Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

SikaDur 53

Caricato da

pnCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

SikaDur 53

Caricato da

pnCopyright:

Formati disponibili

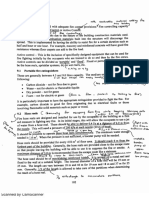

October 2003

SikaDur 53

Underwater Epoxy Crack Injection Resin

Technical Data Sheet

DESCRIPTION

SikaDur 53 is a two component epoxy resin uniquely

formulated for underwater or wet crack injection work and

is of a pourable fine mortar consistency.

Technical Data (typical)

Colour:

Green

Density:

2.0 kg/litre

Application

temperatures:

USES

*

*

*

*

*

*

*

For injection into wet cracks or cracks filled with

water.

Crack width

range:

0.5 mm min

40 mm max

For the repair of water immersed concrete

structures.

Viscosity:

5800(cP) @20C

Fills and seals cavities and cracks in structural

building and civil engineering structural components.

MECHANICAL PROPERTIES

(Applied and cured underwater @ 20C)

Preventing ingress of water.

Compressive

strength gain:

1 day

2 days

5 days

14 days

50

60

75

85

Flexural strength:

45 N/mm2

Tensile strength:

30 N/mm2

4.0 KN/mm2

Good mechanical properties.

Modulus of

Elasticity:

(static)

Low viscosity.

Bond strength:

Concrete: typically 3.0 N/mm2

(concrete failure)

Resists chemicals.

Shrinkage:

Negligible

Suitable for gravity feed or pressure injection.

Pot life:

Structural bonding.

Floor screed stabilisation/bonding.

Underground grouting work.

ADVANTAGES

*

*

*

*

*

*

*

+5C min - +25C max

(substrate and ambient)

Excellent bond to wet/underwater concrete and

masonry.

Low water absorption.

Seals against moisture and oxygen.

20C

N/mm2

N/mm2

N/mm2

N/mm2

30 mins

All above values are approximate.

SURFACE PREPARATION

IMPORTANT CONSIDERATIONS

Concrete/Brickwork Substrates:

Surfaces must be sound, clean, free from standing water

and loosely adhering particles and other contaminants.

Purge cracks with resin after capping until resin runs

contaminant free.

MIXING

For single component dispensing equipment,

sealant cartridge or gravity feed:

Stir component A prior to mixing (resin). The whole of

component A (resin) should be mixed with the whole of

component B (hardener) for a minimum of 2 minutes

using a slow speed electric stirrer (300-600 rpm).

Allow a waiting time of 15 minutes (@20C) for both

products prior to applying in order to allow the mixture to

pre-react for optimal adhesion underwater.

APPLICATION

Pressure Injection:

Select injection port locations, drill hole in substrate

at location of crack and insert socket ports.

Alternatively use surface adaptors bonded to surface

over crack. As a guide ports should be located at a

distance equal to the thickness of the injected

member. Minimum injection port distance

approximately 200 mm.

*

*

*

Cap/seal surface with SikaDur 31 Rapid thixotropic

epoxy adhesive at a thickness of at least 2.0 mm and

allow to cure. Surface preparation should be

sufficient to bond cap/seal and withstand injection

pressures. Guiding surface either side of crack may

be necessary.

Inject the mixed SikaDur 53 using single component

injection dispensing equipment or the unmixed

components of A and B using dual component

dispensing equipment at a pressure and duration

which will allow full penetration of the resin into the

crack. Purge cracks with resin to clean crack.

After injection of SikaDur 53 allow to harden and

grind off SikaDur 31 Rapid cap/seal and injection

ports.

Gravity feed (horizontal surfaces)

Use mechanical equipment to form a V-notch along

the length of the crack. Pour mixed SikaDur 53 into

crack. Top up V-notch as required until notch

remains full and SikaDur 53 hardens. Alternatively

use a bund along crack formed from a fillet of

Sikaflex 11FC.

*

*

*

*

*

*

*

*

Crack injection is a specialist technique. The

success is dependent on the resin, pressure, spacing

of ports and equipment used. Therefore it is

recommended a specialist injection contractor is

used.

At higher temperatures pot life will be shortened.

At lower temperatures the material will become more

difficult to inject and take longer to harden.

Wear suitable protective clothing, gloves and eye

protection.

Do not add solvent to the mix.

Establish cracks are static moving cracks and should

be treated as movement joints.

Thinner C is flammable. NO NAKED FLAMES

Trials should be undertaken to establish suitability of

resin, spacing of injection ports, injection equipment

and injection pressure.

Take cores at locations of cracks to clarify

penetration and method of injection.

CLEANING

All tools should be cleaned with Thinner C immediately

after use. Hardened material must be removed

mechanically.

PACKAGING

Refer to latest price list.

CONSUMPTION (kg/m 2)

SikaDur 53

1 mm thickness

5 mm thickness

10 mm thickness

2.0

10.0

20.0

Excluding allowances for loss wastage surface profile

and porosity.

STORAGE AND SHELF LIFE

Minimum 12 months in sealed containers stored in dry

warehouse conditions (+5C - +25C).

Handling Precautions

Sika products are generally harmless provided that certain precautions normally taken when handling chemicals are observed. The materials must not, for instance, be allowed to come in contact with foodstuffs or food utensils and

measures should also be taken to prevent the uncured materials from coming in contact with the skin, since people with particularly sensitive skin may be affected. The use of protective clothing, goggles, barrier creams and rubber gloves

is required. The skin should be thoroughly cleaned at the end of each working period either by washing with soap and warm water or by using a resin-removing cream - the use of powerful solvents is to be avoided. Disposable paper

towels - not cloth towels - should be used to dry the skin. Adequate ventilation of the working area is recommended. In case of accidental eye or mouth contact, flush with water - consult a doctor immediately. Health and Safety information

on Sika Products is available and we strongly advise that this is read prior to their use. Sika products are for professional use and should be stored in sealed containers away from the reach of children.

Important Note

The information, and, in particular, the recommendations relating to the application and end-use of Sika products, are given in good faith based on Sikas current knowledge and experience of the products when properly stored, handled

and applied under normal conditions. In practice, the differences in materials, substrates and actual site conditions are such that no warranty in respect of merchantability or of fitness for a particular purpose, nor any liability arising out of

any legal relationship whatsoever, can be inferred either from this information, or from any written recommendations, or from any other advice offered. The proprietary rights of third parties must be observed. All orders are accepted subject

to our current terms of sale and delivery. Users should always refer to the most recent issue of the Technical Data Sheet for the product concerned, copies of which will be supplied on request.

Please consult our Technical Sales Department for further information

SIKA LIMITED

Watchmead, Welwyn Garden City, Hertfordshire, AL7 1BQ

Tel: 01707 394444 Email: sika@uk.sika.com

Fax: 01707 329129 www.sika.com

Potrebbero piacerti anche

- Sikadur52 TdsDocumento3 pagineSikadur52 TdsJian HuaNessuna valutazione finora

- Sikadur 52 - PDSDocumento2 pagineSikadur 52 - PDS231340Nessuna valutazione finora

- Sikadur 42 HSDocumento2 pagineSikadur 42 HSthe pilotNessuna valutazione finora

- Sikaflex Construction DDocumento3 pagineSikaflex Construction Dthe pilotNessuna valutazione finora

- Sikadur - 42 HS: High Strength Pourable Epoxy GroutDocumento4 pagineSikadur - 42 HS: High Strength Pourable Epoxy GroutMuhammad Azlan AhmadNessuna valutazione finora

- Sikacryl SDocumento2 pagineSikacryl Sthe pilotNessuna valutazione finora

- Sika Concrete Primer 2011-04-1Documento3 pagineSika Concrete Primer 2011-04-1orgaNessuna valutazione finora

- SikaMembran UniversalDocumento2 pagineSikaMembran UniversalColégio MilitarNessuna valutazione finora

- Sikadur 31, Hi-Mod Gel 1 1 Mix Ratio-UsDocumento2 pagineSikadur 31, Hi-Mod Gel 1 1 Mix Ratio-Usgrats_singcoNessuna valutazione finora

- Sika PDS - E - Sikaflex Construction (NWE)Documento4 pagineSika PDS - E - Sikaflex Construction (NWE)Pisut LeelalumlertNessuna valutazione finora

- Sikadur 52 Method StatementDocumento2 pagineSikadur 52 Method StatementYong Zhi XiangNessuna valutazione finora

- Sikagard 675 ElastocolorDocumento4 pagineSikagard 675 ElastocolorAvan Setyo PratamaNessuna valutazione finora

- Sika Microcrete-3000 PDFDocumento4 pagineSika Microcrete-3000 PDFhks1209Nessuna valutazione finora

- Sikadur 32Documento3 pagineSikadur 32Matteo BreveglieriNessuna valutazione finora

- Sikadur 32Documento2 pagineSikadur 32the pilotNessuna valutazione finora

- Pds CPD Sikadur301 UsDocumento2 paginePds CPD Sikadur301 UsGabriel MazariegosNessuna valutazione finora

- Sika Duoflex NS/SL: Two-Component, Polysulphide SealantDocumento2 pagineSika Duoflex NS/SL: Two-Component, Polysulphide SealantAbu Vulkanik Al-JawiyNessuna valutazione finora

- Sikadur - 53 (UF) : Moisture Insensitive Injection ResinDocumento3 pagineSikadur - 53 (UF) : Moisture Insensitive Injection Resinpramod kumarNessuna valutazione finora

- SikaGrout 212 Product Data B25956Documento2 pagineSikaGrout 212 Product Data B25956Guillermo Garcia50% (2)

- My Con Pds Sikagard 61 TZDocumento3 pagineMy Con Pds Sikagard 61 TZlaurenjiaNessuna valutazione finora

- Chapdur 091228Documento4 pagineChapdur 091228priyanithiNessuna valutazione finora

- Sikafloor - Proseal-22: Curing and Sealing Compound For Concrete FloorsDocumento4 pagineSikafloor - Proseal-22: Curing and Sealing Compound For Concrete FloorsSholikhinIbnuRamadhanNessuna valutazione finora

- Sikadur 752Documento2 pagineSikadur 752Gry ArdiansyahNessuna valutazione finora

- Semen GroutingDocumento3 pagineSemen GroutingMuhammad Iqbal HimawanNessuna valutazione finora

- Sika Seal 105Documento2 pagineSika Seal 105Gabo Tellez100% (1)

- 106 - Sika Waterproofing MortarDocumento2 pagine106 - Sika Waterproofing MortarZack de la RezaNessuna valutazione finora

- Sikadur31 TdsDocumento4 pagineSikadur31 TdsFrederick Linsangan CruzNessuna valutazione finora

- Sikacem Gunit 133Documento2 pagineSikacem Gunit 133the pilotNessuna valutazione finora

- Sika PDS - E - Sika Padding Mortar PDFDocumento2 pagineSika PDS - E - Sika Padding Mortar PDFlwin_oo2435Nessuna valutazione finora

- Sika PDS - E - Sika Padding MortarDocumento2 pagineSika PDS - E - Sika Padding MortarAlbert Wilson PardameanNessuna valutazione finora

- Sikadur - 42 HES: Castable Epoxy Resin Based GroutDocumento4 pagineSikadur - 42 HES: Castable Epoxy Resin Based GroutAjay SastryNessuna valutazione finora

- Sika ChapdurDocumento2 pagineSika ChapdurJim Dry100% (1)

- Sika Chapdur Pds enDocumento2 pagineSika Chapdur Pds enIndra KusumaNessuna valutazione finora

- Cem FlexDocumento3 pagineCem FlexJaneshaNessuna valutazione finora

- Sika Microcrete-217Documento3 pagineSika Microcrete-217hkhcsbNessuna valutazione finora

- Sikagard ElastoColor-675 WDocumento4 pagineSikagard ElastoColor-675 WAgung RahmadiNessuna valutazione finora

- SIKADocumento2 pagineSIKADevri ChristianNessuna valutazione finora

- MS - SikaGrout 212 (Grouting Repairs of Reinforced Concrete) (v.02)Documento11 pagineMS - SikaGrout 212 (Grouting Repairs of Reinforced Concrete) (v.02)angelandlucifergabriel009Nessuna valutazione finora

- Sikaflex 11FCDocumento3 pagineSikaflex 11FCthe pilotNessuna valutazione finora

- MS - SikaWrap 600C2Documento14 pagineMS - SikaWrap 600C2fourNessuna valutazione finora

- Sika Raintite Pds PDFDocumento2 pagineSika Raintite Pds PDFBambang YuliantoNessuna valutazione finora

- Sikasil® Wet Areas: Product Data SheetDocumento3 pagineSikasil® Wet Areas: Product Data SheetMostafa BatanyNessuna valutazione finora

- Sikadur 100Documento2 pagineSikadur 100the pilotNessuna valutazione finora

- SikaGrout 215 NewDocumento2 pagineSikaGrout 215 Newayu2023100% (1)

- Sika Raintite: Acrylic WaterproofingDocumento2 pagineSika Raintite: Acrylic WaterproofingWahyudi AminotoNessuna valutazione finora

- E - 9039 - Sika - Per - 3326 EG-HDocumento4 pagineE - 9039 - Sika - Per - 3326 EG-HBogdan DavidescuNessuna valutazione finora

- Sikagard®-203 W: Product Data SheetDocumento4 pagineSikagard®-203 W: Product Data SheetKhin Sandi KoNessuna valutazione finora

- Antisol S: Curing CompoundsDocumento2 pagineAntisol S: Curing CompoundsDodi DoankNessuna valutazione finora

- HT Sikadur 32gelDocumento4 pagineHT Sikadur 32gelQuerubin EboliNessuna valutazione finora

- Sika® Microcrete®-218: Product Data SheetDocumento3 pagineSika® Microcrete®-218: Product Data SheetthowchinNessuna valutazione finora

- Sikadur®-20 Crack Seal: Product Data SheetDocumento2 pagineSikadur®-20 Crack Seal: Product Data SheetYulis TanNessuna valutazione finora

- Sikagard - 670W: Emulsion Type Protective Coating For ConcreteDocumento2 pagineSikagard - 670W: Emulsion Type Protective Coating For Concretethe pilotNessuna valutazione finora

- Sika PDS - E - Sikadur - 42 TH PDFDocumento2 pagineSika PDS - E - Sikadur - 42 TH PDFlwin_oo2435100% (1)

- Sikaflex Construction (J) SealantDocumento4 pagineSikaflex Construction (J) SealantFronica Litad SamionNessuna valutazione finora

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionDa EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNessuna valutazione finora

- The Science of Superhydrophobicity: Enhancing Outdoor Electrical InsulatorsDa EverandThe Science of Superhydrophobicity: Enhancing Outdoor Electrical InsulatorsNessuna valutazione finora

- Building Engineering HandoutsDocumento82 pagineBuilding Engineering HandoutspnNessuna valutazione finora

- Decking Span Table - TableDocumento1 paginaDecking Span Table - TablepnNessuna valutazione finora

- Z450 Purlin Test ResultsDocumento3 pagineZ450 Purlin Test ResultspnNessuna valutazione finora

- Sandwich Panel SpecificationsDocumento2 pagineSandwich Panel SpecificationspnNessuna valutazione finora

- MY NOTES On Composite Design SteelDocumento3 pagineMY NOTES On Composite Design SteelpnNessuna valutazione finora

- Sandwich - Fire Test ReportDocumento5 pagineSandwich - Fire Test ReportpnNessuna valutazione finora

- NHBC Standards 2020 Complete PDFDocumento401 pagineNHBC Standards 2020 Complete PDFRam Kumar100% (1)

- Fire SafetyDocumento14 pagineFire SafetypnNessuna valutazione finora

- Lysaght Smartdek Structural Decking SheetsDocumento1 paginaLysaght Smartdek Structural Decking SheetspnNessuna valutazione finora

- Specifications For Fills To Support Building FoundationsDocumento5 pagineSpecifications For Fills To Support Building FoundationspnNessuna valutazione finora

- Solar Panelpanel Design (22.8.12)Documento12 pagineSolar Panelpanel Design (22.8.12)Battinapati ShivaNessuna valutazione finora

- Gr-600ex S GDocumento16 pagineGr-600ex S GMuhammad Lukman100% (1)

- SMARTDEK SpecificationsDocumento1 paginaSMARTDEK SpecificationspnNessuna valutazione finora

- The Critical State Friction Angle of Granular Materials: Does It Depend On Grading?Documento15 pagineThe Critical State Friction Angle of Granular Materials: Does It Depend On Grading?pnNessuna valutazione finora

- Soil Pressure PDFDocumento162 pagineSoil Pressure PDFnagesh4189Nessuna valutazione finora

- CPT Guide 6th 2015Documento140 pagineCPT Guide 6th 2015joel_bartley_klohnNessuna valutazione finora

- 2005-Stark - Drained Shear Strength Parameters For AnalysisDocumento14 pagine2005-Stark - Drained Shear Strength Parameters For AnalysisAnonymous KtOY3gFviKNessuna valutazione finora

- Correcting SPT Blow Counts To N60 ValuesDocumento15 pagineCorrecting SPT Blow Counts To N60 ValuesDerek AngNessuna valutazione finora

- Chapter 5 Selection of Characteristic Values For Rock and Soil Properties Using Bayesian Statistics and Prior KnowledgeDocumento27 pagineChapter 5 Selection of Characteristic Values For Rock and Soil Properties Using Bayesian Statistics and Prior KnowledgeAlineNessuna valutazione finora

- 2005-Stark - Drained Shear Strength Parameters For AnalysisDocumento14 pagine2005-Stark - Drained Shear Strength Parameters For AnalysisAnonymous KtOY3gFviKNessuna valutazione finora

- Site InvestigationDocumento11 pagineSite InvestigationrameshkaaNessuna valutazione finora

- Aecome PORT Geotechnical reprotGHD - Aecom - Geotechnical - Interpretive - ReportDocumento153 pagineAecome PORT Geotechnical reprotGHD - Aecom - Geotechnical - Interpretive - ReportpnNessuna valutazione finora

- Jamiolkoski Soil Parametrs Theory To PracticeDocumento42 pagineJamiolkoski Soil Parametrs Theory To PracticepnNessuna valutazione finora

- Geotechnical Parametr ReportDocumento53 pagineGeotechnical Parametr ReportpnNessuna valutazione finora

- Drained Parameters For ClaysDocumento6 pagineDrained Parameters For ClayspnNessuna valutazione finora

- Precast Concrete PDFDocumento154 paginePrecast Concrete PDFPurushotam TapariyaNessuna valutazione finora

- Blockwall DesignDocumento9 pagineBlockwall DesignpnNessuna valutazione finora

- Lecture-7-Practical Design To Eurocode 2Documento71 pagineLecture-7-Practical Design To Eurocode 2jcunha4740Nessuna valutazione finora

- FHWA Geotechnical Engineering Circular No. 6 - Shallow FoundationsDocumento296 pagineFHWA Geotechnical Engineering Circular No. 6 - Shallow FoundationsvNessuna valutazione finora

- DetailingDocumento30 pagineDetailingvasanthk81100% (2)

- Problem Set 2 V2Documento3 pagineProblem Set 2 V2RalphNessuna valutazione finora

- Ch3 Fittinglist 05044 02 FDocumento3 pagineCh3 Fittinglist 05044 02 FZipronNessuna valutazione finora

- FB 16-EDocumento48 pagineFB 16-EserialamineNessuna valutazione finora

- Melaka Refinery Diesel Euro 5 Project: HSE Weekly Walkabout (Scaffold) Finding No. 05Documento4 pagineMelaka Refinery Diesel Euro 5 Project: HSE Weekly Walkabout (Scaffold) Finding No. 05Muhamad Rozee Mat AzmiNessuna valutazione finora

- Ufc 3 430 09Documento106 pagineUfc 3 430 09carlcrowNessuna valutazione finora

- Sheet LaminationDocumento13 pagineSheet LaminationRishika JaiswalNessuna valutazione finora

- Mulberry CatalogDocumento168 pagineMulberry Catalogblue100% (1)

- BWG - Birmingham Wire GaugeDocumento8 pagineBWG - Birmingham Wire GaugepurnawanNessuna valutazione finora

- SATIP-S-030-01, Rev 8 Storm Water Drainage System G FinalDocumento3 pagineSATIP-S-030-01, Rev 8 Storm Water Drainage System G Finalmomin0% (1)

- Bending Stresses in BeamDocumento29 pagineBending Stresses in BeamilhammkaNessuna valutazione finora

- SPAN Part H - Particular Construction...Documento8 pagineSPAN Part H - Particular Construction...ang.xicongNessuna valutazione finora

- 2011 Understanding Stakeholders' Perspective of Cost Estimation in Project ManagementDocumento15 pagine2011 Understanding Stakeholders' Perspective of Cost Estimation in Project ManagementHellen HuamanNessuna valutazione finora

- Universiti Kuala Lumpur Malaysian Spanish Institute: Name: Mohamad Adib Fahmi Bin MahadzirDocumento9 pagineUniversiti Kuala Lumpur Malaysian Spanish Institute: Name: Mohamad Adib Fahmi Bin MahadzirAizzat ZackNessuna valutazione finora

- Muttenz Industrial ChimneyDocumento12 pagineMuttenz Industrial ChimneyAlin ApoNessuna valutazione finora

- Types of Stairs PDFDocumento12 pagineTypes of Stairs PDFAkshay Kumar100% (1)

- DIN Low Pressure Fittings and AccessoriesDocumento184 pagineDIN Low Pressure Fittings and AccessoriesImtiaz NusratNessuna valutazione finora

- Acristar #300Documento1 paginaAcristar #300ChristinaNessuna valutazione finora

- KS Series: Shadowline: Allowable Span TableDocumento1 paginaKS Series: Shadowline: Allowable Span TableAngelica OrnelasNessuna valutazione finora

- CaseStudy-Philippine Procurement Process Loophole InvestigationDocumento7 pagineCaseStudy-Philippine Procurement Process Loophole InvestigationCrestine Lily DongosaNessuna valutazione finora

- PWHT Exempt - PWHT Not RequiredDocumento12 paginePWHT Exempt - PWHT Not RequiredShanmuga NavaneethanNessuna valutazione finora

- Victor Horta-2Documento18 pagineVictor Horta-2PREETHI M ANessuna valutazione finora

- 5 Asme Viii A 24 Clamp ConnectionDocumento6 pagine5 Asme Viii A 24 Clamp ConnectionIrvansyah RazadinNessuna valutazione finora

- Balanced Concession For The Airport Industry PDFDocumento80 pagineBalanced Concession For The Airport Industry PDFPricop CosminNessuna valutazione finora

- Anchor BoltDocumento8 pagineAnchor Boltazwan50% (2)

- Architecture of PakistanDocumento7 pagineArchitecture of PakistanzaraNessuna valutazione finora

- IDOT bd01 - 22x34Documento1 paginaIDOT bd01 - 22x34azsxdcfvgbNessuna valutazione finora

- 2006 Navistar DT466 Engine Torque ValuesDocumento5 pagine2006 Navistar DT466 Engine Torque ValuesMeadows TruckNessuna valutazione finora

- Series 500 Universal Orifice Plates & Seal RingsDocumento2 pagineSeries 500 Universal Orifice Plates & Seal RingsVictorIbañezNessuna valutazione finora

- Ficha Tecnica - Microseal - DSDocumento2 pagineFicha Tecnica - Microseal - DSedocducNessuna valutazione finora

- Caracteristicas Maquina Selladora CrafcoDocumento2 pagineCaracteristicas Maquina Selladora Crafcopapajoel82Nessuna valutazione finora