Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Itp For Construction of Precast Foundation

Caricato da

reachpunnya5538Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Itp For Construction of Precast Foundation

Caricato da

reachpunnya5538Copyright:

Formati disponibili

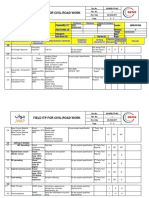

INSPECTION & TEST PLAN (ITP)

TITLE OF ITP:

S.I

No.

1.

2.

3.

INSPECTION/AC

TIVITY/TEST

DESCRIPTION

CONSTRUCTION OF PRECAST FOUNDATIONS.

REFERENCE

DOCUMENT

(Drwg./Spec

s/Contract)

FREQUENCY

OF

TEST/INSPE

CTION

ACCEPTANCE CRITERIA/

TOLERANCE

PARAMETERS

ITP No.

Date:

QUALITY

RECORD

( Forms,

Checklist,

Test

Results))

Rev. No.

RESPONSIBILITY/ACTION

T

P

L

SC

CN

S

PRELIMINARY

Shop Drawing

Project

Specification

& IFC Drawing

Material

Submittal and

Approval

Project

Specification

& Drawing

Concrete Mix

Design

Project

Specification

VOLUME II

Section 4.5

Prior to Start

the Activity

Prior to Start

the Activity

Prior to Start

the Activity

Approved Submittal

Transmittal Sheet with Code

A or Code B

Approved

Submittal

Transmittal

Sheet with

Code A or

Code B

Approved Submittal

Transmittal Sheet with Code

A or Code B

Approved

Submittal

Transmittal

Sheet with

Code A or

Code B.

As per the Project

Specification

Approved

Submittal

Transmittal

sheet with

code A or B

CONSTRUCTION PHASE

Page 1 of 5

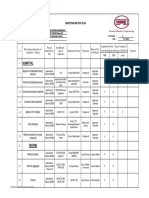

INSPECTION & TEST PLAN (ITP)

TITLE OF ITP:

S.I

No.

4.

5.

6.

CONSTRUCTION OF PRECAST FOUNDATIONS.

INSPECTION/AC

TIVITY/TEST

DESCRIPTION

REFERENCE

DOCUMENT

(Drwg./Spec

s/Contract)

FREQUENCY

OF

TEST/INSPE

CTION

ACCEPTANCE CRITERIA/

TOLERANCE

PARAMETERS

Construction of

Form Work

Support /

Alignment

Project

Specification

VOLUME II

Section 4.32

Every pour

prior to

concreting

will be set to line and level

as detailed in the approved

drawing to ensure the

required thickness of

concrete

Reinforcement/St

eel Fixing

Project

Specification

VOLUME II

Section 4.8 to

4.11

Each

Foundation

Reinforcement shall be

placed and maintained in

the position shown in the

Contract drawings

Cleaning

Project

Specification

VOLUME II

Section 4.32

Prior to cast

concrete

Thoroughly cleaned, free

from all loose rust, grease,

mud, paint and other

deleterious material.

Page 2 of 5

ITP No.

Date:

QUALITY

RECORD

( Forms,

Checklist,

Test

Approved IR

with Status A

or AN

Rev. No.

RESPONSIBILITY/ACTION

T

CN

P SC C

E

A

S

L

Pre-pour check

list F-003

Approved IR

with Status A

or AN

Pre-pour check

list F-003

Prepour check

list F-003

INSPECTION & TEST PLAN (ITP)

TITLE OF ITP:

S.I

No.

INSPECTION/AC

TIVITY/TEST

DESCRIPTION

CONSTRUCTION OF PRECAST FOUNDATIONS.

REFERENCE

DOCUMENT

(Drwg./Spec

s/Contract)

FREQUENCY

OF

TEST/INSPE

CTION

1)All

conditions of

Mix

7.

Concrete Grade

30/20 OPC+GGBS

Project

Specification

VOLUME II

Section 4.8 to

4.15

2), 3), 4)

Each Delivery

prior to

releasing the

concrete

5) Min of one

set (6 nos

cubes) per

casting day

and every 50

m

6) & 7) Each

Pour

ACCEPTANCE CRITERIA/

TOLERANCE

PARAMETERS

1) Ambient temperature is

above 40oC on a rising

thermometer

ITP No.

Date:

QUALITY

RECORD

( Forms,

Checklist,

Test

Rev. No.

RESPONSIBILITY/ACTION

T

CN

P SC C

E

A

S

L

2) C-30/20 SRC

3) Concrete temp shall not

be greater than 32C prior

to placement and

compaction

4) Slump as per approved

Trial mix approval

5) 150 x 150 mm cube

samples prepared in

accordance with BS En

12390-2, demoulded

between 16-24 hrs.

6 ) concrete shall be placed

gently and shall not have a

free fall of more than 2.0 m

7) Level layer no greater

Page 3 of 5

A Approved IR

with Status A

or AN

Concrete

Delivery note

and Test

Report

INSPECTION & TEST PLAN (ITP)

TITLE OF ITP:

S.I

No.

8.

CONSTRUCTION OF PRECAST FOUNDATIONS.

INSPECTION/AC

TIVITY/TEST

DESCRIPTION

REFERENCE

DOCUMENT

(Drwg./Spec

s/Contract)

Concrete pouring

Project

Specification

VOLUME II

Section 4.8 to

4.24

9.

Concrete Curing

Project

Specification

VOLUME II

Section 4.8 to

4.26

10.

Removal of Form

Work

Project

Specification

VOLUME II

Section 4.32

11.

FREQUENCY

OF

TEST/INSPE

CTION

Each

Foundation

Each

Foundation

Each

Foundation

Protective

All external

Bituminous

As per IFC

buried

Coating on

drawing

Concrete

precast

surface

foundation

ERECTION OF PRECAST FOUNDATION

ACCEPTANCE CRITERIA/

TOLERANCE

PARAMETERS

As per Project Specification

VOLUME II Section 4.8 to

4.24

ITP No.

Date:

QUALITY

RECORD

( Forms,

Checklist,

Test

Approved IR

with Status A

or AN

RESPONSIBILITY/ACTION

T

CN

P SC C

E

A

S

L

Check List F003 Rev 0

Project Specification

VOLUME II Section 4.8 to

4.26

Approved IR

with Status A

or AN

Project Specification

VOLUME II Section 4.32

Approved IR

with Status A

or AN

As per IFC Drawing no 6293FFS-FC-DT-501

Approved IR

with Status A

or AN

Page 4 of 5

Rev. No.

INSPECTION & TEST PLAN (ITP)

TITLE OF ITP:

CONSTRUCTION OF PRECAST FOUNDATIONS.

ITP No.

Date:

QUALITY

RECORD

( Forms,

Checklist,

Test

REFERENCE

DOCUMENT

(Drwg./Spec

s/Contract)

FREQUENCY

OF

TEST/INSPE

CTION

ACCEPTANCE CRITERIA/

TOLERANCE

PARAMETERS

Verification of

Original Ground

Level survey

Project

Specification

VOLUME II

Section 6

Clause 6.16

Prior to Start

the Activity

As per IFC Drawing

Approved IR

with Status A

or AN

Check evenness

and level of

surrounding

ground level

Project

Specification

VOLUME II

Section 6

Clause 6.17

Every

excavation

Compaction Test 98% of

M.D.D

Approved IR

with Status A

or AN

14.

Placing of Precast

Foundation

Project

Specification

Volume II-A:

Specification

Section D

Concrete

Works ,

Clause 7.1.9

Each

Foundation

Precast units shall be placed

in the Works to within + 5

mm of their specified plan

position and + 3 mm of the

specified level.

Approved IR

with Status A

or AN

15.

Blinding

Approved

Drawings

Each activity

As per approved drawing

Approved

Drawings

Each activity

As per manufacturers

instruction

S.I

No.

12.

13.

16.

INSPECTION/AC

TIVITY/TEST

DESCRIPTION

Application of

Waterproofing

Membrane

Page 5 of 5

Rev. No.

RESPONSIBILITY/ACTION

T

CN

P SC C

E

A

S

L

Approved IR

with Status A

or AN

Approved IR

with Status A

or AN

INSPECTION & TEST PLAN (ITP)

TITLE OF ITP:

CONSTRUCTION OF PRECAST FOUNDATIONS.

S.I

No.

INSPECTION/AC

TIVITY/TEST

DESCRIPTION

REFERENCE

DOCUMENT

(Drwg./Spec

s/Contract)

FREQUENCY

OF

TEST/INSPE

CTION

ACCEPTANCE CRITERIA/

TOLERANCE

PARAMETERS

17.

Lifting and

Placement of

Precast

Foundation

Approved

Drawings

Each activity

Level and alignment should

be acceptable

Project

Specification

18.

Grouting

19.

Backfilling &

Compaction

Volume II-A:

Specification

Section D

Concrete

Works, Clause

7.1.3

Project

Specification

Volume II :

Section 6

Clause 6.30

Each

Foundation

Each

Foundation

The surfaces of precast

units which will

subsequently receive grout

or concrete to form a

structural connection with

insitu concrete shall be

prepared by removing the

outer mortar skin when the

concrete has set but not

hardened, using a stiff brush

and a fine spray of water, to

the extent that the larger

pieces of coarse aggregate

are exposed but not

backfill material to be laid in

layers, not exceeding 150

mm of each layer of

compacted thickness,

compacted to 95% of MDD

(As per approved site trial)

POST CONSTRUCITON PHASE

Page 6 of 5

ITP No.

Date:

QUALITY

RECORD

( Forms,

Checklist,

Test

Approved IR

with Status A

or AN

Rev. No.

RESPONSIBILITY/ACTION

T

CN

P SC C

E

A

S

L

W

Approved IR

with Status A

or AN

Approved IR

with Status A

or AN

INSPECTION & TEST PLAN (ITP)

TITLE OF ITP:

S.I

No.

INSPECTION/AC

TIVITY/TEST

DESCRIPTION

All As-built

Records

20.

CONSTRUCTION OF PRECAST FOUNDATIONS.

REFERENCE

DOCUMENT

(Drwg./Spec

s/Contract)

General

Specification

Section 2,

Clause 1.4 (i)

FREQUENCY

OF

TEST/INSPE

CTION

ACCEPTANCE CRITERIA/

TOLERANCE

PARAMETERS

On

completion

of the work

1. Prepare and submit 'as

built ' drawings for

foundation drawing or as

per the work carried out

in the site.

2. According to all approved

drawings.

ITP No.

Date:

QUALITY

RECORD

( Forms,

Checklist,

Test

Approved as

built

submittals

Rev. No.

RESPONSIBILITY/ACTION

T

CN

P SC C

E

A

S

L

LEGEND

ACTION CODE:

S Surveillance

W Witness

R Review of Documents

H Hold Point

DATE

Inspection Authority:

TPL Third Party Laboratory

C Contractor

CNS Consultants

PREPARED & REVIEWED BY

APPROVED BY

ACCEPTED BY

QAQC REPRESENTATIVE

PROJECT MANAGER

CONSULTANT REPRESENTATIVE

DATE

DATE

Page 7 of 5

Potrebbero piacerti anche

- 027-ITP For Pre - Cast Concrete PDFDocumento11 pagine027-ITP For Pre - Cast Concrete PDFKöksal Patan75% (4)

- Method Statement For Casting Blinding ConcreteDocumento2 pagineMethod Statement For Casting Blinding ConcreteCrazyBookWorm100% (2)

- Method Statement For ConcretingDocumento23 pagineMethod Statement For ConcretingVinod MasaniNessuna valutazione finora

- 017-W009-2667 - ITP - Precast & Prestressed Concrete - Revc0 PDFDocumento9 pagine017-W009-2667 - ITP - Precast & Prestressed Concrete - Revc0 PDFMohammad Hadoumi Saldan100% (1)

- ITP For CivilDocumento85 pagineITP For CivilBilibili weekly TOP 10 videos100% (6)

- ITP CIVIL WORK-Rev-1Documento6 pagineITP CIVIL WORK-Rev-1Ateeq Rahman100% (1)

- MS For Pre - CastDocumento14 pagineMS For Pre - CastImho TepNessuna valutazione finora

- 027 ITP For Pre Cast Concrete PDFDocumento27 pagine027 ITP For Pre Cast Concrete PDFlinga2014Nessuna valutazione finora

- General Earthwork Procedures: PT Aurecon Indonesia ProcedureDocumento16 pagineGeneral Earthwork Procedures: PT Aurecon Indonesia ProcedureMohamed Amine Zemouri0% (1)

- ITP - Concrete WorksDocumento17 pagineITP - Concrete WorksVasilica BArbarasa100% (2)

- 044-ITP For Installation of Gypsum Board (Buildings) PDFDocumento10 pagine044-ITP For Installation of Gypsum Board (Buildings) PDFKöksal Patan100% (3)

- ITP-CI-026a-02 (Building Finishing Works)Documento4 pagineITP-CI-026a-02 (Building Finishing Works)Delta akathehuskyNessuna valutazione finora

- Inspection and Test Plan For HVAC Cladding Works: 0-WD860-CA250-00312 0Documento3 pagineInspection and Test Plan For HVAC Cladding Works: 0-WD860-CA250-00312 0ResearcherNessuna valutazione finora

- 023-Itp Concrete Works PDFDocumento32 pagine023-Itp Concrete Works PDFKöksal Patan100% (5)

- 022-Itp For Fence & Gate PDFDocumento5 pagine022-Itp For Fence & Gate PDFKöksal Patan83% (6)

- Inspection and Test PlanDocumento6 pagineInspection and Test PlanMadison ChanNessuna valutazione finora

- ITP - ROAD WORK-Rev-01Documento4 pagineITP - ROAD WORK-Rev-01Ateeq Rahman100% (1)

- ITP For RC RC Slab, Beams WorkDocumento3 pagineITP For RC RC Slab, Beams WorkMohammed Ghareib NasrNessuna valutazione finora

- 6.ITP For RebarDocumento1 pagina6.ITP For RebarDaniel Sinaga100% (1)

- Method Statement For Termite Control (AUVA-MS-Civil-MS-023) Rev 01Documento9 pagineMethod Statement For Termite Control (AUVA-MS-Civil-MS-023) Rev 01hammad21100% (1)

- PD-CL-021 - 1 Precast Panel InstallationDocumento1 paginaPD-CL-021 - 1 Precast Panel Installationkimura takuyaNessuna valutazione finora

- MS-CVL-009 Erection of Hollowcore Slabs 1Documento12 pagineMS-CVL-009 Erection of Hollowcore Slabs 1Suju RajanNessuna valutazione finora

- Bored PilingDocumento3 pagineBored PilingTAHER AMMAR100% (1)

- Part 2 - ITP Details: Inspection & Test Plan For Precast Concrete WorksDocumento5 paginePart 2 - ITP Details: Inspection & Test Plan For Precast Concrete WorksErickson Malicsi100% (2)

- Inspection Test Plan For Civil Works Rev 01Documento22 pagineInspection Test Plan For Civil Works Rev 01Eze Nonso50% (2)

- 3.ITP For Erection of Precast - Rev-01Documento3 pagine3.ITP For Erection of Precast - Rev-01Suju Rajan100% (1)

- Civil ItpDocumento60 pagineCivil ItpBiswas100% (1)

- ITP Check List For Metal Deck InstallationDocumento2 pagineITP Check List For Metal Deck InstallationJoyce Gordonio0% (1)

- 18.9 ITP SUB BASE Rev01Documento2 pagine18.9 ITP SUB BASE Rev01YEHIA100% (1)

- Inspection and Test Plan: Cement Stucco (Exterior Plastering)Documento3 pagineInspection and Test Plan: Cement Stucco (Exterior Plastering)Alvene TagocNessuna valutazione finora

- INSPECTION AND TEST PLAN - Driven of Pre Cast Concrete Piles PDFDocumento3 pagineINSPECTION AND TEST PLAN - Driven of Pre Cast Concrete Piles PDFmustafaNessuna valutazione finora

- Method Statement For Earthwork Excavation & BackfillingDocumento6 pagineMethod Statement For Earthwork Excavation & Backfillingjing aytonaNessuna valutazione finora

- Method Statement For Precast Concrete WorksDocumento21 pagineMethod Statement For Precast Concrete WorksBleep NewsNessuna valutazione finora

- ITP - Concrete Works PDFDocumento2 pagineITP - Concrete Works PDFntah8483% (35)

- ITP - Blockwork R0 - HKHDocumento2 pagineITP - Blockwork R0 - HKHabdou89% (9)

- 9686-6130-ITP - 000-1002 - Inspection and Test Plan For General Civil Works Rev A1Documento34 pagine9686-6130-ITP - 000-1002 - Inspection and Test Plan For General Civil Works Rev A1anil pk100% (8)

- Itp PilingDocumento3 pagineItp PilingMikiRoniWijaya50% (6)

- Method Statement For Construction - Method Statement - Non Suspended SlabDocumento3 pagineMethod Statement For Construction - Method Statement - Non Suspended SlabKellyNessuna valutazione finora

- Cb2 Q Zen 05 60211 Itp For Earth Work - Rev.bDocumento6 pagineCb2 Q Zen 05 60211 Itp For Earth Work - Rev.bAnonymous wIPMQ5rhNessuna valutazione finora

- Method Statement For Civil Foundations & GroutingDocumento18 pagineMethod Statement For Civil Foundations & GroutingAbdullah Abdullah100% (1)

- Preparation of Inspection & Test Plans For Civil & Steelworks, Rev.0 Foster Wheeler Energy LTD Work Practice Construction OperationsDocumento5 paginePreparation of Inspection & Test Plans For Civil & Steelworks, Rev.0 Foster Wheeler Energy LTD Work Practice Construction Operationssateeshsingh100% (2)

- Pre-Pouring Concrete ChecklistDocumento4 paginePre-Pouring Concrete Checklistusman82Nessuna valutazione finora

- ITP-Inspection and Test Plan For Camp Construction With CPP Comments PDFDocumento9 pagineITP-Inspection and Test Plan For Camp Construction With CPP Comments PDFanil pk100% (1)

- Foundation Works Method Statement PDFDocumento10 pagineFoundation Works Method Statement PDFKaranja0% (1)

- ITP For PilingDocumento9 pagineITP For PilingAntonio Tomas Gonzalez Losa100% (2)

- 028-Itp For Building Works PDFDocumento10 pagine028-Itp For Building Works PDFKöksal Patan100% (3)

- 5-ITP-Concrete Works PDFDocumento4 pagine5-ITP-Concrete Works PDFShivarajJadhavNessuna valutazione finora

- Itp PlasteringDocumento7 pagineItp PlasteringJervino RuahNessuna valutazione finora

- Itp - Building WorksDocumento15 pagineItp - Building WorksVasilica BArbarasaNessuna valutazione finora

- ITP-01 - BackfillingDocumento1 paginaITP-01 - BackfillingMaddala Srinivasa Rao50% (2)

- INSPECTION & TEST PLAN (ITP) : Anti Termite TreatmentDocumento1 paginaINSPECTION & TEST PLAN (ITP) : Anti Termite TreatmentLOPA THANDAR100% (2)

- Method Statement Steel Structure 1 4 Meg PDFDocumento26 pagineMethod Statement Steel Structure 1 4 Meg PDFemeka2012Nessuna valutazione finora

- Project: Baladna Dairy Farm Phase-2: Inspection and Test PlanDocumento3 pagineProject: Baladna Dairy Farm Phase-2: Inspection and Test PlanMelih SENTURK100% (1)

- MS - Precast Wall Installation Rev 0Documento27 pagineMS - Precast Wall Installation Rev 0Ed Salanga67% (3)

- Inspection and Test Plan For Earthworks NSCR-PSC-N05-CRKDPT-PRO-QA-000000Documento7 pagineInspection and Test Plan For Earthworks NSCR-PSC-N05-CRKDPT-PRO-QA-000000ResearcherNessuna valutazione finora

- RKSDocumento11 pagineRKSDanang HermawanNessuna valutazione finora

- Fahu - AhuDocumento6 pagineFahu - AhuHadi AbdulkaderNessuna valutazione finora

- 01 ITP TemplateDocumento6 pagine01 ITP TemplateHelsy FuentesNessuna valutazione finora

- 025-Pro For Sewer & Drainage PDFDocumento25 pagine025-Pro For Sewer & Drainage PDFKöksal PatanNessuna valutazione finora

- JPK-056-07-Q-0794 - Rev 1Documento84 pagineJPK-056-07-Q-0794 - Rev 1aibekNessuna valutazione finora

- Dewatring Method StatementDocumento8 pagineDewatring Method Statementreachpunnya5538Nessuna valutazione finora

- Pouring SheetDocumento4 paginePouring Sheetreachpunnya5538Nessuna valutazione finora

- Materials Submittal LogDocumento8 pagineMaterials Submittal Logreachpunnya5538Nessuna valutazione finora

- First Aid ManualDocumento32 pagineFirst Aid Manualreachpunnya5538Nessuna valutazione finora

- RFP Document Globally Recognized ERP SolutionDocumento31 pagineRFP Document Globally Recognized ERP SolutionJawad AhmedNessuna valutazione finora

- Material and Equipment Standard: IPS-M-AR-205Documento50 pagineMaterial and Equipment Standard: IPS-M-AR-205reza329329Nessuna valutazione finora

- Mamo CHL Unit 3 Task 8Documento3 pagineMamo CHL Unit 3 Task 8muhammad kaleem100% (2)

- ETP Spec.Documento70 pagineETP Spec.Adam Michael GreenNessuna valutazione finora

- Ansuisa 18.2 2009Documento80 pagineAnsuisa 18.2 2009Sohail Iftikhar100% (1)

- Chlorination SystemDocumento4 pagineChlorination Systemjkhan_724384Nessuna valutazione finora

- Clause 7Documento13 pagineClause 7Sayed WafiullahNessuna valutazione finora

- Satellite L635-S3030Documento4 pagineSatellite L635-S3030NafiNessuna valutazione finora

- Concrete Construction Article PDF - Using The New ACI 301Documento3 pagineConcrete Construction Article PDF - Using The New ACI 301NoNa MohammedNessuna valutazione finora

- Data Sheet ASTM A517 Grade Q 2017-04-19Documento1 paginaData Sheet ASTM A517 Grade Q 2017-04-19FAUSTINO SOLANO SUAREZNessuna valutazione finora

- Vendor EvaluationDocumento11 pagineVendor EvaluationMinh LeNessuna valutazione finora

- Astm A276-06Documento7 pagineAstm A276-06NadhiraNessuna valutazione finora

- Curfew E Pass Management System Project - 180540107175Documento24 pagineCurfew E Pass Management System Project - 180540107175Shivam ViradiyaNessuna valutazione finora

- Research Designs & Standards Organization: QM-G-7.1-3 Guidelines For Vendor ApprovalDocumento24 pagineResearch Designs & Standards Organization: QM-G-7.1-3 Guidelines For Vendor Approvalgopal sharma100% (1)

- COnsultant Procedure Manual ABU DHABIDocumento58 pagineCOnsultant Procedure Manual ABU DHABIYma LNessuna valutazione finora

- Lecture On-Importance of Materials TestingDocumento61 pagineLecture On-Importance of Materials TestingLovely Luna100% (2)

- C242 - Flexible - Pavements-Shellharbour CouncilDocumento21 pagineC242 - Flexible - Pavements-Shellharbour CouncilstefpanNessuna valutazione finora

- Doors, Furniture, Marine: Standard Specification ForDocumento4 pagineDoors, Furniture, Marine: Standard Specification ForRománBarciaVazquezNessuna valutazione finora

- Ieee STD 730 Sqa PlansDocumento17 pagineIeee STD 730 Sqa PlansPatricia LlallicoNessuna valutazione finora

- TN3-0506-Properties and Equivalent GradesDocumento4 pagineTN3-0506-Properties and Equivalent GradesGaurav Narula100% (1)

- Flight Kiosk ProjectDocumento16 pagineFlight Kiosk ProjectPrince Britto DassNessuna valutazione finora

- Loctite Ablestik 8290: Technical Data SheetDocumento2 pagineLoctite Ablestik 8290: Technical Data SheetAl Haba Ahmad Zaki Abdul HamidNessuna valutazione finora

- Project Engineers ManagementDocumento27 pagineProject Engineers ManagementAjayNessuna valutazione finora

- Valve Standards in The PetrochemicalDocumento5 pagineValve Standards in The PetrochemicalSohaib ZafarNessuna valutazione finora

- OOSE Chapter 3 Req Elici Present ConciseDocumento95 pagineOOSE Chapter 3 Req Elici Present ConciseLemi TuroNessuna valutazione finora

- Scrap Specification PDFDocumento62 pagineScrap Specification PDFr mohadiker0% (1)

- Jax Ws SpecDocumento143 pagineJax Ws Specapi-26580974Nessuna valutazione finora

- TS Index of Technical Specifications August 2008 - January 2009Documento125 pagineTS Index of Technical Specifications August 2008 - January 2009Fabio ParceroNessuna valutazione finora

- Sspc-Inspectionplan PDFDocumento28 pagineSspc-Inspectionplan PDFPraditia DanisNessuna valutazione finora

- 510703-7EN1 BCI SpecificationsDocumento124 pagine510703-7EN1 BCI SpecificationsJose VarelaNessuna valutazione finora