Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

C-s101 Dd3 Structural Notes

Caricato da

anthony christian yangDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

C-s101 Dd3 Structural Notes

Caricato da

anthony christian yangCopyright:

Formati disponibili

REPUBLIC OF THE PHILIPPINES

STEEL NOTES

A . GENERAL

4000 PSI

3/4 IN. (19MM.)

4 IN. (100MM)

6. ALL GROUT UNDER STEEL PLATES SHALL BE NON-SHRINK PRE-MIX TYPE AND

SHALL HAVE A MINIMUM COMPRESSIVE STRENGTH OF 5,000psi, TESTED IN

ACCORDANCE WITH CONCRETE SPECIFICATIONS. USE NON-STAINING GROUT

AT EXPOSED LOCATIONS.

CONTRACTOR'S NOTES PRIOR TO FABRICATIONS:

3 . ALL REINFORCING BARS SHALL CONFORM TO ASTM A 615 GRADE 40 FOR DIA. 20mm

& SMALLER BARS & GRADE 60 FOR DIA. 25 & LARGER BARS. COLUMN

HOOPS ARE ALL GRADE 40 BARS.

4 . IN GENERAL, THE LATEST EDITION OF ACI-315, MANUAL OF STANDARD PRACTICE

DETAILING REINFORCED CONCRETE STRUCTURES SHALL BE ADHERED TO UNLESS

OTHERWISE SHOWN OR NOTED.

SHALL SUBMIT SHOP DRAWINGS OF ALL STRUCTURAL

ILLUSTRATE THE SEQUENCE OF WELDING, AND EACH

(25MM.)

WITH QUALIFIED WELDERS. THE QUALIFICATION OF

COMPONENTS, INCLUDING THE LOCATION, TYPE AND

WELDERS AND THE DURATION OF QUALIFICATION

SIZE OF BOLTS, WELDS, MEMBER SIZES AND LENGTHS

PERIOD SHALL BE IN ACCORDANCE

WITH THE

,

CONNECTION DETAILS, BLOCKS, COPES AND CUTS. USE

REQUIREMENTS OF AWS. ANY WELDER FOUND TO BE

AWS STANDARD WELDING SYMBOLS.

(50MM.)

(75MM.)

6 . SPLICES SHALL BE SECURELY WIRED TOGETHER & SHALL LAP OR EXTEND IN

ACCORDANCE WITH TABLE 1 (TABLE OF LAP SPLICE & ANCHORAGE LENGTH)

UNLESS OTHERWISE SHOWN ON DRAWINGS, SPLICES SHALL BE STAGGERED

WHENEVER POSSIBLE.

QUALIFICATION TESTS SHALL

BE IMMEDIATELY

.

INDICATE THE SEQUENCE OF ERECTION, TEMPORARY

RECERTIFIED OR REPLACED WITH A QUALIFIED WELDER.

2 . FOR REINFORCEMENTS SEE

CONSTRUCTION NOTES.

1 - DIA. 16 CONT. HOR. BARS

FOR FLOOR SLAB ONLY

FLR . SLAB OR BEAM

TYPICAL SECTION OF MASONRY

PARTITION REINFORCEMENTS

2-12mm x 1000 LONG AT MID - DEPTH

OF WALL AT EACH CORNER or EACH FACE

30 BAR DIA

OF WELDING INCLUDING EACH WELDING PROCEDURE

REQUIRED.

C . MANUFACTURER' S CERTIFICATES OF CONFORMANCE:

1. STRUCTURAL STEEL

DOOR

OPENING

WINDOW

OPENING

2. BOLTS, NUTS AND WASHERS

1-DIA. 16EACH FACE

(TYPICAL)

3. SHOP PAINTING MATERIALS

9 . ALL CONCRETE SHALL BE KEPT MOIST FOR A MINIMUM OF SEVEN (7)

CONSECUTIVE DAYS IMMEDIATELY AFTER POURING BY THE USE OF WET BURLAP,

FOG SPRAYING, CURING COMPOUNDS OR OTHER APPROVED METHODS.

4. WELDING ELECTRODES AND RODS

5. NON-SHRINK GROUT

COMP. BAR

(mm)

(m)

90DEG

2 . PROVIDE 1-16 VERTICAL BARS AT CORNERS, INTERSECTIONS, END OF

WALLS & EACH SIDE OF OPENINGS.

10 mm

0 . 60

0 . 10

3 . LINTEL BEAMS SHALL BEAR AT LEAST 8 INCHES (200MM.) ON EACH SIDE OF

MASONRY WALL OPENING

.

12 mm

0 . 60

0 . 14

0 . 16

0 . 12

0 . 42

0 . 30

0 . 42

16 mm

0 . 60

0 . 22

0 . 18

0 . 14 .

0 . 73

0 . 52

20 mm

0 . 60

0 . 30

0 . 20

0 . 20

0 . 91

25 mm

0 . 68

0 . 40

0 . 28

0 . 26

28 mm

0 . 86

0 . 48

32 mm

36 mm

1 . 12

0 . 56

0 . 61

4 . WALL REINFORCEMENTS (UNLESS INDICATED) SHALL BE AS FOLLOWS:

WALL THICKNESS

VERTICAL REINFORCEMENT

HORIZONTAL REINFORCEMENT

10 @ 600MM.

8 IN. (200MM.)

12 @ 400MM.

6 IN. (150MM.)

10 @ 400MM.

10 @ 600MM.

10 @ 600MM.

0 . 617

0 . 30

0 . 30

0 . 30

0 . 889

0 . 30

0 . 30

0 . 87

0 . 62

1 . 580

0 . 52

0 . 47

0 . 65

1 . 10

0 . 78

2 . 469

0 . 65

0 . 58

1 . 40

1 . 00

1 . 40

1 . 00

3 . 858

0 . 80

0 . 73

0 . 38

1 . 76

1 . 26

1 . 53

1 . 09

4 . 840

0 . 90

0 . 82

0 . 43

0 . 48

2 . 31

2 . 95

1 . 65

2 . 10

1 . 74

2 . 00

1 . 24

1 . 40

6 . 327

8 . 000

1 . 03

0 . 93

1 . 20

1 . 05

0 . 13

0 . 10

0 . 42

0 . 30

0 . 42

0 . 30

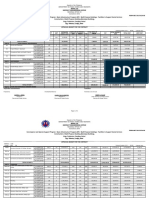

MARK

A (m)

B (m)

t (m)

X-Bars

Y-Bars

F1

0.80

0.80

0.25

4-16

4-16

F2

0.70

0.70

0.25

4-16

4-16

TOP BARS

X-Bars

PEDESTAL SCHEDULE

Y-Bars

BASE PLATE DETAIL

MARK FOUNDATION - GROUND FLR

200

P1

200

40 120 40

HSS4" x 2" x 0.25 (C1) WITH

12mm THK. BASE PL.

W/ 4-22mm HOLES FOR

4-16mm ANCHOR BOLTS (A325)

Y-BARS

N.G.L.

4-16 VERT. BARS W/ 10 TIES

8-75; REST-150 TO MID. HT.

200

40 120 40

HSS4" x 0.125 (C2) WITH

12mm THK. BASE PL.

W/ 4-22mm HOLES FOR

4-16mm ANCHOR BOLTS (A325)

5 . REINFORCING BARS SHALL BE LAPPED A MINIMUM OF 30 BAR DIAMETERS WHERE

SPLICED. DOWELS FROM CONCRETE FOOTINGS OR SLABS SHALL EXTEND INTO

THE BLOCK WALL A MINIMUM OF 30 BAR DIAMETERS, & DOWELS TO MATCH

VERTICAL REINFORCEMENTS OF WALL.

1 . 38

180DEG 133DEG TOP BAR BOT BAR TOP BAR BOT BAR

BOTTOM BARS

FOOTING SCHEDULE

NOTES :

1 . ACI SECTION 12.4 STATES THAT:

DEVELOPMENT LENGTH OF INDIVIDUAL BARS WITHIN A BUNDLE IN TENSION OR COMPRESSION

6 . ALL CELLS CONTAINING REINFORCING BARS OR INSERTS SHALL BE SOLIDLY

FILLED WITH CONCRETE GROUT. (REFER TO SPECIFICATIONS)

SHALL BE THAT FOR THE INDIVIDUAL BAR. INCREASED 20 PERCENT FOR THREE-BAR

BUNDLE AND 33 PERCENT FOR FOUR-BAR BUNDLE.

1 . FOUNDATION IS DESIGNED FOR ASSUMED ALLOWABLE SOIL BEARING

CAPACITY OF 6000 PSF.

4 . AS MUCH AS POSSIBLE SPLICES SUBJECTED TO TENSILE STRESSES ARE DISCOURAGE.

THESE SHOULD BE AVOIDED OR PROVIDED WITH STANDARD HOOKS.

3 . THE CONTRACTOR SHALL NOTIFY THE ENGINEER AFTER FOOTING EXCAVATION

HAVE BEEN COMPLETED & PRIOR TO CONCRETING TO CONFIRM THE DESIGN

SOIL BEARING CAPACITY.

5 . ASSUMED SPECIFIED COMPRESSIVE STRESS FOR CONCRETE f ' c=4000 PSI

MARK PEDESTAL - STEEL BEAM

MATERIAL STRENGTH:

1. CONCRETE COMPRESSIVE STRENGTH............3,000 PSI

2. REBARS:

- 10 REBARS SHALL BE GRADE 33 (FY=33,000 PSI)

- 12 & 16 REBARS SHALL BE GRADE 40 (FY=40,000 PSI)

- 20 & LARGER REBARS SHALL BE GRADE 60 (FY=60,000 PSI)

3 . TOP BARS ARE HORIZONTAL BARS WITH MORE THAN 300 MM DEPTH OF CONCRETE CAST

BELOW THE REINFORCEMENT.

2 . FOUNDATION SHALL REST ON NATURAL SOIL. UNLESS OTHERWISE NOTED BY

THE ENGINEER, NO PART OF THE FOUNDATION SHALL REST ON FILL.

COLUMN SCHEDULE-CONCRETE

TYP. FOOTING DETAIL

2 . FOR COLUMNS AT ANY LEVEL NO MORE THAN ALTERNATE BARS SHOULD BE SPLICED NOT

MORE THAN 33% OF THE BARS SHALL BE SPLICED WITHIN THE REQUIRED LAP LENGTH

MINIMUM DISTANCE BETWEEN TWO ADJACENT BAR SPLICES SHALL BE 600MM.

D . FOUNDATION

C1

HSS4" x 2" x 0.25

C2

HSS4" x 0.125

3. FOUNDATION:

- ALLOWABLE SOIL BEARING CAPACITY= 3,000 PSF

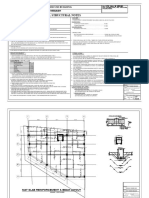

DESIGN DEVELOPMENT

PROJECT NO:15010-C

ERWIN J. PONCE

THE ENCLAVES AT NORTH POINT

CIVIL ENGINEER

ARCHITECTURE

AMENITY CORE : GUARD HOUSE

PRC NO:

11/F AppleOne-Equicom Tower, Mindanao Avenue, cr. Biliran St

Cebu Business Park, Cebu City 6000, Philippines

PTR NO:

Ph: (+63 32) 230 4804

Email: info@re2architecture.com

PLACE:

VALIDITY:

DATE:

TIN:

PROJECT :

LOCATION:

BRGY. MATAB-ANG, TALISAY CITY, NEGROS

OCCIDENTAL, 6115, PHILIPPINES

Rev No.

CAD TECHNICIAN:

jOb

DATE PUBLISHED:

AYALA LAND PREMIER

7/28/2016

CHECKED BY:

ESN

OWNER

ADDRESS: PHILIPPINE STOCK EXCHANGE PLAZA, AYALA AVENUE, DATE CHECKED:

MAKATI CITY, 1207 METRO MANILA, PHILIPPINES

7/28/2016

Descrip on

Date

DD2

PROJECT NUMBER INFORMATION ADDED

07/23/16

DD3

DESIGN DEVELOPMENT ISSUE - INFORMATION ADDED ON FOOTING

AND FOUNDATION DETAILS, PEDESTAL AND BASE PLATE DETAILS,

AND COLUMN SCHEDULE

07/28/16

Rev No.

Descrip on

Date SHEET NAME: STRUCTURAL NOTES

IMPORTANT:

THESE DRAWINGS AS INSTRUMENTS OF SERVICE,

ARE THE PROPERTY AND DOCUMENTS OF THE

ARCHITECT. IT SHALL BE UNLAWFUL FOR ANY

PERSON, WITHOUT THE WRITTEN CONSENT OF

THE SAID DOCUMENTS, TO DUPLICATE OR COPY

SAID DOCUMENTS.

SHEET NO:

REV NO:

C-S101

DD3

BIM Server: ErnestoM-PC - BIM Server 19/15010 TEN Point Negros/TEN Amenity Core GUARD HOUSE

TENSION BAR

UNIT

WEIGHT

(kg/ m)

MIN. LAP SPLICE

LENGTH OF COL

REINFORCEMENT

INDIVIDUAL

BARS

W/ TIES W/ SPIRAL

200

40 120 40

1 . ALL NON- LOAD BEARING TYPE CONCRETE BLOCKS SHALL HAVE A UNIT WEIGHT

NOT TO EXCEED 80PCF. FOR LOAD BEARING TYPE CONCRETE BLOCKS, A

MINIMUM COMPRESSIVE STRENGTH OF 6.90MPA. SHALL BE DEVELOPED.

LAP SPLICES(M)

200

40 120 40

STANDARD

HOOK

(m)

BAR

ANCHORAGE

DIAMETER

LENGTH

X-BARS

& CONCRETE BLOCKS

TYPICAL DOOR OPENING DETAIL

TYPICAL WINDOW OPENING DETAIL

BEAMS ..............................................................14DAYS

200

SPLICING AND ANCHORAGE LENGTH

SCHEDULE

1200

10 . STRIPPING OF FORMS & SHORES:

FOUNDATION

....................................................24HRS .

SUSPENDED SLAB EXCEPT WHEN

ADDITIONAL LOADS ARE IMPOSED

......................8DAYS

WALLS ..............................................................18HRS.

10 @ 400MM.

1 . ALL JOINTS AND CELLS CONTAINING

REINFORCING BARS SHALL BE FILLED

WITH CONCRETE GROUT.

PRODUCING UNSATISFACTORY WORK EVEN HE PASSED

B . ERECTION PLAN: SUBMIT FOR RECORD PURPOSES

8 . CONTRACTOR SHALL NOTE & PROVIDE ALL MISCELLANEOUS CURBS, SILLS,

STOOLS , EQUIPMENT , & MECHANICAL BASES THAT ARE REQUIRED BY THE

ARCHITECTURAL, ELECTRICAL, & MECHANICAL DRAWINGS.

4 IN. (100MM.)

DOWEL BARS TO MATCH

VERT BARS

SHORING AND BRACING, AND A DETAILED SEQUENCE

7 . ALL ANCHOR BOLTS, DOWELS, & OTHER INSERTS, SHALL BE PROPERLY

POSITIONED & SECURED IN PLACE PRIOR TO PLACING OF CONCRETE.

C. MASONRY

WELDING PROCEDURE TO BE USED. PERFORM WELDING

FABRICATION AND ERECTION OF THE STRUCTURE' S

............................1 1/2IN. (38MM.)

WHERE CONCRETE IS DEPOSITED

DIRECTLY AGAINST EARTH

.......................................3 IN.

D. WELDING : SUBMIT DESCRIPTIVE DATA TO

INCLUDE COMPLETE INFORMATION NECESSARY FOR THE

......................................................1 1/2 IN. (38MM.)

WHERE CONCRETE IS EXPOSED TO EARTH

BUT POURED AGAINST FORMS

.................................2 IN.

A . SHOP DRAWINGS: THE GENERAL CONTRACTORS

STEEL FOR APPROVAL PRIOR TO FABRICATION.

5 . MAINTAIN MINIMUM CONCRETE COVER FOR REINFORCING STEEL AS FOLLOWS:

SUSPENDED SLABS

................................................. 3/4 IN. (19MM.)

& COLUMN TIES

FLR. SLAB OR BEAM

30 BAR DIA

ALL OTHERS

INCLUDING BEAMS

SUSPENDED SLABS

& COLUMNS

DATE:

INTERSECTING R.C. COLUMN OR WALL

INTERSECTION WALL

200(DOWEL)

4 IN. (100MM)

BUILDING OFFICIAL

R. C. COLUMN OR WALL

TYPICAL CONNECTION DETAIL OF MASONRY WALL

VERIFY ARCHITECTURAL HEIGHT

3/4 IN. (19MM.)

400

(DOWEL)

CHB WALL

400 (DOWEL)

4 IN. (100MM)

4000 PSI

RECOMMENDING APPROVAL

HEAD:

DATE:

5. ALL WELDING SHALL BE DONE BY CERTIFIED LICENSED WELDERS AND SHALL BE IN

CONFORMANCE WITH THE STRUCTURAL WELDING CODE OF THE AMERICAN WELDING

SOCIETY ANSI / AWS D1.1-90.

MAX . SLUMP

FOUNDATION &

RETAINING WALL

DOWEL BARS TO MATCH

CHB HOR. BARS

12 THK EXPANSION JOINT

WITH MASTIC FILLER

FOR SIZE & SPACING

OF HOR. & VERT. BARS

SEE CONSTRUCTION NOTES

CORNER WALL

TALISAY CITY, NEGROS OCCIDENTAL

CHB WALL

1 - DIA. 16 VERT BARS

12 THK EXPANSION JOINT

WITH MASTIC FILLER

CHB WALL

4. WELDING ELECTRODES SHALL CONFORM TO THE E-70 SERIES OF THE SPECIFICATION

FOR MILD STEEL ARC WELDING ELECTRODES ASTM A233 LATEST EDITION.

2 . ALL CONCRETE SHALL DEVELOP A MINIMUM COMPRESSIVE STRENGTH AT THE

END OF TWENTY EIGHT

( 28 ) DAYS WITH CORRESPONDING MAXIMUM SIZE

AGGREGATE & SLUMP AS FOLLOWS :

MAX . SIZE AGGREGATE

LOCATION

28 DAYS STRENGTH

CURBS & SLAB

2500 PSI

1 IN. (25 MM.)

ON GRADE

EXCEPT FOUND .

..............................................1 IN.

1 - DIA . 16 VERT BARS

FOR SIZE & SPACING

OF HOR . & VERT . BARS

SEE CONSTRUCTION NOTES

3. BOLTS SHALL CONFORM TO THE FOLLOWING ASTM DESIGNATION, LATEST EDITION:

ALL CONNECTIONS SHALL BE HIGH STRENGTH BOLTS-A325; ANCHOR BOLTS-A36

UNLESS NOTED OTHERWISE ON THE DRAWINGS.

1 . ALL MATERIALS & WORKMANSHIP SHALL CONFORM WITH THE LATEST BUILDING

CODE OF AMERICAN CONCRETE INSTITUTE

( ACI - 318 )

BEAM STIRRUPS

400 (DOWEL)

2. THE CONTRACTOR SHALL PROVIDE TWO(2) SETS OF COMPLETE SHOP DRAWINGS FOR

REVIEW PRIOR TO THE FABRICATION OF THE STRUCTURAL ELEMENTS. WELD SIZES

LEGTHS MUST BE SHOWN ON THE SHOP DRAWINGS.

B . CONCRETE & REINFORCEMENT

WALLS ABOVE GRADE

12 THK EXPANSION JOINT

WITH MASTIC FILLER

1. STRUCTURAL STEEL ANGLES, STIFFENER PLATES, BASE PLATES @ GUSSET PLATE

SHALL CONFORM TO ASTM 1-36. ROLLED OR BUILT-UP WIDE FLANGE SECTIONS SHALL

CONFORM TO ASTM A-36, Fy=50 Ksi EXCEPT AS NOTED. ALL STRUCTURAL STEEL SHALL

BE DETAILED, FABRICATED AND ERECTED ACCORDING TO THE SPECIFICATION FOR

DESIGN, FABRICATION AND ERECTION OF STRUCTURAL STEEL FOR BUILDING BY

"AMERICAN INSTITUTE OF STEEL CONSTRUCTION" 9TH EDITION.

1 . CONSTRUCTION NOTES & TYPICAL DETAILS APPLY TO ALL DRAWINGS UNLESS

OTHERWISE SHOWN OR NOTED, MODIFY TYPICAL DETAILS AS DIRECTED TO MEET

SPECIAL CONDITIONS.

2 . SHOP DRAWINGS WITH ERECTION & PLACING DIAGRAMS OF ALL STRUCTURAL

STEEL, MISCELLANEOUS IRON, PRE-CAST CONCRETE ETC. SHALL BE SUBMITTED

FOR ENGINEER'S APPROVAL BEFORE FABRICATION.

3 . CONTRACTOR SHALL VERIFY ALL DIMENSIONS BEFORE ALL WORK IS TO BEGIN,

& ELECTRICAL CONTRACTORS FOR CONDUITS, PIPE

CHECK WITH MECHANICAL

SLEEVES, ETC. TO BE EMBEDDED IN CONCRETE.

SHORINGS & BRACINGS OF THE STRUCTURE FOR ALL LOADS THAT MAYBE

IMPOSED DURING CONSTRUCTION

.

SLAB ON GRADE

1 - DIA. 16 VERT BARS

400(DOWEL)

CONSTRUCTION NOTES

OFFICE OF THE BUILDING OFFICIAL

FOR SIZE & SPACING

OF HOR. & VERT. BARS

SEE CONSTRUCTION

NOTES

Potrebbero piacerti anche

- Cooke Lens Service Drawings CompleteDocumento5 pagineCooke Lens Service Drawings CompleteDarius WhiteNessuna valutazione finora

- BUDO Swimming Pool BOQsDocumento18 pagineBUDO Swimming Pool BOQsaqeel_al_trini100% (9)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDa EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsValutazione: 4.5 su 5 stelle4.5/5 (10)

- BUDO Swimming Pool BOQs PDFDocumento18 pagineBUDO Swimming Pool BOQs PDFMohamed Rushdy79% (14)

- Method Statement - 20 BridgesDocumento109 pagineMethod Statement - 20 BridgesRohit Bali100% (5)

- MATH Formulas PDFDocumento33 pagineMATH Formulas PDFAnonymous 0Mduljho100% (3)

- QT4-15 Concrete Block Making MachineDocumento3 pagineQT4-15 Concrete Block Making Machinetaike1230% (3)

- General NotesDocumento1 paginaGeneral NotesGodino ChristianNessuna valutazione finora

- Request For Variation AuthorizationDocumento11 pagineRequest For Variation AuthorizationsspshuhaimiNessuna valutazione finora

- Reciprocating Compressors For Industrial Refrigeration Grasso VDocumento50 pagineReciprocating Compressors For Industrial Refrigeration Grasso VCUIDAITONessuna valutazione finora

- Material Schedule For 1x3classroom Block For The Newly Up-Graded Secondary Schools-1Documento5 pagineMaterial Schedule For 1x3classroom Block For The Newly Up-Graded Secondary Schools-1Eng Hinji Rudge100% (4)

- GMWS Iss.5 Vol2 Architectural WorksDocumento322 pagineGMWS Iss.5 Vol2 Architectural WorksRodorAramonNessuna valutazione finora

- General Structural NotesDocumento5 pagineGeneral Structural NotesreinerNessuna valutazione finora

- General Notes & SpecificationsDocumento6 pagineGeneral Notes & SpecificationsDon Santos100% (1)

- Shorings and Bracings of The Structure For All Loads That Maybe Imposed During ConstructionDocumento7 pagineShorings and Bracings of The Structure For All Loads That Maybe Imposed During ConstructionNatalie WrightNessuna valutazione finora

- Engineering 20140829 PDFDocumento41 pagineEngineering 20140829 PDFSarah HillNessuna valutazione finora

- PS NotesDocumento6 paginePS NotesnidhisasidharanNessuna valutazione finora

- General Notes 2Documento5 pagineGeneral Notes 2Amer GonzalesNessuna valutazione finora

- General Specifications: I. Clearing and EarthworksDocumento4 pagineGeneral Specifications: I. Clearing and EarthworksFroilan AngbengcoNessuna valutazione finora

- Construction Notes RevisedDocumento3 pagineConstruction Notes RevisedKessler BiatingoNessuna valutazione finora

- Contractor To Check and Verify All Dimensions Before Execution of The WorkDocumento3 pagineContractor To Check and Verify All Dimensions Before Execution of The Worksarathirv6Nessuna valutazione finora

- Generalcons Tructionnot ES: General NotesDocumento10 pagineGeneralcons Tructionnot ES: General NotesJejomar MotolNessuna valutazione finora

- A Proposed Mixed-Use Development: I. Structural Design CriteriaDocumento28 pagineA Proposed Mixed-Use Development: I. Structural Design CriteriaAnonymous sOSxA7SNessuna valutazione finora

- Ppsrigmca2 SP SP r3.2Documento1 paginaPpsrigmca2 SP SP r3.2Mark MerrillNessuna valutazione finora

- A. General NotesDocumento6 pagineA. General NotesNatalie WrightNessuna valutazione finora

- 096 Bel-Ray InstallationDocumento28 pagine096 Bel-Ray InstallationAbsoluto 補劑Nessuna valutazione finora

- Structural Notes and SpecificationsDocumento5 pagineStructural Notes and SpecificationsMohamad Tomindug BauloNessuna valutazione finora

- BT General NotesDocumento14 pagineBT General NotesRufina Patricia MendozaNessuna valutazione finora

- Structural Notes 1Documento1 paginaStructural Notes 1missiklein3Nessuna valutazione finora

- Tennis Court - CentComDocumento4 pagineTennis Court - CentComEppNessuna valutazione finora

- 4802-w2 Concrete Anchor Block - Installation DetailsDocumento2 pagine4802-w2 Concrete Anchor Block - Installation DetailsLorenaNessuna valutazione finora

- NoteDocumento1 paginaNotePom tancoNessuna valutazione finora

- Company ProfileDocumento16 pagineCompany ProfileHarshil PanchalNessuna valutazione finora

- Finalised Mec-10001013-0-1Documento6 pagineFinalised Mec-10001013-0-1MUHAMMAD WARIS SQNessuna valutazione finora

- Highway PlanDocumento11 pagineHighway PlanShine AtanosoNessuna valutazione finora

- 345-001071-1025 - R0 Beam & Slab Formworks Pump Station Bldg.25CDocumento1 pagina345-001071-1025 - R0 Beam & Slab Formworks Pump Station Bldg.25CSatya kaliprasad vangaraNessuna valutazione finora

- Gad NotesDocumento3 pagineGad NotesAssam Green InfrastructuresNessuna valutazione finora

- Aa 036531 001Documento1 paginaAa 036531 001narutothunderjet2160% (1)

- La's (9kv 5ka Line Type) (Ot-155)Documento12 pagineLa's (9kv 5ka Line Type) (Ot-155)Yaswanth ReddyNessuna valutazione finora

- STRUCT ANALfront4 19Documento5 pagineSTRUCT ANALfront4 19Jaybert DumaranNessuna valutazione finora

- Retrofitting Recommendations and SpecificationsDocumento3 pagineRetrofitting Recommendations and SpecificationsJoseph Cloyd LamberteNessuna valutazione finora

- Gearbox AssemblyDocumento1 paginaGearbox AssemblyIan AsNessuna valutazione finora

- Not For Construction: Size REV SheetDocumento1 paginaNot For Construction: Size REV SheetMateo RosasNessuna valutazione finora

- TestDocumento1 paginaTestRob TamaccioNessuna valutazione finora

- Tegene Negash STDocumento18 pagineTegene Negash STrobelbld2015Nessuna valutazione finora

- Kuwait Oil Company (Kusrncu) : Specification NumberDocumento9 pagineKuwait Oil Company (Kusrncu) : Specification Numbernpwal100% (1)

- UIG Specifications For AWWA D103 Glass Fused To Steel Storage Tanks 08.05.14Documento13 pagineUIG Specifications For AWWA D103 Glass Fused To Steel Storage Tanks 08.05.14Claudio Felipe Campos ArayaNessuna valutazione finora

- Slab Design Span 7mDocumento12 pagineSlab Design Span 7mKrish ChandNessuna valutazione finora

- General Notes: Structural DetailsDocumento1 paginaGeneral Notes: Structural DetailsMohammad AlkahteebNessuna valutazione finora

- D8834-Ga-Tk101 10-Sheet Tank Ga's (Signed)Documento7 pagineD8834-Ga-Tk101 10-Sheet Tank Ga's (Signed)Santheep KumarNessuna valutazione finora

- NotesDocumento1 paginaNotesMohammad AlkahteebNessuna valutazione finora

- Drrdock Repair Jobs (Excluding DD Routines) No 1Documento15 pagineDrrdock Repair Jobs (Excluding DD Routines) No 1Amit Raj AnandNessuna valutazione finora

- CB24 - 30 Degree J-Rib Manual - 347862Documento83 pagineCB24 - 30 Degree J-Rib Manual - 347862gechaves1Nessuna valutazione finora

- Epic Hock FastDocumento153 pagineEpic Hock Fastswapneel_kulkarniNessuna valutazione finora

- Manna House: IndexDocumento8 pagineManna House: IndexroshancherryNessuna valutazione finora

- Drawing NotesDocumento8 pagineDrawing NotesPancerniZawszeWierniNessuna valutazione finora

- 0702 Sound and Vibration ControlDocumento7 pagine0702 Sound and Vibration Controlntt_121987Nessuna valutazione finora

- Sb-Ag-39-Rev-A WING SPAR INSPECTION AND FATIGUE LIFE EXTENSIONDocumento14 pagineSb-Ag-39-Rev-A WING SPAR INSPECTION AND FATIGUE LIFE EXTENSIONNathaniel LuraNessuna valutazione finora

- General Notes Earthwork Notes Services: TenderDocumento1 paginaGeneral Notes Earthwork Notes Services: TenderAnonymous qEPNPwANessuna valutazione finora

- SAIC-D-2002 Rev 2Documento5 pagineSAIC-D-2002 Rev 2ரமேஷ் பாலக்காடுNessuna valutazione finora

- Case & Uzun: Mount Pisgah Christian School New Upper School BuildingDocumento20 pagineCase & Uzun: Mount Pisgah Christian School New Upper School Buildingervikas34Nessuna valutazione finora

- Bending Machine CRC Evans Centurion 06 20Documento4 pagineBending Machine CRC Evans Centurion 06 20bharathaninNessuna valutazione finora

- General SpecificationDocumento5 pagineGeneral SpecificationDindo CabudbudNessuna valutazione finora

- Mechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDa EverandMechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDileep SinghNessuna valutazione finora

- Anglo–American Microelectronics Data 1968–69: Manufacturers A–PDa EverandAnglo–American Microelectronics Data 1968–69: Manufacturers A–PNessuna valutazione finora

- TimelineasdDocumento1 paginaTimelineasdanthony christian yangNessuna valutazione finora

- Cabantan - TudtudDocumento3 pagineCabantan - Tudtudanthony christian yangNessuna valutazione finora

- I QWOEREWRJOE222 DDDocumento4 pagineI QWOEREWRJOE222 DDanthony christian yangNessuna valutazione finora

- PWPWOPWOWDocumento5 paginePWPWOPWOWanthony christian yangNessuna valutazione finora

- WAHAHA32412Documento1 paginaWAHAHA32412anthony christian yangNessuna valutazione finora

- Pert CPMDocumento1 paginaPert CPManthony christian yangNessuna valutazione finora

- BILLING NO.2 - Daanlungsod-Calangahan DetailedDocumento1 paginaBILLING NO.2 - Daanlungsod-Calangahan Detailedanthony christian yangNessuna valutazione finora

- Coolray BrochureDocumento2 pagineCoolray Brochureanthony christian yangNessuna valutazione finora

- DPWH Candijay Municipal Building - Mitsubishi ElevatorDocumento6 pagineDPWH Candijay Municipal Building - Mitsubishi Elevatoranthony christian yangNessuna valutazione finora

- BILLING NO.2 - Daanlungsod-Calangahan DetailedDocumento1 paginaBILLING NO.2 - Daanlungsod-Calangahan Detailedanthony christian yangNessuna valutazione finora

- BILLING NO.2 - Daanlungsod-Calangahan DetailedDocumento1 paginaBILLING NO.2 - Daanlungsod-Calangahan Detailedanthony christian yangNessuna valutazione finora

- A-101 Basement Floor Plan-ModelDocumento1 paginaA-101 Basement Floor Plan-Modelanthony christian yangNessuna valutazione finora

- Portland Cement Concrete Pavement (0.230m THK., 3500 Psi)Documento1 paginaPortland Cement Concrete Pavement (0.230m THK., 3500 Psi)anthony christian yangNessuna valutazione finora

- BILLING NO. 4-Daanlungsod-Calangahan (Draft 1)Documento61 pagineBILLING NO. 4-Daanlungsod-Calangahan (Draft 1)anthony christian yangNessuna valutazione finora

- 2 3 PDFDocumento1 pagina2 3 PDFanthony christian yangNessuna valutazione finora

- BILLING NO.2 - Daanlungsod-Calangahan DetailedDocumento1 paginaBILLING NO.2 - Daanlungsod-Calangahan Detailedanthony christian yangNessuna valutazione finora

- BILLING NO.2 - Daanlungsod-Calangahan DetailedDocumento1 paginaBILLING NO.2 - Daanlungsod-Calangahan Detailedanthony christian yangNessuna valutazione finora

- E8 XertDocumento1 paginaE8 Xertanthony christian yangNessuna valutazione finora

- Mounting Heights:: LegendDocumento1 paginaMounting Heights:: Legendanthony christian yangNessuna valutazione finora

- Alcoy Resrt Model - NFFDocumento1 paginaAlcoy Resrt Model - NFFanthony christian yangNessuna valutazione finora

- 2 2 PDFDocumento1 pagina2 2 PDFanthony christian yangNessuna valutazione finora

- 2 2 PDFDocumento1 pagina2 2 PDFanthony christian yangNessuna valutazione finora

- A-103 1st Floor Plan-ModelDocumento1 paginaA-103 1st Floor Plan-Modelanthony christian yangNessuna valutazione finora

- BILLING NO 4 (DRAFT) CanalDocumento1 paginaBILLING NO 4 (DRAFT) Canalanthony christian yangNessuna valutazione finora

- Ground Floor Lighting System Lay-Out PlanDocumento1 paginaGround Floor Lighting System Lay-Out Plananthony christian yangNessuna valutazione finora

- Fast Fast FastDocumento1 paginaFast Fast Fastanthony christian yangNessuna valutazione finora

- A-106 4th Floor Plan-ModelDocumento1 paginaA-106 4th Floor Plan-Modelanthony christian yangNessuna valutazione finora

- FewfweefwDocumento1 paginaFewfweefwanthony christian yangNessuna valutazione finora

- AfasdadffffffDocumento1 paginaAfasdadffffffanthony christian yangNessuna valutazione finora

- Bill No. 4 - Cluster A, C & EDocumento183 pagineBill No. 4 - Cluster A, C & EmimrusfanNessuna valutazione finora

- Construction Estimate FormDocumento16 pagineConstruction Estimate Formjerichochan88% (8)

- Two (2) Storey Residential BuildingDocumento10 pagineTwo (2) Storey Residential BuildingAlly Son de LagdamenNessuna valutazione finora

- Cantilever Masonry Manual Nov 03Documento27 pagineCantilever Masonry Manual Nov 03Dwi SulistyoNessuna valutazione finora

- Supervision Check ListDocumento38 pagineSupervision Check ListBikila M. KejelaNessuna valutazione finora

- Comparative Study On The Compressive Strength and Production Cost of Hollow Concrete Block (HCB) With and Without Red Ash in Tepi Town, EthiopiaDocumento7 pagineComparative Study On The Compressive Strength and Production Cost of Hollow Concrete Block (HCB) With and Without Red Ash in Tepi Town, EthiopiaKaramara Training & ConsultancyNessuna valutazione finora

- Lorna Taira General Construction SpecificationsDocumento3 pagineLorna Taira General Construction SpecificationsLimar SetatraNessuna valutazione finora

- Book 1 - Gyproc PlastersDocumento24 pagineBook 1 - Gyproc PlastersFariz AbdullaNessuna valutazione finora

- Package B-Lot 1-Chikowa BOQ UnpricedDocumento308 paginePackage B-Lot 1-Chikowa BOQ UnpricedChobwe Stephano KanyinjiNessuna valutazione finora

- Building Constructi ON II: Wood Frame and Light RC ConstructionDocumento144 pagineBuilding Constructi ON II: Wood Frame and Light RC ConstructionMonique AguinaldoNessuna valutazione finora

- The Design and Structural Analysis of A Steel Portal Framed Shed For The Darling Downs Historical Rail SocietyDocumento169 pagineThe Design and Structural Analysis of A Steel Portal Framed Shed For The Darling Downs Historical Rail SocietyDarren TurnerNessuna valutazione finora

- Building SSR 2011-12Documento403 pagineBuilding SSR 2011-12Guru Prasad0% (1)

- Proposed Eatery and Sari-Sari Store: General ConditionsDocumento1 paginaProposed Eatery and Sari-Sari Store: General ConditionsEdwin BansagNessuna valutazione finora

- CH08 MasonryDocumento16 pagineCH08 Masonrycjones2013Nessuna valutazione finora

- Hilti Tech PublicationDocumento178 pagineHilti Tech Publicationmuh2006Nessuna valutazione finora

- Low Cost Housing DesignDocumento27 pagineLow Cost Housing Designdillishwar bishwaNessuna valutazione finora

- Installation Main Ten Ace Manual Grasso 10 PDFDocumento60 pagineInstallation Main Ten Ace Manual Grasso 10 PDFAhmad HamedNessuna valutazione finora

- Assignment No.1 - Types and Costs of Materials in The Civil Engineering IndustryDocumento17 pagineAssignment No.1 - Types and Costs of Materials in The Civil Engineering Industryvarun100% (1)

- Ancon AMR Data SheetDocumento6 pagineAncon AMR Data SheetIOANNOU ENGINEERSNessuna valutazione finora

- Superlite ShapesDocumento72 pagineSuperlite Shapesdennis moreyNessuna valutazione finora

- Non-Engineered BuildingsDocumento48 pagineNon-Engineered Buildingsmassive85Nessuna valutazione finora

- Masonry ManualDocumento114 pagineMasonry Manualdpdqh0Nessuna valutazione finora

- Method Statement Submittal (V1.0) : Feb 3, 2022, ID #1734 Report DetailsDocumento19 pagineMethod Statement Submittal (V1.0) : Feb 3, 2022, ID #1734 Report DetailsArumugam RajNessuna valutazione finora

- Bos Hollow BlocksDocumento7 pagineBos Hollow BlocksRiz MarieNessuna valutazione finora

- 100 Bed Hospital Okpala StructuralDocumento83 pagine100 Bed Hospital Okpala StructuralEngr Josh ChisimdiNessuna valutazione finora

- Boq Gaza Park BoqDocumento13 pagineBoq Gaza Park Boqraitan1158Nessuna valutazione finora