Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Heater

Caricato da

rupesh1000Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Heater

Caricato da

rupesh1000Copyright:

Formati disponibili

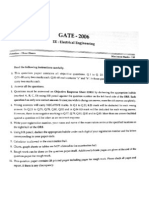

191 (REF)

184 (REF)

'E'

IMMERSED LENGTH 'A'

23.8

119 (REF)

THERMOSTAT POCKET 'B'

S1 PROCESS CONTROL

THERMOSTAT POCKET

S2 OVER TEMPERATURE

LIMIT DEVICE POCKET

INACTIVE 'C'

TERMINAL BOX

0081

WARNING: DO NOT OPEN WHILE ENERGISED

DO NOT OPEN IN THE PRESENCE

OF EXPLOSIVE ATMOSPHERE

NAME PLATE

CABLE ENTRY M20

O-RING SEALS

CABLE ENTRY

WeEXTERNAL

have commented

earlier to provide 3Ph heater.

As this heater is single

phase vendor to

M25

EARTH POST M5

BOX BASE

provide intermediate JB at skid edge for power cable from Dodsal MCC. Cabling from the said

intermediate JB to the heater terminal box shall be in vendor scope.

Power cable from Dodsal MCC to the intermediate JB shall be 3CX35 sq. mm. The terminals

shall be suitable for same.

ELEMENT SLEEVES

& THERMOSTAT

POCKET(S)

WELDED TO SEAL

BAFFLE

SUPPORT S

FLANGE

THERMOSTAT POCKET

CARTRIDGE ELEMENT

HEATER

BUNDLE

SIZE 'D'

3" 150lb FLANGE

Vendor also to submit the drawing of the intermediate JB.

NOTES:

1.

RATING:

3KW ON 250V, 1PH, 50/60HZ.

2.

MATERIAL:

CARTRIDGE TYPE ELEMENTS: 6 OFF 12MM REMOVABLE 304 STAINLESS

STEEL

CARTRIDGE ELEMENT SHEATH: 16MM PLAIN SURFACE 316L STAINLESS

STEEL

THERMOSTAT POCKET(S): 316L STAINLESS STEEL

TERMINAL BOX: MILD STEEL FP4 TERMINAL BOX IP66 RATED

PROCESS FIXING: 3" NB 150LB ANSI RF BLIND 316L STAINLESS STEEL

FLANGE

3.

FINISH:

TERMINAL BOX LID POWDERCOATED RAL 2010 (ORANGE).

TERMINAL BOX BODY POWDERCOATED RAL 9007 (GREY)

FLANGE - STAINLESS NATURAL

Colour finish

REMAINDER NATURAL

7.

ONLY APPLIES TO DUAL PHASED HEATERS:

HEATERS ARE SUPPLIED SUITABLE FOR 1PH SUPPLY, IF 3PH SUPPLY IS

BEING USED, THEN THE 'LIVE' LINK(S) MUST BE REMOVED IN ACCORDANCE

WITH THE HEATER INSTRUCTIONS (IOM)

8.

CONTROLS:

S1: 1 X AUTO RESET CONTROL THERMOSTAT RANGE +7/+100C

MAX SET POINT +90 C (5-7C HYSTERESIS)

S2: 1 X MANUAL RESET THERMOSTAT SET AT + 110C

S3: 1 X MANUAL RESET BOX CUT OUT

(LOCATED IN TERMINAL BOX TO PREVENT OVERHEATING)

9.

HEATER CERTIFICATION :

ATEX / IECEx CERTIFIED Ex II 2 G D Ex d IIC T4 Gb Ex tb IIIC T135C Db

10.

OVERTEMPERATURE PROTECTION:

EACH HEATER SHALL BE FITTED WITH 1 OFF (MINIMUM) SENSOR FOR THE

HEATER MOUNTING FLANGE/PROCESS TEMPERATURE AND 1 OFF TERMINAL

BOX CUT-OUT SENSOR. THE SENSORS SHALL BE THERMOSTAT,

THERMOCOUPLE OR RTD. THE SENSORS SHALL BE CONNECTED TO A

SUITABLE TEMPERATURE CONTROL SYSTEM TO SHUT DOWN THE HEATER

IN THE EVENT THE MAXIMUM TEMPERATURE IS EXCEEDED.

OVERTEMPERATURE SENSOR & CUT-OUT MUST BE MANUAL RESET EITHER

BY:

a.) AUTO-RESET THERMOSTAT & AUTO RESET CUT-OUT BEING, RESET AT

CONTROL PANEL BY KEY SWITCH OR SPECIAL TOOL.

b.) SENSOR & CUT-OUT BEING MANUAL RESET UNITS, ie MANUAL RESET

INSIDE TERMINAL BOX.

shall be as per KOC spec.

4.

MAX WORKING PRESSURE 13 BARg

5.

INSPECTION AND TESTING:

HYDRO TEST TO WI/09/110

TEST METHOD 1. TO 20 BARg FOR 15 MINUTES

TEST METHOD 2.

REFER TO LATEST REVISION OF CERTIFICATE LCIE 01 ATEX 6056 X

ELECTRICAL TEST TO WI/09/114.

100% VISUAL AND DIMENSIONAL CHECK

6.

CABLE ENTRIES:

1x M25 x1.5p (POWER), 1x M20 x1.5p (CONTROL).

CABLE ENTRIES FITTED WITH TEMPORARY PLUGS

ANY UNUSED ENTRIES MUST BE FITTED WITH

SUITABLE CERTIFIED BLANKING PLUGS AT ALL TIMES.

UNDER NO CIRCUMSTANCES ARE ANY ENTRIES TO BE LEFT OPEN

DUE TO THE NATURE OF THE SCREW THREADS ON THE TERMINAL

BOX,THE CABLE ENTRIES MAY NOT BE IN THE POSITION SHOWN

ON THE DRAWING.

11.

TAG INFORMATION (WHERE APPLICABLE) :

REFER TO RELEVANT ITEM ON SALES ORDER

Any thermostat wiring/ control wiring of

the heater will be connected to DCS.

Suitable plugs shall be provided for all spare entry openings.

FOR WIRING

INFORMATION

SEE: 017326.01.03

VARIABLE DETAILS

LENGTH 'A'

1400mm

SIZE 'D'

72mm

LENGTH 'B'

485mm

LENGTH 'E'

100mm

LENGTH 'C'

300mm

LENGTH 'F'

N/A

Potrebbero piacerti anche

- 503 Systems - Indirect Fired Heaters - Eng - Apr2010 PDFDocumento8 pagine503 Systems - Indirect Fired Heaters - Eng - Apr2010 PDFsvnaik14Nessuna valutazione finora

- 880 Series Inverted Bucket Steam TrapsDocumento2 pagine880 Series Inverted Bucket Steam TrapsCherbee FerrerNessuna valutazione finora

- Ijiset V3 I10 10Documento11 pagineIjiset V3 I10 10Diki PrayogoNessuna valutazione finora

- 02-10 Scope ADocumento6 pagine02-10 Scope ASalman FaisalNessuna valutazione finora

- Energy Conversion SystemDocumento43 pagineEnergy Conversion SystemshaniNessuna valutazione finora

- PE-D-A06124222143-01-ME-DAS-015-01-E - Net Oil Storage Tanks - TFRJ-33-TK-1101A - BDocumento7 paginePE-D-A06124222143-01-ME-DAS-015-01-E - Net Oil Storage Tanks - TFRJ-33-TK-1101A - B7radu7Nessuna valutazione finora

- A 1 KDocumento5 pagineA 1 KSumantrra ChattopadhyayNessuna valutazione finora

- Boiler and Its AuxilliariesDocumento22 pagineBoiler and Its Auxilliariesabhijit.adgube3376Nessuna valutazione finora

- Steam Boiler Spec.Documento17 pagineSteam Boiler Spec.bandithaguru6338100% (1)

- Appendix 41 PDFDocumento5 pagineAppendix 41 PDFHanafi BasriNessuna valutazione finora

- CH-14 Design Fundamentals of BoilerDocumento15 pagineCH-14 Design Fundamentals of BoilerRavi ShankarNessuna valutazione finora

- Air Fin Coolers: BGR Energy Systems LimitedDocumento6 pagineAir Fin Coolers: BGR Energy Systems LimitedPrabu100% (1)

- Sparklet EngineersDocumento2 pagineSparklet Engineershappale2002Nessuna valutazione finora

- Un 2004-02 - Ud-Au-000-Eb-0008 PDFDocumento4 pagineUn 2004-02 - Ud-Au-000-Eb-0008 PDFManjeet SainiNessuna valutazione finora

- Data Sheet For Spray NozzleDocumento3 pagineData Sheet For Spray Nozzlebecpavan100% (1)

- Individual Solutions: Air-Cooled Heat ExchangersDocumento22 pagineIndividual Solutions: Air-Cooled Heat ExchangersMiguel SoteloNessuna valutazione finora

- 2 Psychrometry PDFDocumento24 pagine2 Psychrometry PDFFaiz FauziNessuna valutazione finora

- 35-69-17 Standard Index FileDocumento23 pagine35-69-17 Standard Index FileJKKNessuna valutazione finora

- Summary of ASME BPVC Section VIII Div 1 (Part 2) - Welding & NDTDocumento14 pagineSummary of ASME BPVC Section VIII Div 1 (Part 2) - Welding & NDTTin Aung KyiNessuna valutazione finora

- FW Utility Boiler PDFDocumento12 pagineFW Utility Boiler PDFChandan AulakhNessuna valutazione finora

- De ApplicationsFirstOrderDocumento51 pagineDe ApplicationsFirstOrdergaryart111Nessuna valutazione finora

- May 93Documento28 pagineMay 93yundtech974Nessuna valutazione finora

- C9709 Foam ChamberDocumento1 paginaC9709 Foam Chamberkalimutu2010Nessuna valutazione finora

- Checklist For Economiser Element DrawingDocumento2 pagineChecklist For Economiser Element DrawingRamalingam PrabhakaranNessuna valutazione finora

- 7-12-0026 Rev 5Documento1 pagina7-12-0026 Rev 5cynideNessuna valutazione finora

- KA143FA6Documento76 pagineKA143FA6TreeNessuna valutazione finora

- O&Msec2 Heat & Material BalanceDocumento8 pagineO&Msec2 Heat & Material Balanceugun87Nessuna valutazione finora

- Sea - TECH NC 16ADocumento32 pagineSea - TECH NC 16AReach HomeNessuna valutazione finora

- 2phase Flow and Boiling Heat TransferDocumento218 pagine2phase Flow and Boiling Heat TransfercmegmhiNessuna valutazione finora

- Spec BoilerDocumento9 pagineSpec BoilerAchmad MakmuriNessuna valutazione finora

- Steam Tracing StudyDocumento4 pagineSteam Tracing StudypalluraviNessuna valutazione finora

- CPP Iom ManualDocumento98 pagineCPP Iom ManualAgnel StanleyNessuna valutazione finora

- Method Statement For Flue Gas DuctDocumento7 pagineMethod Statement For Flue Gas DuctWASIM MAKANDARNessuna valutazione finora

- TLV - Manifolds Vapor y Condensado PDFDocumento4 pagineTLV - Manifolds Vapor y Condensado PDFsirballesterosNessuna valutazione finora

- Design of Incinerator Plant For Vasai-Virar RegionDocumento4 pagineDesign of Incinerator Plant For Vasai-Virar RegionVIVA-TECH IJRINessuna valutazione finora

- Power Generation From Combustion NEWDocumento49 paginePower Generation From Combustion NEWhridita purbaNessuna valutazione finora

- Isogen Isometrics Creation and Setup WebinarDocumento5 pagineIsogen Isometrics Creation and Setup WebinarCarlos LopezNessuna valutazione finora

- Modeling of Fire Tube BoilerDocumento16 pagineModeling of Fire Tube BoilerVignesh AlagesanNessuna valutazione finora

- Brochure Condenser Feedwater HeaterDocumento8 pagineBrochure Condenser Feedwater Heaterhuynhthanhtamga19810% (1)

- Safety Valve Technical DetailsDocumento5 pagineSafety Valve Technical DetailsvineethvskkdNessuna valutazione finora

- CryogenicsDocumento27 pagineCryogenicsmech1212100% (1)

- Request Form JaimonDocumento306 pagineRequest Form JaimonjaimonjoyNessuna valutazione finora

- Petrofac International LTD.: Document TransmittalDocumento2 paginePetrofac International LTD.: Document TransmittalbelhaskaNessuna valutazione finora

- Boiler Warburton 1981Documento197 pagineBoiler Warburton 1981Sai AravindNessuna valutazione finora

- Cooling WaterDocumento4 pagineCooling WaterChristian SusantoNessuna valutazione finora

- FRP Tank PDFDocumento4 pagineFRP Tank PDFSunil KumarNessuna valutazione finora

- Carbon FilterDocumento12 pagineCarbon FilterCalin SeraphimNessuna valutazione finora

- Eil Spec For Architechture-6-75-0051 - Rev 0Documento14 pagineEil Spec For Architechture-6-75-0051 - Rev 0innovativekarthiNessuna valutazione finora

- 02 MAA - SiDocumento138 pagine02 MAA - Sinowruzi8460% (5)

- MEC551 Assignment - Design September 2015Documento7 pagineMEC551 Assignment - Design September 2015SyafiqAsyrafNessuna valutazione finora

- BP Variable Catalog 09VDocumento52 pagineBP Variable Catalog 09VPetros IosifidisNessuna valutazione finora

- Product Specification: Forbes-Bryan Low Corrosion Tray Type Deaerator - 5Mw To 400MwDocumento3 pagineProduct Specification: Forbes-Bryan Low Corrosion Tray Type Deaerator - 5Mw To 400MwCarlos ACNessuna valutazione finora

- Instrumentation Scheme of Thermal Power PlantDocumento39 pagineInstrumentation Scheme of Thermal Power Plantgdreddy25Nessuna valutazione finora

- Kuppan-Heat Exchanger Design Handbook-2-Heat Exchanger Thermohydraulic FundamentalsDocumento77 pagineKuppan-Heat Exchanger Design Handbook-2-Heat Exchanger Thermohydraulic FundamentalsJavier FrancesconiNessuna valutazione finora

- Yanbu: Export Refinery ProjectDocumento6 pagineYanbu: Export Refinery ProjectJanakiraman MalligaNessuna valutazione finora

- Siemens Building Technologies: HVAC ProductsDocumento4 pagineSiemens Building Technologies: HVAC ProductsahoirebaNessuna valutazione finora

- RAK TR.1000S H DatabladDocumento4 pagineRAK TR.1000S H DatabladPhuc HuynhNessuna valutazione finora

- Technical Specification 92835016 - 02 040516 PDFDocumento27 pagineTechnical Specification 92835016 - 02 040516 PDFDuong BuiNessuna valutazione finora

- Data Sheet For Air Cooled Scroll Chillers: 2 Nosas Per BoqDocumento3 pagineData Sheet For Air Cooled Scroll Chillers: 2 Nosas Per BoqHemanti SharmaNessuna valutazione finora

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDa EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNessuna valutazione finora

- GATE 2022 General Aptitude (GA) : Q.1 - Q.5 Carry ONE Mark EachDocumento36 pagineGATE 2022 General Aptitude (GA) : Q.1 - Q.5 Carry ONE Mark Eachvaibhav pandeyNessuna valutazione finora

- Electrical Engineering Objective 5Documento1 paginaElectrical Engineering Objective 5rupesh1000Nessuna valutazione finora

- Solution Ee Set C 2018Documento16 pagineSolution Ee Set C 2018Dharmender KumarNessuna valutazione finora

- Electrical Engineering Objective 1Documento1 paginaElectrical Engineering Objective 1rupesh1000Nessuna valutazione finora

- Pearson Gate 2015 Set 1 Ee PDFDocumento20 paginePearson Gate 2015 Set 1 Ee PDFBhargov TamulyNessuna valutazione finora

- Electrical Engineering Objective 2Documento1 paginaElectrical Engineering Objective 2rupesh1000Nessuna valutazione finora

- Ee 2005Documento20 pagineEe 2005Kalyan ReddyNessuna valutazione finora

- Gate 2007 Solved Paper EE-2007Documento13 pagineGate 2007 Solved Paper EE-2007Dhruv TomarNessuna valutazione finora

- Gate Ee 2006Documento13 pagineGate Ee 2006Anonymous X4suyBSyNessuna valutazione finora

- Gate Ee - 2001Documento15 pagineGate Ee - 2001Johnfinn CaddickNessuna valutazione finora

- Ee 2002Documento18 pagineEe 2002Koushik RayNessuna valutazione finora

- CCTV Camera 5Documento1 paginaCCTV Camera 5rupesh1000Nessuna valutazione finora

- Gate Ee 2006Documento13 pagineGate Ee 2006Anonymous X4suyBSyNessuna valutazione finora

- Ee 2003 PDFDocumento24 pagineEe 2003 PDFArjun MudlapurNessuna valutazione finora

- Train Route MumbaiDocumento1 paginaTrain Route Mumbairupesh1000Nessuna valutazione finora

- The Study of 220 KV Power Substation Equipment Details 5Documento1 paginaThe Study of 220 KV Power Substation Equipment Details 5rupesh1000Nessuna valutazione finora

- Ee Gate 2000 PDFDocumento13 pagineEe Gate 2000 PDFJoseph LiNessuna valutazione finora

- Notification For ELBO Regulation-2014-1Documento1 paginaNotification For ELBO Regulation-2014-1rupesh1000Nessuna valutazione finora

- Odisha Gazette.: Chapter - I. PreliminaryDocumento145 pagineOdisha Gazette.: Chapter - I. PreliminaryVaishnaviZ434Nessuna valutazione finora

- Modified - As - Per - Proceedings - RDA - PBSR-2017 (1) Rourkela PDFDocumento162 pagineModified - As - Per - Proceedings - RDA - PBSR-2017 (1) Rourkela PDFSUHANI VERMANessuna valutazione finora

- Annexure-C Wapcos Limited: Sl. No. Designation Qualification ExperiencesDocumento5 pagineAnnexure-C Wapcos Limited: Sl. No. Designation Qualification Experiencesrupesh1000Nessuna valutazione finora

- Trading Station User Guide UkDocumento43 pagineTrading Station User Guide Ukrupesh1000Nessuna valutazione finora

- Schema Elettrico: Electrical DrawingDocumento1 paginaSchema Elettrico: Electrical Drawingrupesh1000Nessuna valutazione finora

- The Study of 220 KV Power Substation Equipment Details 3Documento1 paginaThe Study of 220 KV Power Substation Equipment Details 3rupesh1000Nessuna valutazione finora

- Site VisitDocumento1 paginaSite Visitrupesh1000Nessuna valutazione finora

- CCTV Camera 3Documento1 paginaCCTV Camera 3rupesh1000Nessuna valutazione finora

- CCTV Camera 4Documento1 paginaCCTV Camera 4rupesh1000Nessuna valutazione finora

- Generator Set Capability Curve Vectors Colour ADocumento1 paginaGenerator Set Capability Curve Vectors Colour Atingulover100% (1)

- CCTV Camera 2Documento1 paginaCCTV Camera 2rupesh1000Nessuna valutazione finora

- CCTV Camera 1Documento1 paginaCCTV Camera 1rupesh1000Nessuna valutazione finora

- Translating Child Development Research Into Practice - Can Teachers Foster Children's Theory of Mind in Primary SchoolDocumento14 pagineTranslating Child Development Research Into Practice - Can Teachers Foster Children's Theory of Mind in Primary SchoolpecescdNessuna valutazione finora

- JAMB Biology Past Questions 1983 - 2004Documento55 pagineJAMB Biology Past Questions 1983 - 2004Keith MooreNessuna valutazione finora

- Hydraulic Fluid CategoriesDocumento3 pagineHydraulic Fluid CategoriesJako MishyNessuna valutazione finora

- Cardiac AmyloidosisDocumento3 pagineCardiac AmyloidosisPrasad SrbNessuna valutazione finora

- Les Essences D'amelie BrochureDocumento8 pagineLes Essences D'amelie BrochuresayonarasNessuna valutazione finora

- Banco de Oro (Bdo) : Corporate ProfileDocumento1 paginaBanco de Oro (Bdo) : Corporate ProfileGwen CaldonaNessuna valutazione finora

- Fire Alarm SymbolsDocumento6 pagineFire Alarm Symbolscarlos vasquezNessuna valutazione finora

- q5 Nursery SchoolDocumento4 pagineq5 Nursery SchoolPK CheahNessuna valutazione finora

- Rodents and Sectional Title ComplexDocumento2 pagineRodents and Sectional Title ComplexFredSmith777Nessuna valutazione finora

- Polymer ProDocumento25 paginePolymer ProJeerisuda KingklangNessuna valutazione finora

- English CV Chis Roberta AndreeaDocumento1 paginaEnglish CV Chis Roberta AndreeaRoby ChisNessuna valutazione finora

- Chapter 2Documento5 pagineChapter 2ERICKA MAE NATONessuna valutazione finora

- Health and Illness Answer-8Documento2 pagineHealth and Illness Answer-8June DumdumayaNessuna valutazione finora

- Liquid Epoxy Type E: Force-Cure Epoxy For Superior 3-Layer Corrosion ProtectionDocumento2 pagineLiquid Epoxy Type E: Force-Cure Epoxy For Superior 3-Layer Corrosion ProtectionamirhosseinNessuna valutazione finora

- Hand-Pallet Truck - NewDocumento2 pagineHand-Pallet Truck - NewAkhilNessuna valutazione finora

- Geographical Perspective On Selected Issues and Problems #ToppersnotesDocumento16 pagineGeographical Perspective On Selected Issues and Problems #ToppersnotesParidhi JainNessuna valutazione finora

- 8DJ - 8DH Katalog en PDFDocumento32 pagine8DJ - 8DH Katalog en PDFJosue Espinoza YachachinNessuna valutazione finora

- QuestionnaireDocumento2 pagineQuestionnaireMili Gada100% (8)

- FALLSEM2021-22 EEE3004 ETH VL2021220100810 Reference Material I 16-Aug-2021 7 Controlled Rectifier NewDocumento51 pagineFALLSEM2021-22 EEE3004 ETH VL2021220100810 Reference Material I 16-Aug-2021 7 Controlled Rectifier NewVAHEESNessuna valutazione finora

- 50-Article Text-116-1-10-20191113Documento6 pagine50-Article Text-116-1-10-20191113Annisa FauziahNessuna valutazione finora

- I. Choose The Meaning of The Underlined Words Using Context CluesDocumento4 pagineI. Choose The Meaning of The Underlined Words Using Context CluesMikko GomezNessuna valutazione finora

- Separating Mixtures: Techniques and Applications: Evaporation, Distillation and FiltrationDocumento4 pagineSeparating Mixtures: Techniques and Applications: Evaporation, Distillation and FiltrationAndrea SobredillaNessuna valutazione finora

- Transaction AnalysisDocumento34 pagineTransaction AnalysisSunil Ramchandani100% (1)

- Extubation After Difficult IntubationDocumento3 pagineExtubation After Difficult Intubationramanrajesh83Nessuna valutazione finora

- From Crème Fraîche To Sour Cream: What's The Difference?Documento14 pagineFrom Crème Fraîche To Sour Cream: What's The Difference?Maricel BautistaNessuna valutazione finora

- Classroom Readiness ChecklistDocumento2 pagineClassroom Readiness ChecklistRoseman Tumaliuan100% (1)

- Doka H20 BeamDocumento20 pagineDoka H20 Beamshoaib100% (1)

- Scots-Supply Chain ManagementDocumento3 pagineScots-Supply Chain Managementgamer godNessuna valutazione finora

- Conceptual Design and Development of Shredding Machine For Agricultural WasteDocumento7 pagineConceptual Design and Development of Shredding Machine For Agricultural WasteVJ CarbonellNessuna valutazione finora