Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Chapter 2 PDF

Caricato da

Santosh IyerTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Chapter 2 PDF

Caricato da

Santosh IyerCopyright:

Formati disponibili

5

CAMTECH/E/2002/AT/1.

CHAPTER 2

MAINTENANCE

2.1

MAINTENANCE SCHEDULE - MONTHLY

1.

2.

3.

Clean the transformer externally including bushing, conservator tank with dry

cloth.

Check the silicagel for its colour. Reactivate/replace if colour is pink.

Check the LT and HT connections for tightness. Clean the same if found

oxidized.

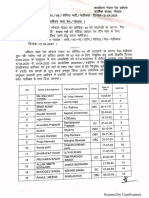

FIGURE 2.1

LT CONNECTIONS INSIDE THE TANK

4.

5.

6.

7.

8.

9.

2.2

Check the oil level and top up if required with new oil of 60 kV BDV.

Check the arcing horns for its gap and flashover and correct the same. Gap is

82.5mm in split type two halves on each side.

Clean the insulators of the D.O. fuse assembly.

Check the tightness of all the connections and fixing.

Check the tightness of earthing connection.

Clean the AT enclosure and remove the surrounding vegetation .

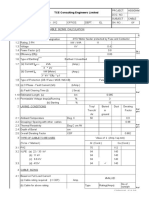

MAINTENANCE SCHEDULE -QUARTERLY

S. No

Work to be carried out

Observations

1.

Clean tank, conservator, bushings, oil gauge, top and bottom valve

2.

Check the BDV of oil with 2.5mm gap(Min-30kV)

Check the condition of silicagel. Dehydrate if pink. Check oil in

3.

the silicagel breather cup and also check for air passage through

the hole of breather.

Measure the arcing horn gap for HV bushing (Split arcing Horn

4.

Gap of 82.5 mm)

5.

Check the condition of the D.O. fuse barrel and fuse element

(1Amp. for 10 KVA AT)

6.

7.

8.

9.

Check the oil level in the conservator.

Check LT main box for any abnormalities and earthing.

Check for any oil leakages.

Check all nuts and bolts including earth connections.

Maintenance Handbook on Auxiliary Transformer

February, 2002

CAMTECH/E/2002/AT/1.

S.

No

Work to be carried out

Observations

Measure IR Values Between

10.

a.

HV-earth - 200 M ohm min. (Use 2.5 kV megger)

b. HV-LV - 200 M ohm min.

(use 2.5 kV megger)

c.

(use 500 V megger)

LV-Earth - 2 M ohm min.

11.

Check LT fuse for its proper rating.

12.

Check condition of foundation

13.

Check structure bond & earth connection

14.

Check availability of caution board

15.

Check availability of anti climbing device

16.

Check any unusual sound of equipment.

Check secondary voltage on each tap

17.

2.3

No load

Full load (Change the tap if necessary)

MAINTENANCE SCHEDULE (YEARLY)

S.

Work to be carried out

Observation

No

1.

Repeat all steps of quarterly maintenance.

2.

Check acidity of Transformer oil (Max. 0.5 mg KOH/gm).

Conduct ratio test by applying 240 V ac supply to HV winding and

3.

LV side voltage to be measured.

4.

Check tap changer for smooth operation.

5.

Measure the secondary current with clip-on-ammeter.

6.

Check water content (ppm), tan delta of transformer oil.

7.

Check dissolve gas analysis (DGA) of transformer oil and

polarisation index. Time index is 600 sec/60 sec.

8.

9.

Measure the earth resistance (not more than 10 ohm)

Check winding continuity on all tapings

10.

Painting to be done, if required.

*****

GO TO CONTENTS

Maintenance Handbook on Auxiliary Transformer

February, 2002

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Solution Manual For Investment Science by David LuenbergerDocumento94 pagineSolution Manual For Investment Science by David Luenbergerkoenajax96% (28)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Ra 6938Documento2 pagineRa 6938GaryNessuna valutazione finora

- S406 Specifications For The Supply of Stone PDFDocumento6 pagineS406 Specifications For The Supply of Stone PDFMfanelo MbanjwaNessuna valutazione finora

- 542 FormationDocumento1 pagina542 FormationSantosh IyerNessuna valutazione finora

- CementDocumento1 paginaCementSantosh IyerNessuna valutazione finora

- Government of India (Bharat Sarkar) Mantralaya) Board) : Ministry of Railways (RailDocumento2 pagineGovernment of India (Bharat Sarkar) Mantralaya) Board) : Ministry of Railways (RailSantosh IyerNessuna valutazione finora

- Model Processor RAM Storage GraphicsDocumento6 pagineModel Processor RAM Storage GraphicsSantosh IyerNessuna valutazione finora

- App. Supervisor PostingDocumento1 paginaApp. Supervisor PostingSantosh IyerNessuna valutazione finora

- Conferencing With Google MeetDocumento9 pagineConferencing With Google MeetSantosh IyerNessuna valutazione finora

- Gopal Udhyog: Plot No. 5&6, Suruchi Nagar, Bhopal (M.P) - 462003 Daily Progress Report of Foundation WorkDocumento1 paginaGopal Udhyog: Plot No. 5&6, Suruchi Nagar, Bhopal (M.P) - 462003 Daily Progress Report of Foundation WorkSantosh IyerNessuna valutazione finora

- Technical Paper - IPWE 2018 PDFDocumento410 pagineTechnical Paper - IPWE 2018 PDFSantosh IyerNessuna valutazione finora

- Traction Distribution Management System (TDMS) : ObjectivesDocumento1 paginaTraction Distribution Management System (TDMS) : ObjectivesSantosh IyerNessuna valutazione finora

- Viewnitpdf 2641980 1Documento24 pagineViewnitpdf 2641980 1Santosh IyerNessuna valutazione finora

- E-Mobility in Indian Railways: Railway Electrification: R K Pandey Tata Projects Limited 04th Sep'2018, New DelhiDocumento16 pagineE-Mobility in Indian Railways: Railway Electrification: R K Pandey Tata Projects Limited 04th Sep'2018, New DelhiSantosh IyerNessuna valutazione finora

- Earthing Practices For 25Kv/50Kv Railways - Engineering ChangeDocumento8 pagineEarthing Practices For 25Kv/50Kv Railways - Engineering ChangeSantosh IyerNessuna valutazione finora

- Breifcase PolicyDocumento1 paginaBreifcase PolicySantosh IyerNessuna valutazione finora

- KPTL Senior Engineer OHEDocumento1 paginaKPTL Senior Engineer OHESantosh IyerNessuna valutazione finora

- Form 26AS: Annual Tax Statement Under Section 203AA of The Income Tax Act, 1961Documento4 pagineForm 26AS: Annual Tax Statement Under Section 203AA of The Income Tax Act, 1961Santosh IyerNessuna valutazione finora

- Model SOP 2018Documento421 pagineModel SOP 2018B KRISHNA RAONessuna valutazione finora

- 812652file1 PDFDocumento3 pagine812652file1 PDFSantosh IyerNessuna valutazione finora

- Core Approve List PDFDocumento42 pagineCore Approve List PDFSantosh IyerNessuna valutazione finora

- Date Transaction Description Amount (In RS.)Documento2 pagineDate Transaction Description Amount (In RS.)Santosh IyerNessuna valutazione finora

- Final Handbook On OHE InspectionDocumento36 pagineFinal Handbook On OHE InspectionSantosh Iyer100% (1)

- TRF - Policyunion BearerDocumento14 pagineTRF - Policyunion BearerSantosh IyerNessuna valutazione finora

- LCS21 - 35 - Polar PlotsDocumento14 pagineLCS21 - 35 - Polar Plotsgosek16375Nessuna valutazione finora

- Safe Bearing Capacity of Soil - Based On Is: 6403 Sample CalculationDocumento1 paginaSafe Bearing Capacity of Soil - Based On Is: 6403 Sample CalculationSantosh ZunjarNessuna valutazione finora

- Soiling Rates of PV Modules vs. Thermopile PyranometersDocumento3 pagineSoiling Rates of PV Modules vs. Thermopile PyranometersAbdul Mohid SheikhNessuna valutazione finora

- Sti260N6F6 Stp260N6F6: N-Channel 60 V, 0.0024 Ω, 120 A Stripfet™ Vi Deepgate™ Power Mosfet In To-220 And I²Pak PackagesDocumento14 pagineSti260N6F6 Stp260N6F6: N-Channel 60 V, 0.0024 Ω, 120 A Stripfet™ Vi Deepgate™ Power Mosfet In To-220 And I²Pak PackagesRyn YahuFNessuna valutazione finora

- Partea I .60p I. Read The Text Below and Complete The Following Tasks. Write All Your Answers On The Answer SheetDocumento4 paginePartea I .60p I. Read The Text Below and Complete The Following Tasks. Write All Your Answers On The Answer SheetaaddniaNessuna valutazione finora

- Beginners Tutorial: Issue Status/Number - 1.0 Issue Date - 10 November, 2002Documento17 pagineBeginners Tutorial: Issue Status/Number - 1.0 Issue Date - 10 November, 2002nathulalusaNessuna valutazione finora

- Gantt ChartDocumento4 pagineGantt ChartSyed FaridNessuna valutazione finora

- Fluid Mechanics EXERCHAP08Documento3 pagineFluid Mechanics EXERCHAP08scribdgggNessuna valutazione finora

- Nozzle Loads - Part 2 - Piping-EngineeringDocumento3 pagineNozzle Loads - Part 2 - Piping-EngineeringShaikh AftabNessuna valutazione finora

- Ball Charge ManagementDocumento14 pagineBall Charge ManagementSalud Y SucesosNessuna valutazione finora

- Cable Size Calculations SpreadsheetDocumento4 pagineCable Size Calculations Spreadsheetbhavin24uNessuna valutazione finora

- Epson L6170 Wi-Fi Duplex All-in-One Ink Tank Printer With ADFDocumento3 pagineEpson L6170 Wi-Fi Duplex All-in-One Ink Tank Printer With ADFCarl DonaireNessuna valutazione finora

- MTH 108Documento10 pagineMTH 108GetlozzAwabaNessuna valutazione finora

- Dot NetDocumento9 pagineDot NetSuruBabuThalupuruNessuna valutazione finora

- Hiley TableDocumento5 pagineHiley TableHanafiahHamzahNessuna valutazione finora

- Opatch AutoDocumento2 pagineOpatch Autoshuvo_ami24Nessuna valutazione finora

- Solution of Linear System Theory and Design 3ed For Chi Tsong ChenDocumento106 pagineSolution of Linear System Theory and Design 3ed For Chi Tsong ChensepehrNessuna valutazione finora

- Configuration A: Unloaded BJT Transistor AmplifiersDocumento3 pagineConfiguration A: Unloaded BJT Transistor AmplifiersdasdNessuna valutazione finora

- Robot Sensors and TransducersDocumento176 pagineRobot Sensors and TransducerssakthivelNessuna valutazione finora

- Installation, Operation, and Maintenance ManualDocumento54 pagineInstallation, Operation, and Maintenance ManualIsmael Berlanga ResNessuna valutazione finora

- Hot and Cold ApplicDocumento33 pagineHot and Cold Appliccamille_12_15100% (1)

- Optical Properties of Gem Substances Educational Objective: This Exercise, Unit 7 in The Above Syllabus, Will Introduce Students To Skills andDocumento19 pagineOptical Properties of Gem Substances Educational Objective: This Exercise, Unit 7 in The Above Syllabus, Will Introduce Students To Skills andCarl SoriaNessuna valutazione finora

- Rekonfigurasi Jaringan Distribusi Radial Untuk Mengurangi Rugi Daya Pada Penyulang Jatirejo Rayon Mojoagung Menggunakan Metode BinaryDocumento4 pagineRekonfigurasi Jaringan Distribusi Radial Untuk Mengurangi Rugi Daya Pada Penyulang Jatirejo Rayon Mojoagung Menggunakan Metode BinaryNurindra CahyantaNessuna valutazione finora

- Prosper & Sucker RodDocumento20 pagineProsper & Sucker RodOmar AbdoNessuna valutazione finora

- UMTS Optimization GuidelineDocumento84 pagineUMTS Optimization GuidelineEvelio Sotolongo100% (3)

- Cable Sizing CalculationDocumento72 pagineCable Sizing CalculationHARI my songs100% (1)

- Switching Circuits & Logic Design: Registers and CountersDocumento37 pagineSwitching Circuits & Logic Design: Registers and Counters555-193614Nessuna valutazione finora