers. If the higher whiteness

as 29% is required, the additional chemical bleaching is

necessary. The correlation between lightness difference

and whiteness obtained with different experimental

methods has been observed. Splitting of the warp and

weft yarns after enzyme treatment appears.

REFERENCES

Bernava A., Reihmane S. Influence of Pectinases Enzyme

Retting on Hemp Fibers Quality, Abstracts of the RTU

53rdInternational Scientific Conference; Riga, Latvia; 24,

2012.

Biscaro Pedrolli B.D., Costa MonteiroA., Gomes E. and Cano

FIG. 5 MICROSCOPY OF SURFACE OF PRE-WASHED LINEN

FABRIC

Carmona

E.

Pectin

and

Pectinases:

Production,

Characterization and Industrial Application of Microbial

Pectinolytic

Enzymes

The

Open

Biotechnology

Journal,Vol. 3., 9-18, 2009.

CieL*a*b* color Csale; Inside of Color Vol.8,Nr7; Copyright;

1-4, 2008.

Kozlowsky R., Batog J., Konczewicz W. Enzymes in Bast

Fibrous Plant Processing, Biotechnology Letters, Vol.28,

Is.10; 761-765, 2006.

Marek J., Antonov V., Bjelkova M., Smirous P., Fischer

H.,Janosik S. Enzymatic Bioprocessing New Tool of

Extensive Natural Fibre Source Utilization. Abstract

FIG. 6 MICROSCOPY OF SURFACE OF PECTINASE (P2) TREATED

LINEN FABRIC

of International Conference on Flax and Other Bast

Plants, 159-169; 2008.

135

www.tlist-journal.org

Textiles and Light Industrial Science and Technology (TLIST) Volume 2 Issue 3, July 2013

Miettinen Oinonen A., Cellulases in the Textiles Industry,

Industrial Enzymes edited by Polaina J. and MacCabe

A.P., 2007 Springer; 51-63; 2007.

Montazer M., Sadeghian Maryan A Influences of Different

Enzymatic Treatment on Denim GarmentAppl. Biochem.

Biotechnol., 2010 Apr; 160(7):2114-28. 877-883; 2010.

Rasheedha Banu A., Kalpana Devi M., Gnanaprabhal G. R.,

Pradeep B. V. and Palaniswamy M. Production and

Characterization of Pectinase Enzyme from Penicillium

Chrysogenum,

Indian

Journal

of

Science

and

Technology Vol. 3, No. 4; 377-381; 2010.

Rhopoint novo-shade duotm 45/00 reflectometer. User Manual.

www.rhopointinstruments.com

Roy Choudhury A.K. Textile Preparation and Dyeing,

Science Publishers; 834; 2006

Shaikh M. A. Enzymes: a Revaluation in Textile Processing,

Dyeing Printing Finishing, PTJ, April 2010; 48-51; 2010

Wei Q Surface Modification of Textiles edited by Wei Q.,

Woodhead Publishing Limited, Oxford, Cambridge, New

Delhi; 280-281; 2009.

136

Bernava Aina, Scientific Assistant. Born in Latvia, Liepaja

on 9 of May 1958. Professional Master Degree in Material

Design and Technology of Riga Technical Univesity; Institute

of Textile Materials Technologies and Design 2011. Master of

the Latvian Chamber of Crafts since 2004. More than 30 years

practical working experience in field of fabric design and

hand made weaving. Researcher in national scientific

projects of Institute of Polymer Materials since 2011. Field of

research is connected with innovative weaved textile

structures processing and textile materials modification for

use in ordinary textiles and composite materials.

Reihmane Skaidrite, Dr.Sc. Eng., Prof. Born in Latvia,

Bauska district 28 of February 1945. Dipl. Eng. qualification

of Riga Polytechnical Institute Faculty of Chemistry in

specialty chemical technology and equipment of textiles

treatment, 1968; Dr. Sc. Engineering 26 of June 1992, Riga,

Riga Technical University (RTU) in the field of chemical

technology of fiber materials. Head of Department of

Polymer Materials Chemical Technology of RTU, lecture

courses at Riga Technical University connected with textile

materials, their modification and use in composites. Leading

researcher of collaborative international and national

scientific projects, more than 120 research publications

connected with textile materials finishing and application.

Potrebbero piacerti anche

- Microstructure and Wear Properties of Laser Clad NiCrBSi-MoS2 CoatingDocumento5 pagineMicrostructure and Wear Properties of Laser Clad NiCrBSi-MoS2 CoatingSEP-PublisherNessuna valutazione finora

- Mill's Critique of Bentham's UtilitarianismDocumento9 pagineMill's Critique of Bentham's UtilitarianismSEP-PublisherNessuna valutazione finora

- Quantum Meditation: The Self-Spirit ProjectionDocumento8 pagineQuantum Meditation: The Self-Spirit ProjectionSEP-PublisherNessuna valutazione finora

- Mindfulness and Happiness: The Empirical FoundationDocumento7 pagineMindfulness and Happiness: The Empirical FoundationSEP-PublisherNessuna valutazione finora

- Cold Mind: The Released Suffering StabilityDocumento3 pagineCold Mind: The Released Suffering StabilitySEP-PublisherNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Electrolux Eww1476wd ManualDocumento36 pagineElectrolux Eww1476wd ManualVíctor DTNessuna valutazione finora

- (1891) Illustrated Catalogue DR - Jaeger's Sanitary Woolen System CompanyDocumento76 pagine(1891) Illustrated Catalogue DR - Jaeger's Sanitary Woolen System CompanyHerbert Hillary Booker 2nd100% (1)

- Electrolux EWW1292Documento30 pagineElectrolux EWW1292monalisa2570Nessuna valutazione finora

- Dwnload Full Good Earth Introduction To Earth Science 3rd Edition Mcconnell Test Bank PDFDocumento22 pagineDwnload Full Good Earth Introduction To Earth Science 3rd Edition Mcconnell Test Bank PDFcadgerstubbyvv8fwj100% (10)

- Types of LinenDocumento24 pagineTypes of LinenDemie Anne Alviz BerganteNessuna valutazione finora

- 07 Quiz 1Documento2 pagine07 Quiz 1Andre ObedozaNessuna valutazione finora

- Care Label Instructions ExplainedDocumento37 pagineCare Label Instructions ExplainedMard GeerNessuna valutazione finora

- School Needlework. A Course of Study in Sewing PDFDocumento184 pagineSchool Needlework. A Course of Study in Sewing PDFJAREK MBAREKNessuna valutazione finora

- Executive Manager Is The Chief of Housekeeping Department. The Deputy Housekeeper andDocumento4 pagineExecutive Manager Is The Chief of Housekeeping Department. The Deputy Housekeeper andRenz KunNessuna valutazione finora

- Linen Inventory Worksheet 2023Documento8 pagineLinen Inventory Worksheet 2023hospitalitylakhaniNessuna valutazione finora

- Paper Laundry & CSSD PDFDocumento8 paginePaper Laundry & CSSD PDFerpNessuna valutazione finora

- Bag Technique Lecture NotesDocumento4 pagineBag Technique Lecture NotesSarahLabadanNessuna valutazione finora

- Contemporary Fashion From The Land of Pharaohs: EgyptDocumento10 pagineContemporary Fashion From The Land of Pharaohs: EgyptVivék Gaharwar OdétNessuna valutazione finora

- Exhibitor and Visitor Statistics For Heimtextil 2020Documento1 paginaExhibitor and Visitor Statistics For Heimtextil 2020Ricardo PereiraNessuna valutazione finora

- Placemat From Millionaire Vines (Cissus Verticillata)Documento39 paginePlacemat From Millionaire Vines (Cissus Verticillata)rhea parajesNessuna valutazione finora

- Color Fastness To WashingDocumento11 pagineColor Fastness To WashingTarang Mathur80% (5)

- Mamta JadhavDocumento43 pagineMamta JadhavPranay PiyushNessuna valutazione finora

- Care and Maintanance of FabricDocumento19 pagineCare and Maintanance of FabricBalbir Singh0% (1)

- The Linen RoomDocumento21 pagineThe Linen RoomNishant KumarNessuna valutazione finora

- Apparel and Fashion Design: Parameters of Quality Standard Between Indian and International BrandsDocumento17 pagineApparel and Fashion Design: Parameters of Quality Standard Between Indian and International BrandsSaumyaNessuna valutazione finora

- 3w Laundry Week IxDocumento10 pagine3w Laundry Week IxAri RuandaNessuna valutazione finora

- Textile Fibers: Created By: Mrs. Christine Holt FACS Educator Westlake High SchoolDocumento49 pagineTextile Fibers: Created By: Mrs. Christine Holt FACS Educator Westlake High SchoolAnonymous 51N3PEzjNessuna valutazione finora

- Full Download Test Bank For Essentials of Sociology 13th Edition James M Henslin PDF Full ChapterDocumento22 pagineFull Download Test Bank For Essentials of Sociology 13th Edition James M Henslin PDF Full Chapteranalcitedonary46f2d100% (13)

- Honing Razors and Nihonkamisori New PDFDocumento22 pagineHoning Razors and Nihonkamisori New PDFEdgar ShahbazoffNessuna valutazione finora

- Module5 Linen RoomDocumento9 pagineModule5 Linen RoomAman KeltaNessuna valutazione finora

- Tecoya Trend 16 November 2019 PDFDocumento4 pagineTecoya Trend 16 November 2019 PDFRamarthnam SivaramakrishnanNessuna valutazione finora

- MacraméDocumento22 pagineMacraméChen TY100% (1)

- Women S Textiles Forecast S S 25 Restorative Realms enDocumento20 pagineWomen S Textiles Forecast S S 25 Restorative Realms enhlaimisana37100% (1)

- Ii Puc English Model Question Paper 2022Documento5 pagineIi Puc English Model Question Paper 2022PrasadNessuna valutazione finora

- He1-Production of Household LinensDocumento3 pagineHe1-Production of Household LinensJellian LibresNessuna valutazione finora