Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Data Sheet

Caricato da

MarcoAntonioCamanTraihuelCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Data Sheet

Caricato da

MarcoAntonioCamanTraihuelCopyright:

Formati disponibili

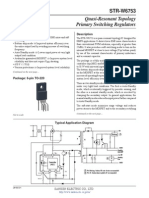

STR-W605xS

Current Mode Control PWM Regulator IC

For Switching Power Supplies

Features and Benefits

Description

TO-220F power package with 30 to 90 W power output

Current Mode PWM control

Built-in Random Switching function, reducing EMI noise,

and simplifying EMI filters, and therefore reducing cost

Built-in Slope Compensation function, avoiding

subharmonic oscillation

Built-in Auto Standby function (Input Power, PIN < 30 mW

at no load)

Normal operation: PWM mode

Light load operation: Standby mode (burst oscillation)

Built-in Audible Noise Suppression function during

Standby mode

Built-in Startup Circuit, reducing power consumption in

standby operation, and eliminating external components.

Bias-Assist function, improving startup operation,

suppressing VCC voltage drop in operation, and allowing

use of smaller VCC capacitor

Built-in Leading Edge Blanking function

The STR-W605xS series are power ICs for switching power

supplies, incorporating a power MOSFET and a current mode

PWM controller IC. Including a startup circuit and a standby

function in the controller, the product achieves low power

consumption, low standby power, and high cost-effectiveness

power supply systems with few external components.

Continued on the next page

Package: 6-Pin fully molded

TO-220F-6L (FM207)

The STR-W605xS internal MOSFET has a VDSS of 650 V (min),

and an RDS(on) of 1.9 (max) to 3.95 (max) with a frequency

of 67 kHz. Power output is rated at 45 to 90 W at 230 VAC

input and 30 to 60 W at wide input range (85 to 265 VAC).

The device is provided in an industry-standard TO-220 package,

with heatsink mounting flange and pin 2 removed for increased

supply isolation.

Applications:

For switching power supplies used in:

White goods

Consumer electronics

Office automation

Industrial equipment

Communication equipment

http://www.DataSheet4U.net/

Not to scale

Typical Application

VOU T

VAC

GND

D/ST

S/ OCP

V CC

GND

FB/OLP

BR

STR-W6000S

3 4 5 6 7

Brown-In/Brown-Out function

disabled by connecting BR

terminal to GND.

STR-W605xS-DS

datasheet pdf - http://www.DataSheet4U.net/

Current Mode Control PWM Regulator IC

For Switching Power Supplies

STR-W605xS

Features and Benefits (continued)

compensation circuit to minimize OCP point variation on

Two-chip structure, with a controller and a power MOSFET

with guaranteed avalanche energy available to simplify surge

AC input voltage

absorber circuits

Overload Protection function (OLP): auto-restart, built-in

Protection functions:

timer, reduces heat during overload condition, and no external

Brown-In and Brown-Out Protection function: auto-restart,

components required

prevention of excess input current and heat rise at low

Overvoltage Protection function (OVP): Auto-restart

input voltage

Overcurrent Protection function (OCP): pulse-by-pulse built-in Thermal Shutdown Protection function (TSD): Auto-restart

Selection Guide

Part Number

fOSC

(kHz)

MOSFET

VDSS(min)

(V)

67

650

STR-W6051S

STR-W6052S

STR-W6053S

RDS(on)

(max)

()

POUT*

(W)

230 V

Package

Packing

Wide

3.95

45

30

2.8

60

40

1.9

90

60

TO-220F-6L (Sanken FM207)

with pin 2 removed

50 pieces per tube

http://www.DataSheet4U.net/

* The listed output power is based on the package thermal ratings, and the peak output power can be 120% to 140% of the

value stated here. At low output voltage and short duty cycle, the output power may be less than the value stated here.

datasheet pdf - http://www.DataSheet4U.net/

Current Mode Control PWM Regulator IC

For Switching Power Supplies

STR-W605xS

Absolute Maximum Ratings1 Valid at TA = 25C, unless otherwise specified

Characteristic

Drain Peak

Current2

Maximum Switching Current3

Symbol

IDpeak

IDMAX

EAS

Notes

Single pulse

TA = 20C to 125C

Single pulse, VDD = 99 V,

L = 20 mH

Single Pulse Avalanche Energy4

ILpeak

Single pulse, VDD = 99 V,

L = 20 mH

Terminals

Rating

Unit

STR-W6051S

13

5.0

STR-W6052S

13

7.0

STR-W6053S

13

9.5

STR-W6051S

13

5.0

STR-W6052S

13

7.0

STR-W6053S

13

9.5

STR-W6051S

13

47

mJ

STR-W6052S

13

62

mJ

STR-W6053S

13

86

mJ

STR-W6051S

13

2.0

STR-W6052S

13

2.3

STR-W6053S

13

2.7

S/OCP Terminal Voltage

VOCP

35

2 to 6

Controller IC (MIC) Supply Input Voltage

VCC

45

32

FB/OLP Terminal Voltage

VFB

65

0.3 to 14

FB/OLP Terminal Sink Current

IFB

65

1.0

mA

BR Terminal Voltage

VBR

75

0.3 to 7

BR Terminal Sink Current

http://www.DataSheet4U.net/

IBR

MOSFET Power Dissipation5

PD1

Controller IC (MIC) Power Dissipation

PD2

Internal Frame Temperature in Operation

TF

With infinite heatsink

75

1.0

mA

STR-W6051S

13

22.3

STR-W6052S

13

23.6

STR-W6053S

13

26.5

Without heatsink

13

1.3

Specified by VCC ICC

45

0.13

20 to 115

20 to 115

Maximum recommended

internal leadframe

temperature, TF(max) = 105C

Operating Ambient Temperature

TOP

Storage Temperature

Tstg

40 to 125

Channel Temperature

Tch

150

1Current

characteristics are defined based on IC as sink ( +), or source ( ).

2Refer to MOSFET Safe Operating Area Curve.

3I

DMAX is the drain current on the D/ST pin determined by the drive voltage of the IC and the threshold voltage, Vth , of the MOSFET.

4Refer to MOSFET Avalanche Energy Derating Coefficient Curve.

5Refer to MOSFET Temperature versus Power Dissipation Curve.

datasheet pdf - http://www.DataSheet4U.net/

Current Mode Control PWM Regulator IC

For Switching Power Supplies

STR-W605xS

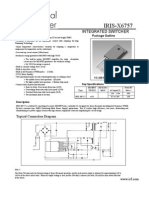

Functional Block Diagram

VCC

Startup

UVLO

BR

REG

VREG

OVP

D/ST

TSD

Brown-In/

Brown-Out

PWM OSC

DRV

SQ

R

OCP

VCC

Drain Peak Current

Compe nsa tion

OLP

Fe edback

Control

FB/OLP

6

LEB

S/OCP

GND

Slope

Compensation

http://www.DataSheet4U.net/

Pin-out Diagram

Terminal List Table

Number

Name

D/ST

Function

MOSFET drain, and input for startup current

S/OCP

(Pin removed)

VCC

Input for power supply for control circuit

GND

Ground

FB/OLP

BR

MOSFET source, and input for Overcurrent Protection detection signal

Input for constant voltage control signal, and input for Overload Protection signal

Input for Brown-In and Brown-Out Protection detection voltage

1 2 3 4 5 6 7

datasheet pdf - http://www.DataSheet4U.net/

STR-W605xS

Current Mode Control PWM Regulator IC

For Switching Power Supplies

Electrical Characteristics1 Valid at VCC = 18 V, TA = 25C, unless otherwise specified

Characteristic

Symbol

Terminal

Min.

Typ.

Max.

Unit

Operation Start Voltage

VCC(ON)

45

13.8

15.3

16.8

Operation Stop Voltage2

VCC(OFF)

45

7.3

8.1

8.9

ICC(ON)

45

2.5

mA

Minimum Startup Voltage

VST(ON)

45

40

Startup Current

ISTARTUP

45

3.9

2.5

1.1

mA

Startup Current Supply Threshold Voltage2

VCC(BIAS)

45

8.5

9.5

10.5

fOSC(av)

15

60

67

74

kHz

Circuit Current in Operation

Average Switching Frequency

Switching Frequency Variance Range

15

kHz

DMAX

15

63

71

79

Leading Edge Blanking Time

tBW

390

ns

OCP Compensation Coefficient

DPC

18

mV/s

Maximum Duty Cycle

DDPC

36

OCP Threshold Voltage at Zero Duty Cycle

Maximum Duty Cycle for OCP Compensation

VOCP(L)

35

0.70

0.78

0.86

OCP Threshold Voltage at 36% Duty Cycle

VOCP(H)

35

0.79

0.88

0.97

Maximum Feedback Current

IFB(MAX)

65

340

230

150

Minimum Feedback Current

IFB(MIN)

65

30

15

Oscillation Stop FB/OLP Voltage

VFB(OFF)

65

0.85

0.95

1.05

OLP Threshold Voltage

VFB(OLP)

65

7.3

8.1

8.9

Operation Current After OLP

ICC(OLP)

45

300

15

54

68

82

ms

OLP Delay Time

tOLP

FB/OLP Terminal Clamp Voltage

Brown-In Threshold Voltage

Brown-Out Threshold Voltage

http://www.DataSheet4U.net/

VFB(CLAMP)

65

11

12.8

14

VBR(IN)

75

5.2

5.6

V

V

VBR(OUT)

75

4.45

4.8

5.15

VBR(CLAMP)

75

6.4

BR Function Disabling Threshold

VBR(DIS)

75

0.3

0.48

0.7

OVP Threshold Voltage

VCC(OVP)

45

26

29

32

TJ(TSD)

130

BR Terminal Clamp Voltage

Thermal Shutdown Operating Temperature

1Current

characteristics are defined based on IC as sink ( +), or source ( ).

VCC(OFF).

2V

CC(BIAS) >

MOSFET Electrical Characteristics Valid at TA = 25C, unless otherwise specified

Characteristic

Symbol

Device

Terminal

Min.

Typ.

Drain-to-Source Breakdown Voltage

VDSS

13

650

Drain Leakage Current

IDSS

13

300

STR-W6051S

13

3.95

STR-W6052S

13

2.8

STR-W6053S

13

1.9

13

250

ns

STR-W6051S

2.63

C/W

STR-W6052S

2.26

C/W

STR-W6053S

1.95

C/W

On-Resistance

RDS(on)

Switching Time

tf

Thermal Resistance*

RchF

Max.

Unit

*Between channel and internal frame.

datasheet pdf - http://www.DataSheet4U.net/

Current Mode Control PWM Regulator IC

For Switching Power Supplies

STR-W605xS

Characteristic Performance

STR-W6051S

MOSFET Safe Operating Area Curve

100

TA = 25C;

Single pulse

100

Drain current limited

by on-resistance

10

80

Drain Current, ID (A)

Safe Operating Area

Temperature Derating Coefficient (%)

S. O. A. Temperature Derating Coefficient Curve

60

40

20

0.1 ms

1 ms

0.1

0

20

40

60

80

100

120

To use this graph, apply the S.O.A

temperature derating coefficient

taken from the graph at the left

Internal Frame Temperature, TF (C)

0.01

10

100

1000

Drain-to-Source Voltage, VDS (V)

MOSFET Temperature versus Power Dissipation Curve

100

http://www.DataSheet4U.net/

80

60

40

20

0

25

50

75

100

125

150

Allowable Power Dissipation, PD1 (W)

EAS

Temperature Derating Coefficient (%)

MOSFET Avalanche Energy Derating Coefficient Curve

25

With infinite heatsink

PD1 = 22.3 W at TA 25C

20

15

10

Without heatsink

PD1 = 1.3 W at TA 25C

0

Channel Temperature, Tch (C)

40

60

80

100 120 140 160

Transient Thermal Resistance Curve

10

Transient Thermal

Resistance, Rch-c (C/W)

20

Ambient Temperature, TA (C)

0.1

0.01

10-6

10-5

10-4

10-3

10-2

10-1

Time (s)

datasheet pdf - http://www.DataSheet4U.net/

Current Mode Control PWM Regulator IC

For Switching Power Supplies

STR-W605xS

Characteristic Performance

STR-W6052S

MOSFET Safe Operating Area Curve

100

TA = 25C;

Single pulse

Drain current limited

by on-resistance

100

0.1 ms

10

80

Drain Current, ID (A)

Safe Operating Area

Temperature Derating Coefficient (%)

S. O. A. Temperature Derating Coefficient Curve

60

40

20

1 ms

1

0.1

0

20

40

60

80

100

120

To use this graph, apply the S.O.A

temperature derating coefficient

taken from the graph at the left

Internal Frame Temperature, TF (C)

0.01

10

100

1000

Drain-to-Source Voltage, VDS (V)

MOSFET Temperature versus Power Dissipation Curve

100

http://www.DataSheet4U.net/

80

60

40

20

0

25

50

75

100

125

150

Allowable Power Dissipation, PD1 (W)

EAS

Temperature Derating Coefficient (%)

MOSFET Avalanche Energy Derating Coefficient Curve

25

With infinite heatsink

PD1 = 23.6 W at TA 25C

20

15

10

Without heatsink

PD1 = 1.3 W at TA 25C

0

Channel Temperature, Tch (C)

40

60

80

100 120 140 160

Transient Thermal Resistance Curve

10

Transient Thermal

Resistance, Rch-c (C/W)

20

Ambient Temperature, TA (C)

0.1

0.01

10-6

10-5

10-4

10-3

10-2

10-1

Time (s)

datasheet pdf - http://www.DataSheet4U.net/

Current Mode Control PWM Regulator IC

For Switching Power Supplies

STR-W605xS

Characteristic Performance

STR-W6053S

MOSFET Safe Operating Area Curve

100

TA = 25C;

Single pulse

Drain current limited

by on-resistance

100

0.1 ms

10

80

Drain Current, ID (A)

Safe Operating Area

Temperature Derating Coefficient (%)

S. O. A. Temperature Derating Coefficient Curve

60

40

20

1 ms

1

0.1

0

20

40

60

80

100

120

To use this graph, apply the S.O.A

temperature derating coefficient

taken from the graph at the left

Internal Frame Temperature, TF (C)

0.01

10

100

1000

Drain-to-Source Voltage, VDS (V)

MOSFET Temperature versus Power Dissipation Curve

100

http://www.DataSheet4U.net/

80

60

40

20

0

25

50

75

100

125

150

Allowable Power Dissipation, PD1 (W)

EAS

Temperature Derating Coefficient (%)

MOSFET Avalanche Energy Derating Coefficient Curve

30

With infinite heatsink

PD1 = 26.5 W at TA 25C

25

20

15

10

Without heatsink

PD1 = 1.3 W at TA 25C

5

0

Channel Temperature, Tch (C)

40

60

80

100 120 140 160

Transient Thermal Resistance Curve

10

Transient Thermal

Resistance, Rch-c (C/W)

20

Ambient Temperature, TA (C)

0.1

0.01

10-6

10-5

10-4

10-3

10-2

10-1

Time (s)

datasheet pdf - http://www.DataSheet4U.net/

Current Mode Control PWM Regulator IC

For Switching Power Supplies

STR-W605xS

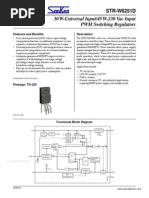

Typical Application

VOU T

VAC

GND

D/ST

S/ OCP

V CC

GND

FB/OLP

BR

STR-W6000S

3 4 5 6 7

Brown-In/Brown-Out function

enabled by connecting BR

terminal to resistive divider.

http://www.DataSheet4U.net/

datasheet pdf - http://www.DataSheet4U.net/

Current Mode Control PWM Regulator IC

For Switching Power Supplies

STR-W605xS

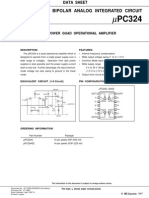

Package Outline Drawing, TO-220F-6L (FM207)

10.00.2

4.20.2

Gate burr

3.20.2

7.90.2

16.90.3

40.2

0.5

2.80.2

STR

a

b

(5.4)

R-end

)

-R1

(2

6-0.65 +0.2

-0.1

10.40.5

6-0.740.15

5.00.5

2.8

2.60.1

Dimensions from root

http://www.DataSheet4U.net/

6P1.270.15=7.620.15

Dimensions between roots

0.45 +0.2

-0.1

5.080.6

Dimensions between roots

0.5

1 2 3 4 5 6 7

Leadform: 2003

Material of terminal: Cu

Treatment of terminal: Solder plating (Pb-free)

Weight: Approximately 2.3 g

Dashed line at Gate Burr indicates

protrusion of 0.3 mm (max)

Unit: mm

0.5

Plan view

0.5

0.5

Side view

a. Type Number: W6051S

b. Lot Number:

1st letter: Last digit of year

2nd letter: Month

1 to 9 for Jan. to Sept.

O for Oct.

N for Nov.

D for Dec.

3rd and 4th letter: Day of month

5th letter: Sanken Registration Number

Leadframe plating Pb-free. Device composition

compliant with the RoHS directive.

datasheet pdf - http://www.DataSheet4U.net/

STR-W605xS

Current Mode Control PWM Regulator IC

For Switching Power Supplies

Packing Specifications

+0.4

0

1.4

5.1

9 R0.6

35.0

(15.4)

9.50.1

+0.3

8.9

4.8

Side marked

ANTISTATIC

2.85

+0.3

(3.6)

1.3 0.2

14.3

Tube dimensions (mm)

http://www.DataSheet4U.net/

Spacer

Carton

(side

view)

620

Tube

Tube

125

Spacer

185

Carton dimensions (mm)

Capacity:

36 tubes per carton (3 rows, 12 tubes per row)

50 pieces per tube

1800 pieces maximum per carton

datasheet pdf - http://www.DataSheet4U.net/

Current Mode Control PWM Regulator IC

For Switching Power Supplies

STR-W605xS

Because reliability can be affected adversely by improper storage

environments and handling methods, please observe the following

cautions.

Cautions for Storage

Ensure that storage conditions comply with the standard

temperature (5C to 35C) and the standard relative humidity

(around 40% to 75%); avoid storage locations that experience

extreme changes in temperature or humidity.

Avoid locations where dust or harmful gases are present and

avoid direct sunlight.

Reinspect for rust on leads and solderability of products that have

been stored for a long time.

Cautions for Testing and Handling

When tests are carried out during inspection testing and other

standard test periods, protect the products from power surges

from the testing device, shorts between the product pins, and

wrong connections.

Remarks About Using Silicone Grease with a Heatsink

When silicone grease is used in mounting this product on a

heatsink, it shall be applied evenly and thinly. If more silicone

grease than required is applied, it may produce excess stress.

Volatile-type silicone greases may crack after long periods of

time, resulting in reduced heat radiation effect. Silicone grease

with low consistency (hard grease) may cause cracks in the mold

resin when screwing the product to a heatsink.

Our recommended silicone greases for heat radiation purposes,

which will not cause any adverse effect on the product life, are

indicated below:

Type

Suppliers

G746

Shin-Etsu Chemical Co., Ltd.

YG6260

Momentive Performance Materials Holding, Inc.

SC102

Dow Corning Toray Co., Ltd.

Soldering

Leadframe temperature, TF , should not exceed 115(max)

When soldering the products, please be sure to minimize the

working time, within the following limits:

2605C 10 s

3505C 3 s (solder iron)

To avoid an internal chip damaged, soldering on each of lead-pins

should be at a distance of at least 2 mm away from the body of

the products

Assembly

Recommended screw torque through the mounting tab is 0.588 to

0.785 N m (6 to 8 kgf cm).

Electrostatic Discharge

When handling the products, the operator must be grounded.

Grounded wrist straps worn should have at least 1 M of

resistance from the operator to ground to prevent shock hazard,

and it should be placed near the operator.

Workbenches where the products are handled should be

grounded and be provided with conductive table and floor mats.

When using measuring equipment such as a curve tracer, the

equipment should be grounded.

When soldering the products, the head of soldering irons or the

solder bath must be grounded in other to prevent leak voltages

generated by them from being applied to the products.

The products should always be stored and transported in Sanken

shipping containers or conductive containers, or be wrapped in

aluminum foil.

http://www.DataSheet4U.net/

datasheet pdf - http://www.DataSheet4U.net/

Potrebbero piacerti anche

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Da EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Nessuna valutazione finora

- DatasheetDocumento12 pagineDatasheetDjalma MoreiraNessuna valutazione finora

- STR W6000S Series Application NoteDocumento20 pagineSTR W6000S Series Application NoteSutrisno OkNessuna valutazione finora

- STR W6735Documento14 pagineSTR W6735proctepNessuna valutazione finora

- PDF Sanken 882276Documento13 paginePDF Sanken 882276Moises CelosoNessuna valutazione finora

- Allegro STR-W6765 PDFDocumento15 pagineAllegro STR-W6765 PDFcomportNessuna valutazione finora

- Data SheetDocumento7 pagineData SheetOvi PanteaNessuna valutazione finora

- Datasheet STR 6757Documento11 pagineDatasheet STR 6757Walter CarreroNessuna valutazione finora

- STR W6735 DatasheetDocumento13 pagineSTR W6735 DatasheetloagerNessuna valutazione finora

- STR W6053SDocumento14 pagineSTR W6053SMarcos Rangel100% (1)

- STR W6753 DatasheetDocumento8 pagineSTR W6753 DatasheetjgerabmNessuna valutazione finora

- Dse STR A6000mDocumento13 pagineDse STR A6000mAlanNessuna valutazione finora

- 12 Volt Smps Circuit DiagramDocumento7 pagine12 Volt Smps Circuit DiagramAnura MaddumageNessuna valutazione finora

- STRW6754Documento9 pagineSTRW6754electronicaliderNessuna valutazione finora

- Off-Line Quasi-Resonant Switching Regulators: STR-X6769Documento9 pagineOff-Line Quasi-Resonant Switching Regulators: STR-X6769Alfredo Valencia RodriguezNessuna valutazione finora

- A6052M Allegro MicroSystemsDocumento15 pagineA6052M Allegro MicroSystemsLuis CampagnoliNessuna valutazione finora

- Off-Line Quasi-Resonant Switching Regulators: STR-X6729Documento9 pagineOff-Line Quasi-Resonant Switching Regulators: STR-X6729perro sNessuna valutazione finora

- A6251 6252Documento7 pagineA6251 6252Giovanni Carrillo VillegasNessuna valutazione finora

- DM0265Documento19 pagineDM0265liberthNessuna valutazione finora

- P1027P65 (SMPS)Documento30 pagineP1027P65 (SMPS)Jesus Silva67% (3)

- 60 W-Universal Input/90 W-230 Vac Input PWM Switching RegulatorsDocumento14 pagine60 W-Universal Input/90 W-230 Vac Input PWM Switching RegulatorsIBSDIALLO0% (1)

- Quasi-Resonant Topology Primary Switching Regulators: STR-W6756Documento8 pagineQuasi-Resonant Topology Primary Switching Regulators: STR-W6756perro sNessuna valutazione finora

- STRW6252Documento15 pagineSTRW6252miltoncgNessuna valutazione finora

- PWM Off-Line Switching Regulator Ics: Str-A6000H SeriesDocumento13 paginePWM Off-Line Switching Regulator Ics: Str-A6000H SeriesAnonymous Lfgk6vygNessuna valutazione finora

- Uc3842b 3843BDocumento10 pagineUc3842b 3843Bbob75Nessuna valutazione finora

- Iris-W 6754Documento8 pagineIris-W 6754Fatah MedAmineNessuna valutazione finora

- Ane Str3a100Documento17 pagineAne Str3a100vietanh_askNessuna valutazione finora

- Go-iris-A6159 Fuente TV Samsung LCD 32"Documento7 pagineGo-iris-A6159 Fuente TV Samsung LCD 32"Daniel GómezNessuna valutazione finora

- Data SheetDocumento7 pagineData Sheetitamar_123Nessuna valutazione finora

- Quasi-Resonant Topology Primary Switching Regulators: STR-W6735Documento13 pagineQuasi-Resonant Topology Primary Switching Regulators: STR-W6735perro sNessuna valutazione finora

- 1565 RTDocumento24 pagine1565 RTJose Samuel Robelto RNessuna valutazione finora

- Mip 2 C 2Documento3 pagineMip 2 C 2Shubham AdkeNessuna valutazione finora

- IC-ON-LINE - CN dm0365r 44840Documento20 pagineIC-ON-LINE - CN dm0365r 44840MoscandoNessuna valutazione finora

- SG3525A Pulse Width Modulator Control Circuit: 1% and The ErrorDocumento10 pagineSG3525A Pulse Width Modulator Control Circuit: 1% and The ErrorJayesh SuryavanshiNessuna valutazione finora

- SSC2001S Application NoteDocumento18 pagineSSC2001S Application NoteGerardo Mendez CamarilloNessuna valutazione finora

- SG 6841 TDocumento14 pagineSG 6841 TBayron Salazar SaborioNessuna valutazione finora

- STR A6252 PDFDocumento9 pagineSTR A6252 PDFFernando ChingaNessuna valutazione finora

- IRIS-X6757: FeaturesDocumento10 pagineIRIS-X6757: Featuresmiguel angel jaramilloNessuna valutazione finora

- DatasheetDocumento13 pagineDatasheetebertecnicoNessuna valutazione finora

- STR-A6151 STR-A6159: Universal-Input/13 or 16 W Flyback Switching RegulatorsDocumento7 pagineSTR-A6151 STR-A6159: Universal-Input/13 or 16 W Flyback Switching RegulatorsmilebaleNessuna valutazione finora

- OB2269Documento12 pagineOB2269Juan Ballon100% (1)

- Datasheet PDFDocumento15 pagineDatasheet PDFperro sNessuna valutazione finora

- Tle6220gp DatasheetDocumento18 pagineTle6220gp Datasheetmaelo99999Nessuna valutazione finora

- Iramx 16 Up 60 ADocumento17 pagineIramx 16 Up 60 AJandfor Tansfg ErrottNessuna valutazione finora

- 230D6 - Low Standby Power High Performance PWM ControllerDocumento21 pagine230D6 - Low Standby Power High Performance PWM ControllerAVAZONENessuna valutazione finora

- Ap5002 - PWM Control 2a Step-Down ConverterDocumento10 pagineAp5002 - PWM Control 2a Step-Down ConverterAmador Garcia IIINessuna valutazione finora

- FAN7602 - Green Current Mode PWM Controller - Fairchild SemiconductorDocumento17 pagineFAN7602 - Green Current Mode PWM Controller - Fairchild SemiconductorVijay MistryNessuna valutazione finora

- Ncl30160 1.0A Constant-Current Buck Regulator For Driving High Power LedsDocumento10 pagineNcl30160 1.0A Constant-Current Buck Regulator For Driving High Power LedsKhúc Hành QuânNessuna valutazione finora

- CQ 0765RTDocumento24 pagineCQ 0765RTsonivitel100% (2)

- IC 3842 para FonteDocumento8 pagineIC 3842 para FonteTomNedscNessuna valutazione finora

- C324G Low Power Quad OpAmpDocumento12 pagineC324G Low Power Quad OpAmpwhynot05Nessuna valutazione finora

- Document - SG3525A DDocumento10 pagineDocument - SG3525A Donlinerahul823405Nessuna valutazione finora

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsDa EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsValutazione: 3.5 su 5 stelle3.5/5 (6)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Da EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Valutazione: 2.5 su 5 stelle2.5/5 (3)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDa EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNessuna valutazione finora

- Analog Circuit Design Volume Three: Design Note CollectionDa EverandAnalog Circuit Design Volume Three: Design Note CollectionValutazione: 3 su 5 stelle3/5 (2)

- LEARJET 45 AC Electrical SystemDocumento4 pagineLEARJET 45 AC Electrical SystemRAFAEL MANZANILLANessuna valutazione finora

- Eaton Cutler-Hammer Motor Control Center Info Cat.71.01t.e. - 2 PDFDocumento42 pagineEaton Cutler-Hammer Motor Control Center Info Cat.71.01t.e. - 2 PDFDaniel Ajailla AveNessuna valutazione finora

- Home Automation Using Android123Documento18 pagineHome Automation Using Android123newNessuna valutazione finora

- Remote Control Light Circuit Using 555 TimerDocumento16 pagineRemote Control Light Circuit Using 555 TimerHubert SemenianoNessuna valutazione finora

- Cairo Mini 3d-Printer Parts ListDocumento9 pagineCairo Mini 3d-Printer Parts ListAliNessuna valutazione finora

- Electric PotentialDocumento10 pagineElectric PotentialSrishti PathakNessuna valutazione finora

- LTE 700 Activity ReportDocumento42 pagineLTE 700 Activity ReportaliNessuna valutazione finora

- Unit 4Documento8 pagineUnit 4Sri ChandanaNessuna valutazione finora

- MB319M MLA Manual ServicoDocumento40 pagineMB319M MLA Manual ServicoAlcir OliveiraNessuna valutazione finora

- Magnetism and Matter - INSPDocumento31 pagineMagnetism and Matter - INSPdevansh dewan100% (1)

- Floodlight FLM9Documento1 paginaFloodlight FLM9EliasNessuna valutazione finora

- 1 CapacitanceEx-I1Documento6 pagine1 CapacitanceEx-I1Ashwani KumarNessuna valutazione finora

- Manual Eng 10-01-01Documento19 pagineManual Eng 10-01-01EASY TECHNessuna valutazione finora

- Marshall Bass Amp dbs7200Documento5 pagineMarshall Bass Amp dbs7200Dean LombardNessuna valutazione finora

- Zero Ohm Jumper Chip Resistor: Type L 1F (01005) W C D T Dimensions InchesDocumento2 pagineZero Ohm Jumper Chip Resistor: Type L 1F (01005) W C D T Dimensions InchesOlney JonerNessuna valutazione finora

- BOQ No. 10-Guard HouseDocumento24 pagineBOQ No. 10-Guard HouseUsman NadeemNessuna valutazione finora

- Dewalt d25481Documento12 pagineDewalt d25481Vasilic NikolaNessuna valutazione finora

- 06Documento146 pagine06Eli RochaNessuna valutazione finora

- D D D D D D D D D: Description/ordering InformationDocumento13 pagineD D D D D D D D D: Description/ordering InformationAdilson ToledoNessuna valutazione finora

- HEA Igniter CatalogueDocumento4 pagineHEA Igniter Cataloguemohan babuNessuna valutazione finora

- OMRONDocumento87 pagineOMRONEnrique Villamizar LaguadoNessuna valutazione finora

- Manual Servicio Sony - kdl-32 - 40 - 46 - 55hx750 - 751 - 753 - 755 - 756 - 757 - 758 - 759 - 75g - Chassiaz3fDocumento145 pagineManual Servicio Sony - kdl-32 - 40 - 46 - 55hx750 - 751 - 753 - 755 - 756 - 757 - 758 - 759 - 75g - Chassiaz3fIgnacio SerradillaNessuna valutazione finora

- 1-04-012-11 - 0 TrafoDocumento9 pagine1-04-012-11 - 0 TrafonishantpsbNessuna valutazione finora

- IC Interconnect AnalysisDocumento316 pagineIC Interconnect AnalysisRavi Singh0% (1)

- Datasheet 586320 (50-8231) en 120V 60Hz Motor BobinadoDocumento5 pagineDatasheet 586320 (50-8231) en 120V 60Hz Motor BobinadoMelissa AlvaradoNessuna valutazione finora

- Especificaciones Sismografo 1225Documento3 pagineEspecificaciones Sismografo 1225Ivan VillarrealNessuna valutazione finora

- Lab 1 Completed 2-6-17Documento17 pagineLab 1 Completed 2-6-17Cameron TaylorNessuna valutazione finora

- Compressor EMI60HER (LBP) - DatasheetDocumento5 pagineCompressor EMI60HER (LBP) - DatasheetSamuel OsmagNessuna valutazione finora

- BS en 61606-1 2009Documento34 pagineBS en 61606-1 2009Modern DesignsNessuna valutazione finora