Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Synthron Final Report1 PDF

Caricato da

Vipin NairTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Synthron Final Report1 PDF

Caricato da

Vipin NairCopyright:

Formati disponibili

CASE STUDY

Runaway Chemical Reaction and Vapor

Cloud Explosion

No. 2006-04-I-NC

July 31, 2007

Worker Killed, 14 Injured

This Case Study describes a

runaway chemical reaction and

subsequent vapor cloud

explosion and fires that killed

one worker and injured 14 (two

seriously). The explosion

destroyed the facility and

damaged structures in the nearby

community. The incident

occurred at the Synthron, LLC

facility in Morganton, North

Carolina, on January 31, 2006.

The CSB issues this Case Study

to emphasize the importance of

implementing comprehensive

safety management practices to

control reactive hazards.

Synthron, LLC

Morganton, NC

January 31, 2006

KEY ISSUES:

INSIDE . . .

Reactive Hazards and Safeguards

Corporate Oversight

Safe Operating Limits

Lessons Learned

Evacuation Planning and Drills

Recommendations

Incident Description

Synthron Operations

Incident Analysis

References

Synthron Case Study

1.0 Incident Summary

This incident occurred at Synthron, LLCs

Morganton, North Carolina, facility. The

company manufactured a variety of powder

coating and paint additives by polymerizing

acrylic monomers in a 1,500 gallon reactor.

The company had received an order for

slightly more of an additive than the normal

size recipe would produce. Plant managers

scaled up the recipe to produce the required

larger amount of polymer, and added all of

the additional monomer needed into the

initial charge to the reactor. This more than

doubled the rate of energy release in the

reactor, exceeding the cooling capacity of

the reactor condenser and causing a runaway

reaction.

The reactor pressure increased rapidly.

Solvent vapors vented from the reactors

manway, forming a flammable cloud inside

the building. The vapors found an ignition

source, and the resulting explosion killed

one worker and injured 14. The blast

destroyed the facility (Figure 1) and

damaged off-site structures.

The U.S. Chemical Safety Board (CSB)

found that the reactor lacked basic

safeguards to prevent, detect, and mitigate

runaway reactions, and that essential safety

management practices were not in place.

1.1

The Incident

The production department began preparing

a 6,080 pound acrylic polymer batch the day

before the incident, approximately 12

percent more material than would normally

be made in a single batch. The plant

superintendent determined the quantities of

solvent, monomer, and initiator needed for

July 31, 2007

the batch. 1 The day shift operators then

blended the solvents and used some of the

blend to prepare the initiator solution. They

added the balance to the 1,500 gallon

reactor. The second shift operators, in

accordance with written instructions, added

some of the monomer to the reactor and held

back the remainder for use later in the

reaction sequence.

The day shift arrived on the morning of

January 31 and added steam to the reactor

jacket (Figure 2) to heat the reactor to the

temperature specified on the batch sheet,

then shut off the steam.

The senior operator took the final step to

start the reaction by pumping initiator

solution into the reactor. He then visually

checked the flow of condensed solvent

through the condenser sight glass to monitor

the rate of reaction. While the reaction

initially did not proceed as vigorously as he

expected, the condensed solvent flow later

increased and appeared to be in the normal

range.

Several minutes later, the senior operator

heard a loud hissing and saw vapor venting

from the reactor manway. The irritating

vapor forced him out of the building.

Three other employees were also forced

from the building by the release. Joined by

the plant superintendent and the plant

manager, the employees gathered outside an

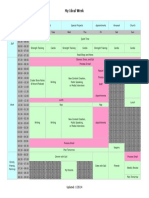

upper level doorway (Figure 3). The senior

operator re-entered the building wearing a

respirator, and was able to start emergency

cooling water flow to the reactor jacket.

However, the building exploded less than 30

seconds after he exited.

Refer to section 2.2 for an explanation of the

chemistry involved.

Synthron Case Study

July 31, 2007

Photo courtesy of Morganton Department of Public Safety

Figure 1. Synthron facility after the explosion

The blast knocked down the personnel

gathered outside the doorway. All were

injured, and one required helicopter

transport to hospital. Administrative

personnel working in an onsite trailer also

suffered minor injuries.

The maintenance supervisor was near the lab

on the lower level when the explosion

occurred (Figure 3). He was severely

burned over most of his body and was

transported by helicopter to a regional burn

center, where he died five days later.

The blast damaged structures in the nearby

community. Two church buildings and a

house were condemned, and glass was

broken up to one-third of a mile from the

site. Two citizens driving by the site were

slightly injured.

The Environmental Protection Agency

(EPA) federalized the site under the

CERCLA

(Superfund)

regulation,

remediated the site and eventually razed the

heavily damaged structures at Synthrons

facility.

1.2

Community Emergency

Response

The Morganton Department of Public Safety

responded rapidly and called in mutual aid

support from Burke County and nearby

municipalities.

Employees and Public

Safety officers assisted injured employees.

The fires following the explosion generated

thick smoke, and local residents were asked

to shelter-in-place for several hours. 2 The

fires were extinguished the next day.

Shelter-in-place can protect people in emergencies

by reducing their exposure to toxic substances.

People should take refuge in a small interior room,

close windows, seal openings, and shut off heating

and air conditioning systems.

Synthron Case Study

2.0 Synthron Operations

2.1

Company Overview

Protex International has owned a controlling

interest in Synthron since 1972, and Protex

president is also president of Synthron.

Protex, based in Paris, France, is a privately

held company with over $100 million a year

in sales, and operations in Europe, Asia, and

North and South America. In addition to the

Synthron facility, Protex operates chemicalrelated businesses in Massachusetts, New

Jersey, and Florida.

Synthrons single U.S. facility was located

in

Morganton,

North

Carolina,

approximately 70 miles northwest of

Charlotte. The 17 Morganton employees

included the companys vice president, who

was responsible for day-to-day operations.

Synthron had 2004 sales of approximately

$3 million.

Following the explosion, Synthron, LLC

filed for bankruptcy under Chapter 7 of the

bankruptcy laws.

2.2

Reaction Overview

Synthron produced acrylic polymers, 3

primarily additives for the powder coating

and paint industries. 4 The polymers were

produced by the free-radical polymerization

of acrylic monomers in various flammable

solvents. 5 Synthron converted many of its

July 31, 2007

liquid products into free-flowing powders by

adsorbing them onto silica.

The product being manufactured on the day

of the incident, Modarez MFP-BH, was a

liquid acrylic polymer. It was produced

using acrylic monomer purchased through a

national chemical distributor. The batch

was intended to fill an order for a major

diversified chemical manufacturer.

Polymerization was performed in a 1,500

gallon reactor, rated at 75 psig maximum

operating pressure and designated as reactor

M1 (Figure 2). The reactor was located in

a manufacturing area adjacent to the

warehouse (Figure 3).

In a typical reaction sequence, operators

added a mixture of solvents and monomers

to the reactor. They then injected steam into

the reactors jacket to heat the reaction

mixture to a specified temperature, usually

the expected mixture boiling point. The

steam was turned off and initiator solution

metered into the reactor to start

polymerization.

The heat given off by the reaction boiled the

solvent and monomer mixture, causing hot

vapors to flow to an overhead water-cooled

heat exchanger where they were totally

condensed.

Acrylic polymers are produced from monomers

based on acrylic acid or related esters, known as

acrylates.

Synthron used a variety of acrylic

monomers to produce polymer resin additives for

paint and powder coating manufacturers.

4

Powder coatings are mixtures of resins and

pigments that are applied to goods, such as

appliances, and then baked at high temperature to

fuse the powder into a smooth polymer surface.

5

Free radical polymerization uses thermally unstable

initiators, typically peroxides, persulfates, or azo

compounds, to promote controlled polymerization

and obtain desired product properties. Manufacturers

can customize product properties by selecting

appropriate monomers and initiators and by

controlling reaction conditions such as monomer

concentration and temperature. Unlike catalysts,

which promote reactions but are not consumed or

modified by them, initiators are consumed in the

polymerization reaction.

Synthron Case Study

Liquid solvent drained from the bottom of

the condenser back into the reactor. 6 The

outlet of the condenser vented to the

atmosphere through a small pipe, keeping

the pressure in the reactor very near

atmospheric under normal operation. In an

emergency, water could be manually

directed through the reactors jacket to

increase cooling.

A complete manufacturing cycle could

include several reaction steps. The finished

liquid polymer was stripped of solvent,

cooled, and packaged into drums for

shipment to customers.

July 31, 2007

3.0 Incident Analysis

The CSB investigators determined that the

key factors leading to this incident included

3.1

a lack of hazard recognition,

poorly documented process safety

information,

ineffective control of product recipe

changes,

a lack of automatic safeguards to

prevent or mitigate the effects of loss

of control over the reaction,

improper manway bolting practices,

poor operator training,

inadequate emergency plans drills,

and

inadequate corporate oversight of

process safety.

Hazard Identification

When performing reactive chemistry,

companies should maintain a high degree of

awareness of the hazards involved.

Synthron combined monomers and reaction

initiators in the presence of flammable

solvent to produce polymer products, but

failed to identify the hazards associated with

this type of chemistry.

Figure 2. Reactor M1

Operators could monitor the condensed solvent

flow, known as reflux, through a sight glass

(Figure 2).

Texts such as Loss Prevention in the

Process Industries (Mannan, 2005) and

Brethericks Chemical Reaction Hazards

(Urban, 2000) describe appropriate means

for characterizing industrial chemical

reactions. These include determining the

heat generation rate as a function of

temperature, the available heat removal

capacity, and the potential for excessive

monomer or initiator accumulation in the

reactor. Failure to control these critical

characteristics can lead to severe upsets,

including runaway reactions.

Managers can detect hazards by asking

What can go wrong? to identify the

5

Synthron Case Study

July 31, 2007

potential consequences of inappropriate

mixing, recipe changes, greater- and lowerthan-normal heating, lack of mixing, etc.

The answers can be used to develop

improvements or changes that can prevent

reactive

upsets

or

mitigate

their

consequences.

Synthron had not identified the hazards of

its reactive chemical operations. No formal

hazard review (also known as a process

hazard analysis, or PHA) was conducted to

address What could go wrong? during

reactor operations. 7

Furthermore, most of the management and

operations personnel at Synthron had been

on the job for less than a year, in some cases

much less (Table 1), and lacked previous

polymer manufacturing experience. 8

In

addition, Synthrons training program was

informal and did not include reactive

hazards training.

Employee

Time at

Synthron

Polymer

Experience?

Manager

Superintendent

Vice President

2nd Shift Op-1

2nd Shift Opt-2

Chemist

9 months

8 months

5 months

3 months

3 months

3 weeks

No

No

No

No

No

No

Personnel, including site managers, were

thus poorly prepared to recognize potentially

hazardous changes to product recipes, or to

respond to an incipient runaway reaction.

Additionally, Synthron had no chemical or

other engineers on staff, and none had been

contracted to evaluate the hazards associated

with reactive operations at the site.

3.2

Lack of Process Safety

Information and Training

Synthron had minimal safety information on

its polymerization process, even though this

was the core of its manufacturing business.

Synthron optimized product formulations to

meet customer specifications. However,

reaction characterization and calorimetry 9

were not performed to establish process

equipment performance requirements and

operating limits for safe operations.

When scaling-up new products from the

laboratory, the previous Synthron plant

manager had typically estimated initial

production batch sizes based on past

experience. He then gradually increased

batch quantities until the sight glass in the

condensate return line showed that the

condenser was close to flooding, 10 or that

another performance limit was being

approached (e.g., the reactor pressure

Table 1: Management and operations

personnel tenure at Synthron

Guidance on conducting hazard assessments is

available from the Center for Chemical Process

Safety (CCPS):, Guidelines for Hazard Evaluation

Procedures, 2nd ed., and other CCPS publications.

8

Synthrons president had replaced the management

team in an attempt to increase sales. A variety of

causes had simultaneously contributed to high

operator turnover. The senior operator had been

brought back from retirement to provide a degree of

continuity.

Reaction calorimetry uses specialized instruments to

measure heat flow from a laboratory-scale reacting

mixture under controlled conditions. Calorimetry

results can be extrapolated to full-scale processes.

10

Condensers flood when vapors condense faster

than the liquid produced can flow back to the reactor.

Liquid begins to fill the condenser, blocking off the

heat transfer area. The resulting loss of cooling can

result in a sharp increase in pressure and possible loss

of reaction temperature control. The M1 condenser

was located only slightly above the reactor, which

made it prone to flooding.

Synthron Case Study

July 31, 2007

Figure 3. Synthron facility layout

increased). Polymerization scale-up to their

standard batch sizes had historically been

done by simple trial-and-error.

The

condensers cooling capacity was not

documented, nor could the cooling load

placed on the condenser be determined with

the available instrumentation. As a result,

information essential to the safe operation of

the

reactor

was

not

available.

Polymerization reactors can runaway with

disastrous consequences if they are not

carefully controlled. 11

They had not been trained on, 12 and did not

understand, the margin of safety needed or

available in their polymerization operations.

Furthermore, they had little knowledge of

the sensitivity of the reactor to changes in

product recipes, batch sizes, or reaction

conditions.

Synthrons employees were thus unprepared

to recognize and respond to the reactive

hazards they faced the day of the incident.

3.3

Based on interviews the CSB conducted,

Synthron employees and managers had little

or no understanding of reactive hazards.

11

In a runaway reaction, the pressure, and thus the

boiling temperature, in the reactor increases, further

increasing the rate of reaction, and leading to higher

pressures and heating rates.

Batch Recipe Changes

In planning the MFP-BH batch, Synthron

managers made several changes that greatly

increased the heat released by the reaction in

reactor M1 and the potential for a runaway

12

Synthrons training program was informal, relying

on unstructured on-the-job training.

Testimony

indicated that reactive hazards were not

systematically addressed.

Synthron Case Study

reaction. However, the changes were not

effectively reviewed and the hazards went

unrecognized. Synthron:

increased the total amount of

monomer to be charged to the reactor

by 12 percent.

The additional

monomer, with a Normal Boiling

Point Temperature (NBPT 13) of

147oC (297oF), was placed in the

initial reactor charge.

reduced the amount of aliphatic

solvent, with an NBPT of 81oC

(178oF), charged to the reactor by 12

percent.

increased the amount of aromatic

solvent, with an NBPT of 111oC

(234oF), by 6 percent.

The customer had ordered 12 percent more

MFP-BH than a standard batch would

produce. To avoid the additional time and

effort of running two half-size batches, the

superintendent scaled up the recipe to

produce the order in a single batch.

MFP-BH was produced in two stages. In

the first, an initial charge of acrylic

monomer and solvent was loaded into

reactor M1, heated, and then reacted by

adding an initiator over a brief period. In

the second, the remaining monomer and

initiator were co-fed into the reactor over an

extended period.

Unfortunately, the

superintendent placed almost all of the

additional monomer for the larger batch into

the initial charge of chemicals loaded into

the reactor.

July 31, 2007

available in storage. To compensate, the

superintendent and manager decided to

make up half the shortfall using the higher

boiling aromatic solvent, and to run the

batch with slightly less total solvent than

specified in the recipe.

Together, these changes:

increased the total amount of

monomer in the reactor by 45

percent,

increased the concentration of

monomer by 27 percent, and

increased the atmospheric boiling

point temperature of the mixture by

almost 5oC (9oF). 14

Each of these changes would be expected to

increase the rate of heat release in the

reactor. When asked to review the changes

in the solvent quantities, the plant chemist

estimated that the boiling point of the

solvent mixture would increase about 1oC

(1.8o F). However, the chemist, manager,

and superintendent did not recognize or

address the potential impact of the increased

monomer amount and concentration on the

mixture boiling point, reaction rate, or total

rate of heat release.

The combined effect of the changes was to

increase the maximum heat output from the

reaction to at least 2.3 times that of the

standard recipe. Figure 4 illustrates the

results of reaction calorimetry performed to

simulate the early stages of the incident.

According to the batch sheet, roughly equal

amounts of aromatic and aliphatic solvent

should have been added to the reactor.

However, there was not enough of the lower

boiling temperature aliphatic solvent

13

NBPT is the boiling temperature at 1 atmosphere

absolute pressure.

14

The CSB measured the boiling points of laboratory

mixtures with the same compositions.

Synthron Case Study

July 31, 2007

Figure 4. Reaction calorimetry heating curves for standard (lower) and modified (upper) recipes

The lower curve shows the heat release rate

(thermal power) versus time for the standard

recipe, while the upper curve shows the heat

release rate for the modified recipe. 15 The

lower solid horizontal line is the estimated

cooling capacity of the reactor condenser on

the day of the incident (see section 3.6 for a

discussion of condenser fouling). Once the

heating curve exceeded the condenser

cooling line, control of the reaction was lost,

resulting in a runaway reaction.

15

Each curve was generated isothermally at the

NBPT of the mixture, closely simulating the

operation of the reactor up to the time when control

was lost. Heat generation rates during the subsequent

runway reaction were higher.

3.4

Chemical Process

Safeguards

The incident occurred before the second,

continuous feed phase of the manufacturing

process could begin.

Synthron relied primarily on a procedural

safeguard to prevent loss of reactor control:

the batch sheet, which was used as an

operating procedure at the site. Procedures

are essential for safety in chemical

processing operation, but are the least

reliable form of safeguard for preventing

process incidents (CCPS, 2004).

Failures

with

potentially

severe

consequences, such as runaway reactions,

should

have

multiple

independent

safeguards.

Synthron Case Study

Examples of safeguards that could have

prevented or mitigated this incident, but

were not installed at Synthron, include:

July 31, 2007

atmospheric pressure, for which four clamps

were thought to be adequate.

high pressure alarms to notify

operators of problems early in the

incident when action to control the

reaction might still be possible,

automatic emergency cooling water

flow to the reactor jacket,

automatic shut-off of initiator feed,

automatic or remotely operated

injection of short stop solution to

stop the polymerization reaction, 16

and

automatic or remotely operated

venting or dumping of the reactor to

a safe location.

Photo courtesy of Morganton Department of Public Safety

Good practice is to review the adequacy of

safeguards on chemical reactors using a

structured method such as Layers of

Protection Analysis (CCPS, 2001). Such

reviews can help ensure that runaway

reactions are prevented or are rapidly and

reliably detected and controlled.

3.5

Manway Bolting Practice

Operators opened the reactor manway after

every batch cycle to clean the reactor.

Long-standing practice at the facility was to

then close the manway and secure it using

only four of the 18 clamps specified by the

manufacturer (Figure 5). 17 The risk posed by

this practice had not been recognized

because the reactor normally ran at near-

Figure 5. One of four installed manway

clamps

The CSB investigators calculated that, with

only four clamps installed, the manway

began to leak flammable solvent vapors

when the reactor pressure reached

approximately 23 psig, well below the

reactors maximum allowable working

pressure (and likely relief valve set point) of

75 psig. 18 The vapor leak path is clearly

visible in Figure 6 (arrow).

16

Chemicals, such as phenothiazine, can be injected

into a reactor to slow or stop free-radical

polymerizations such as the reaction at Synthron.

17

The reactor manufacturer specified 18 clamps to

maintain a tight seal at the reactor maximum working

pressure of 75 psig. The clamps were not

permanently attached to the manway, and no

markings on the manway indicated the required

number of clamps.

18

The reactor M1 relief valve could not be recovered

from the debris, and the relief valve records were

destroyed in the explosion and subsequent fires.

Other relief valves examined were set at the rated

operating pressure of the vessels they protected.

10

Synthron Case Study

July 31, 2007

company had no program to systematically

monitor and control water side fouling. 20

The CSB found no evidence that the water

side of the condenser had ever been

inspected or cleaned to remove the scale,

rust, and sediment that had accumulated

during 30 years of service. Synthrons

employees lacked the expertise and

experience to recognize the risk posed by

water side fouling of the condenser.

Figure 6. Damaged manway gasket, showing

vapor release path

3.6

Process Equipment

Fouling

Synthron failed to establish procedures to

maintain the performance of the M1

condenser, an inclined shell-and-tube heat

exchanger essential to safe operation of the

reactor.

In the condenser, solvent vapors flow inside

the tubes and are cooled and condensed by

cooling water flowing through the shell

(Figure 2). Inspection of the cooling water

side of the condenser after the incident

revealed that it was badly fouled, likely

reducing condenser capacity at least 25

percent (Figure 7).

The condensers design, with the tubes

permanently bonded to plates at both ends of

the condenser, made inspecting or cleaning

the water side difficult. 19 Furthermore, the

19

The condenser was a Tubular Exchanger

Manufacturers Association (TEMA) type BEM,

fixed tubesheet exchanger with the process fluid on

the tube side and cooling water on the shell side. The

tubes could not be removed for inspection or

cleaning. This design may require periodic chemical

cleaning of the shell side to maintain good thermal

performance.

Figure 7. Deposits fouling the water side of

the M1 reactors condenser.

A clean condenser, combined with

automatic emergency jacket cooling (Figure

4, upper dashed line), would likely have

prevented the runaway reaction and

subsequent explosion.

3.7

Emergency Evacuation

Procedures and Training

Effective evacuation plans are important for

minimizing injuries and fatalities in

chemical emergencies.

During this incident, none of the production

employees evacuated to a safe location. At

the time of the explosion, six employees,

20

Chemical treatment of the cooling water is almost

always required to prevent biological growth,

fouling, and/or corrosion. The cooling water at

Synthron was not treated.

11

Synthron Case Study

including the manager and superintendent,

gathered outside a doorway on the upper

level while a seventh was on the lower level

by the lab. The employee on the lower level

was killed, while all the employees outside

the doorway were injured, two seriously.

Synthron was unprepared for an emergency;

specifically,

The facility Emergency Action Plan

did not list events or describe

situations that might necessitate a

plant evacuation.

Operating procedure did not specify

employees actions in the event of a

chemical release or loss of reactor

control.

Employees were not trained on the

Emergency

Action

Plan

and

evacuation drills were not conducted.

The facility was not equipped with

an emergency alarm system.

In this incident, there was sufficient time

after the release began to evacuate

employees to a safe location. Adequate

emergency response planning by Synthron

could have prevented the death and serious

injuries caused by the explosion.

3.8

Corporate Oversight

Synthron was part of Protex International, a

much larger organization. However, the

parent company provided little safety

oversight or support to Synthron.

July 31, 2007

including reaction calorimetry, at its

European facilities. It is good practice

(CCPS, 2003) to ensure that reactive safety

programs at small facilities are adequately

supported by technically qualified resources.

Protex did not provide adequate reactive

safety support to Synthron.

Furthermore, in the summer and fall of

2005, Synthrons president (also the

president of Protex) hired a new vice

president, plant manager, and plant

superintendent for the Morganton site.

While two of these key management

employees had degrees in chemistry, they

had no previous polymerization experience

and were not trained on the parent

companys process safety procedures or its

testing capabilities. Having little reactive

chemistry background or training, they did

not recognize the reactive hazards at the

Morganton site.

CCPS (1995) stresses that expertise in

managing process safety must be ensured

when making staffing changes. Synthrons

president failed to ensure that the new team

he installed at the Morganton site had the

requisite

training,

knowledge,

and

experience to operate the facility safely.

Finally, Protex did not comprehensively

audit or review Synthrons safety program.

Such a review should have identified the

absence of an effective reactive hazard

control program.

While Synthron performed quality control

testing and limited product development

work in Morganton, the procedures,

equipment, and trained personnel needed to

characterize reactive hazards were not in

place.

However, Protex had the ability to perform

detailed reaction characterization work,

12

Synthron Case Study

4.0 Regulatory Analysis

Synthron had not implemented a Process

Safety

Management

(PSM)

system

consistent with the requirements of the

Occupational

Safety

and

Health

Administrations (OSHA) PSM regulation

(29 CFR 1910.119). 21 The site had last

been inspected by North Carolina OSHA

(NC-OSH) in 1996. No PSM citations were

issued following that inspection. Following

the explosion, NC-OSH proposed numerous

PSM citations, which Synthron contested.

The batch being processed at the time of the

explosion, had it been completed, would

have contained in excess of the OSHA PSM

threshold of 10,000 pounds of flammable

liquid. However, only 4,500 pounds of

material were in the reactor at the time of

the incident, well below the PSM threshold

quantity.

Nonetheless, a catastrophic

incident occurred. Synthrons experience

demonstrates that companies working with

reactive chemical quantities less than the

PSM flammables threshold still need to

consider and guard against potentially

catastrophic accidents.

July 31, 2007

5.0 The CSB Reactives

Study

In its comprehensive 2002 report,

Improving Reactive Hazard Management

(CSB, 2002), the CSB found that reactive

incidents are a serious problem in the United

States, and that both management system

and regulatory improvements are needed to

help facilities control reactive hazards. This

report studied reactive incidents, causal

factors, and preventive measures, 22 and

outlined the screening, hazard identification,

hazard review, operating procedures, and

training needed to prevent reactive incidents.

The report documented 167 serious reactive

incidents in the United States between

January 1980 and June 2001 that resulted in

108 deaths, hundreds of injuries, and

significant public impacts.

Ongoing

monitoring by the CSB indicates that

reactive incidents, such as the Synthron

explosion, continue to occur.

The CSB report also found that 70 percent

of reactive incidents occurred in the

chemical manufacturing industry, with 35

percent due to runaway reactions, such as

that which occurred at Synthron.23 While 42

percent of reactive incidents resulted in fires

and explosions, another 37 percent caused

toxic emissions. Many reactive incidents

occurred at small manufacturing sites such

as Synthron.

More than 50 percent of the 167 incidents

documented in the CSB report involved

chemicals not covered by existing OSHA

PSM (29 CFR 1910.119) or EPA Risk

Management Program (40 CFR Part 68)

regulations. The CSB recommended better

21

OSHA Process Safety Management regulation, 29

CFR 1910.119, is a performance-based processsafety regulation requiring manufacturers to

implement certain management practices on

processes containing greater than threshold quantities

of toxic or flammable chemicals.

22

Available for download at http://www.csb.gov.

Of reactive incidents, 25 percent originate in

reactors, with the rest occurring in a wide range of

equipment.

23

13

Synthron Case Study

coverage of reactive hazards by these

regulations. EPA now requires reporting of

reactive chemical incidents under RMP

reporting rules. OSHA has taken steps to

increase industry awareness of reactive

hazards, but has not fully implemented the

CSB recommendations.

The CSB report identified many valuable

sources of good practices for managing

reactive hazards.

Since the reports

publication, additional guidance has become

available. The Center for Chemical Process

Safety (CCPS) published Essential Practices

for Managing Chemical Reactivity Hazards

(CCPS, 2003), which can be downloaded at

no cost from http://info.knovel.com/ccps/

(January 2007). This book lays out the basic

steps manufacturers should take to protect

against reactive hazards.

Other valuable sources of guidance are

available. The EPAs Chemical Emergency

Preparedness and Prevention web page

http://yosemite.epa.gov/oswer/ceppoweb.nsf

/content/ap-book.htm (May 2007) contains

useful links. The United Kingdoms Health

and Safety Executive also offers an

informative

web

page,

http://www.hse.gov.uk/pubns/indg254.htm

(May 2007) and the comprehensive booklet,

Designing and Operating Safe Chemical

Reaction Processes (HSE Books, 2000).

July 31, 2007

6.0 Lessons Learned

This incident provides important lessons for

manufacturers with operations involving

reactive chemistry.

6.1

Identify and Control

Reactive Hazards

Manufacturers should take a comprehensive

approach, and:

6.2

identify and characterize reactive

hazards;

systematically evaluate what can go

wrong, including mis-charging of

reagents, loss of cooling, instrument

malfunction, and other credible

failure scenarios; and

implement, document, and maintain

adequate safeguards against the

identified

failure

scenarios.

Multiple, independent safeguards

may be needed to reliably ensure the

safety of the reactive process.

Control Change

Chemical manufacturers and others with

reactive chemistry operations should control

changes to batch recipes, including key

operating conditions, such as:

the quantities, proportions, and

sequencing of reactor feeds,

reaction temperature,

conditions that could cause initiator

or monomer accumulation, and

conditions that could affect the

deactivation of monomer inhibitors

or stabilizers.

14

Synthron Case Study

6.3

and the Local Emergency Planning

Committee (LEPC).

Maintain Process

Equipment Capability

Manufacturers with

operations should:

July 31, 2007

reactive

chemistry

document

the

performance

requirements and capabilities of

process equipment, such as the

reactor condenser at Synthron; and

periodically inspect and service

process equipment, including the

water side of heat exchangers, to

maintain appropriate safety margins.

7.0

Recommendation

Protex International

2006-04-I-NC-R1

Establish a program to ensure that reactive

hazards at Protex U.S. facilities are

managed in accordance with good industry

practices.

At a minimum, the program should:

6.4

Train Personnel on

Hazards and Procedures

Manufacturers should ensure that worker

training includes:

6.5

the nature of the reactive hazards,

including process safety margins;

and

operating procedures, including

appropriate cautions and warnings,

the consequences of deviations,

recognition of deviations and

abnormal operations, and the

appropriate responses to control or

mitigate their effects.

Prepare for Emergencies

identify and characterize reactive

hazards;

implement, document, and maintain

appropriate safeguards;

manage changes to recipes;

document and maintain safetycritical

process

equipment

capabilities;

train personnel on reactive hazards,

safe operating limits, and the

consequences of and responses to

deviations;

train personnel on emergency

evacuation alarms and procedures,

and conduct emergency drills; and,

conduct periodic audits of program

implementation to identify and

address weaknesses.

Manufacturers should:

implement an effective emergency

plan,

train employees on the plan,

install an evacuation alarm system

that is audible and/or visible

throughout the facility,

conduct regular exercises to help

ensure rapid evacuation to a safe

location in an emergency, and

coordinate their emergency planning

with offsite response organizations

15

Synthron Case Study

8.0

July 31, 2007

References

Health and Safety Executive (HSE) [Online], 2007. Chemical Reaction Hazards and the Risk of

Thermal Runaway, www.hse.gov.uk/pubns/indg254.htm, London, UK: HSE.

HSE. Designing and Operating Safe Chemical Reaction Processes, Rugby, UK: HSE Books, 2000.

Center for Chemical Process Safety (CCPS). Guidelines for Hazard Evaluation Procedures - With

Worked Examples, 2nd ed, New York: American Institute of Chemical Engineers (AIChE), 1992.

CCPS. Plant Guidelines for Technical Management of Chemical Process Safety (Revised Edition),

New York: AIChE, 1995.

CCPS. Layer of Protection Analysis - Simplified Process Risk Assessment, New York: AIChE,

2001.

CCPS. Essential Practices for Managing Chemical Reactivity Hazards, New York: AIChE, 2003.

CCPS. Inherently Safer Chemical Processes, A Life Cycle Approach, New York: AIChE, 2004.

Mannan, S., Lees Loss Prevention in the Process Industries, 3rd ed., Burlington, MA: Elsevier

Butterworth-Heinemann, 2005.

Urban, P. G., Ed. Brethericks Handbook of Reactive Chemical Hazards, 6th ed., St. Louis, MO:

Elsevier Science and Technology Books, 2000.

The United States Chemical Safety and Hazard Investigation Board (CSB). Improving Reactive

Hazard Management, Washington, DC: CSB, 2002.

16

Synthron Case Study

July 31, 2007

The U.S. Chemical Safety and Hazard Investigation Board (CSB) is an independent Federal agency

whose mission is to ensure the safety of workers, the public, and the environment by investigating

and preventing chemical incidents. The CSB is a scientific investigative organization; it is not an

enforcement or regulatory body. Established by the Clean Air Act Amendments of 1990, the CSB is

responsible for determining the root and contributing causes of accidents, issuing safety

recommendations, studying chemical safety issues, and evaluating the effectiveness of other

government agencies involved in chemical safety.

No part of the conclusions, findings, or recommendations of the CSB relating to any chemical

accident may be admitted as evidence or used in any action or suit for damages. See 42 U.S.C.

7412(r)(6)(G). The CSB makes public its actions and decisions through investigation reports,

summary reports, safety bulletins, safety recommendations, case studies, incident digests, special

technical publications, and statistical reviews. More information about the CSB is available at

www.csb.gov.

CSB publications can be downloaded at

www.csb.gov or obtained by contacting:

U.S. Chemical Safety and Hazard

Investigation Board

Office of Congressional, Public, and Board Affairs

2175 K Street NW, Suite 400

Washington, DC 20037-1848

(202) 261-7600

CSB Investigation Reports are formal,

detailed reports on significant chemical

accidents and include key findings, root causes,

and safety recommendations. CSB Hazard

Investigations are broader studies of significant

chemical hazards. CSB Safety Bulletins are

short, general-interest publications that provide

new or noteworthy information on

preventing chemical accidents. CSB Case

Studies are short reports on specific accidents

and include a discussion of relevant prevention

practices. All reports may include safety

recommendations when appropriate. CSB

Investigation Digests are plain-language

summaries of Investigation Reports.

17

Potrebbero piacerti anche

- Introduction to Petroleum Process SafetyDa EverandIntroduction to Petroleum Process SafetyValutazione: 3 su 5 stelle3/5 (2)

- Quality Control OF Bulk Drug FormulationsDa EverandQuality Control OF Bulk Drug FormulationsNessuna valutazione finora

- Runaway Chemical Reaction and Vapor Cloud Explosion at Synthron FacilityDocumento17 pagineRunaway Chemical Reaction and Vapor Cloud Explosion at Synthron FacilityThing90Nessuna valutazione finora

- Bangot - CaseStudy01 - Synthron Explosion PDFDocumento5 pagineBangot - CaseStudy01 - Synthron Explosion PDFCj BangotNessuna valutazione finora

- Explosion X Reaccion Descontr de Polimero Acrilico FGyS - 9 Ago 07 PDFDocumento17 pagineExplosion X Reaccion Descontr de Polimero Acrilico FGyS - 9 Ago 07 PDFjuan_balderramaNessuna valutazione finora

- ReportDocumento25 pagineReportMohd Hafiz AhmadNessuna valutazione finora

- Case StudyDocumento13 pagineCase StudyYustinus Selis ToronNessuna valutazione finora

- SEPT 2022 - CLD 20002 - Chap 1 - Industrial SafetyDocumento104 pagineSEPT 2022 - CLD 20002 - Chap 1 - Industrial SafetyAirish AirishNessuna valutazione finora

- Case Studymajor Chemical Disasters FILEminimizerDocumento73 pagineCase Studymajor Chemical Disasters FILEminimizeridigitiNessuna valutazione finora

- Formosa Plastics Fire Case Study: Evaluating Process HazardsDocumento16 pagineFormosa Plastics Fire Case Study: Evaluating Process HazardsSaurabh ShahNessuna valutazione finora

- Safety Alert - Fire and Explosion Risk - Reactive MonomersDocumento2 pagineSafety Alert - Fire and Explosion Risk - Reactive MonomersSteve ForsterNessuna valutazione finora

- Case Study Major Chemical Disasters File MinimizeDocumento73 pagineCase Study Major Chemical Disasters File MinimizeAyush ShrimalNessuna valutazione finora

- Safety and Major Chemical DisastersDocumento30 pagineSafety and Major Chemical DisastersganeshNessuna valutazione finora

- Case Study On Major Chemical DisastersDocumento6 pagineCase Study On Major Chemical DisastersMukund P RaoNessuna valutazione finora

- 1 - Introduction To Chemical Process IndustriesDocumento13 pagine1 - Introduction To Chemical Process IndustriesVenus Abigail GutierrezNessuna valutazione finora

- Goodyear Houston Ammonia Release Case StudyDocumento10 pagineGoodyear Houston Ammonia Release Case StudyMas Arman TewoNessuna valutazione finora

- Basic Principle in CPIDocumento28 pagineBasic Principle in CPIDion VixNessuna valutazione finora

- Chemical Reaction Safety: Paul Sharratt 19 August 2019Documento32 pagineChemical Reaction Safety: Paul Sharratt 19 August 2019Chuah Chong YangNessuna valutazione finora

- Epcsm Term PaperDocumento13 pagineEpcsm Term PaperFake accNessuna valutazione finora

- CH3044 Plant Safety and Loss PreventionDocumento4 pagineCH3044 Plant Safety and Loss PreventionAchini NawarathnaNessuna valutazione finora

- Osha Individual ReportDocumento9 pagineOsha Individual ReportpuraniNessuna valutazione finora

- CompilationDocumento7 pagineCompilationQistyNessuna valutazione finora

- Why Use Silicones in Personal Care Part 1Documento8 pagineWhy Use Silicones in Personal Care Part 1JulioNessuna valutazione finora

- Assignment 3-Case Study PDFDocumento7 pagineAssignment 3-Case Study PDFazhani rosliNessuna valutazione finora

- G.chem Bhopal Gas TragedyDocumento16 pagineG.chem Bhopal Gas Tragedymrmy88tm46Nessuna valutazione finora

- Reactive Polymer ProcessingDocumento12 pagineReactive Polymer ProcessingVanNessuna valutazione finora

- Propylene ProductionDocumento1 paginaPropylene ProductionWade ColemanNessuna valutazione finora

- Machinery Safety Xbos 3103Documento11 pagineMachinery Safety Xbos 3103abdulhafidzrc939Nessuna valutazione finora

- The Bhopal Gas Tragedy: A Case Study on the World's Worst Industrial DisasterDocumento41 pagineThe Bhopal Gas Tragedy: A Case Study on the World's Worst Industrial DisasterVivek GurjarNessuna valutazione finora

- HIRA-Assignment 2Documento4 pagineHIRA-Assignment 2Naveen PrakashNessuna valutazione finora

- An Engineer S Guide To MocDocumento5 pagineAn Engineer S Guide To MocAnonymous 1XHScfCI100% (1)

- Study and Improvement in Operations of Chemical Plant: Guide: Shri. Mahesh DhawalikarDocumento68 pagineStudy and Improvement in Operations of Chemical Plant: Guide: Shri. Mahesh DhawalikarPrathamesh NaikNessuna valutazione finora

- LECTURE - 03 - CDB 3044 - Conceptual Process Design - Synthesis of Reaction System (I)Documento29 pagineLECTURE - 03 - CDB 3044 - Conceptual Process Design - Synthesis of Reaction System (I)Ong Jia YeeNessuna valutazione finora

- Bhopal Disaster ReportDocumento1 paginaBhopal Disaster ReportshaniaNessuna valutazione finora

- Cpi PPT Enrollment No 10 To 13Documento32 pagineCpi PPT Enrollment No 10 To 13arshit5dobriyaNessuna valutazione finora

- Texas City Refinery Explosion ReportDocumento10 pagineTexas City Refinery Explosion ReportNimra JalilNessuna valutazione finora

- Green Chem Practical ValiDocumento15 pagineGreen Chem Practical ValiKomalpreet KaurNessuna valutazione finora

- Major Accidents in Oil and Gas, Petrochemicals Slide PresentationsDocumento16 pagineMajor Accidents in Oil and Gas, Petrochemicals Slide PresentationsAimi Saari100% (1)

- Group 1 - Section 01G - Separation Project PDFDocumento46 pagineGroup 1 - Section 01G - Separation Project PDFHatta AimanNessuna valutazione finora

- Bayer CropScience Runaway ReactionDocumento10 pagineBayer CropScience Runaway ReactionSatish JadhavNessuna valutazione finora

- Fire & Explosion During Tank Cleaning On A Chemical TankerDocumento4 pagineFire & Explosion During Tank Cleaning On A Chemical TankerHoàng Anh PhạmNessuna valutazione finora

- Bhopal Gas Tragedy Case StudyDocumento17 pagineBhopal Gas Tragedy Case StudyArijit PatiNessuna valutazione finora

- Principle 9 12Documento18 paginePrinciple 9 12taayush86Nessuna valutazione finora

- Background To Ioc FireDocumento7 pagineBackground To Ioc FirePratyaksh JainNessuna valutazione finora

- A Written Report in The: Introduction To Industrial ChemistryDocumento4 pagineA Written Report in The: Introduction To Industrial ChemistryJulius Supe-riorNessuna valutazione finora

- Top 27 Chemical Engineer Interview Questions and Answers - WiseStepDocumento7 pagineTop 27 Chemical Engineer Interview Questions and Answers - WiseStepAkash BodekarNessuna valutazione finora

- Bhopal LOPADocumento3 pagineBhopal LOPAFakhrul RaziNessuna valutazione finora

- Bhopal Gas Tragedy Case StudyDocumento12 pagineBhopal Gas Tragedy Case StudyMary Grace D. AlmiranezNessuna valutazione finora

- Synthesis of Tramadol LabDocumento3 pagineSynthesis of Tramadol Labchedhed50% (2)

- SANYO Semiconductor's Environmental ManagementDocumento6 pagineSANYO Semiconductor's Environmental ManagementDeign SeseNessuna valutazione finora

- Module 4Documento11 pagineModule 4yiyiyi7699Nessuna valutazione finora

- Bhopal PDFDocumento2 pagineBhopal PDFRatna Paramitha SariNessuna valutazione finora

- Prevent runaway phenol-formaldehyde reactionsDocumento6 paginePrevent runaway phenol-formaldehyde reactionsElena TodorovskaNessuna valutazione finora

- DIPLOMA IN OCCUPATIONAL SAFETY AND HEALTHDocumento10 pagineDIPLOMA IN OCCUPATIONAL SAFETY AND HEALTHsyukreenNessuna valutazione finora

- FA7 - Confined Space Case StudyDocumento7 pagineFA7 - Confined Space Case StudyaleanneNessuna valutazione finora

- Examples For Process SynthesisDocumento14 pagineExamples For Process SynthesisgoldflackNessuna valutazione finora

- Spe 123072Documento13 pagineSpe 123072Jose Gregorio Fariñas GagoNessuna valutazione finora

- Mechanical Properties of Polycarbonate: Experiment and Modeling for Aeronautical and Aerospace ApplicationsDa EverandMechanical Properties of Polycarbonate: Experiment and Modeling for Aeronautical and Aerospace ApplicationsNessuna valutazione finora

- Polyoxymethylene Handbook: Structure, Properties, Applications and their NanocompositesDa EverandPolyoxymethylene Handbook: Structure, Properties, Applications and their NanocompositesNessuna valutazione finora

- Recent Trends and Innovations in Sustainable Treatment Technologies for Heavy Metals, Dyes and Other XenobioticsDa EverandRecent Trends and Innovations in Sustainable Treatment Technologies for Heavy Metals, Dyes and Other XenobioticsNessuna valutazione finora

- Input FileDocumento10 pagineInput FileVipin NairNessuna valutazione finora

- X-1-Estimating Tool - Rev 0Documento10 pagineX-1-Estimating Tool - Rev 0Vipin NairNessuna valutazione finora

- Blackjack Cheat Sheet PDF Color PDFDocumento1 paginaBlackjack Cheat Sheet PDF Color PDFVipin NairNessuna valutazione finora

- Corsair 7 MIRs Feb 20 Feb 2717 NM 13 UsDocumento1 paginaCorsair 7 MIRs Feb 20 Feb 2717 NM 13 UsVipin NairNessuna valutazione finora

- Steel Cals SimpleDocumento53 pagineSteel Cals SimpleVashish RamrechaNessuna valutazione finora

- Circuitization Project Workflow GuideDocumento1 paginaCircuitization Project Workflow GuideVipin NairNessuna valutazione finora

- Stream Inspection Criteria FormDocumento4 pagineStream Inspection Criteria FormVipin NairNessuna valutazione finora

- DIY Cloth Face Covering Instructions PDFDocumento3 pagineDIY Cloth Face Covering Instructions PDFnathanNessuna valutazione finora

- 965 B10193 05,00Documento1 pagina965 B10193 05,00Vipin NairNessuna valutazione finora

- Texas MudHensDocumento1 paginaTexas MudHensVipin NairNessuna valutazione finora

- Xref Lines Not in LCI DBDocumento8 pagineXref Lines Not in LCI DBVipin NairNessuna valutazione finora

- CUI Project ExchnagersDocumento5 pagineCUI Project ExchnagersVipin NairNessuna valutazione finora

- Static Head Calculation For B-31Documento1 paginaStatic Head Calculation For B-31Vipin NairNessuna valutazione finora

- Terminal 3 Map2 - 2015 - R3 - tcm13-4102Documento2 pagineTerminal 3 Map2 - 2015 - R3 - tcm13-4102Vipin NairNessuna valutazione finora

- Sphere MAWPDocumento2 pagineSphere MAWPVipin NairNessuna valutazione finora

- Management of Critical Process Equipment To Ensure It Is Designed and Installed Correctly, and That It Operates and Is Maintained ProperlyDocumento2 pagineManagement of Critical Process Equipment To Ensure It Is Designed and Installed Correctly, and That It Operates and Is Maintained ProperlyVipin NairNessuna valutazione finora

- LWN TablesDocumento7 pagineLWN TablesVipin NairNessuna valutazione finora

- Vibration Related Failures of Small Bore AttachmentsDocumento13 pagineVibration Related Failures of Small Bore AttachmentsJose PradoNessuna valutazione finora

- Excel VBA For Dummies. BonusChapter02Documento4 pagineExcel VBA For Dummies. BonusChapter02nick_giannNessuna valutazione finora

- A-18 Top HeadDocumento1 paginaA-18 Top HeadVipin NairNessuna valutazione finora

- Redlined DWGDocumento1 paginaRedlined DWGVipin NairNessuna valutazione finora

- Pressure Vessel MI Field TemplateDocumento1 paginaPressure Vessel MI Field TemplateVipin NairNessuna valutazione finora

- E Battery TanksDocumento8 pagineE Battery TanksVipin NairNessuna valutazione finora

- College Engineering Commencement TicketDocumento1 paginaCollege Engineering Commencement TicketVipin NairNessuna valutazione finora

- PVElite Installation MethodDocumento1 paginaPVElite Installation MethodadnaniaziNessuna valutazione finora

- 60CSTL H2SDocumento2 pagine60CSTL H2SVipin NairNessuna valutazione finora

- 05 Minor Moc SDR FormDocumento23 pagine05 Minor Moc SDR FormVipin NairNessuna valutazione finora

- 15CSTL NaDocumento3 pagine15CSTL NaVipin NairNessuna valutazione finora

- 30S316 H2SDocumento2 pagine30S316 H2SVipin NairNessuna valutazione finora

- CTLS Interface Developers GuideDocumento242 pagineCTLS Interface Developers GuideLucas Pires SimãoNessuna valutazione finora

- Hospital Building Civil ProjectDocumento128 pagineHospital Building Civil ProjectArun Ragu100% (6)

- To Civil Engineering: RoadsDocumento30 pagineTo Civil Engineering: Roadshemant kumarNessuna valutazione finora

- Abstract Substructure Conc - Frame Westgate RealDocumento4 pagineAbstract Substructure Conc - Frame Westgate RealTashamiswa MajachaniNessuna valutazione finora

- Ansaldo Thomassen - Flexible Service Agreements (2014)Documento4 pagineAnsaldo Thomassen - Flexible Service Agreements (2014)guerrezNessuna valutazione finora

- KSSR - MatematikDocumento6 pagineKSSR - MatematikFaris FarhanNessuna valutazione finora

- DevelopmentThatPays ScrumToScrumban CheatSheet 2 - 0Documento1 paginaDevelopmentThatPays ScrumToScrumban CheatSheet 2 - 0tarikNessuna valutazione finora

- Ticketreissue PDFDocumento61 pagineTicketreissue PDFnicoNicoletaNessuna valutazione finora

- Feature Setup Description: Software Basic Data Mcs - TCBCDocumento77 pagineFeature Setup Description: Software Basic Data Mcs - TCBCAlexis MauricioNessuna valutazione finora

- Floor ManualDocumento35 pagineFloor ManualGihan ChathurangaNessuna valutazione finora

- HRIS1Documento24 pagineHRIS1UMESH VINAYAK ARVINDEKARNessuna valutazione finora

- Sch40 80 ASTM A53Documento2 pagineSch40 80 ASTM A53Keshia Murillo PinnockNessuna valutazione finora

- Learjet 45 Pilot Traning Manual Volumen 2Documento539 pagineLearjet 45 Pilot Traning Manual Volumen 2Agustin Bernales88% (8)

- My Ideal Week PDFDocumento1 paginaMy Ideal Week PDFAnonymous QE45TVC9e3Nessuna valutazione finora

- By Himanshu Panwar Asst. Prof. Civil Engineering Department AkgecDocumento34 pagineBy Himanshu Panwar Asst. Prof. Civil Engineering Department AkgecAlok0% (1)

- Co-Ordinated By: DR Parul Presented By: DR GurneetDocumento45 pagineCo-Ordinated By: DR Parul Presented By: DR Gurneetreenujohney100% (2)

- Multipoint Socket Profile VW 010 43: KonzernnormDocumento4 pagineMultipoint Socket Profile VW 010 43: KonzernnormRicardo Vitoriano100% (1)

- Insulation ProductsDocumento1 paginaInsulation ProductsDygoPalNessuna valutazione finora

- Specialized Epic EVO 2021Documento3 pagineSpecialized Epic EVO 2021MTB-VCONessuna valutazione finora

- Side Wall SprinklerDocumento6 pagineSide Wall SprinklerLasandu WanniarachchiNessuna valutazione finora

- VF1 Technicalspecifications 031997 EN PDFDocumento43 pagineVF1 Technicalspecifications 031997 EN PDFelectricistNessuna valutazione finora

- 1989 Volvo 740 Instruments and ControlsDocumento107 pagine1989 Volvo 740 Instruments and Controlsskyliner538Nessuna valutazione finora

- Project: Water Supply Layout Finals Drawn By: 20141142805 Date: 10/11/2018 Sheet No. 1 of 2Documento1 paginaProject: Water Supply Layout Finals Drawn By: 20141142805 Date: 10/11/2018 Sheet No. 1 of 2Jabber Reyes AmborNessuna valutazione finora

- Restaurant Pub VIP Lounge Camp Pune SaleDocumento4 pagineRestaurant Pub VIP Lounge Camp Pune SaleChandrashekhar Naikare0% (1)

- Casing & Compressor of Air ConditionerDocumento22 pagineCasing & Compressor of Air ConditionerAbdullah Zakirin Abdul 'AzamNessuna valutazione finora

- ACEEE - Best Practices For Data Centres - Lessons LearnedDocumento12 pagineACEEE - Best Practices For Data Centres - Lessons LearnedtonybudgeNessuna valutazione finora

- Sustainable Energy and Resource ManagementDocumento318 pagineSustainable Energy and Resource ManagementRajdeepSenNessuna valutazione finora

- Text Programming Guide For iOSDocumento106 pagineText Programming Guide For iOSPetr MánekNessuna valutazione finora

- Pyxis SPT HepDocumento597 paginePyxis SPT HepanithaarumallaNessuna valutazione finora

- I2C Bus ManualDocumento51 pagineI2C Bus Manualapi-26349602100% (6)