Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Gear Tooth Vernier Caliper

Caricato da

arun2386Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Gear Tooth Vernier Caliper

Caricato da

arun2386Copyright:

Formati disponibili

8/4/2016

MeasurementofIndividualElements(Metrology)

whatwhenhow

InDepthTutorialsandInformation

MeasurementofIndividualElements(Metrology)

15.7.

15.7.1.Measurementoftooththickness.

Thepermissibleerrororthetoleranceonthicknessoftoothisthevariationofactualthicknessoftoothfrom

itstheoreticalvalue.Thetooththicknessisgenerallymeasuredatpitchcircleandistherefore,thepitchline

thicknessoftooth.Itmaybementionedthatthetooththicknessisdefinedasthelengthofanarc,whichis

difficulttomeasuredirectly.Inmostofthecases,itissufficienttomeasurethechordalthicknessi.e.,the

chordjoiningtheintersectionofthetoothprofilewiththepitchcircle.Alsothedifferencebetweenchordal

tooththicknessandcirculartooththicknessisverysmallforgearofsmallpitch.Thethicknessmeasurement

isthemostimportantmeasurementbecausemostofthegearsmanufacturedmaynotundergocheckingofall

otherparameters,butthicknessmeasurementisamustforallgears.Therearevariousmethodsofmeasuring

thegeartooththickness.

(i)Measurementoftooththicknessbygeartoothverniercalliper,(ii)Constantchordmethod.(iii)Base

tangentmethod,(iv)Measurementbydimensionoverpins.

Thetooththicknesscanbeveryconvenientlymeasuredbyageartoothvernier.Sincethegeartooththickness

variesfromthetipofthebasecircleofthetooth,theinstrumentmustbecapableofmeasuringthetooth

thicknessataspecifiedpositiononthetooth.Furtherthisispossibleonlywhenthereissomearrangementto

fixthatpositionwherethemeasurementistobetaken.Thetooththicknessisgenerallymeasuredatpitch

circleandis,therefore,referredtoaspitchlinethicknessoftooth.Thegeartoothvernierhastwovernier

scalesandtheyaresetforthewidth(w)ofthetoothandthedepth(d)fromthetop,atwhichwoccurs.

Consideringonegeartooth,thetheoreticalvaluesofwanddcanbefoundoutwhichmaybeverifiedbythe

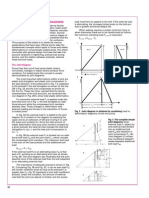

instrument.InFig.15.14,itmaybenotedthatwisachordADB,buttooththicknessisspecifiedasanarc

distanceAEB.AlsothedistancedadjustedoninstrumentisslightlygreaterthantheaddendumCE,wis

thereforecalledchordalthicknessanddiscalledthechordaladdendum.

InFig.15.14,w=AB=2AD

Now,AdD=8=36074N,whereNisthenumberofteeth,

Fig.15.14

Anyerrorintheoutsidediameterofthegearmustbeallowedforwhenmeasuringtooththickness.

Inthecaseofhelicalgears,theaboveexpressionshavetobemodifiedtotakeintoaccountthechangein

curvaturealongthepitchline.ThevirtualnumberofteethNvforhelicalgear=Mcos3a(a=helixangle)

http://whatwhenhow.com/metrology/measurementofindividualelementsmetrology/

1/12

8/4/2016

MeasurementofIndividualElements(Metrology)

Theseformulaeapplywhenbacklashisignored.Onmatinggearshavingequaltooththicknessandwithout

addendummodifications,thecirculartooththicknessequalshalfthecircularpitchminushalfthebacklash.

GearToothCalliper.

(ReferFig.15.15).Itisusedtomeasurethethicknessofgearteethatthepitchlineorchordalthicknessof

teethandthedistancefromthetopofatoothtothechord.Thethicknessofatoothatpitchlineandthe

addendumismeasuredbyanadjustabletongue,eachofwhichisadjustedindependentlybyadjustingscrew

ongraduatedbars.Theeffectofzeroerrorsshouldbetakenintoconsideration.

Thismethodissimpleandinexpensive.Howeveritneedsdifferentsettingforavariationinnumberofteeth

foragivenpitchandaccuracyislimitedbytheleastcountofinstrument.Sincethewearduringuseis

concentratedonthetwojaws,thecalliperhastobecalibratedatregularintervalstomaintaintheaccuracyof

measurement.

Fig.15.15.GearToothVernierCalliper.

15.7.2.ConstantChordMethod.

Intheabovemethod,itisseenthatboththechordalthicknessandchordaladdendumaredependentupon

thenumberofteeth.Henceformeasuringalargenumberofgearsforset,eachhavingdifferentnumberof

teethwouldinvolve

separatecalculations,inustneproceaureDecomeslaboriousandtimeconsumingone.

Theconstantchordmethoddoesawaywiththesedifficulties.Constantchordofagearismeasuredwherethe

toothflankstouchtheflanksofthebasicrack.Theteethoftherackarestraightandinclinedtotheircentre

linesatthepressureangleasshowninFig.15.16.

Alsothepitchlineoftherackistangentialtothepitchcircleofthegearand,bydefinition,thetooth

thicknessoftherackalongthislineisequaltothearctooththicknessofthegearrounditspitchcircle.Now,

sincethegeartoothandrackspaceareincontactinthesymmetricalpositionatthepointsofcontactofthe

flanks,thechordisconstantatthispositionirrespectiveofthegearofthesysteminmeshwiththerack.

http://whatwhenhow.com/metrology/measurementofindividualelementsmetrology/

2/12

8/4/2016

MeasurementofIndividualElements(Metrology)

Fig.15.16

Thisisthepropertyutilisedintheconstantchordmethodofthegearmeasurement.

Themeasurementoftooththicknessatconstantchordsimplifiedtheproblemforallnumberofteeth.Ifan

involutetoothisconsideredsymmetricallyinclosemeshwithabasicrackform,thenitwillbeobservedthat

regardlessofthenumberofteethforagivensizeoftooth(samemodule),thecontactalwaysoccursattwo

fixedpointAandB.ABisknownasconstantchord.Theconstantchordisdefinedasthechordjoiningthose

points,onoppositefacesofthetooth,whichmakecontactwiththematingteethwhenthecentrelineofthe

toothliesonthelineofthegearcentres.ThevalueofABanditsdepthfromthetip,whereitoccurscanbe

calculatedmathematicallyandthenverifiedbyaninstrument.Theadvantageoftheconstantchordmethodis

thatforallnumberofteeth(ofsamemodule)valueofconstantchordissame.Inotherwords,thevalueof

constantchordisconstantforallgearsofameshingsystem.Secondlyitreadilylendsitselftoaformof

comparatorwhichismoresensitivethanthegeartoothvernier.

15.7.3.BasePitch.

Thisisdefinedasthecircularpitchoftheteethmeasuredonthebasecircle.InFig.15.17,ABrepresentsthe

portionofagearbasecircle,CDandEFthesides

oftwoteeth,FDbeingthebasepitch.Fromthepropertyofinvolute,ifanylineasGHisdrawntocutthe

involutesandtangentialtothebasecircle,theGH=FD.

Thusbasepitchcouldalsobedefinedasequaltothelineardistancebetweenapairofinvolutesmeasured

alongacommongenerator.

Basecircumference=2kRb

..Basepitch=2kRb/N

Ifisthepressureangle,then

RB=P.C.R.xcos<t>=(P.C.D./2)cos<J>..Basepitch=(2nlN)x(P.C.D./2)xcos(j)=nmcos(|>

Thisisthedistancebetweentangentstothecurvedportionsofanytwoadjacentteethandcanbemeasured

eitherwithaheightgaugeoronanenlargedprojectedimageoftheteeth.ThisprincipleisutilisedinDavid

Borwntangentcomparatoranditisthemostcommonlyusedmethod.

Fig.15.17

15.7.4.BasePitchMeasuringInstrument.

Thisinstrumenthasthreetips.Oneisthefixedmeasuringtip,otheroneisthesensitivetipwhoseposition

canbeadjustedbyascrewandthefurthermovementofitistransmittedthroughaleveragesystemtothedial

indicator

andthethirdtipisthesupplementaryadjustablestopwhichismeantforthestabilityoftheinstrumentandits

positioncanalsobeadjustedbyascrew.Thedistancebetweenthefixedandsensitivetipissettobe

http://whatwhenhow.com/metrology/measurementofindividualelementsmetrology/

3/12

8/4/2016

MeasurementofIndividualElements(Metrology)

equivalenttothebasepitchofthegearwiththehelpofslipgauges.Theproperlysetupinstrumentisapplied

tothegearsothatallthethreetipscontactthetoothprofile.Thereadingondialindicatoristheerrorinthe

basepitch.

Fig.15.18

15.7.5.TheBaseTangentMethod.(DavidBrowntangentcomparator).

Inthismethod,thespanofaconvenientnumberofteethismeasuredwiththehelpofthetangentcomparator.

Thisusesasingleverniercalliperandhas,therefore,thefollowingadvantagesovergeartoothvernierwhich

usedtwovernierscales:

(i)themeasurementsdonotdependontwovernierreadings,eachbeingfunctionofthe

other.

(ii)themeasurementisnotmadewithanedgeofthemeasuringjawwiththeface.Considerastraight

generator(edge)ABCbeingrolledbackandforthalongabasecircle

(Fig.15.19).ItsendsthussweepoutopposedinvolutesA2AA^andC2CCirespectively.Thusthe

measurementsmadeacrosstheseopposedinvolutesbyspangaugingwillbeconstant(i.e.AC=AiCi=

A2C2=A0Cq)andequaltothearclengthofthebasecirclebetweentheoriginsofinvolutes.

Furtherthepositionofthemeasuringfacesisunimportantaslongastheyareparallel\andonanopposed

pairofthetrueinvolutes.Asthetoothformismostlikelytoconformtoatrueinvoluteatthepitchpointof

thegear,itisalwayspreferabletochooseanumberofteethsuchthatthemeasurementismade

approximatelyatthepitchcircleofthegear.

Thevalueofthedistancebetweentwoopposedinvolutes,orthedimensionoverparallelfacesisequaltothe

distanceroundthebasecirclebetweenthepointswherethecorrespondingtoothflankscuti.e.,ABCinFig.

15.19.Itcanbederivedmathematicallyasfollows:

Fig.15.19.Generationofpairofinvolutesbyacommongenerator.

TheanglebetweenthepointsAandConthepitchcirclewheretheflanksoftheopposedinvoluteteethof

thegearcutthiscirclecanbeeasilycalculated.

LetussaythatthegearhasgotWnumberofteethandAConpitchcirclecorrespondstoSnumberofteeth.

(Fig.15.20)..DistanceAC=(S1/2)pitches

..AnglesubtendedbyAC=(S1/2)x2rc/A7radians.

AnglesofarcsBEandBD

Itmaybenotedthatwhenbacklashallowanceisspecifiednormaltothetoothflanks,thismustbesimply

subtractedfromthisderivedvalue.

TablesarealsoavailablewhichdirectlygivethisvalueforthegivenvaluesofS,Nandm.

ThisdistanceisfirstcalculatedandthensetintheDavidBrowntangentcomparator(Fig.15.21)withthe

helpofslipgauges.Theinstrumentessentiallyconsistsofafixedanvilandamovableanvil.Thereisa

micrometeronthemovinganvilsideandthishasaverylimitedmovementoneithersideofthesetting.The

distanceisadjustedbysettingthefixedanvilatdesiredplacewiththehelpoflookingringandsettingtubes.

http://whatwhenhow.com/metrology/measurementofindividualelementsmetrology/

4/12

8/4/2016

MeasurementofIndividualElements(Metrology)

15.7.6.TangentialGearToothCalliper.

Itisutilisedformeasuringvariationsonthebasictoothprofilefromtheoutsidediameterofspurandhelical

gears.Theinstrumentconsistsofbody,ontheundersideofwhichtherearetwoslideshavingthetipsacting

likemeasuringcontacts.TheextendedspindleofadialindicatorwiththecontactpointA

Fig.15.20

passesbetweenthetwotipsalongtheverticalaxisofsymmetryoftheinstrument.Themeasuringtipsare

spreadapartorbroughttogethersimultaneouslyandsymmetricallyinreferencetothecentralaxisbyascrew

whichhasarighthandandalefthandthread.Thecontactfacesofthemeasuringtipsareflatandarrangedat

anglesof

Fig.15.21.DavidBrownBaseTangentComparator.

14.5or20withthecentralaxis.Thecalliperissetupbymeansofacylindricalmastergaugeofproper

diameterbasedonthemoduleofthegearbeingchecked.Afteradjustingthetipsbythescrew,theseare

lockedinpositionbylockingnuts.Theproperlysetupinstrumentisappliedtothegeartoothandthedial

indicatorreadingshowshowmuchthepositionofthebasictoothprofiledeviatesinreferencetotheoutside

diameterofthegear.

15.7.7.TestPlugMethodforCheckingPitchDiameterandToothSpacing.Measurementovertherollers

placedinthespacebetweenapairofgearteethgivesaconvenientmethodforcheckingtoothspacingand

thepitchdiameter.Thespecialcaseoftherollerwithitscentreonthepitchcirclesimplifiestheproblem.It

is,therefore,considereddesirabletofindthediameterontherollerwhosecentrewilllieonthepitchcircle

andtoderiveanexpressionforthedistanceovertherollersplacedinoppositeteethspaceswiththecentres

ofrollerslyingonthepitchcircle.

Fig.15.22

http://whatwhenhow.com/metrology/measurementofindividualelementsmetrology/

5/12

8/4/2016

MeasurementofIndividualElements(Metrology)

Fig.15.23

InFig.15.23aracktoothisshownsymmetricallyinmeshwithageartoothspace,thecurvedsidesofthe

geartoothtouchingthestraightracksidesatAandBonthelineofaction.Letusassumethatthecentreof

therollerliesonthepitchpointO.Now,iftheracktoothbeconsideredasanemptyspaceboundedbyits

outline,acirclewithcentreOandradiusOBwouldfitandtouchtherackspaceatAandBsinceOAandOB

areperpendiculartothesidesoftheracktooth.ThusthecirclewouldtouchthegearteethatAandB.

InAOBD,OBistheradiusofroller

OD=Circularpitch/2=(7t/4)m

OBD=90,BdD=<|>=pressureangle,..OB=ODcos<j>=(re/4)mcos<(>

Dia.ofroller=2xOB=2x(ron/4)cos<|)=(rc/4)mcos<|>.

Thisisthediameterofarollerwhichwillrestintoothspaceandliewithitscentreonthepitchcircle.This

valueisconstantforallgearsofsamepitchandpressureangle.

Forgearswithevennumberofteeth,adirectmeasurementbyplacingtworollersinexactlyoppositetooth

spacesispossible.Inthiscase,thegaugingdiameterovertherollers

Ifthegearhasanoldnumberofteeth,aradialmeasurementwiththegearbetweencentrescanbecarriedout,

usingacomparatorwiththegear.Theaccuracyofthespacingoveranynumberofteethmaybecheckedby

findingtheanglessubtendedatthecentreandcomparingthiswiththatobtainedfromachordalcheckofthe

plugs.

Asalreadyindicated,precisiongearsandothergearsaregenerallycheckedfortooththicknessbydimension

overpins,asthedimensionsoverpinsreadingismathematicallyrelatedtothetooththickness.Thisalso

verifiesthecorrectnessofprofileandotherelementsofgear.Underthismethodtwopinsofequaldiameter

areplacedintwooppositetoothspaces

forgearshavingoddnumberofteeth.

whereM=Requiredsizeoverthewires,m=Module,(j)=Pressureangle,d=Diameterofwire=1.728x

m,m=Pressureangleatcentreofpinandisgivenbytherelation

Usingtheaboveequations,thesizeAToverwirescanbecalculated.Incaseofhelicalgearstheformulae

usedareasbelow:

Thehelicalgearswithoddnumberofteethshouldnotbemeasuredwithtwowires,becauseinthiscasethe

correctionfactorcos(90/iV)isnotvalidandcanresultinseriouserrors.Insuchcasesthegearcanbe

mountedonanarbourandaradialmeasurementmadefromthetopofthewiretotheaxisofgear.

Sizeoverwires/ballsforhelicalgears

http://whatwhenhow.com/metrology/measurementofindividualelementsmetrology/

6/12

8/4/2016

MeasurementofIndividualElements(Metrology)

15.7.8.CheckingofProfileofInvoluteShapeofGear.

Profileistheportionoftoothflankbetweentheoutsidecircleorstartoftoothtipandthespecifiedform

circleofdiameterapproximatelyequaltopitchcirclediameterminustwicethemodule.

Profileerroristhedeviationoftheactualtoothfromthetheoreticalprofileinthedesignedreferenceplaneof

rotation.Fortestingprofile,tipreliefandanyportionofthetoothsurfacebelowtheactiveprofileisnottobe

considered.Thetoleranceontheprofileerrorispermittedasperthefollowingtable.

Table

AccuracyClassorGradeofGear ProfileToleranceinMicrons

1

2.0+0.06x*

2

2.5+0.10xk

3

3.0+0.16xA

4

4.0+0.25xh

5

5.0+0.40xk

6

6.3+0.63xk

7

8.0+1.0xk

8

10+1.6xk

9

16+2.5xk

10

25+4.0xk

11

40+6.3xk

12

63+10xA

Wheremismodule,andDisthepitchcirclediameterinmm.

(a)Inspectionofprofileusingdividingheadandheightgauge.

ThismethodhasbeenderivedfromthepropertyoftheinvoluteasshowninFig.15.24.Thedistancebetween

pointsAandBmeasuredonthegeneratixtangenttothebasecircleisequaltothearcfromthetangentpoint

BtotheoriginPoftheinvoluteonthebasecircle,i.e.arcBP=AB=(Dbji/360)xez

S.No. DividingHeadReading ezvalues DbxnABvalues=.xe,obu

1

ez

http://whatwhenhow.com/metrology/measurementofindividualelementsmetrology/

7/12

8/4/2016

2

CO

4

5

6

7

CO

9

10

MeasurementofIndividualElements(Metrology)

ez+10

ez+20

ez10

e,20

Wheninvoluteprofileisrotatedondividingheadbysmallrollangles,thentheconsecutiveprofilepointsA

fallontotheverticaltangentline.ItispossibletocomputesuitablerollanglesforanydiameterDzfromthe

correspondingpressureanglebyequations:DJDb=sec<j>z,ez=(180/rc)xtan

Initiallyforanyknowndiametersaypitchdiameter,thevalueofezandsoABisfound.Thehighestgauge

issettozeroatthisheightabovethegearcentrebymeansofslipgauges,thenthecorrespondingpositionof

gearprofileisobtainedbyrotatingthegeartoothtowardsindicatingstylusuntilzeroisobtained.Numberof

anglesisincreasedordecreasedinstepsof10orhalfdegreeasisconvenientandforthesevaluesofezthe

valuesofABarecalculated,andtheheightgaugeissettothisheightbymeansofslipsandthenthedial

readingoverthetoothiscompared.Thedeviationofdialreadinggivestheerrorofprofileatthesepoints.

Thisisaverytimeconsumingmethodbutbestsuitedforcalibrationofmasterinvolute.Itisthereforeuseful

onlyforveryprecisioncomponentsandinvolutemastercams.

(b)Gearinvolutemeasuringmachine.Thismachineisdesignedforcheckingtheinvoluteprofilesofthe

spurandothergears.Themachineissuitableforinspectionofgearhavingmodulefrom1to10mmhaving

maximumoutsidediameterupto300mm.Themachineisprovidedwithameasuringstylus.Thekinematic

designofthemachineissuchthatwhenjobisrotatedthemeasuringstyluswhichisinitiallysetatbasecircle

radiusofthegearbymeansofslipgauge,isalsoslidedalongtheinvolutecurve.Thedeviationofthetooth

profilefromthecorrectinvoluteisindicatedbyadialindicatorofaccuracy0.001mmconnectedbylever

mechanismwiththestylus.Amasterinvolutetemplateisalsoprovidedwiththemachineforsettingand

calibrationofthemachine.

(c)Checkingofinvoluteshapeofgear.AstheinvolutecurveistracedbytheendAofastraightedge

whichrollswithoutslippingonabasecirclediametercylinder,anypointConthecurvewillcorrespondto

thepositionCEofthestraightedge,which,therefore,alwaysremainstangentialtothebasecircle.

Converselyifthebasecirclecylinderweretorollonafixedstraightedge,anyfixedpointe.g.,Cwould

moveinaninvolutepath,suchasCA,asthecylinderrollsalongthestraightedgeCE.

Astraightedgerolledontheedgeofadiscwillbeseentobetheequivalentofthisarrangement,and

providestheprincipleonwhichtheinvolutetesteroperates.Thegeartobetestedisheldonthemandrelm,

whichcarriesagrounddiscdhavingexactlythesamediameterasthebasecircleofthegearundertest(Fig.

15.25).Astraightedgeeismountedonaslideonthebodyoftheinstrumentandincontactwithbasecircle

disc,sothatasthestraightedgemovesalongtheslide,thebasecirclediscandgeararerotatedwithoutslip.

Apointonstraightedgethusdescribesthetrueinvolutecorrespondingtothebasecircle,andifthetopofan

indicatorofsomekindis

mountedexactlyintheplaneoftheedgeofthestraightedgeandincontactwiththetoothflankitwill

registerbyitsmovementsanydepartureofthetoothprofilefromthetheoreticalinvoluteresultingeither

fromerrorsorfromdeliberatemodificationoftheprofile.Theindicatorcanalsobereplacedbythesensing

elementofarecordersothatpermanentrecordsofthegearteethprofilescanbemade.

http://whatwhenhow.com/metrology/measurementofindividualelementsmetrology/

8/12

8/4/2016

MeasurementofIndividualElements(Metrology)

Fig.15.25.PrincipleofInvoluteTester.

(d)Involuteprofiletestingmachine.Suchmachinescanbesettodesiredbasecircleradiusvalues,thus

doingawaythenecessityofhavingbasediscforeachgearofdifferentdimensions.Thisfacilityisprovided

byamasterbase,discorinvolutecam,builtintothemachine,andcoupledtoalinkagesystemwhichenables

thebaseradiusofthegeneratedcurvetobevariedbyadjustmentofthelinkagebarpositions.

Thesemachinesgeneratetherequiredinvoluteshape,measurethedeparturesfromitthatexistontheactual

toothflanksofthegear.Theprincipleofoperationisthatofabasecirclerollingwithoutslipalongastraight

edge,orviceversa.Astylusdetectsthedeviationsinthemetalconditionofthetoothflankfromthetrue

involuteintheformofacontinuoustraceonastripchartrecorder.Aperfectprofilewillresultinastraight

traceparalleltothelongitudinalaxisofthechartpaper.

15.7.9.MeasurementofGearPitch.Gearpitchcanbemeasuredinthefollowing

ways:

(i)Cumulativecircularpitcherroroveraspanofteeth.

(ii)Adjacentpitcherrororpitchvariation.(iii)Basepitchvariation.

HereL=Knm2,whereIfisthesectorofpitchesoverwhichpitcherroristobechecked.

Thepitcherrorofgearcanbeeasilydeterminedbycomparingthespanlengthoveraspecifiednumberof

teethi.e.,thecumulativeerroronasectorofpredeterminedpitchesismeasured.

Thepitchvariationisthedifferencebetweenthelongestandshortestcircularpitchinthewholegear.

Themeasurementofcumulativeerroroveraspanofteethandalsothepitchvariationscanbeconveniently

measuredusingadividingheadandheightgaugefittedwithdialindicator.Thebasicmethodof

measurementinvolvesindexingthegearthroughsingleormultipletoothanglesanddeterminingflank

positioncircumferentiallybymeansofaprecisionindicatormountedonaradiallydisposedslide.Bymeans

ofthedividinghead,rotationtothegearisgivenbytheamountoftheoreticalangularpitch,thevariationin

thepositionoftoothismeasuredbythedialindicator.Forlargergears,theangularaccuracyofthedividing

tablemustbehigherinorderthatpitcherrorisdeterminedaccurately.Thoughdividingtableswith10

secondsofarcresolutionarecommon,dividingtablesareavailablewhichcanbereadtothenearestsecond

ofarc.Ofcourse,thesehavetobecalibratedusingprecisionpolygonandphotoelectricautocollimator.The

indicatorunitshouldbecapableofmeasuringreliablyupto0.001mmoverarangeof0.025mm.Forgears

havinglargercumulativepitcherrors,indicatorsoflowersensitivityhavetobeused.

TolerancesonpitcherrorsA.ToleranceoverasectorofKPitches

GradeofAccuracyClassofgear PermissibleErrorinMicrons

1

0.25<L+0.6

2

0.4a/L+1.0

3

0.63VZT+1.6

4

1.0+2.5

5

1.6<L+4.0

6

2.5VT+6.0

7

3.55^+8.0

8

5.0<L+12

9

7.1VT+17

10

10+28

11

144L+33

12

20VT+83

B.ToleranceonPitchVariations

Class PermissibleErrorinMicrons

http://whatwhenhow.com/metrology/measurementofindividualelementsmetrology/

9/12

8/4/2016

1

2

3

4

5

6

7

8

9

10

11

12

MeasurementofIndividualElements(Metrology)

0.80+0.06F

1.25+0.1F

2.0+0.16F

3.2+0.25F

5.0+0.40F

8.0+0.63F

11+0.90F

16+1.25F

22+1.80F

32+2.50F

45+3.55F

63+5.0F

Thebasepitchisthecircularpitchoftheteethmeasuredonthebasecircle,asweknowthatthebasepitch=

pxcos.Thisisalsothedistancebetweenthetangenttothecurvedpositionsofanytwoadjacentteeth.The

basepitchcanbeveryconvenientlymeasuredusingordinarybasepitchmeasuringinstrumentswhich

measurethestraightdistancebetweentangentstotheadjacentteeth.

Basepitchcanbeaccuratelymeasuredusingtoolmakersoruniversalmicroscope.

HereF=m+0.25H5whereDisthepitchcirclediameterinmm.

Toothtotoothpitcherrorscanbeeasilydeterminedbyuseoftwodialgaugesbymeasuringthepositionofa

suitablepointonatoothafterthegearhasbeenindexedthroughasuitableangle.

Thegearismountedinthecentrewithindexingarrangement.TwodialgaugesaremountedasshowninFig.

15.26.Thereisaspindlebelowthedialgaugehavingasmallsphereattheendandtouchingthegeartoothat

thepitchcircle.Thegearisthenindexedthroughsuccessivepitchestogiveaconstantreadingondialgauge

A.AnychangesinthereadingondialgaugeBindicatethatpitcherrorsarepresent.Theactualerrorcanbe

determinedbydeductingtheindividualreadingondialBfromthemeanofthereadings.

Thepitchofthegearteethcanalsobemeasuredbymeasuringthedistancefromapointononetoothtoa

suitablepointonthenexttooth.

CircularPitchMeasuringMachine.

Thisinstru

Fig.15.26

mentisusedlorcheckingthecircularpitcholgeartooth.Thetwomeasuringcontacttipsareappliedonthe

samesidesofadjacentteethofthegear.Thelefthandtipisfirstsetuptotherequiredmodulebymeansof

somesuitablearrangement.Therighthandtipisatwoarmedleverwhoseonecontactsthegeartoothandthe

otheroneactuatesthecontactpointofthedialindicator.Twoguidepointsarealsoprovidedforthestability

oftheinstrument.

ThepitchvariationscanalsobemeasuredbytheinstrumentshowninFig.15.27.Itemploysafixedfinger

andstopforconsistentpositioningonsuccessivepairsofteeth,andamovablefingerwhosemovementcan

besensedbyadialindicator.

Itmaybenotedthatreadingsobtainedbyaboveinstrumentwillbeaffectedbyprofilevariationsandrunout

ofthegear.

Inthecaseofhelicalgears,measurementsmaybemadeinthenormalplaneoftheconjugaterackand

http://whatwhenhow.com/metrology/measurementofindividualelementsmetrology/

10/12

8/4/2016

MeasurementofIndividualElements(Metrology)

dividedbythecosineofhelixangleforcomparisonwithstandardtolerances.

Itmaybementionedthattheabovemethodofmeasuringpitcherrorcanbeappliedtomediumsizedgears

measuringfromafewcmsuptoaboutametrediameter.Smallgearsasusedinwatchesandclockare

inspectedbyopticalprojectioninwhichtheenlargedimagesofsomeoftheteetharecompared

Fig.15.27.Schematicarrangementofapitchcheckinginstrument.

againstamasterdiameteratthescreenoftheprojector,borthickgearsconvergentilluminationisusedto

enableopticalfocussingataselectedsectionacrossthefacewidth.EffectofEccentricityofPitchError

Itmaybeemphasizedthatgearpitcherrorandtootheccentricityareinseparablebecausepresenceofone

affectstheother.Sinceeccentricitycantakeanypositionwithreferencetothetoothunderconsideration,the

effectiveeccentricityforvariouspositionsofgearrotationatangle6isexpressedasequaltoesecsin(cj)

+8),wheree=eccentricityand<|>=pressureangle.

Thusifagearhasbeenmeasuredfortoothspacingerror,theeffectofitsmountingeccentricallyonpitch

errorcanbetakencareofbyapplyingcorrectionsprogressivelytotheobservederrorvaluesbycalculating

thecorrectionapplicabletoeachtoothfromtheaboveequation.

15.7.10.Runout.Runoutmeanstheeccentricityinthereferenceorpitchcircle.

Gearsthatareeccentrictendtohaveavibrationperrevolution.Abadlyeccentrictoothmaycauseanabrupt

gearfailure.Therunoutinthegearsismeasuredbyemployinggeareccentricitytesters.Thegearisheldona

mandrelinthecentresandthedialindicatorofthetesterpossessesthespecialtipdependinguponthemodule

ofgearbeingchecked.Thetipisinsertedinbetweenthetoothspaces.Thegearisrotatedtoothbytooth.The

maximumvariationisnotedfromthedialindicatorreadinganditgivestherunoutofthegear.Therunoutis

twicetheeccentricity.Theadjoiningtableindicatesthepermissiblerunouts.

ClassorGrade PermissibleRunout

inMicrons

1

0.224F+3.0

2

0.335F+4.5

3

0.560F+7.0

4

0.900F+11

5

1AF+18

6

2.24F+28

7

3.15^+40

8

4.0F+50

9

5.CF+63

10

6.3F+80

11

8.0+100

12

10.0F+125

http://whatwhenhow.com/metrology/measurementofindividualelementsmetrology/

11/12

8/4/2016

MeasurementofIndividualElements(Metrology)

15.7.11.Lead.

Itistheaxialadvanceofthehelixorthewormthreadperturn.Thecontrolofthreadleadisnecessaryto

ensureadequatecontactacrossthefacewidth.Therelationshiptothehelixanglehasalreadybeenexplained

earlier.

Theinstrumentwhichcheckstheleadconsistsofaprobebeingadvancedalongatoothsurface,parallelto

theaxis.Theprobeisasuitabledialindicatortipfixedinasuitabledevice.

Whenthegearisrotated,thedisplacementoftheprobeinonecompleterevolutionofgearisfoundwhichis

thelead.

Inthecaseofwormthread,theaxialpitchofthethreadisfirstmeasuredwhichmultipliedbythenumberof

threadsinthewormgivesthelead.

15.7.12.Backlash.

Backlashinthegearsistheplaybetweenthematingtoothsurfaces.Forthepurposesofmeasurementand

calculations,backlashisdefinedastheamountbywhichatoothspaceexceedsthethicknessonanengaging

tooth.Backlashinthegearteethresultsonaccountoferrorsinprofile,pitchthicknessofteethetc.Itis

measuredbymountingthegearsinspecifiedposition.Backlashshouldbemeasuredatthetightestpointof

themesh.Thepinionisheldsolidlyagainstrotationandarigidlymounteddialindicatorisplacedagainstthe

toothattheextremeheelperpendiculartothesurface.Thebacklashisdeterminedbymovingthegearback

andforth.Thebacklashvariationismeasuredbylocatingthepointsofmaximumandminimumbacklashin

thepairandobtainingthedifference.Forprecisiongearsthevariationshouldnotexceed0.02to0.03mm.

15.7.13.LeadMeasurement.

Inorderthattoothloadbeuniformlydistributedacrossthefacewidthofthegears,itisessentialthatleadper

toothofmatinggearsshouldbecloselymatched.Errorsinthehelixofeithergearwouldresultinnon

uniformloadconcentration,resultinginnoisyoperationanddamage.Irregularitiesinleadcouldoccurdueto

eitherpoormanufactureorfromthepresenceoftoothundulations.

Itisimportanttonotethatwhilethehelixangleofpinionandgearissamebuttheirleadisdifferent

dependingontheirdiameters.Alsothehelixanglevalueincreasesfromtherootstothetipsoftheteeth.

Leadcanbemeasuredeitheronapointtopointbasis,orbymeansofcontinuousgenerationusingspecial

purposemeasuringmachines.Onetypeofgeneratingmachineincorporatesasinebarmechanismtogether

withameansofconvertingaderivedlinearmotionintoarotarymotion.

Nextpost:CompositeMethodofGearChecking(Metrology)

Previouspost:RollingTests(Metrology)

RelatedLinks

Metrology

WhatisMetrology

PhysicalMeasurement(Metrology)

NeedofInspection(Metrology)

MeasuringInstruments(Metrology)

SelectionofInstruments(Metrology)

::SearchWWH::

Search

CustomSearch

HelpUnprivilegedChildrenCareersPrivacyStatementCopyrightInformation

http://whatwhenhow.com/metrology/measurementofindividualelementsmetrology/

12/12

Potrebbero piacerti anche

- Axial Alignment and Thermal Growth Effects On Turbomachinery Trains With Double-Helical GearingDocumento12 pagineAxial Alignment and Thermal Growth Effects On Turbomachinery Trains With Double-Helical GearingAnton HidayatNessuna valutazione finora

- Structural Health MonitoringDa EverandStructural Health MonitoringDaniel BalageasNessuna valutazione finora

- Design Optimization of Fluid Machinery: Applying Computational Fluid Dynamics and Numerical OptimizationDa EverandDesign Optimization of Fluid Machinery: Applying Computational Fluid Dynamics and Numerical OptimizationNessuna valutazione finora

- Laminar Flow and Convective Transport Processes: Scaling Principles and Asymptotic AnalysisDa EverandLaminar Flow and Convective Transport Processes: Scaling Principles and Asymptotic AnalysisNessuna valutazione finora

- Influence of The Number of Blades of Miniature Centrifugal Impeller On Compressor PerformanceDocumento6 pagineInfluence of The Number of Blades of Miniature Centrifugal Impeller On Compressor PerformanceSuherman MuktiNessuna valutazione finora

- (Paper) (Balancing of Integral Gear-Driven Centrifugal Compressors)Documento8 pagine(Paper) (Balancing of Integral Gear-Driven Centrifugal Compressors)aref_tmuNessuna valutazione finora

- Seismic Migration: Imaging of Acoustic Energy by Wave Field ExtrapolationDa EverandSeismic Migration: Imaging of Acoustic Energy by Wave Field ExtrapolationNessuna valutazione finora

- Numerical Solution of Partial Differential Equations—II, Synspade 1970: Proceedings of the Second Symposium on the Numerical Solution of Partial Differential Equations, SYNSPADE 1970, Held at the University of Maryland, College Park, Maryland, May 11-15, 1970Da EverandNumerical Solution of Partial Differential Equations—II, Synspade 1970: Proceedings of the Second Symposium on the Numerical Solution of Partial Differential Equations, SYNSPADE 1970, Held at the University of Maryland, College Park, Maryland, May 11-15, 1970Bert HubbardNessuna valutazione finora

- "About Mr. Slim Air Conditioners Training" For Pme Staff 21st September 2015Documento165 pagine"About Mr. Slim Air Conditioners Training" For Pme Staff 21st September 2015Tun Lin AungNessuna valutazione finora

- Nanofluid in Heat Exchangers for Mechanical Systems: Numerical SimulationDa EverandNanofluid in Heat Exchangers for Mechanical Systems: Numerical SimulationNessuna valutazione finora

- Mitsubishi Air ConditionerDocumento68 pagineMitsubishi Air ConditionerbrianatburleighNessuna valutazione finora

- Engineering Design: Papers Given at the University of Nottingham, September, 1964Da EverandEngineering Design: Papers Given at the University of Nottingham, September, 1964T. F. RoylanceValutazione: 1 su 5 stelle1/5 (1)

- Solutions For Reduced Life Cycle Costs of Centrifugal Compressors in Oil and Gas IndustryDocumento7 pagineSolutions For Reduced Life Cycle Costs of Centrifugal Compressors in Oil and Gas Industryzeinab_jahani5799Nessuna valutazione finora

- Free Vibrations of Circular Cylindrical ShellsDa EverandFree Vibrations of Circular Cylindrical ShellsNessuna valutazione finora

- FLUENT Tutorial 5 - BlowerDocumento26 pagineFLUENT Tutorial 5 - BlowerKwanchai ChoicharoenNessuna valutazione finora

- Inlet Flow Distortion in A Centrifugal CompressorDocumento110 pagineInlet Flow Distortion in A Centrifugal CompressorAmbrish SinghNessuna valutazione finora

- Radial Flow Gas TurbinesDocumento20 pagineRadial Flow Gas TurbinesAnggita Dwi LiestyosiwiNessuna valutazione finora

- J-Series IM20140521E TornilloDocumento210 pagineJ-Series IM20140521E TornilloFernando David RamirezNessuna valutazione finora

- Ebae 161 92 Ram Pump JenningsDocumento6 pagineEbae 161 92 Ram Pump JenningsGaguk Triosona PraditaNessuna valutazione finora

- Campus® Datasheet: Pocan® BF 4235 - Pbt-Gf30 FR Lanxess Deutschland GMBHDocumento2 pagineCampus® Datasheet: Pocan® BF 4235 - Pbt-Gf30 FR Lanxess Deutschland GMBHAngererNessuna valutazione finora

- Analysis of Self Excited Induction Generator Delta Connected Resistive LoadDocumento24 pagineAnalysis of Self Excited Induction Generator Delta Connected Resistive LoadHemant KumarNessuna valutazione finora

- Study, Analysis and Design of Automobile Radiator PDFDocumento10 pagineStudy, Analysis and Design of Automobile Radiator PDFRamón G. PachecoNessuna valutazione finora

- TM9-243 Use and Care of ToolsDocumento310 pagineTM9-243 Use and Care of ToolsMary CasillasNessuna valutazione finora

- Bolt Joint-DiagramsDocumento6 pagineBolt Joint-Diagramskulov1592Nessuna valutazione finora

- Part A: Content DesignDocumento16 paginePart A: Content DesignAnuNessuna valutazione finora

- Servomotor - Sizing and ApplicationDocumento12 pagineServomotor - Sizing and ApplicationSebastianNessuna valutazione finora

- PHD Pajaczkowski Piotr PDFDocumento162 paginePHD Pajaczkowski Piotr PDFChristopher GarciaNessuna valutazione finora

- Advanced Machinery Dynamics Course ContentDocumento2 pagineAdvanced Machinery Dynamics Course ContentLe Thanh HaiNessuna valutazione finora

- Dynamic Behaviour of High Speed RotorDocumento59 pagineDynamic Behaviour of High Speed Rotorkiran2381Nessuna valutazione finora

- ME 202 Advanced Mechanics of SolidsDocumento3 pagineME 202 Advanced Mechanics of SolidsMohammed Asif NNessuna valutazione finora

- Heat and Mass TransferDocumento1 paginaHeat and Mass TransferSanjay GomastaNessuna valutazione finora

- Vibration AnalysisDocumento4 pagineVibration AnalysisJournalNX - a Multidisciplinary Peer Reviewed JournalNessuna valutazione finora

- English For Mechanical Engineerin 2Documento12 pagineEnglish For Mechanical Engineerin 2galih hardikaNessuna valutazione finora

- Dimensional Analasys and Scaling LawsDocumento30 pagineDimensional Analasys and Scaling LawsSharath ChandraNessuna valutazione finora

- Rao Mechanical Vibrations 5th Txtbk2Documento7 pagineRao Mechanical Vibrations 5th Txtbk2Daniel CBNessuna valutazione finora

- ARaymond QC Thermal-Management Booklet 2019Documento16 pagineARaymond QC Thermal-Management Booklet 2019TUNCAY GUMUSNessuna valutazione finora

- Vibration MeasurementDocumento9 pagineVibration MeasurementvikasinmumbaiNessuna valutazione finora

- FEA-ABODE - Common Errors and Warnings in Convergence Problems-AbaqusDocumento5 pagineFEA-ABODE - Common Errors and Warnings in Convergence Problems-Abaqusmithun5v5v5Nessuna valutazione finora

- Axial Turbine Stages Design 1D 2D 3D Simulation Experiment OptimizationDocumento10 pagineAxial Turbine Stages Design 1D 2D 3D Simulation Experiment OptimizationAditya SawantNessuna valutazione finora

- Compressor Divider Block InstructionDocumento19 pagineCompressor Divider Block InstructionDibyendu ChakrabortyNessuna valutazione finora

- Joint Press FitDocumento11 pagineJoint Press Fitthulasi_krishnaNessuna valutazione finora

- Hydraulics Vs PneumaticsDocumento22 pagineHydraulics Vs Pneumaticsscorpionarnold100% (1)

- MODULE 3 Cascade Theory, Axial Flow Turbine and Propulsion SystemDocumento43 pagineMODULE 3 Cascade Theory, Axial Flow Turbine and Propulsion SystemantonNessuna valutazione finora

- Construction VocabularyDocumento6 pagineConstruction VocabularyraMunNessuna valutazione finora

- Hydrocarbon Turbo ExpandersDocumento20 pagineHydrocarbon Turbo ExpandersPakde NdokNessuna valutazione finora

- 1 Download Template (Free) 2 Start Download - View PDF: American Standard Steel ChannelsDocumento7 pagine1 Download Template (Free) 2 Start Download - View PDF: American Standard Steel ChannelsHiongyiiNessuna valutazione finora

- Electric Vehicle Battery Technologies: January 2013Documento44 pagineElectric Vehicle Battery Technologies: January 2013VENKATA SWAMY NAIDU NIMMAKAYALANessuna valutazione finora

- An Insight Into Magneto Rheological DampersDocumento239 pagineAn Insight Into Magneto Rheological DampersashutoshmanchandaNessuna valutazione finora

- Chapter 23 - Preparation For CAE InterviewDocumento6 pagineChapter 23 - Preparation For CAE InterviewdeepakNessuna valutazione finora

- TEH-1109 - Parallel and Series Pump ApplicationDocumento20 pagineTEH-1109 - Parallel and Series Pump Applicationmngearhead100% (2)

- FesafeFatigueTheory PDFDocumento264 pagineFesafeFatigueTheory PDFbalijajagadishNessuna valutazione finora

- P178Documento9 pagineP178keepmoshingNessuna valutazione finora

- Geardrives For TurbomachineryDocumento22 pagineGeardrives For Turbomachineryhumayun121Nessuna valutazione finora

- Burkert Angle Seat - Globe Valve Maintenance Manual-EnglishDocumento21 pagineBurkert Angle Seat - Globe Valve Maintenance Manual-Englishjadetorres100% (1)

- Machine DesigningDocumento147 pagineMachine DesigningSiddharth VatsNessuna valutazione finora

- Shock Response Spectrum at Low FrequenciesDocumento10 pagineShock Response Spectrum at Low FrequenciesjackNessuna valutazione finora

- Fma3602 Asign1memoDocumento15 pagineFma3602 Asign1memoKasturie Pillay100% (1)

- Additive Manufacturing Question Bank - Part ADocumento2 pagineAdditive Manufacturing Question Bank - Part Aarun2386100% (3)

- AgniDocumento3 pagineAgniarun2386Nessuna valutazione finora

- Lec 1Documento15 pagineLec 1arun2386Nessuna valutazione finora

- Nurturing Young Minds - Approaches and BenefitsDocumento12 pagineNurturing Young Minds - Approaches and Benefitsarun2386Nessuna valutazione finora

- Mcts Lab ManualDocumento27 pagineMcts Lab Manualarun2386Nessuna valutazione finora

- Additive Manufacturing Question Bank - Part BDocumento2 pagineAdditive Manufacturing Question Bank - Part Barun2386100% (1)

- Exp. 4 Introduction To Hydraulic Trainer New 2017Documento16 pagineExp. 4 Introduction To Hydraulic Trainer New 2017arun2386Nessuna valutazione finora

- India 'To Test Agni-II Missile': CircumspectDocumento2 pagineIndia 'To Test Agni-II Missile': Circumspectarun2386Nessuna valutazione finora

- Exp. 4 Introduction To Hydraulic Trainer New 2017Documento16 pagineExp. 4 Introduction To Hydraulic Trainer New 2017arun2386Nessuna valutazione finora

- Wind Tunnel Calibration PDFDocumento1 paginaWind Tunnel Calibration PDFarun2386Nessuna valutazione finora

- Basics of AeronauticsDocumento216 pagineBasics of Aeronauticsmanisekar87Nessuna valutazione finora

- UNIT 4 CHM-min-minDocumento34 pagineUNIT 4 CHM-min-minarun2386Nessuna valutazione finora

- Normal Shock: P M V P M VDocumento4 pagineNormal Shock: P M V P M VTeja SandugaNessuna valutazione finora

- Airplane Performance Climb and TurnDocumento35 pagineAirplane Performance Climb and Turnarun2386Nessuna valutazione finora

- Aerodynamics of Cars PDFDocumento4 pagineAerodynamics of Cars PDFPrakhar AggarwalNessuna valutazione finora

- Windtunneltesting PDFDocumento4 pagineWindtunneltesting PDFarun2386Nessuna valutazione finora

- Airplane Performance Range and EnduranceDocumento45 pagineAirplane Performance Range and Endurancearun2386Nessuna valutazione finora

- Mcts List of ExperimentsDocumento2 pagineMcts List of Experimentsarun2386Nessuna valutazione finora

- Blooms Taxonomy PDFDocumento27 pagineBlooms Taxonomy PDFarun2386Nessuna valutazione finora

- Reliance Jio Versus The RestDocumento1 paginaReliance Jio Versus The Restarun2386Nessuna valutazione finora

- Mechatronics Lab ManualDocumento44 pagineMechatronics Lab Manualarun2386Nessuna valutazione finora

- Objective QADocumento7 pagineObjective QAarun2386Nessuna valutazione finora

- Pesarattu DosaDocumento12 paginePesarattu Dosaarun2386Nessuna valutazione finora

- Screw Threads TerminologyDocumento5 pagineScrew Threads Terminologyarun2386Nessuna valutazione finora

- 10m712 Mechatronics LaboratoryDocumento4 pagine10m712 Mechatronics Laboratoryarun2386Nessuna valutazione finora

- Banjari Gosht RecipeDocumento1 paginaBanjari Gosht Recipearun2386Nessuna valutazione finora

- 15hc04 Metrology and Computer Aided InspectionDocumento1 pagina15hc04 Metrology and Computer Aided Inspectionarun2386Nessuna valutazione finora

- Advanced Cad Cam Lab ViisemDocumento0 pagineAdvanced Cad Cam Lab Viisemmadansiyag3Nessuna valutazione finora

- Ucm SyllabusDocumento2 pagineUcm Syllabusarun2386Nessuna valutazione finora

- Differential Carrier: ComponentsDocumento16 pagineDifferential Carrier: Componentspriyankar007Nessuna valutazione finora

- Kubota B7100 Engine ManualDocumento6 pagineKubota B7100 Engine ManualDoug WilsonNessuna valutazione finora

- Calculation of A Cylindrical Spur Gear Pair: Important Hint: at Least One Warning Has Occurred During The CalculationDocumento9 pagineCalculation of A Cylindrical Spur Gear Pair: Important Hint: at Least One Warning Has Occurred During The CalculationDaggupati PraveenNessuna valutazione finora

- Adaptive Control of Uncertain Gear Transmission Servo Systems With Deadzone NonlinearityDocumento9 pagineAdaptive Control of Uncertain Gear Transmission Servo Systems With Deadzone Nonlinearitysaleh1978Nessuna valutazione finora

- Evaluation of Load-Carrying Capacity of Lubricants Under Conditions of Low Speed and High Torque Used For Final Hypoid Drive AxlesDocumento18 pagineEvaluation of Load-Carrying Capacity of Lubricants Under Conditions of Low Speed and High Torque Used For Final Hypoid Drive AxlesahmedNessuna valutazione finora

- Haas Service and Operator Manual Archive SL-Series Service Manual 96-8710 English January 1999Documento244 pagineHaas Service and Operator Manual Archive SL-Series Service Manual 96-8710 English January 1999danyfNessuna valutazione finora

- Mooring Winch Brake TestDocumento4 pagineMooring Winch Brake TestAli Punga100% (2)

- TROUBLESHOOTING OF Cement Plant Mechanical and Electrical EquipmentDocumento66 pagineTROUBLESHOOTING OF Cement Plant Mechanical and Electrical EquipmentCorrosion FactoryNessuna valutazione finora

- Lesson Common Troubles of Differential SystemDocumento71 pagineLesson Common Troubles of Differential SystemalbertlumotosNessuna valutazione finora

- Spicer Info - AXSM-8663 PDFDocumento28 pagineSpicer Info - AXSM-8663 PDFRay Ayala100% (1)

- Zero Backlash in Rack and Pinion Drive SystemsDocumento2 pagineZero Backlash in Rack and Pinion Drive Systemssuresh muthuramanNessuna valutazione finora

- Kiln DriveDocumento83 pagineKiln DriveMohammed BNessuna valutazione finora

- Synchroflex Timing BeltsDocumento84 pagineSynchroflex Timing BeltsBarNessuna valutazione finora

- 364 21262 PDFDocumento24 pagine364 21262 PDFIonut-Catalin DimacheNessuna valutazione finora

- Disassemble DifferentialDocumento11 pagineDisassemble DifferentialAnonymous cS9UMvhBqNessuna valutazione finora

- Book 6.3.1 Gear Terms Lesson Rev3Documento16 pagineBook 6.3.1 Gear Terms Lesson Rev3Wil NelsonNessuna valutazione finora

- 416F2 Center Pivot Backhoe Loader LBF00001-UP Differential Backlash and Bearings - AdjustDocumento15 pagine416F2 Center Pivot Backhoe Loader LBF00001-UP Differential Backlash and Bearings - AdjustCEVegaONessuna valutazione finora

- Rack-And-Pinion or Screw Driven SystemDocumento2 pagineRack-And-Pinion or Screw Driven Systemnima_matrix20028550Nessuna valutazione finora

- Manual de Servicio MC350EDocumento31 pagineManual de Servicio MC350EHenry zambranoNessuna valutazione finora

- JANOME 423S Maintenance ManualDocumento45 pagineJANOME 423S Maintenance ManualdalceggioNessuna valutazione finora

- TIL 2363 R1 - IGV Inspection and Maintenance For Gear & Rack TypeDocumento15 pagineTIL 2363 R1 - IGV Inspection and Maintenance For Gear & Rack TypeBouazzaNessuna valutazione finora

- 850-860-870-D670 Planned Maintenance SM - SM - 5718529-1EN - 7Documento218 pagine850-860-870-D670 Planned Maintenance SM - SM - 5718529-1EN - 7rao3farhat3masoodNessuna valutazione finora

- Couplings PDFDocumento48 pagineCouplings PDFBudi SantosoNessuna valutazione finora

- Secondary Encoder FlyerDocumento2 pagineSecondary Encoder FlyerxNessuna valutazione finora

- How To Measure Gear Backlash - It Still RunsDocumento8 pagineHow To Measure Gear Backlash - It Still RunsvamsiNessuna valutazione finora

- Unit 2 Screw Thread - Gear Elements - Surface FinishDocumento53 pagineUnit 2 Screw Thread - Gear Elements - Surface FinishDeepak MisraNessuna valutazione finora

- Gear Group (Front) - Install - Idler Gear Only: Desmontagem e MontagemDocumento6 pagineGear Group (Front) - Install - Idler Gear Only: Desmontagem e MontagemJose nildo lobato Mendes MendesNessuna valutazione finora

- Renishaw Ballbar LaserDocumento21 pagineRenishaw Ballbar LaserPham LongNessuna valutazione finora

- 6.3.1 Gear Terms Lesson Rev3Documento19 pagine6.3.1 Gear Terms Lesson Rev3Deepak GirotraNessuna valutazione finora

- 303-01 - 2.3L EcoBoost - General Procedures - Balance Shaft BacklashDocumento22 pagine303-01 - 2.3L EcoBoost - General Procedures - Balance Shaft BacklashCARLOS LIMADANessuna valutazione finora