Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

TotalValve 6820TRV PDF

Caricato da

Oswaldo GuerraTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

TotalValve 6820TRV PDF

Caricato da

Oswaldo GuerraCopyright:

Formati disponibili

6820 TR

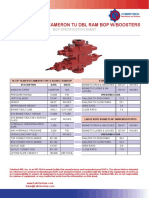

Model: 6820 TRV

A Patented Total Relief Valve System

Trusted Solutions for over 25 years

Total Relief Valve

Model 6820 TRV

6820 TRV

6820 TRV is our proprietary system to open or close a

valve at desired set pressure. This patented system

includes the TRV module, an actuator and an isolation

valve. The typical isolation valves are triple offset

butterfly valves due to the performance and durability.

This system allows the user to operate to within 1% to

3% of the desired set pressure of the valve. The relief

capacity is much greater than typical relief systems on

the market today which allows for lower overall system

costs. No external power is required for the device. It

is independent of system back pressure. When

coupled with a ball valve it offers the capability of

being pigged and provides the overpressure or

shutdown protection.

Sizes from 6 to 48 are available

with the 6820 TRV system

Flange Ratings: 150, 300, 600

Set Pressures : 3 psi to 1500 psi

Temperatures: -450F to 1500F

Accuracy: +/- 2% of set pressure

Meets API and ASME standards

Markets Served

Model 6820 TRV

6820-TRV-DP - Differential Pressure Model

6820-TRV-SP - Single Sensing Pressure Model

6820-TRV-XX - Custom Pressure Sensing Model

Gas Processing

Oil & Gas / Refining

Chemical Processing

Municipal Service

Nuclear Power

Midstream/Pipeline

Pulp & Paper Mills

Special Applications

*Patented

See our TRV video at TotalValve.com

Trusted Solutions for over 25 years

Proven system with the following components:

1 - TRV Module

6820 TRV

Our patented technology allows for complete control of valve set pressures (+/- 2%).

Set pressures can be adjusted. Key options for dual sensing lines and fluid media filters

provide industry leading system reliability. Suitable for severe service where dirt,

hydrates and high moisture levels occur in the fluid media.

2 - Triple-Offset valve - 6820 Model

Triple-offset valves deliver proven performance across the spectrum of temperature,

pressure and sealing classes. They operate from -450F to 1500F in accordance with

valve specifications. Non-rubbing seat design offers bubble tight sealing performance.

Options include all standard pressure classes.

3 - Actuation System with key system options

Proven pneumatic and hydraulic actuation systems are integrated to the valve and

TRV module. The modular design allows the use of special valve features including

accumulator tanks, thermal protection plugs and other devices according to customer

specifications.

Set Pressure Capability, Certification and Tolerance -

All 6820 TRVs are calibrated before

shipment to meet the users required set or differential pressure and tolerance with a set point reliability of +/-2%

Operating Pressure Ratio -

TRVs technology provides outstanding resistance to operating pressure conditions.

System performance is not impacted by system backpressures.

Pressure Cycling Service - This system has superior performance to pin type valves and rupture discs due to the

TRV modules advanced design. The system does not rely on a prediction of a material failure as in pin valves and rupture discs.

Installation - The TRV 6820 is designed for in line installation between pipe flanges. Each device is a full face design

with pipe flange bolting for lug, wafer and short pattern body configurations.

Field Testing and Resetting - The units field test connection port affords in-the-field testing. New settings can be

reset in the field if a desired set pressure change is required. The feature allows smoother start-ups and quicker resets (in less

than 3 seconds) when the device opens, versus the processes required for pin type valves or rupture discs.

Valve Activation - The 6820 TRV has two basic configurations the 6820 TRV-DP model for positive differential pressure

applications. The 6820 TRV-SP is the model for single positive sensing line pressure applications.

National Board Tested/ASME UD Certified

Total Valve Systems

1300 East Memphis

Broken Arrow, OK 74012

Capacity Certification, Valve Type:

TRV 6820 NB Cap Cert. No.: TVO-M00606

We design, manufacture and ship from our vertically

integrated 65,000 sq. ft. facility in Tulsa, Oklahoma.

VALVE WARRANTIES Standard Products and Services :

L6, Inc. d/b/a Total Valve Systems, hereinafter called Total Valve warrants as follows: (a) That each new Total Valve product and service is free from defects in

material and workmanship if installed and used in accordance with ASME and other accredited agency certifications. Any valve repair/service not performed

under ASME or accredited symbol has no implied or express warranty. (b) That each new Total Valve product and service is fit for the purpose for which similar

type product and services are ordinarily intended. Purchaser shall be solely responsible for determining suitability for use and in no event shall Total Valve be

liable in this respect.

DURATION The warranty period shall begin on the date of shipment to the first purchaser and extend for twelve (12) months.

EXCLUSIVE REMEDY Total Valve will repair or replace at its sole discretion, any product and service it finds to be defective under this warranty, upon return

of the product and service, prepaid, to Total Valve at 1300 East Memphis, Broken Arrow, Oklahoma 74012 or any warehouse designated by Total Valve. Such

repairs or replacements are clients exclusive remedy and Total Valve SHALL NOT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES RESULTING FROM BREACH OF THIS WRITTEN WARRANTY OR ANY IMPLIED WARRANTY OR ANY OTHER THEORY OR RECOVERY.

DISCLAIMER Total Valve excludes from this warranty failures due to corrosion, erosion, abrasion, cavitations, or other application related failures. Further, it is

the end users responsibility to account for environmental influences such as traffic, wind, earthquake or other external loadings, decomposition of unstable fluids,

simultaneous loadings or loadings due to fluid weight. There are no warranties that extend beyond the terms hereof and no one is authorized to assume for

TOTAL VALVE any other liability in connection with the sale of TOTAL product and services. This warranty supersedes all previous warranties.

CUSTOM VALVE WARRANTY (manufactured valves to customer specifications): Total Valve personnel shall perform the services in accordance with the

care, skill and diligence of applicable industry standards currently recognized as of the date of the execution of this agreement. Total Valve disclaims all other

warranties, presentations and statements, express or implied, statutory or otherwise. No oral or written information or advice given by Total Valve or its agents,

Representatives or employees, shall create a warranty or in any way increase the scope of these warranties and the client may not rely on any such information

or advice unless it is set forth in writing signed by an authorized officer of Total Valve.

Design: We reserve the right to make design changes without notice.

Trusted Solutions for over 25 years

Toll Free: 1.800.324.7035 Phone: 918.258.7035 Fax: 918.251.6426 Email: sales@totalvalve.com

1300 East Memphis Broken Arrow, Oklahoma 74012

www.totalvalve.com

Potrebbero piacerti anche

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryDa EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNessuna valutazione finora

- Model DUC-AUS: Dual Check ValvesDocumento2 pagineModel DUC-AUS: Dual Check ValvesWattsNessuna valutazione finora

- Prevention of Actuator Emissions in the Oil and Gas IndustryDa EverandPrevention of Actuator Emissions in the Oil and Gas IndustryNessuna valutazione finora

- Va18 Va19Documento59 pagineVa18 Va19joymotiNessuna valutazione finora

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideDa EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideValutazione: 4 su 5 stelle4/5 (8)

- Efcv PDFDocumento20 pagineEfcv PDFSudarshan ChandraNessuna valutazione finora

- Safety Relief ValvesDocumento52 pagineSafety Relief ValvesHamza NoumanNessuna valutazione finora

- The Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsDa EverandThe Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsValutazione: 3.5 su 5 stelle3.5/5 (14)

- X-Stream XS3 0406Documento20 pagineX-Stream XS3 0406akhileshkuniyilNessuna valutazione finora

- Diesel Engine Care and Repair: A Captain's Quick GuideDa EverandDiesel Engine Care and Repair: A Captain's Quick GuideValutazione: 5 su 5 stelle5/5 (1)

- Cartridge Valves CT 198974Documento312 pagineCartridge Valves CT 198974oleg-spb100% (2)

- LuoDocumento20 pagineLuohacenescribdNessuna valutazione finora

- Boat Mechanical Systems Handbook (PB): How to Design, Install, and Recognize Proper Systems in BoatsDa EverandBoat Mechanical Systems Handbook (PB): How to Design, Install, and Recognize Proper Systems in BoatsNessuna valutazione finora

- BirkettDocumento104 pagineBirkettscribdkhatnNessuna valutazione finora

- Hydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&ADa EverandHydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&ANessuna valutazione finora

- PRV ScenariosDocumento5 paginePRV Scenariosaugur886Nessuna valutazione finora

- Total Product CatalogueDocumento37 pagineTotal Product CatalogueFARIDNessuna valutazione finora

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1Da EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Valutazione: 3.5 su 5 stelle3.5/5 (3)

- Cylinder Pressure Transducer: Product UpdateDocumento2 pagineCylinder Pressure Transducer: Product UpdateJose Luis RattiaNessuna valutazione finora

- DBB CatalogueDocumento28 pagineDBB CatalogueHeri SetyantoNessuna valutazione finora

- LS-16 Sullair ManualDocumento112 pagineLS-16 Sullair Manualbinhleduc36100% (2)

- HT TT11Documento2 pagineHT TT11dungtran77Nessuna valutazione finora

- FMC Flowline Products and Services CatalogDocumento74 pagineFMC Flowline Products and Services Catalogisamelgq100% (1)

- Pressure Seal Valves-GateDocumento24 paginePressure Seal Valves-GateHieu NguyenNessuna valutazione finora

- FMC Flowline Products and Services 002Documento74 pagineFMC Flowline Products and Services 002Agustin ParadisoNessuna valutazione finora

- Severe Service Control Valves DetailsDocumento11 pagineSevere Service Control Valves DetailsAnupam A. GandhewarNessuna valutazione finora

- Sullivan-Palatek Industrial Air CompressorDocumento114 pagineSullivan-Palatek Industrial Air CompressorYahya BANessuna valutazione finora

- 11 Catalog-2017Documento29 pagine11 Catalog-2017chetan_thakur4278Nessuna valutazione finora

- K3VDocumento15 pagineK3VJacques Van Niekerk100% (14)

- EAMII0001 Axial Flow Valves 9710 7 032713ADocumento30 pagineEAMII0001 Axial Flow Valves 9710 7 032713AMisael Cardenas BarriosNessuna valutazione finora

- Gates CatalogDocumento170 pagineGates CatalogIasm1neNessuna valutazione finora

- Fluids Entry HBV Cetop 7 & 8 Series 101109Documento12 pagineFluids Entry HBV Cetop 7 & 8 Series 101109Enhtuwshin BarkhasbadiNessuna valutazione finora

- Product Specification VC25 SRV 12BDocumento6 pagineProduct Specification VC25 SRV 12BAnuradha SivakumarNessuna valutazione finora

- DO10 ValveDocumento6 pagineDO10 ValvetunradotNessuna valutazione finora

- Hydraulic Engine Control ManualtflexDocumento36 pagineHydraulic Engine Control ManualtflexJulie LafranceNessuna valutazione finora

- 2214Documento8 pagine2214Ken ArokNessuna valutazione finora

- 767FR/LF767FR Installation InstructionsDocumento2 pagine767FR/LF767FR Installation InstructionsFEBCONessuna valutazione finora

- Microsoft Word - SV - Part2Documento6 pagineMicrosoft Word - SV - Part2aftabulalamNessuna valutazione finora

- Goldcup Denison p24 - 01Documento72 pagineGoldcup Denison p24 - 01thierrylindo100% (1)

- 3-5400 SERIES Safety Relief Valves: Instruction ManualDocumento16 pagine3-5400 SERIES Safety Relief Valves: Instruction ManualPrashant ChauhanNessuna valutazione finora

- SRHDocumento2 pagineSRHTeree Sanches SaLazNessuna valutazione finora

- Hose Usage Guide PDFDocumento10 pagineHose Usage Guide PDFKaustav SahaNessuna valutazione finora

- Combining The Use of Rupture Discs With Relief ValvesDocumento6 pagineCombining The Use of Rupture Discs With Relief Valveskronaf100% (1)

- WT.050.200.001.UA - Im.0814 - Series 50-200 Evaporator ChlorineDocumento118 pagineWT.050.200.001.UA - Im.0814 - Series 50-200 Evaporator ChlorineSad LiveNessuna valutazione finora

- Training Program On: Pressure Relief ValveDocumento71 pagineTraining Program On: Pressure Relief ValveShoaib JadoonNessuna valutazione finora

- K3V K5V eDocumento15 pagineK3V K5V evyvy83Nessuna valutazione finora

- Tanque Presurizado de Acero Pro-Source Plus - Manual Del Propietario - 1000000173 - 2010 - PENTAIR WATER PDFDocumento24 pagineTanque Presurizado de Acero Pro-Source Plus - Manual Del Propietario - 1000000173 - 2010 - PENTAIR WATER PDFpevareNessuna valutazione finora

- Opw 2000 Series Installation ManualDocumento16 pagineOpw 2000 Series Installation ManualrubenNessuna valutazione finora

- Telide Safety Valve Test Bench Product BrochureDocumento28 pagineTelide Safety Valve Test Bench Product Brochuremahesh070Nessuna valutazione finora

- Rupture Pin BrochureDocumento12 pagineRupture Pin BrochureAlvi AliNessuna valutazione finora

- 7 Com PDFDocumento16 pagine7 Com PDFMarco AntonioNessuna valutazione finora

- ESD Valve Self Testing SystemDocumento24 pagineESD Valve Self Testing SystempcherukaraNessuna valutazione finora

- Senator LSV Series With Mam-660 ControllerDocumento64 pagineSenator LSV Series With Mam-660 ControllerRomanCHubaNessuna valutazione finora

- 7.06 EC 10M SINGLE BOP ManDocumento20 pagine7.06 EC 10M SINGLE BOP ManRafael BolivarNessuna valutazione finora

- Method Statement For Modifications in Low Power Circuit Breaker Ds-206S For New Compressor SystemsDocumento8 pagineMethod Statement For Modifications in Low Power Circuit Breaker Ds-206S For New Compressor SystemsJohn Philip BuntalesNessuna valutazione finora

- Quick Exh Valves 13QS1 Rev 0110Documento2 pagineQuick Exh Valves 13QS1 Rev 0110136339Nessuna valutazione finora

- SPFM 001 PDFDocumento1 paginaSPFM 001 PDFOswaldo GuerraNessuna valutazione finora

- Compressor Magazine March 2014 PDFDocumento97 pagineCompressor Magazine March 2014 PDFOswaldo GuerraNessuna valutazione finora

- Z Blokrefractoryfibremodulesenglish New PDFDocumento2 pagineZ Blokrefractoryfibremodulesenglish New PDFOswaldo GuerraNessuna valutazione finora

- Description: North America: +1 (0) 706 796 4200 / Asia: +65 (0) 6595 0000Documento2 pagineDescription: North America: +1 (0) 706 796 4200 / Asia: +65 (0) 6595 0000Oswaldo GuerraNessuna valutazione finora

- Honeywell Slate PDFDocumento136 pagineHoneywell Slate PDFOswaldo GuerraNessuna valutazione finora

- CD-0218 Car Tank DesignDocumento38 pagineCD-0218 Car Tank DesignOswaldo GuerraNessuna valutazione finora

- LV Line Burner MaxonDocumento44 pagineLV Line Burner MaxonOswaldo GuerraNessuna valutazione finora

- Case 1 e 002 D - H Rev 0Documento16 pagineCase 1 e 002 D - H Rev 0Oswaldo GuerraNessuna valutazione finora

- 461-DB02 Rev1Documento174 pagine461-DB02 Rev1Oswaldo GuerraNessuna valutazione finora

- Analisis of Stress in BellowsDocumento101 pagineAnalisis of Stress in BellowsOswaldo GuerraNessuna valutazione finora

- ASTM A182 Grade F22Documento2 pagineASTM A182 Grade F22Oswaldo GuerraNessuna valutazione finora

- Juntas Segun Ejma.20150301.12Documento10 pagineJuntas Segun Ejma.20150301.12Oswaldo GuerraNessuna valutazione finora

- Suction Line Strainers - BHDECat - WebDocumento1 paginaSuction Line Strainers - BHDECat - WebAzhar HussainNessuna valutazione finora

- Series 900 BrochureDocumento40 pagineSeries 900 BrochureLungisaniNessuna valutazione finora

- DFT Check Valve - Product SummaryDocumento4 pagineDFT Check Valve - Product Summaryvishal.nithamNessuna valutazione finora

- UDR-1 Excel FileDocumento5 pagineUDR-1 Excel FileshazanNessuna valutazione finora

- Etscc HRF Cable TrayDocumento2 pagineEtscc HRF Cable TrayLakshmi PNessuna valutazione finora

- Sizes: 4-Inch and Larger: Typical SetupDocumento4 pagineSizes: 4-Inch and Larger: Typical SetupMartin Andrade100% (2)

- Mechanical Engineering Design Criteria PDFDocumento44 pagineMechanical Engineering Design Criteria PDFadca100% (1)

- FAS Produk LPGDocumento10 pagineFAS Produk LPGYogi MaulanaNessuna valutazione finora

- Moment Connection - Flush End Plate-19.01.06Documento48 pagineMoment Connection - Flush End Plate-19.01.06kalpanaadhi83% (6)

- Saudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingDocumento12 pagineSaudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingAnonymous 4e7GNjzGWNessuna valutazione finora

- Class P15A6Documento7 pagineClass P15A6SalimNessuna valutazione finora

- (5.h.53.a) PROMAG 55S Operation Manual PDFDocumento118 pagine(5.h.53.a) PROMAG 55S Operation Manual PDFnovtechNessuna valutazione finora

- Sitrans FX300Documento80 pagineSitrans FX300Fredy Rojas BarraNessuna valutazione finora

- Albion Valves Product Price List 2017 PDFDocumento60 pagineAlbion Valves Product Price List 2017 PDFtridata triNessuna valutazione finora

- Peco Gas Scrubber Fs 85 SL 01Documento4 paginePeco Gas Scrubber Fs 85 SL 01Rigoberto LozanoNessuna valutazione finora

- Mechanical Valves & Flexible Joints: Leading The Way in Piping NeedsDocumento40 pagineMechanical Valves & Flexible Joints: Leading The Way in Piping NeedsTanveer AzizNessuna valutazione finora

- Parts Manual Compressor Model P425WIR, XP375WIR, HP375WIR, VHP300WIRDocumento157 pagineParts Manual Compressor Model P425WIR, XP375WIR, HP375WIR, VHP300WIRVicctor Piña100% (3)

- Piping Valve Specifications: Company Technical StandardDocumento27 paginePiping Valve Specifications: Company Technical StandardrameshqcNessuna valutazione finora

- H12 M-10 H12 MV-10: Data SheetDocumento4 pagineH12 M-10 H12 MV-10: Data SheetDirceu ValadaresNessuna valutazione finora

- Asme B31.8Documento8 pagineAsme B31.8deepndeepsi100% (1)

- Pressure Measurement Part2Documento7 paginePressure Measurement Part2salemNessuna valutazione finora

- Kemper DistributionDocumento16 pagineKemper Distributionerminhusagic2308Nessuna valutazione finora

- Pressure Vessel Itp PDFDocumento4 paginePressure Vessel Itp PDFkorbelNessuna valutazione finora

- BLACKMER PD PumpsDocumento8 pagineBLACKMER PD PumpsrasottoNessuna valutazione finora

- Flange Management Procedure IFUDocumento32 pagineFlange Management Procedure IFUMarvan Audy Buriko100% (1)

- Starline VALVESDocumento16 pagineStarline VALVESmanmohansingh1999Nessuna valutazione finora

- Best Practice Bolting FMDocumento11 pagineBest Practice Bolting FMAlfonsus W.M.Nessuna valutazione finora

- 18.750 10000 Cameron Double Ram Bop Lbs Bonnets Spec SheetDocumento1 pagina18.750 10000 Cameron Double Ram Bop Lbs Bonnets Spec SheetJoel SNessuna valutazione finora

- Cable Lugs Bonding WireDocumento3 pagineCable Lugs Bonding WireJwalaNessuna valutazione finora

- API 570 Certification Module #1 Homework Open Book: Terms in This SetDocumento4 pagineAPI 570 Certification Module #1 Homework Open Book: Terms in This SetNIMANessuna valutazione finora

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionDa EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionValutazione: 4.5 su 5 stelle4.5/5 (3)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedDa EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedValutazione: 5 su 5 stelle5/5 (1)

- The Laws of Thermodynamics: A Very Short IntroductionDa EverandThe Laws of Thermodynamics: A Very Short IntroductionValutazione: 4.5 su 5 stelle4.5/5 (10)

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterDa EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterNessuna valutazione finora

- Bulk Material Handling: Practical Guidance for Mechanical EngineersDa EverandBulk Material Handling: Practical Guidance for Mechanical EngineersValutazione: 5 su 5 stelle5/5 (1)

- Machinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionDa EverandMachinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionNessuna valutazione finora

- Electric Motor Control: DC, AC, and BLDC MotorsDa EverandElectric Motor Control: DC, AC, and BLDC MotorsValutazione: 4.5 su 5 stelle4.5/5 (19)

- Well Integrity for Workovers and RecompletionsDa EverandWell Integrity for Workovers and RecompletionsValutazione: 5 su 5 stelle5/5 (3)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisDa EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisValutazione: 4 su 5 stelle4/5 (2)

- Electric Motors and Drives: Fundamentals, Types and ApplicationsDa EverandElectric Motors and Drives: Fundamentals, Types and ApplicationsValutazione: 4.5 su 5 stelle4.5/5 (12)

- Chasing the Demon: A Secret History of the Quest for the Sound Barrier, and the Band of American Aces Who Conquered ItDa EverandChasing the Demon: A Secret History of the Quest for the Sound Barrier, and the Band of American Aces Who Conquered ItValutazione: 4 su 5 stelle4/5 (25)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesDa EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesValutazione: 4.5 su 5 stelle4.5/5 (21)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialDa EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNessuna valutazione finora

- Building Energy Management Systems and Techniques: Principles, Methods, and ModellingDa EverandBuilding Energy Management Systems and Techniques: Principles, Methods, and ModellingNessuna valutazione finora

- Basic Digital Signal Processing: Butterworths Basic SeriesDa EverandBasic Digital Signal Processing: Butterworths Basic SeriesValutazione: 5 su 5 stelle5/5 (1)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ADa EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANessuna valutazione finora

- Safety Theory and Control Technology of High-Speed Train OperationDa EverandSafety Theory and Control Technology of High-Speed Train OperationValutazione: 5 su 5 stelle5/5 (2)

- The Journeyman Electrician Exam Study Guide: Proven Methods for Successfully Passing the Journeyman Electrician Exam with ConfidenceDa EverandThe Journeyman Electrician Exam Study Guide: Proven Methods for Successfully Passing the Journeyman Electrician Exam with ConfidenceNessuna valutazione finora

- A Practical Handbook for Drilling Fluids ProcessingDa EverandA Practical Handbook for Drilling Fluids ProcessingNessuna valutazione finora

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseDa EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseValutazione: 4.5 su 5 stelle4.5/5 (51)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentDa EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentValutazione: 4.5 su 5 stelle4.5/5 (21)

- Laminar Flow Forced Convection in Ducts: A Source Book for Compact Heat Exchanger Analytical DataDa EverandLaminar Flow Forced Convection in Ducts: A Source Book for Compact Heat Exchanger Analytical DataNessuna valutazione finora

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsDa EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsValutazione: 3.5 su 5 stelle3.5/5 (3)

- Air Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&ADa EverandAir Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&ANessuna valutazione finora

- Cyber-Physical Systems: Foundations, Principles and ApplicationsDa EverandCyber-Physical Systems: Foundations, Principles and ApplicationsHoubing H. SongNessuna valutazione finora