Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Stavax ESR

Caricato da

Balram JiCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Stavax ESR

Caricato da

Balram JiCopyright:

Formati disponibili

STAVAX ESR

UDDEHOLM

STAVAX ESR

STAVAX ESR

REFERENCE STANDARD

ASSAB DF-2

ARNE

ASSAB DF-3

AISI

WNr.

JIS

O1

(1.2510)

(SKS 3)

O1

(1.2510)

(SKS 3)

D6 (D3)

(1.2436)

(SKD 2)

ASSAB XW-5

SVERKER 3

ASSAB XW-10

RIGOR

A2

1.2363

SKD 12

ASSAB XW-41

SVERKER 21

D2

1.2379

SKD 11

1.2379

SKD 11

ASSAB XW-42

D2

CARMO

CARMO

1.2358

CALMAX

CALMAX

1.2358

CALDIE

CALDIE

ASSAB 88

SLEIPNER

ASSAB PM 23 SUPERCLEAN

VANADIS 23 SUPERCLEAN

(M3:2)

1.3395

SKH 53

ASSAB PM 30 SUPERCLEAN

VANADIS 30 SUPERCLEAN

(M3:2 + Co)

1.3294

SKH 40

ASSAB PM 60 SUPERCLEAN

VANADIS 60 SUPERCLEAN

VANADIS 4 EXTRA SUPERCLEAN

VANADIS 4 EXTRA SUPERCLEAN

VANADIS 6 SUPERCLEAN

VANADIS 6 SUPERCLEAN

VANADIS 10 SUPERCLEAN

VANADIS 10 SUPERCLEAN

VANCRON 40 SUPERCLEAN

VANCRON 40 SUPERCLEAN

ELMAX SUPERCLEAN

ELMAX SUPERCLEAN

(1.3292)

ASSAB 518

P20

1.2311

ASSAB 618

P20 Mod.

1.2738

ASSAB 618 HH

P20 Mod.

1.2738

ASSAB 618 T

P20 Mod.

1.2738 Mod.

ASSAB 718 SUPREME

IMPAX SUPREME

P20 Mod.

1.2738

ASSAB 718 HH

IMPAX HH

P20 Mod.

1.2738

NIMAX

NIMAX

MIRRAX 40

MIRRAX 40

420 Mod.

VIDAR 1 ESR

VIDAR 1 ESR

H11

1.2343

SKD 6

UNIMAX

UNIMAX

CORRAX

CORRAX

420

1.2083

SUS 420J2

1.2083 ESR

SUS 420J2

1.2714

SKT 4

ASSAB 2083

STAVAX ESR

STAVAX ESR

420 Mod.

MIRRAX ESR

MIRRAX ESR

420 Mod.

POLMAX

POLMAX

RAMAX HH

RAMAX HH

ROYALLOY

ROYALLOY

420 F Mod.

PRODAX

ASSAB PT18

ASSAB MMXL

ASSAB MM40

ALVAR 14

ALVAR 14

ASSAB 2714

ASSAB 8407 2M

ORVAR 2M

ASSAB 8407 SUPREME

ORVAR SUPREME

DIEVAR

DIEVAR

HOTVAR

HOTVAR

QRO 90 SUPREME

QRO 90 SUPREME

1.2714

SKT 4

H13

1.2344

SKD 61

H13 Premium

1.2344 ESR

SKD 61

ASSAB 705

4340

1.6582

SNCM8

ASSAB 709

4140

1.7225

SCM4

ASSAB 760

1050

1.1730

S50C

ASSAB is a trademark of ASSAB Pacific Pte Ltd.

The information contained herein is based on our present state of knowledge and is intended to provide general notes on our products and their uses.

It should not therefore be construed as a warranty of specific properties of the products described or a warranty for fitness for a particular purpose.

Each user of ASSAB products is responsible for making its own determination as to the suitability of ASSAB products and services.

Edition 140205

STAVAX ESR

STAVAX ESR

The plastic product is only as good as the surface finish of the mould steel

in which the product is formed. The presence of non-metallic inclusions

and segregation within the steel, limit the polishability of the mould steel.

Thanks to the electroslag remelting (ESR) process that is utilised to

produce Stavax ESR, this steel is capable of being polished to a very high

surface finish. The ESR process is an additional step during the steelmaking,

which ensures very clean steel with low sulphur content (0.003% max.) and

non-metallic inclusions.

Stavax ESR is an excellent choice for small and medium inserts and cores.

Properties

Stavax ESR combines corrosion and wear resistance with excellent

polishability, and offers good machinability.

Advantages

Clean and homogeneous mould steel improves polishability, photoetchability

and texture.

Benefits

Reduce mould maintenance as the mould made of Stavax ESR maintains

its original surface finish over a long period of production.

When compared with non-stainless mould steels, Stavax ESR offers

lower production costs through clean cooling channels that assure

uniform cooling and consistent cycle times.

Especially suitable for applications within the medical industry, optical

industry and for other high quality transparent parts when rust in

production is unacceptable and where requirements for good hygiene

are high.

Stavax ESR is a product within the ASSAB Stainless Concept.

The Stainless Concept is our own programme of metallurgically balanced

stainless grades that has been specially developed and continually expanded

to meet the needs of todays fast-changing plastic moulding industry. The

problems are well known: rust problems with moulds, surface that need

repolishing, cooling channels that have to be redrilled, and parts that

rust together. Choosing the right product within our Stainless Concept,

which can be used individually or in combination to produce the highest

quality tooling for the full range of moulding applications, will minimise the

problems above.

STAVAX ESR

General

Applications

Stavax ESR is a premium grade stainless tool steel with

the following properties:

Whilst Stavax ESR is recommended for all types of

moulding tools, its special properties make it particularly

suitable for moulds with the following demands:

good corrosion resistance

Corrosion/staining resistance

Moulding of corrosive plastics, e.g., PVC, acetates,

and for moulds subjected to humid working/storage

conditions.

excellent polishability

good wear resistance

good machinability

good dimensional stability during heat treatment

The combination of these properties provides a steel

with outstanding production performance. The practical

benefits of good corrosion resistance of a plastic mould

can be summarised as follows:

Lower mould maintenance costs

The surface of cavity impressions retain their original

finish over an extended service life. Moulds stored

or operated in humid conditions require no special

protection.

Lower production costs

Since cooling channels are less likely to be affected

by corrosion (unlike conventional mould steels),

heat transfer characteristics, and therefore cooling

efficiency, are constant throughout the mould life,

ensuring consistent cycle times.

Wear resistance

Moulding abrasive/ filled materials, including injection

moulded thermosetting grades. Stavax ESR is

recommended for moulds with long production runs,

e.g., disposable cutlery and containers.

High surface finish

Production of optical parts, e.g., camera and sunglass

lenses. Moulding of medical components, e.g., syringes

and analysis vials.

These benefits, coupled with the high wear resistance of

Stavax ESR, offer the moulder low-maintenance, long-life

moulds for the greatest overall tooling economy.

Note: Stavax ESR is produced using the Electroslag

Remelting (ESR) technique. The result is a mould steel

with a very low inclusion level providing excellent

polishability characteristics.

Typical analysis %

C

0.38

Si

0.9

Mn

0.5

Cr

13.6

V

0.3

Standard

specification

AISI 420 modified, WNr. 1.2083 ESR,

SUS 420J2

Delivery condition

Soft annealed to approx. 200 HB

Colour code

Black / Orange

Stavax ESR core to make disposable polystyrene beakers.

Millions of close tolerance mouldings with a very high surface

finish have been produced.

Stavax ESR is the right choice for lens mould with extreme

demand on polishability.

Type of mould

Recommended

hardness HRC

Injection moulds for thermoplastics

45-52

Injection moulds for thermosetting

plastics

45-52

Compression / transfer moulds

50-52

Blow moulds for PVC, PET etc.

45-52

Extrusion, pultrusion dies

45-52

STAVAX ESR

Properties

PHYSICAL DATA

Hardened and tempered to 50 HRC.

Temperature

20C

200C

400C

Density

kg/m3

7800

7750

7700

Modulus of elasticity

MPa

200 000

190 000

180 000

Coefficient of

thermal expansion

per C from 20C

11.0 x 10 -6

11.4 x 10 -6

Thermal conductivity

W/m C

19

20

24

Specific heat

J/kg C

460

Stavax ESR is a desirable choice for the medical industry, which

operates in clean room environments, and cannot accept any

rust on the moulds.

*Thermal conductivity is very difficult to measure.

The scatter can be as high as 15%

CORROSION RESISTANCE

TENSILE STRENGTH

The tensile strength values are to be considered as

approximate only. All samples were taken from a bar

(in the rolling direction) with 25 mm diameter.

Hardened in oil from 1025 10C and tempered twice

to the indicated hardness.

Hardness

50 HRC

45 HRC

Tensile strength, Rm

1780 MPa

1420 MPa

Yield strength, Rp0.2

1460 MPa

1280 MPa

Stavax ESR is resistant to corrosive attack by water,

water vapour, weak organic acids, dilute solutions of

nitrates, carbonates and other salts.

A tool made from Stavax ESR will have good resistance

to rusting and staining due to humid working and storage

conditions, and when moulding corrosive plastics under

normal production conditions.

Note: Special protectants are not recommended

during mould storage. Many protectants are chloride

based and may attack the passive oxide film, resulting in

pitting corrosion. Tools should be thoroughly cleaned

and dried prior to storage.

Stavax ESR shows the best corrosion resistance when

tempered at low temperature and polished to a mirror

finish.

Increasing corrosion resistance

The influence of tempering temperature on

corrosion resistance

Stavax ESR is especially suitable for moulding application

requiring good hygiene such as clear plastic beer mug made of

SAN copolymer.

Corrosion

resistance

100

200

300

400

500

Tempering temperature

600C

STAVAX ESR

Heat treatment

Hardness, grain size and retained austenite as a

function of austenitising temperature

SOFT ANNEALING

Protect the steel and heat through to 890C. Then cool

in the furnace at 20C per hour to 850C, then at 10C

per hour to 700C, then freely in air.

Grain size

ASTM Hardness, HRC

60

10

STRESS RELIEVING

58

After rough machining, the tool should be heated

through to 650C, holding time 2 hours. Cool slowly to

500C, then freely in air.

8

7

56

54

52

50

48

HARDENING

4

3

Preheating temperature: 600850C.

Austenitising temperature: 10001050C, but usually

1020C1030C.

46

44

42

40

Temperature

C

Soaking time

minutes

Hardness before

tempering

Retained austenite, %

Grain size

Holding time

60 min.

40

30

Retained

austenite

Holding time

20 min.

20

10

960 980 1000 1020 1040 1060 1080C

Austenitising temperature

QUENCHING MEDIA

1020

30

562 HRC

1050

30

572 HRC

Vacuum with sufficient positive pressure

High speed gas/circulating atmosphere

Fluidised bed or salt bath at 250550C, then cool in

air blast

Soaking time = time at hardening temperature after the

tool is fully heated through.

Hardness, HRC

Warm oil, approx. 80C

60

Retained austenite, %

14

1050C

In order to obtain optimum properties

for the tool, the

55

cooling rate should be fast, but not at a rate that gives 12

Protect the tool against decarburisation and oxidation during

austenitising.

excessive distortion or crack. When heat treating in a

10

vacuum furnace, a minimum

1020Cof 45 bars overpressure

is recommended. Temper immediately when the tool 8

45

reaches 5070C.

50

CCT graph

40

Austenitising temperature 1030C. Holding time 30 minutes.

Retained

austenite

1030C

35

C

1100

30

4

2

Austenitising temperature 1030C

Holding

time 30 minutes

25

1000

100

900

= 980C

200

300 AC400

500

600C

1f

Tempering temperature (2 x 2h)

AC = 860C

1s

800

Pearlite

Carbides

700

Dimensional change, %

+0.16

+0.12

600

500

400

+0.04

MS

300

Mf

Martensite

100

10

100

1

1 000

10

1.5

- 0.08

- 0.12

8

100

100

10

1 000

Minutes

10

90

649

634

613

592

585

421

274

500

206

1

31

105

316

526

1052

2101

600

4204

200 300

Tempering temperature (2 x 2h)

100 000 Seconds

10 000

1

0.2

1

2

3

4

5

6

7

400

8

0

- 0.04

200

Cooling

Curve Hardness T800500

HV 10

sec.

No.

+0.08

600

100 Hours

Air cooling

of bars, mm

700C

Grain size

58

8

7

56 60 min.

54

52

50

48

4

3

2

1

46

44

42

Holding time

40

STAVAX ESR

30

Holding time

20 min.

Retained

austenite

20

DIMENSIONAL

CHANGES

40

10

960 980 1000 1020 1040 1060 1080C

Austenitising

temperature

The dimensional changes

during

hardening and tempering

vary depending on temperatures, type of equipment and

cooling media used during heat treatment.

The size and geomety of the tool are also of essential

importance. Thus, the tool shall always be manufactured

with enough working allowance to compensate for

dimensional changes. Use 0.15% as a guideline for Stavax

ESR

provided that a stress relief is performed

between

Hardness, HRC

Retained austenite, %

rough

and semi-finish machining as recommended.

60

14

1050C

Grain size

ASTM Hardness, HRC

60

10

58

8

7

56 60 min.

54

52

Retained austenite, %

Grain size

Holding time

40

30

50 mould made of Stavax ESR.

A5preform

48

4

Retained

3

46

Holding time

austenite

TEMPERING

2

44 20 min.

42

1

20

Choose the tempering temperature according to the 10

40

hardness required

reference

the tempering

graph.

960 980 by 1000

1020 to1040

1060 1080C

55

Dimensional

changes during hardening

12

50

10

An example of dimensional

1020Cchanges on a plate, hardened

under

ideal conditions 100 x 100 x 25 mm is shown below. 8

45

40

Hardening from

Width

1020C

%

Retained

35

austenite

Martempered

Min.

+0.02

1030C -0.03

30

Max.

Length

%

0

+0.03

Thickness 6

%

4

-0.04

2

Air hardened

25

100

Min.

-0.02

0

0

200

500

600C Max. 300+0.02400

-0.03

Tempering temperature (2 x 2h)

Vacuum hardened Min.

+0.01

0

-0.04

Max.

-0.02

+0.01

-

Austenitising temperature

Temper at least twice with intermediate cooling to room

temperature. The preferred tempering temperature is

250C minimum. On exceptional occasion, the lowest

temperature of 180C is used for small simple inserts

that require a hardness of 52-54 HRC.

Hardness, HRC

60

55

Retained austenite, %

14

1050C

12

50

10

1020C

45

40

6

Retained

austenite

1030C

30

25

100

Dimensional change, %

+0.16

+0.12

+0.08

+0.04

Tempering graph

35

Dimensional changes during tempering

0

- 0.04

- 0.08

- 0.12

100

200 300

400 500

600

Tempering temperature (2 x 2h)

700C

Note: Dimensional changes during hardening and tempering

should be added together.

4

2

200

300

400

500

600C

Tempering temperature (2 x 2h)

Note: The curves as shown in the tempering graph are

valid for small samples. Actual hardness achieved after

hardening and tempering depends on the mould size.

Dimensional change, %

+0.16

Tempering at 250C is recommended for the best combination

+0.12

of toughness, hardness and corrosion resistance.

+0.08

+0.04

A

combination of high austenitising temperature and low

0

tempering

temperature <250C gives a high stress level

in

the mould, and should be avoided.

- 0.04

- 0.08

- 0.12

100

200 300

400 500

600

Tempering temperature (2 x 2h)

700C

Motorcycle helmet lens made of polycarbonate was initially

moulded using AISI 420, but was later moulded using Stavax ESR

due to the very severe demands on polishability.

STAVAX ESR

Machining recommendations

The cutting data below are to be considered as guiding

values and as starting points for developing your own

best practice.

MILLING

Face and square shoulder milling

Condition: Soft annealed condition ~200 HB

Cutting data

parameters

TURNING

Cutting data

parameters

Turning

with HSS

Turning with carbide

Rough milling

Fine milling

Cutting speed

(vc)

m/min

180 - 260

260 - 300

Feed (f z)

mm/tooth

0.2 - 0.4

0.1 - 0.2

2-4

0.5 - 2

P20 - P40

Coated carbide

P10 - P20

Coated carbide

or cermet

Rough

turning

Fine

turning

Fine

turning

Cutting speed

(vc)

m/min

160 - 210

210 - 260

18 - 23

Feed (f)

mm/r

0.2 - 0.4

0.05 - 0.2

0.05 - 0.3

2-4

0.5 - 2

0.5 - 3

Carbide

designation

ISO

P20 - P30

Coated

carbide

P10

Coated

carbide or

cement

End milling

Depth of cut (ap)

mm

Carbide

designation

ISO

Milling with carbide

Depth of cut (ap)

mm

Type of milling

Cutting data

parameters

DRILLING

Solid

carbide

Carbide

indexable

insert

High speed

steel

120 - 150

170 - 230

25 - 301

Feed (f z)

mm/tooth

0.01 - 0.022

0.06 - 0.22

0.01 - 0.302

Carbide

designation

ISO

P20 - P30

Cutting speed

(vc)

m/min

High speed steel twist drill

Drill diameter

mm

Cutting speed (vc)

m/min

Feed (f)

mm/r

12 - 14*

0.05 - 0.10

5 - 10

12 - 14*

0.10 - 0.20

10 - 15

12 - 14

0.20 - 0.30

15 - 20

12 - 14*

0.30 - 0.35

* For coated HSS drill, vc= 2022 m/min

For coated HSS end mill, vc~ 4550 m/min

GRINDING

Wheel recommendation

Carbide drill

Type of grinding

Soft

annealed

condition

Hardened

condition

Face grinding straight wheel

A 46 HV

A 46 HV

Face grinding segments

A 24 GV

A 36 GV

Cylindrical grinding

A 46 LV

A 60 KV

Internal grinding

A 46 JV

A 60 IV

Profile grinding

A 100 LV

A 120 KV

Type of drill

Cutting data

parameters

Cutting speed

(vc)

m/min

Feed (f)

mm/r

1

Indexable

insert

Solid

carbide

Carbide

tip

210 - 230

80 - 100

70 - 80

0.03 - 0.101

Depending on drill diameter

0.10 - 0.251

0.15 - 0.251

STAVAX ESR

Electrical discharge machining

Polishing

If EDM is performed in the hardened and tempered

condition, the EDMd surface is covered with a

resolidified layer (white layer) and a rehardened and

untempered layer, both of which are very brittle and

hence detrimental to the tool performance. It is

recommended to finish with fine-sparking, i.e., low

current, high frequency. For optimal performance, the

EDMd surface should be ground/polished to remove

the white layer completely. The tool should then be

retempered at approx. 25C below the highest previous

tempering temperature.

Stavax ESR has a very good polishability in the hardened

and tempered condition.

Welding

There is a general tendency for tool steel to crack

after welding. When welding is required, take proper

precautions with regards to joint preparation, filler

material selection, preheating, welding procedure and

post weld heat treatment to ensure good welding

results.

For best result after polishing and photo-etching, use

the recommended filler materials as shown in the table

below.

Welding method

Preheating

temperature1

TIG

MMA

200 - 250C (soft annealed ~200 HB)

200C (hardened 56 HRC)

250C (hardened 52 HRC)

Filler material

STAVAX

TIG-WELD

Maximum interpass

temperature2

400C (soft annealed ~200 HB)

350C (hardened 56 HRC)

400C (hardened 52 HRC)

Postweld cooling

STAVAX

WELD

A slightly different technique, in comparison with other

ASSAB mould steels, should be used. The main principle

is to use smaller steps at the fine grinding and polishing

stages, and not to start polishing on too rough a surface.

It is also important to stop the polishing operation

immediately, after the last scratch from the former grain

size has been removed.

More detailed information on polishing techniques is

given in the brochure Polishing of Tool Steel.

Photo-etching

Stavax ESR has a very low content of slag inclusions,

making it suitable for photoetching. The special photoetching process that might be necessary because of

Stavax ESRs good corrosion resistance is familiar to all

the leading photo-etching companies.

Further information

For further information, i.e., steel selection, heat

treatment, application and availability, please contact our

ASSAB office* nearest to you.

*See back cover page

20 - 40C/h for the first two hours

and then freely in air

Hardness after

welding

54 - 56 HRC

Heat treatment after welding

Hardened condition

Temper at 10-20C below the

orginial tempering temperature.

Soft annealed

condition

Heat through to 890C in protected

atmoshpere. Then cool in the

furnace at 20C per hour to 850C,

then at 10C per hour to 700C,

then freely in air.

Preheating temperature must be established throughout the tool and must

be maintained for the entire welding process, to prevent weld cracking.

For hardened and tempered tool, the actual preheat temperature used is

typically lower than the original tempering temperature to prevent a drop

in hardness.

2 The temperature of the tool in the weld area immediately before the second

and subsequent pass of a multiple pass weld. When exceeded, there is a

risk of distortion of the tool or soft zones around the weld.

A clean steel with very good polishability gives the final medical

product an excellent surface finish.

STAVAX ESR

Relative comparison of ASSAB plastic mould steels

RESISTANCE TO FAILURE MECHANISMS AND CRITICAL MOULD STEEL PROPERTIES

ASSAB grade

Plastic

deformation

Cracking

Wear

Corrosion

Polishability

Thermal

conductivity

Machinability

618

ROYALLOY

718 HH

NIMAX

CORRAX

POLMAX

MIRRAX ESR

STAVAX ESR

8407 SUPREME

UNIMAX

ELMAX

XW-10

The starting material for our tool steel is carefully

selected from high quality recyclable steel. Together

with ferroalloys and slag formers, the recyclable steel

is melted in an electric arc furnace. The molten steel is

then tapped into a ladle.

The deslagging unit removes oxygen-rich slag. Then

deoxidation, alloying and heating of the steel bath are

carried out in the ladle furance. Vacuum degassing

removes elements such as hydrogen, nitrogen and

sulphur.

Subsequently, the steel can go directly to our rolling

mill or to the forging press. Our premium steel grades

to to our ESR furnance, where they are melted once

again in an electroslag remelting process. This is done

by melting a consumable electrode immersed in an

overheated slag bath. Controlled solidification in the

steel bath results in an ingot of high homogeneity, thereby

removing macrosegregation. Melting under a protective

atmosphere gives an even better steel cleanliness.

HOT WORKING

From the ESR plant, the steel goes ot the rolling mill or

to our forging press to be formed into round or flat bars.

Prior to delivery, all bar materials are heat treated to

either soft annealed condition or hardened and tempered

condition.

MACHINING

Electroslag remelting (ESR)

ESR PLANT

In uphill casting, a controlled flow of molten steel from

the ladle filled the prepared moulds, and solidifies into

ingots.

10

Before putting into stock, flat bar profiles are machined

to the required size and exact tolerance. Whilst larger

round dimensions are turned in lathe, where the steel

bars rotate against a stationery cutting tool. Peeling

is performed on smaller round dimensions via cutting

tools that revolve around the bars for removal of surface

defects.

To safeguard the quality and integrity of our tool steels,

we perform surface inspection and ultrasonic testing on

all bars. WE then cut off and discard the bar ends and

any defects that are found during inspection.

STAVAX ESR

Relative comparison of ASSAB plastic mould steels

RESISTANCE TO FAILURE MECHANISMS AND CRITICAL MOULD STEEL PROPERTIES

ASSAB grade

618

ROYALLOY

718 HH

NIMAX

CORRAX

POLMAX

MIRRAX ESR

STAVAX ESR

8407 SUPREME

UNIMAX

ELMAX

XW-10

10

Plastic

deformation

Cracking

Wear

Corrosion

Polishability

Thermal

conductivity

Machinability

STAVAX ESR

Ningbo

ASSAB Tooling Technology

(Ningbo) Co., Ltd.

Tel : +86 574 8680 7188

Fax: +86 574 8680 7166

info.ningbo@assab.com

Cikarang*

PT. ASSAB Steels Indonesia

Tel : +62 21 461 1314

Fax: +62 21 461 1306/

+62 21 461 1309

info.cikarang@assab.com

MALAYSIA

Kuala Lumpur - Head Office

ASSAB Steels (Malaysia) Sdn. Bhd.

Tel : +60 3 6189 0022

Fax: +60 3 6189 0044/55

info.kualalumpur@assab.com

Jiangxi*

ASSAB Tooling (Dong Guan)

Co, Ltd., Jiangxi Branch

Tel : +86 769 2289 7888

Fax : +86 769 2289 9312

info.jiangxi@assab.com

11

STAVAX ESR

Choosing the right steel is of vital importance. ASSAB engineers

and metallurgists are always ready to assist you in your choice of

the optimum steel grade and the best treatment for each application.

ASSAB not only supplies steel products with superior quality, we offer

the state-of-the-art machining, heat treatment and surface treatment

services to enhance steel properties to meet your requirement in

the shortest lead time. Using holistic approach as a one-stop solution

provider, we are more than just another tool steel supplier.

ASSAB and Uddeholm are present on every continent. This ensures

you that high-quality tool steels and local support are available

wherever you are. Together, we secure our position as the world's

leading supplier of tooling materials.

For more information, please visit www.assab.com

Potrebbero piacerti anche

- Michael S. Lewis-Beck-Data Analysis - An Introduction, Issue 103-SAGE (1995)Documento119 pagineMichael S. Lewis-Beck-Data Analysis - An Introduction, Issue 103-SAGE (1995)ArletPR100% (1)

- Tootan Wala KhoohDocumento92 pagineTootan Wala KhoohBalram Ji100% (3)

- Route Card: Material SummaryDocumento7 pagineRoute Card: Material SummaryBalram Ji100% (1)

- A705F Schematic Circuit Diagram HALABTECHDocumento11 pagineA705F Schematic Circuit Diagram HALABTECHbcscneg0% (1)

- Comparing Steel Plate Grades Ebook PDFDocumento5 pagineComparing Steel Plate Grades Ebook PDFJayaseelan GNessuna valutazione finora

- A Complete Guide to Watch Repair - Barrels, Fuses, Mainsprings, Balance Springs, Pivots, Depths, Train Wheels and Common Stoppages of WatchesDa EverandA Complete Guide to Watch Repair - Barrels, Fuses, Mainsprings, Balance Springs, Pivots, Depths, Train Wheels and Common Stoppages of WatchesValutazione: 4 su 5 stelle4/5 (1)

- Technical Delivery Condition: Applicable To Parts: Ring WCFN0055Documento4 pagineTechnical Delivery Condition: Applicable To Parts: Ring WCFN0055Balram JiNessuna valutazione finora

- Preventive Maintenance PlanDocumento3 paginePreventive Maintenance PlanBalram Ji86% (7)

- Student Exploration: Electron Configuration: 8-27-2005 Joshua Perez-LunaDocumento14 pagineStudent Exploration: Electron Configuration: 8-27-2005 Joshua Perez-LunaJoshua Perez-Luna67% (3)

- Sample CBAP Elicitation Scenario Based Questions Set 01Documento31 pagineSample CBAP Elicitation Scenario Based Questions Set 01Rubab Javaid100% (1)

- Assab TableDocumento8 pagineAssab TableIhfan MohdNessuna valutazione finora

- Grade 316 316LDocumento9 pagineGrade 316 316LvsajuNessuna valutazione finora

- 2205 InfoDocumento6 pagine2205 InfoMave75Nessuna valutazione finora

- Duplex Stainless Steels - A Simple Guide: How The Austenite/Ferrite Balance Is AchievedDocumento4 pagineDuplex Stainless Steels - A Simple Guide: How The Austenite/Ferrite Balance Is AchievedAndy PhoenixNessuna valutazione finora

- 2002catalog PDFDocumento21 pagine2002catalog PDFPH "Pete" PetersNessuna valutazione finora

- A Us TemperingDocumento46 pagineA Us TemperingPaul RosiahNessuna valutazione finora

- WC 6000Documento3 pagineWC 6000Sameer KhanNessuna valutazione finora

- PB Uddeholm Stavax Esr EnglishDocumento12 paginePB Uddeholm Stavax Esr EnglishDanu MamlukatNessuna valutazione finora

- 410S Data BulletinDocumento4 pagine410S Data BulletinkatchaniNessuna valutazione finora

- Grade 2205 DuplexDocumento9 pagineGrade 2205 Duplexkresimir.mikoc9765Nessuna valutazione finora

- Steel Handbook: Materials Reference BookDocumento35 pagineSteel Handbook: Materials Reference BookChinmoy BaruahNessuna valutazione finora

- Duplex Stainless SteelsDocumento7 pagineDuplex Stainless SteelsRizalzi BachtiarNessuna valutazione finora

- WaterfordDocumento12 pagineWaterfordCamilo MorenoNessuna valutazione finora

- Welding WireDocumento20 pagineWelding WirefoxmancementNessuna valutazione finora

- LSS A286Documento2 pagineLSS A286anhntran4850Nessuna valutazione finora

- Dievar D20140715Documento16 pagineDievar D20140715Keattikhun ChaichanaNessuna valutazione finora

- 25CR20NIDocumento2 pagine25CR20NIShariq KhanNessuna valutazione finora

- What Is Corten SteelDocumento11 pagineWhat Is Corten SteelNavneet SinghNessuna valutazione finora

- ASSAB PM 23 SuperClean Brochure English PDFDocumento12 pagineASSAB PM 23 SuperClean Brochure English PDFnithiNessuna valutazione finora

- 2003catalog PDFDocumento25 pagine2003catalog PDFPH "Pete" PetersNessuna valutazione finora

- Bimetallic FastenersDocumento8 pagineBimetallic FastenersMark Cristian Delas AlasNessuna valutazione finora

- Steels For Oil - Gas - ExplorationDocumento16 pagineSteels For Oil - Gas - Explorationدكتور مهندس جمال الشربينىNessuna valutazione finora

- ST Stainless CatalogueDocumento71 pagineST Stainless CatalogueBenjamin RattharojthakunNessuna valutazione finora

- North American Stainless: Long Products Stainless Steel Grade SheetDocumento8 pagineNorth American Stainless: Long Products Stainless Steel Grade Sheettejap314Nessuna valutazione finora

- Materials ProjectDocumento4 pagineMaterials Projectxtopherus124Nessuna valutazione finora

- Welding Domex SteelsDocumento16 pagineWelding Domex Steelspozolab100% (1)

- Arc Welding ElectrodesDocumento6 pagineArc Welding ElectrodeswaleedyossefNessuna valutazione finora

- Calmax D20140711 PDFDocumento12 pagineCalmax D20140711 PDFSinan YıldızNessuna valutazione finora

- Pro Dec PlateDocumento9 paginePro Dec PlateAbe VoigNessuna valutazione finora

- Die Casting GuidelinesDocumento12 pagineDie Casting GuidelinesMichael Arvin GabineteNessuna valutazione finora

- Hardox I WeldoxDocumento6 pagineHardox I Weldoxbosnamontaza5869Nessuna valutazione finora

- A 286 PropertiesDocumento1 paginaA 286 PropertiesJitendra SoniNessuna valutazione finora

- Assab - XW 10 D20140711Documento8 pagineAssab - XW 10 D20140711Orlando CellanNessuna valutazione finora

- Alloy A286 Ams 5731 Ams 5732 Ams 5737Documento2 pagineAlloy A286 Ams 5731 Ams 5732 Ams 5737gowtham raju buttiNessuna valutazione finora

- Wear Plate PDFDocumento19 pagineWear Plate PDFNorma SalazarNessuna valutazione finora

- Damasteel Martensitic Damascus SteelDocumento6 pagineDamasteel Martensitic Damascus SteelsurintanNessuna valutazione finora

- Soldadura de Hierro ColadoDocumento10 pagineSoldadura de Hierro ColadoclnNessuna valutazione finora

- 1.2 Mechanical Design: 1.2.1 Material Selection Based On Corrosion ResistanceDocumento12 pagine1.2 Mechanical Design: 1.2.1 Material Selection Based On Corrosion ResistanceYusuf Shano100% (1)

- Steel Bearings GuideDocumento13 pagineSteel Bearings Guidefog900Nessuna valutazione finora

- Welding Cast IronDocumento10 pagineWelding Cast IronRoberto CordovaNessuna valutazione finora

- 15-5 PHDocumento2 pagine15-5 PHfedaquiNessuna valutazione finora

- Datasheet-Sandvik-254-Smo-En-V2021-04-22 18 - 35 Version 1Documento10 pagineDatasheet-Sandvik-254-Smo-En-V2021-04-22 18 - 35 Version 1darioNessuna valutazione finora

- Designing With Ductile IronDocumento4 pagineDesigning With Ductile IronCarlos LaoNessuna valutazione finora

- Atlas 3CR12 DatasheetDocumento3 pagineAtlas 3CR12 DatasheettridatylNessuna valutazione finora

- Hastelloy X Alloy: High-Temperature AlloysDocumento16 pagineHastelloy X Alloy: High-Temperature AlloysNatalia D'Ambrosio MarcozziNessuna valutazione finora

- Fiche z38cdv5Documento1 paginaFiche z38cdv5Emmanuel LAIZETNessuna valutazione finora

- Esab DublexDocumento8 pagineEsab DublexSuphi YükselNessuna valutazione finora

- Stainless Steel From JindalDocumento35 pagineStainless Steel From Jindalrajbir_singhNessuna valutazione finora

- Stainless Steel Material PropertiesDocumento4 pagineStainless Steel Material PropertiesMohammed RiyazNessuna valutazione finora

- AK Hot Rolled Steel 062212 HSLA 60Documento6 pagineAK Hot Rolled Steel 062212 HSLA 60Alexandre Lima LopesNessuna valutazione finora

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkDa EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkNessuna valutazione finora

- The Value of Science in the Smithy and ForgeDa EverandThe Value of Science in the Smithy and ForgeNessuna valutazione finora

- Tool-Steel - A Concise Handbook on Tool-Steel in General - Its Treatment in the Operations of Forging, Annealing, Hardening, Tempering and the Appliances ThereforDa EverandTool-Steel - A Concise Handbook on Tool-Steel in General - Its Treatment in the Operations of Forging, Annealing, Hardening, Tempering and the Appliances ThereforNessuna valutazione finora

- Forging - Manual of Practical Instruction in Hand Forging of Wrought Iron, Machine Steel and Tool Steel; Drop Forging; and Heat Treatment of Steel, Including Annealing, Hardening and TemperingDa EverandForging - Manual of Practical Instruction in Hand Forging of Wrought Iron, Machine Steel and Tool Steel; Drop Forging; and Heat Treatment of Steel, Including Annealing, Hardening and TemperingValutazione: 5 su 5 stelle5/5 (1)

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonDa EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonValutazione: 4 su 5 stelle4/5 (1)

- A Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesDa EverandA Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesNessuna valutazione finora

- Chap-02 Pair ofDocumento9 pagineChap-02 Pair ofBalram JiNessuna valutazione finora

- Handling of InstrumentsDocumento10 pagineHandling of InstrumentsBalram JiNessuna valutazione finora

- Rework Record For Heat Treated Parts: Original Production DetailsDocumento1 paginaRework Record For Heat Treated Parts: Original Production DetailsBalram Ji100% (2)

- Oerlikon Checklist 2012Documento14 pagineOerlikon Checklist 2012Balram JiNessuna valutazione finora

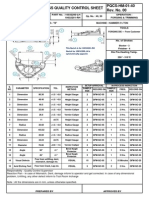

- PQCS Tube Flange Rough - ForgingDocumento1 paginaPQCS Tube Flange Rough - ForgingBalram JiNessuna valutazione finora

- PQCS Tube Flange Rough - CuttingDocumento1 paginaPQCS Tube Flange Rough - CuttingBalram JiNessuna valutazione finora

- Work Instructions - Nickel Spot TestDocumento2 pagineWork Instructions - Nickel Spot TestBalram JiNessuna valutazione finora

- Lea - 5SDocumento1 paginaLea - 5SallanjulesNessuna valutazione finora

- Kmpnai Ko Inayama: Kma-Caari Ka Naama À Idpat-MaomtDocumento1 paginaKmpnai Ko Inayama: Kma-Caari Ka Naama À Idpat-MaomtBalram JiNessuna valutazione finora

- Ramya Balaji Alloy Pvt. Limited: Record No.: Date: Page 1 of 1 Title: Code of Conduct For Employees (Staff)Documento1 paginaRamya Balaji Alloy Pvt. Limited: Record No.: Date: Page 1 of 1 Title: Code of Conduct For Employees (Staff)Balram JiNessuna valutazione finora

- Jominy Formula SheetDocumento2 pagineJominy Formula SheetBalram JiNessuna valutazione finora

- Shewhart Individuals Control ChartDocumento2 pagineShewhart Individuals Control ChartBalram JiNessuna valutazione finora

- Quick Die Change in HammersDocumento16 pagineQuick Die Change in HammersBalram JiNessuna valutazione finora

- Why SpiritualityDocumento37 pagineWhy SpiritualityBalram JiNessuna valutazione finora

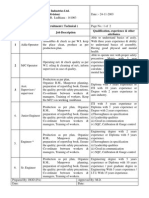

- Job Specification For Recruitment (Electrical)Documento2 pagineJob Specification For Recruitment (Electrical)Balram JiNessuna valutazione finora

- Job Specification For Recruitment (MACHINE SHOP)Documento2 pagineJob Specification For Recruitment (MACHINE SHOP)Balram JiNessuna valutazione finora

- Job Specification For Recruitment Forging - Page 2Documento1 paginaJob Specification For Recruitment Forging - Page 2Balram JiNessuna valutazione finora

- Job Specification For Recruitment (HEAT SHOP)Documento2 pagineJob Specification For Recruitment (HEAT SHOP)Balram JiNessuna valutazione finora

- Green ICT: A Study of Awareness, Attitude and Adoption Among IT/Computer Engineering Students of LDRP-ITR, GandhinagarDocumento13 pagineGreen ICT: A Study of Awareness, Attitude and Adoption Among IT/Computer Engineering Students of LDRP-ITR, GandhinagarAHMAD ARESYADNessuna valutazione finora

- CS221 - Artificial Intelligence - Search - 4 Dynamic ProgrammingDocumento23 pagineCS221 - Artificial Intelligence - Search - 4 Dynamic ProgrammingArdiansyah Mochamad NugrahaNessuna valutazione finora

- Disconnect Cause CodesDocumento2 pagineDisconnect Cause Codesdungnt84Nessuna valutazione finora

- Dyn ST 70 Ser 2Documento12 pagineDyn ST 70 Ser 2alexgirard11735100% (1)

- PQA824 ManualDocumento100 paginePQA824 ManualElkin AguasNessuna valutazione finora

- Lifestyle Mentor. Sally & SusieDocumento2 pagineLifestyle Mentor. Sally & SusieLIYAN SHENNessuna valutazione finora

- (Dust of Snow) & 2 (Fire and Ice) - NotesDocumento3 pagine(Dust of Snow) & 2 (Fire and Ice) - NotesdakshNessuna valutazione finora

- 2 Design Thinking - EN - pptx-ALVDocumento18 pagine2 Design Thinking - EN - pptx-ALVSalma Dhiya FauziyahNessuna valutazione finora

- Mbeya University of Science and TecnologyDocumento8 pagineMbeya University of Science and TecnologyVuluwa GeorgeNessuna valutazione finora

- Semantic SearchMonkeyDocumento39 pagineSemantic SearchMonkeyPaul TarjanNessuna valutazione finora

- Addis Ababa University Lecture NoteDocumento65 pagineAddis Ababa University Lecture NoteTADY TUBE OWNER100% (9)

- Headworks & Barrage: Chapter # 09 Santosh Kumar GargDocumento29 pagineHeadworks & Barrage: Chapter # 09 Santosh Kumar GargUmer WaheedNessuna valutazione finora

- GS Ep Tec 260 enDocumento61 pagineGS Ep Tec 260 enCesarNessuna valutazione finora

- NRP Grade 11 READING ENHANCEMENT March 1Documento3 pagineNRP Grade 11 READING ENHANCEMENT March 1LORELYN DELA CRUZNessuna valutazione finora

- En 10143-1993Documento7 pagineEn 10143-1993Eduardo TeixeiraNessuna valutazione finora

- Simulation of Inventory System PDFDocumento18 pagineSimulation of Inventory System PDFhmsohagNessuna valutazione finora

- 翻译件 2021 The - Early - Life - of - Marx's - "Mode - 【彩云小译】Documento61 pagine翻译件 2021 The - Early - Life - of - Marx's - "Mode - 【彩云小译】James BNessuna valutazione finora

- Configuration Diagrams: Group 80ADocumento24 pagineConfiguration Diagrams: Group 80ASaHdo AbdelHamid100% (1)

- Brittan Bradford ResumeDocumento2 pagineBrittan Bradford Resumeapi-574584381Nessuna valutazione finora

- Guidelines and Standards For External Evaluation Organisations 5th Edition v1.1Documento74 pagineGuidelines and Standards For External Evaluation Organisations 5th Edition v1.1Entrepre NurseNessuna valutazione finora

- D4530Documento5 pagineD4530rimi7al100% (1)

- Grade 8 For Demo Cigarette SmokingDocumento3 pagineGrade 8 For Demo Cigarette SmokingSteven TaperoNessuna valutazione finora

- Floor DiaphragmDocumento24 pagineFloor DiaphragmChristian LeobreraNessuna valutazione finora

- SRM OverviewDocumento37 pagineSRM Overviewbravichandra24Nessuna valutazione finora

- Intro To Geometric Design and Vertical AlignmentDocumento25 pagineIntro To Geometric Design and Vertical AlignmentAhsan ArfanNessuna valutazione finora

- Perkins - General Ti BulletinDocumento65 paginePerkins - General Ti BulletinUTEL CARTERNessuna valutazione finora