Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Civil Engineering Project On Mini Civil Station

Caricato da

MahaManthraDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Civil Engineering Project On Mini Civil Station

Caricato da

MahaManthraCopyright:

Formati disponibili

1

Project Report 2012

Mini Civil Station at Chittur

1. INTRODUCTION

The urban society lures people with better job opportunities and better

standard of living resulting in population explosion and scarcity of habitable

space. The construction of multi-storied building will help to incorporate

various building of some nature under the same shelter to serve a common

purpose. The vertical growth of buildings also helps to save a large area of

land also the various offices which come under the Taluk Office, Chittur are

situated in different parts of the taluk. There are many other govt. offices in

Chittur which functioned in rented buildings, so all these officer can be

incorporated in a single building called Mini Civil Station Chittur, so that the

public an avail all the services from a common civic centre.

Dept of Civil Engineering

College, Palakkad

Govt Polytechnic

Project Report 2012

Mini Civil Station at Chittur

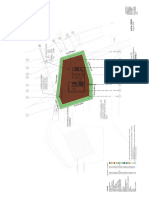

2. LOCATION

The proposed site is situated in near the existing sub-court Chittur. It is near

by the Chittur-Gopalapuram-Pollachiroad, 15KM away from the Palakkad

town. The proposed office complex has a north orientation facing the ChitturGopalapuram-Pollachi highway.

Dept of Civil Engineering

College, Palakkad

Govt Polytechnic

Project Report 2012

Dept of Civil Engineering

College, Palakkad

Mini Civil Station at Chittur

Govt Polytechnic

Project Report 2012

Mini Civil Station at Chittur

TOPOGRAPHY

The site is having a plane topography.

SOIL CHARACTERISTICS

Soil stratum in the region is uniform.

FUTURE NEEDS

The mini civil station Chittur is in order to incorporate all the govt.

offices in Chittur under one shelter. So this will help the people of Chittur to

get things done easily and speedily.

Dept of Civil Engineering

College, Palakkad

Govt Polytechnic

Project Report 2012

Mini Civil Station at Chittur

3. DATA COLLECTION

GENERAL

The information regarding the proposed building was obtained

from the Executive Engineer-P.W.D-Palakkad. And Assistant-Executive

Engineer, Palakkad surveyand got rough idea about the site and

surroundings. Then for getting the detailed site plan filed survey were

conducted. Along with this to get information regarding soil characteristics,

soil investigation is done.

RECONNAISSANCE SURVEY

It is process the preliminary inspection of area to be surveyed. In

this we should not the boundaries, the position of building, road etc.

After completion of the reconnaissance a rough sketch is prepared

which is known as index sketch or key plan. The key plan shows the position

of salient features on the ground such as buildings, roads, boundaries with

respect to north direction.

PREPARATION OF SITE PLAN

After completing the key plan, the process chain survey is done

and the site plan is prepared.

Dept of Civil Engineering

College, Palakkad

Govt Polytechnic

Project Report 2012

Mini Civil Station at Chittur

ORIENTATION

The planning of the building with respect to the geographical

direction of wind and azimuth, of sun is known as orientation of building.

The building should be placed to attain maximum benefit from same air and

nature and the same time it is protected from their harmful effect. In towns

orientation of building is decided on various factor like the position and

direction of steeds and position of gardens and parks, the shape and size of

the plot of land etc. in such cases the orientation should be fixed with respect

to the frontage of building only.

Dept of Civil Engineering

College, Palakkad

Govt Polytechnic

Project Report 2012

Mini Civil Station at Chittur

4. DATA SURVEY

Total number of offices to be provided

= 9 Nos. 3EF

Total number of staff calculated

= 145 Nos.

Gazette Officers

= 13 Nos.

Non Gazette Officers

= 132 Nos.

Canteen

= 1 No.

Toilet and A/c

= 3 sets/E

Area required for G.O

Office

= 14.86 m2

Toilet

= 1.5 m2

Area required for N.G.O

Office

= 3.72 m2 /E

Records

= 0.37 m2

Dining

= 0.46m2/Each Office

Toilet

Male

= 1.5 m2

Female

= 1.5 m2

Urinal

Male

= 1.5 m2

Female

= 1.5 m2

Dept of Civil Engineering

College, Palakkad

Govt Polytechnic

Project Report 2012

Mini Civil Station at Chittur

5. SPACE REQUIREMENTS

Sl. No.

Name of office

Space required

Space provided

1.

Taluk Industries

40.05 m2

47.50 m2

2.

Taluk Supply Office

90.14 m2

99.75 m2

76.47 m2

80.75 m2

3.

4.

Town Employment Exchange

44.61 m2

47.50 m2

5.

Taluk Statical

90.14 m2

99.75 m2

6.

A.R.CO.OP (G) Chittur

76.47 m2

80.75 m2

7.

Sub R.T.O, Chittur

71.92 m2

79.75 m2

8.

Asst.Director-Agricultural

44.61 m2

47.50 m2

9.

Soil Conservation

94.68 m2

99.75 m2

10.

Food Inspector

35.50 m2

49.75 m2

11.

A.R.CO.OP (A), Chittur

80.01 m2

80.75 m2

12.

A.E.O, Chittur

71.92 m2

79.75 m2

Dept of Civil Engineering

College, Palakkad

Govt Polytechnic

Project Report 2012

Mini Civil Station at Chittur

6. STRUCTURAL DESIGN

Dept of Civil Engineering

College, Palakkad

Govt Polytechnic

Project Report 2012

Dept of Civil Engineering

College, Palakkad

10

Mini Civil Station at Chittur

Govt Polytechnic

Project Report 2012

Dept of Civil Engineering

College, Palakkad

11

Mini Civil Station at Chittur

Govt Polytechnic

12

Project Report 2012

Mini Civil Station at Chittur

A. ABBREVIATIONS USED

A

= Area

= Overall depth of beam or slab

= Effective depth of beam or slab

Ld

= Development length

Ix

= Length of shorter side of slab

Iy

= Length of longer side of slab

= Bending moment

= Modular ratio

= Spacing of stirrups

= Torsional moment

= Shear force

cbc

= Permissible stress in concrete

st

= Permissible stress in steel

Ast

= Area of tension steel

= Leverarm constant

bf

= Effective width of flange

bw

= Breadth of web

Df

= Thickness of flange

= Total load

= Modulus of section

= Shear stress in concrete

c max

= Maximum shear stress in concrete

= Normal shear stress

= Diameter of the bar

B. ROOF SLAB S1

Dept of Civil Engineering

College, Palakkad

Govt Polytechnic

13

Project Report 2012

Mini Civil Station at Chittur

Wall thickness

= 24 cm

Size of room

= 9.5 x 5.00 m

Height of room

= 3.60 m

Grade of concrete

= M20

Grade of steel

= Fe415

PROPERTIES OF THE SECTION

cbc

= 7 N/mm2

st

= 230 N/mm2

= 13.3

= 0.904 d

= 0.914 bd2

Basic value of l/d ratio

= 32

Assume a modification factor

= 1.6

Approximate effective depth required

= 4870 / (32 x 1.6)

= 95.20

Provide an effective depth of 105mm and an overall depth of 125mm

EFFECTIVE SPAN

C/C distance of supports

= 4.87 & 5.24 m

Width of support

= 0.24 m

Clear span

= 4.87 0.24

= 4.63 m

= 5.24 0.24

= 5.00 m

lx

= 4.63 + 0.105

= 4.735 m

Ly

= 5.00 + 0.105

= 5.105 m

= 5.105/4.735

= 1.10 <2

Effective span,

Ly / lx ratio

Hence two way slab

LOADS

Live load

= 1.5 KN/m2

Weight of weathering course

= 1.5 KN/m2

Dept of Civil Engineering

College, Palakkad

Govt Polytechnic

14

Project Report 2012

Mini Civil Station at Chittur

Self weight of slab

= 1x 0.125 x 25

Total load, W

= 6.125 KN/m2

= 3.125 KN/m2

DESIGN OF PANEL-1

In panel 1, three edges are continuous and one short edge

is discontinuous

Bending moment :Consider 1m width of middle strips

+mx

= x x W x lx2

= 0.032 x 6.125 x 4.7352

= 4.39 KNm

-my

= x x W x lx2

= 0.043 x 6.125 x 4.7352

= 5.90 KNm

+mx

= y x W x lx2

= 0.028 x 6.125 x 4.7352

= 3.84 KNm

-my

= y x W x lx2

= 0.037 x 6.125 x 4.7352

= 5.08 KNm

Depth required for strength :Z

= 0.904d

M.R

Effective depth required

= 0.914bd2

5.90 x 106

0.914 x 1000

Eff depth, d provide

= 80.34mm

= 105mm > 80.34 mm

Hence O.K

Middle strip reinforcement :Using 8mm bars with a clear cover of 16mm,

Dept of Civil Engineering

College, Palakkad

Govt Polytechnic

Project Report 2012

15

Mini Civil Station at Chittur

Effective depth available in longer span

= 125-16-4

= 105mm

Effective depth available in shorter span

= 105-8

= 97mm

Width of middle strip in longer span

= x 5.24

= 3.93m

Width of middle strip in shorter span

= x 4.87

= 3.65m

Longer span:

Ast required at midspan

= 3.84 x 106

_____________

230 x 0.904 x 97

Ast required at support

= 190.39mm2

= 5.08 x 106

_____________

230 x 0.904 x 97

= 251.88mm2

Shorter span:

Ast required at midspan

= 4.39 x 106

_____________

230 x 0.904 x 105

Ast required at support

= 201.08mm2

= 5.90 x 106

_____________

230 x 0.904 x 105

Minimum area of steel to be provided

= 270.25mm2

= 0.12/100 x 1000 x 125

= 150 mm2

Spacing:Longer span:

Spacing at middle

= 50 x 1000 x 190.39

= 262.60mm

= Say 260mm

Spacing at support

= 50 x 1000/251.88

= 198.49mm

= Say 195mm

Shorter span:

Dept of Civil Engineering

College, Palakkad

Govt Polytechnic

Project Report 2012

Spacing at middle

16

Mini Civil Station at Chittur

= 50 x 1000/201.08

= 248.60mm

= Say 245mm

Spacing support

= 50 x 1000/270

= 185.18mm

= Say 185mm

Edge strip reinforcement:Area of steel required for edge strip

= 150 mm2

Spacing of 8mm bars

= 50 x 1000/150

= 333mm

= Say 330mm

Maximum permitted spacing

= 450mm

DESIGN OF PANEL 2

In panel-2, two adjacent sides are discontinuous.

Bending moment:Consider 1m width of middle strips

+mx

= x x W x lx2 = 0.040 x 6.125 x 4.7352

= 5.49 KNm

-my

= x x W x lx2 = 0.053 x 6.125 x 4.7352

= 7.23 KNm

+mx

= y x W x lx2 = 0.035 x 6.125 x 4.7352

= 4.81 KNm

-my

= y x W x lx2 = 0.047 x 6.125 x 4.7352

= 6.45 KNm

Middle strip reinforcement :Longer span:

Ast required at midspan

Dept of Civil Engineering

College, Palakkad

= 4.81 x 106

Govt Polytechnic

Project Report 2012

17

Mini Civil Station at Chittur

_____________

230 x 0.904 x 97

Ast required at support

= 238.49mm2

= 6.45 x 106

_____________

230 x 0.904 x 97

= 319.86mm2

Shorter span:

Ast required at midspan

= 5.49 x 106

_____________

230 x 0.904 x 105

Ast required at support

= 251.47mm2

= 7.23 x 106

_____________

230 x 0.904 x 105

Minimum area of steel to be provided

= 331.17mm2

= 0.12/100 x 1000 x 125

= 150 mm2

Spacing:Longer span:

Spacing at middle

= 50 x 1000 x 238.49

= 209.65mm

= Say 205mm

Spacing at support

= 50 x 1000/319.81

= 156.3mm

= Say 155mm

Shorter span:

Spacing at middle

= 50 x 1000 x 51.47

= 209.65mm

= Say 205mm

Dept of Civil Engineering

College, Palakkad

Govt Polytechnic

18

Project Report 2012

Spacing at support

Mini Civil Station at Chittur

= 50 x 1000/331.17

= 154.96mm

= Say 150mm

Edge strip reinforcement:Area of steel required for edge strip

= 150 mm2

Spacing of 8mm bars

= 50 x 1000/150

= 333mm

= Say 330mm

Torsion reinforcement :Corners having two discontinuous edges,

Size of reinforcement mesh

= 0.2 lx

= 0.2 x 4.735 = 0.947m

Area of steel req. at midspan of middle strip

= 251.47mm2

Area of steel req./ one layer of torsion reinforcement 75%

= x 251.47 x 0.947

Number of 6mm bars/layer

= 178.60mm2

= 178.60/28

= 7 Nos.

Provide 4 layers of 6Nos x 6mm bars at corners having two discontinuous edges.

Check for stiffness :Area of steel provided at midspan of shorter span.

% of steel

= 195

_______

50 x 1000

= 256.41mm2

= 256.41 x 100

= 0.24%

_____________

1000 x 105

M.F

= 1.50

Effective depth required

B.V = 32

= 4735/ (32 x 1.5)

= 98.64mm

Dept of Civil Engineering

College, Palakkad

Govt Polytechnic

19

Project Report 2012

Effective depth provided, d

Mini Civil Station at Chittur

= 105mm>98.64mm, Hence O.K

Wall thickness

= 24 cm

Size of room

= 10.4 x 9.50 m

Height of room

= 3.60 m

Grade of concrete

= M20

Grade of steel

= Fe415

PROPERTIES OF THE SECTION

cbc

= 7 N/mm2

st

= 230 N/mm2

= 13.3

= 0.904 d

= 0.914 bd2

SIDE RATIO

The side ratio of each panel

= 9.5/3.467

= 2.74>2

This slab is designed as continuous one way slab

DEPTH REQUIRED FOR STIFFNESS

C/C distance of supports

= 3.467m

Basic value

= 26

M.F

= 1.4

Approx. effective depth req. = 3467/ (26 x 1.4) = 95.24mm

Provide overall depth of 125mm and effective depth 105mm

EFFECTIVE SPAN

Width of supports

= 240mm

Clear span/12

= 268.9mm

Width of support < clearspan/12

240 <268.9mm

Effective span is the least of,

1. Clear span + effective depth

Dept of Civil Engineering

College, Palakkad

= 3.467 + 0.015

= 3.572m

Govt Polytechnic

20

Project Report 2012

2. C/C distance of supports

Mini Civil Station at Chittur

= 3.467 + 0.24

= 3.707m

Effective span

= 3.57m

LOADS

Consider 1m width of slab,

Live load

= 1.5 KN/m2

Weight of weathering course

= 1.5 KN/m2

Self weight of slab

= 1 x 0.125 x 25

Total load, W

= 6.125 KN/m2

= 3.125 kN/m2

MAXIMUM B.M

WL2 /10 WL2/9

= 1.5 X 3.572/10 4.625 X 3.572/9

= 8.45 KNm

DEPTH REQUIRED FOR STRENGTH

Z

= 0.904d

Effective depth required

M.R

= 0.914bd2

8.45 x 106

0.914 x 1000 = 96.15mm

Eff depth , d provided

= 105mm > 96.15

Hence O.K

DESIGN BENDING MOMENT

1.B.M near middle of end span

= M1

= 4.625 x 3.572/12 + 1.5 x 3.572/10

= 6.82 KNm

2. B.M at middle of interior span

= M2

= 4.625 x 3.572/24 + 1.5 x 3.572/12

= 4.04 KNm

3. B.M at support next to end support

= M3

= 1.5 x 3.572/10-4.625 x 3.572/9

= 8.45 KNm

2. B.M at interior support

= M4

= 4.625 x 3.572/24 - 1.5 x 3.572/9

= 7.03 KNm

Dept of Civil Engineering

College, Palakkad

Govt Polytechnic

21

Project Report 2012

Mini Civil Station at Chittur

MAIN REINFORCEMENT

Minimum area of steel provided

= 0.15 x 1000 x 125

____

100

= 187.5mm2

Area of steel Ast1

= 6.82 x 106

_________

230 x 0.904 x 105

Area of steel Ast2

4.04 x 106

_________

230 x 0.904 x 105

Area of steel Ast3

= 387.05mm2

7.03 x 106

_________

230 x 0.904 x 105

Area of steel Ast5

= 185.05mm2

8.45 x 106

_________

230 x 0.904 x 105

Area of steel Ast4

= 312.39mm2

= 322.01mm2

3.25 x 106

_________

230 x 0.904 x 105

= 148.98mm2

S1

= 50 X 1000/312.39

= 160mm c/c

S2

= 50 X 1000/185.05

= 270mm c/c

S3

= 50 X 1000/387.05

= 125mm c/c

S4

= 50 X 1000/322.01

= 155mm c/c

S5

= 50 X 1000/148.98

= 315mm c/c

SPACING OF MAIN BARS

DISTRIBUTORS

Area of steel required (0.12%)

Dept of Civil Engineering

College, Palakkad

= 0.12 x 1000 x 125

_____

100

= 150 mm2

Govt Polytechnic

22

Project Report 2012

Mini Civil Station at Chittur

Spacing of 8mm bars = 50 x 1000/150

Maximum permitted spacing

= 333.33

= 5d or 450mm

Provide 8mm Fe415 distributors at 330mm c/c

CHECK FOR SHEAR

Maximum S.F at the outer side of support next to end support,

V = 0.6 Wdl + 0.6Wsl

= 0.6 x 3.57 (3125+3000)

= 13119.75KN

Nominal stress, v

= 13119.75

_________

1000 x 105

Minimum value of v

= 0.24

= 0.17

Hence O.K

CHECK FOR STIFFNESS

% Steel

= 100As

______

bd

13119.75

_________

1000 x 105

M.F

= 1..42

Mid span Ast

= 50 x 1000/160

Effective depth req. for stiffness

= 0.29%

= 312.5mm2

= 3.57

______

26 x 1.42

= 96.69 mm2

Effective depth provided 105> 96.69mm

Hence O.K

Dept of Civil Engineering

College, Palakkad

Govt Polytechnic

Project Report 2012

Dept of Civil Engineering

College, Palakkad

23

Mini Civil Station at Chittur

Govt Polytechnic

Project Report 2012

Dept of Civil Engineering

College, Palakkad

24

Mini Civil Station at Chittur

Govt Polytechnic

Project Report 2012

Dept of Civil Engineering

College, Palakkad

25

Mini Civil Station at Chittur

Govt Polytechnic

26

Project Report 2012

Mini Civil Station at Chittur

C. T BEAM UNDER ROOF SLAB

SIZE OF BEAM

Clear span

= 5000mm

Span/12

= 5000/12

= 416.67mm

Span/15

= 5000/15

= 333.33mm

The overall depth may be assumed as 410mm and

effective depth 370mm

Thickness of slab, Df

= 125mm

Depth of web

= 410 125

Assume, Breadth of the web

= 205mm

= 285mm

LOAD / METRE LENGTH OF BEAM

Since the beam are spaced at 4.87m centre. One metre length

Of beam carries load transferred from 4.87 m2 area of slab

Live load from slab

= 1.5 x 4.87

= 7.305KN

Weight of slab

= 4.87 x 0.125 x 25

= 15.22KN

Weight of weathering coarse

= 1.5 x 4.87

= 7.305KN

Self weight of web

= 0.205 x 0.285 x s 25= 1.710KN

Total

= 31.54KN/m

EFFECTIVE SPAN

Effective depth of beam is greater than the width of supports,

Effective span of the beam is

= C/C distance of supports

= 5.00 + 0.24

= 5.24m

DESIGN B.M

Maximum B.M midspan = Wl2/8

M = 31.54 x 5.242/8

= 108.25 x 106 Nmm

APPROXIMATE LEVER ARM

Z = Assume

= 0.9d

Z = 0.9 x 370

= 333mm

APPROXIMATE AREA OF STEEL

Dept of Civil Engineering

College, Palakkad

Govt Polytechnic

27

Project Report 2012

Approximate tension steel required

Mini Civil Station at Chittur

=

M

st x Zapp

= 108.25 x 106

230 x 333

= 1413.36 mm2

= 1570 mm2

Provide 5 Nos of 20mm bar

EFFECTIVE WIDTH OF FLANGE

bf

= 10/ 6+bw + 6Df

= 5240/6 + 205 + 6 x 125

= 1828.33mm

ACTUAL N.A

Moment of flange area about its bottom

= 1828.33 x 125 x125/2

= 14.28 x 106

Modular ratio, m

= 13.3

Moment of equivalent steel area about the bottom of flange,

= 13.3 x 1570 x 45

= 5.11 x 106 KNm

The moment of flange area is more the neutral axis lies with in the flange.

Taking moments of area about the N.A

= 1828.33/2 x2a

= 13.3 x 1570 (370-xa)

= 914 x2a

= 7725970 20881 xa

= xa

= 81.22mm

ACTUAL LEVER ARM

Lever arm,

= 370 81.22/3

= 342.43mm

STRESS IN CONCRETE

Actual compressive stress in concrete and tensile stress in steel cbc

And st respectively.

= bf.xa/2 . cbc .z

=M

= 1828.33/2 x 81.22 x cbc x 342.93

= cbc

Dept of Civil Engineering

College, Palakkad

= 108.25 x 106

= 2 x 108.25 x106

1828.33 x 81.22 x 342.93

Govt Polytechnic

28

Project Report 2012

Mini Civil Station at Chittur

= cbc

= 4.25N/mm2

cbc = 4.25 < 7 N/mm2 ,

Hence O.K

STRESS IN STEEL

= Ast . st . z = M

= st

=M

Ast . z

= 108.25 x 106

1570 x 342.93

= st

= 201.1N/mm2

st = 201.1 < 230 N/ mm2

CHECK FOR STIFFNESS

B.V

= 20

% Tension reinforcement

= 1570 x 100

1828.33 x 370

M.F

= 1.85

Web width /Flange width

= 205 / 1828.33

Reduction factor

= 0.76

Effective depth required for stiffness

= 5240

20 x 1.85 x 0.76

Provide effective depth, d

= 370> 186.34mm,

= 0.23%

= 0.112

= 186.34mm

Hence O.K

D. T- BEAM UNDER FLOOR SLAB

Dept of Civil Engineering

College, Palakkad

Govt Polytechnic

29

Project Report 2012

Mini Civil Station at Chittur

SIZE OF BEAM

Clear span

= 5240mm

Span/12

= 5000/12

= 436mm

Span/15

= 5000/15

= 349mm

The overall depth may be assumed as 435mm and

effective depth 395mm

Thickness of slab Df

= 135mm

Depth of web

=435 135

Assume, Breadth of the web

= 300mm

= 240mm

LOAD / METRE LENGTH OF BEAM

Since the beam are spaced at 4.87m centre. One metre length

of beam carries load transferred from 4.87 x 1

= 4.87m2 area of slab

Live load from slab

= 3.0 x 4.87

= 14.61KN

Weight of slab

= 4.87 x 0.135 x 25

= 16.44KN

Weight of floor finish

= 1.0 x 4.87

= 4.870KN

Self weight of web

= 0.300 x 0.240 x 25 = 1.800KN

Total

= 37.72KN/m

EFFECTIVE SPAN

Effective depth of beam is greater than the width of supports,

Effective span of the beam is

= C/C distance of supports

= 5.24 + 0.24

= 5.48m

DESIGN B.M

Maximum B.M at midspan

= Wl2 / 8

M = 37.72 x 5.482 /8

= 141.59 x 106 Nmm

APPROXIMATE LEVER ARM

Z = Assume

= 0.9d

Z = 0.9 x 395

= 355.50mm

APPROXIMATE AREA OF STEEL

Approximate tension steel required

M

st x Zapp

= 141.59 x 106

Dept of Civil Engineering

College, Palakkad

Govt Polytechnic

30

Project Report 2012

Mini Civil Station at Chittur

230 x 355.5

= 1835 mm2

= 1884mm2

Provide 6 Nos of 20mm bar

EFFECTIVE WIDTH OF FLANGE

bf

= 10 /6+bw + 6Df

= 5480 / 6 +240 +6 x 135

= 1963mm

ACTUAL N.A

Moment of flange area about its bottom = 1963 x 135 x135 /2

= 17.89 x 106

Modular ratio, m

= 13.3

Moment of equivalent steel area about the bottom of flange,

= 13.3 x 1884 x 260

= 6.51 x 106 KNm

The moment of flange area is more the neutral axis lies with in the flange.

Taking moments of area about the N.A

= 1963/2 x2 a

= 13.3 x 1884 (395-xa)

= 981.5 x2 a

= 9897594 25057.2 xa

= xa

= 88.46mm

ACTUAL LEVER ARM

Lever arm,

= 395 88.46/3

= 365.51mm

STRESS IN CONCRETE

Actual compressive stress in concrete and tensile stress in steel cbc

And st respectively.

= bf . xa/2 . cbc . z

=M

= 1963/2 x 88.46 x cbc x 365.51

= cbc

= 141.59 x 106

= 2 x 141.59 x 106

1963 x 88.46 x 365.51

= cbc

= 4.46 N/mm2

cbc = 4.46 < 7 N/ mm2, Hence O.K

Dept of Civil Engineering

College, Palakkad

Govt Polytechnic

31

Project Report 2012

Mini Civil Station at Chittur

STRESS IN STEEL

= Ast . st. z = M

= st

= M

Ast.z

= 141.59 x 106

1884 x 365.51

= 205.61 N/mm2

= st

CHECK FOR STIFFNESS

B.V

= 20

% Tension reinforcement

= 1884 x 100

1963 x 370

M.F

= 1.55

Web width ? Flange width

= 240 / 1963

Reduction factor

= 0.76

Effective depth required for stiffness

= 5480

= 0.26%

= 0.12

20 x 1.55 x 0.76

Provide effective depth, d

Dept of Civil Engineering

College, Palakkad

= 395> 232.60mm ,

= 232.60mm

Hence O.K

Govt Polytechnic

Project Report 2012

Dept of Civil Engineering

College, Palakkad

32

Mini Civil Station at Chittur

Govt Polytechnic

Project Report 2012

33

Mini Civil Station at Chittur

E. DESIGN OF STAIR

Assume width of flight

= 1.50m

Height up to middle landing

= 1.80m

Rise

= 150mm

Tread

= 300mm

No. of riser

= 1800/150

No. of tread

= 12 1 = 11 Nos

Assume support beams

= 300 x 300mm

= 12 Nos

EFFECTIVE SPAN

Horizontal distance c/c of beams

= 11 300 300

= 3.00m

Effective width of waist slab,

Since on of the edge of the slab is embedded in to the wall for a

length of 120mm.

Effective width of waist slab

= 1500 + 75

= 1575mm

Width of loaded area

= 1500 150

= 1350mm

Live load

= 5000 x 1.35 x 1

= 6750 N/m

Weight of step

= 1000/30 x 1/12 x 0.3 x 0.15 x 19000

LOADS

Consider full width of slab,

= 2137.5 N/m

Assume the thickness of waist as span in metres 50mm,

i.e,

= 3.00 x 50

= 150mm

Weight of waist slab,metre inclined length = 1.5 x 0.15 x 1 x 25000

= 5625 N

Weight of waist slab /metre horizontal length = 5625 3002 + 1502

300

= 6525 N/m

Weight of finish

= 800 x 1.5 x 1

Total load

= 6750 + 2137.5 + 6525 + 1200

Dept of Civil Engineering

College, Palakkad

= 1200 N/m

Govt Polytechnic

34

Project Report 2012

Mini Civil Station at Chittur

= 16612.5 N/m

B.M & S.F

Maximum B.M at midspan

= 16612.5 x 32 / 8

= 18.689 KNm

Maximum S.F at support

= 16612.5 x 3 / 2

= 24.918 KN

DEPTH REQUIRED

M20 , Fe415 grade concrete and steel are used,

Z

= 0.904d

M.R

= 18.689 x 103

0.914 x 1575

= 0.914bd2

= 113.95

= Say 115mm

= 115 + 15 + 10/2

= 135mm

Providing 10mm bar with 15mm clear cover,

Total thickness required

Provide 135mm thick slab with an effective depth of 115mm

MAIN REINFORCEMENT

Area of steel required

= 18689.1 103

= 781.61mm2

230 x 0.904 x 115

Number of 10mm bar required

= 781.61/78.5

= 9.95

= Say 10 Nos

DISTRIBUTORS

Area of steel required

= 0.12/100 x 1000 x 135

= 162mm2

Spacing of 8mm bars

= 50 x 1000/162

= 308.64mm

Provide 8mm bars distributor at 300mm c/c

CHECK FOR SHEAR

Nominal shear stress

= 24918.75

1575 x 115

= 0.14 N/mm2

Minimum value of permissible shear stress

= 0.22 N/mm2

Hence the slab is safe against shear.

CHECK FOR STIFFNESS

Dept of Civil Engineering

College, Palakkad

Govt Polytechnic

Project Report 2012

B.V

35

Mini Civil Station at Chittur

= 20

% of tension reinforcement

= 10 x 78.5 x 100

1575 x 115

M.F

= 0.43%

= 1.34

Effective depth required for stiffness

= 3000

20 x 1.34

= 111.94mm

d provided 115mm>111.94mm, Hence O.K

Dept of Civil Engineering

College, Palakkad

Govt Polytechnic

36

Project Report 2012

Mini Civil Station at Chittur

F. DESIGN OF FOUNDATION

Thickness of brick wall

= 240mm

Angle of repose

= 300

Weight of brick masonry

= 19 KN/m3

Safe bearing capacity of soil

= 150KN/m3

Specific weight of soil

= 16 KN/m3

Ultimate crushing strength of c.c foundation

= 15N/mm2

LOADS

Weight from wall

= 1 x 10.8 x 0.24 x 19

= 49.25KN/m

Weight of slab

Ground floor

= Dead + Live + Weathering coarse or Floor finish

= (3.125 +3 +1) 4.47

= 31.85KN/m

First floor

= (3.125 +3 +1) 4.47

= 31.85KN/m

Roof

= (3.125 +1.5 +1) 4.47

= 25.14KN/m

Total

= 138.1 KN

Add 10% for foundation design

Total load

= 13.8 KN

= 138.1 + 13.8

= 151.9KN

WIDTH OF FOUNDATION

= Total load/ Bearing capacity of soil

= 151.9 / 150 = 1.01m

DEPTH REQUIRED

Rankines formula

= D1

= po

r

D1

= 150

16

Depth required

Dept of Civil Engineering

College, Palakkad

[ 1-sin ]2

1-sin

[ 1-sin 30 ]2

1-sin 30

= 1.04 m

Govt Polytechnic

37

Project Report 2012

Mini Civil Station at Chittur

G. DESIGN

OF LINTEL CUM

SUNSHADE OVER 100 x

150mm WINDOW

DESIGN OF SUNSHADE

Effective span

= 600mm,

Clear projection

Assume uniform thickness of 60mm with an effective depth of 42mm

= 60 15 6/2 = 42mm

Considering one metre length of sunshade,

Self weight of sunshade

= 10.6 x 0.06 x 25000

= 900N

Live load of sunshade

= 450N

Total

= 1350N

Maximum B.M at support

= 1350 x 600 / 2

= 405000Nmm

Using M20 and Fe415 grade concrete and steel,

Z=

0.904d

Effective depth required

0.914bd2

M.R =

=

405000

0.914 x 1000

= 21.61m

d provide = 42mm> 21.61mm. Hence O.K

Area of steel required

405000

230 x 0.914 x 42 = 50.74mm2

Minimum area of steel to be provided

= 0.10/100 x 1000 x 60

= 60mm2

Spacing of 6mm bars

= 28 x 1000/60

= 466mm

= Say 200mm c/c

Provide 4 Nos of 6mm bars as distributor

Dept of Civil Engineering

College, Palakkad

Govt Polytechnic

38

Project Report 2012

Mini Civil Station at Chittur

DESIGN OF LINTEL

Assume size of lintel

= 240 x 150mm

Using 6mm bars,

cover

= 20mm

Effective depth available

= 150 20 6/2

= 127mm

1. C/C of bearings

= 1.0 + 0.15

= 1.150m

2. Opening + Effective depth

= 1.0 + 0.127

= 1.127m

Effective span

Effective span, l

Height of triangle

= 1.127m

= 0.866l

Height of wall above opening

= 0.976m

= 1.50m

Height of wall above the lintel

= 1.50 0.15

= 1.35m

The height of wall above the lintel is greater than 0.866l, triangular

Loading has to be assumed on the lintel.

Weight of triangular portion of masonry,

W1

= x 1.127 x 0.976 x 0.24 x 19000

= 2507.89N

Weight of sunshade

= 1.127 x 0.6 x 0.06 x 25000

= 1014.3N

Self weight of lintel

= 0.24 x 0.15 x 1.127 x 25000

= 1014.3N

Live load on sunshade

Total UDL

= 1.127 x 0.6 x 50

W2

= 507.15N

= 1014.3 + 507.15 + 1014.3

= 2535.75N

Maximum B.M

Maximum B.M at midspan

= W1l / 6 + W2 l/ 8

= 2507.89 1.127 + 2535.75 1.127

6

Dept of Civil Engineering

College, Palakkad

= 828.3Nm

Govt Polytechnic

39

Project Report 2012

Mini Civil Station at Chittur

DESIGN OF LINTEL CUM

SUNSHADE OVER 150 x 150mm

WINDOW

DESIGN OF SUNSHADE

Effective span

= 600mm,

Clear projection

Assume uniform thickness of 60mm with an effective depth of 42mm

= 60 15 6/2 = 42mm

Considering one metre length of sunshade,

Self weight of sunshade

= 10.6 x 0.06 x 25000

= 900N

Live load of sunshade

= 450N

Total

= 1350N

Maximum B.M at support

= 1350 x 600 / 2

= 405000Nmm

Using M20 and Fe415 grade concrete and steel,

Z=

0.904d

Effective depth required

0.914bd2

M.R =

=

405000

0.914 x 1000

= 21.61m

d provide = 42mm> 21.61mm. Hence O.K

Area of steel required

405000

230 x 0.914 x 42 = 50.74mm2

Minimum area of steel to be provided

= 0.10/100 x 1000 x 60

= 60mm2

Spacing of 6mm bars

= 28 x 1000/60

= 466mm

= Say 200mm c/c

Provide 4 Nos of 6mm bars as distributor

Dept of Civil Engineering

College, Palakkad

Govt Polytechnic

40

Project Report 2012

Mini Civil Station at Chittur

DESIGN OF LINTEL

Assume size of lintel

= 240 x 150mm

Using 6mm bars,

cover

Effective depth available

= 20mm

= 150 20 6/2

= 127mm

1. C/C of bearings

= 1.5 + 0.15

= 1.650m

2. Opening + Effective depth

= 1.5 + 0.127

= 1.627m

Effective span

Effective span, l

Height of triangle

= 1.627m

= 0.866l

Height of wall above opening

Height of wall above the lintel

= 1.627m

= 1.50m

= 1.50 0.15

= 1.35m

The height of wall above the lintel is less than 0.866l, the total rectangular

Portion of the masonry above the lintel is considered

Weight of triangular portion of masonry,

= 1.627 x 1.35 x 0.24 x 19

= 9.27 KN

Self weight of lintel

= 0.24 x 0.15 x 1.627 x 25

= 1046 KN

Total UDL

= 10.73 KN

Maximum B.M

Maximum B.M at midspan

= 10.73 x 1.6272 / 8

Effective depth required

3.50 x 106

0.914 240

= 3.5 KNm

= 126.87mm

Effective depth provided

= 127mm> 126.87 Hence O.K

Area of tension steel required

= 3.5 x 106

230 x 0.904 x 127

Provide 5 numbers of 6mm bars at bottom

= 31.36mm2

= 140 mm2

Provide 2 numbers of 6mm bars at top as hangers

Dept of Civil Engineering

College, Palakkad

Govt Polytechnic

Project Report 2012

Dept of Civil Engineering

College, Palakkad

41

Mini Civil Station at Chittur

Govt Polytechnic

Project Report 2012

Dept of Civil Engineering

College, Palakkad

42

Mini Civil Station at Chittur

Govt Polytechnic

Project Report 2012

43

Mini Civil Station at Chittur

7. DETAILED SPECIFICATION

1.EARTH WORK EXCAVATION IN FOUNDATION.

Foundation trenches shall be dug out to the exact width of foundation

concrete and the side be vertical, the sides should be stopped back of

protected with timber shoring. Excavation earth shall not be placed within in

of edge of the trench.

Bottom of the foundation trenches shall be perfectly leveled both

longitudinally and transversely and the side of the trench shall be dress

perfectly vertical from bottom up to the least thickness of loose concrete so

that concrete may be laid to the exact width as per design. The bed of the

trench shall be slightly watered and well rammed. Excess deigning done

through shall be filled with concrete at the expense of contractor. If the rocks

of builders are in foundation during excavation, these should be removed.

The measurements of excavation trench shall be taken in cubic meter as for

rectangular trench bottom width of concrete multiplied by the vertical depth

of foundation from ground level and multiplied by the length of trenches.

The measurement shall be taken separately every 50m lead and 1.5m lift.

2. CEMENT CONCRETE 1:4:8 FOR FOUNDATION

Fine aggregate should be clean, hard sand and durable, course aggregated

should be of hard broken stone of granite of similar stone. Free from dust or

other matter. Size of course aggregate shall be 40mm, cement shall be fresh

Portland cement of I S I specification. The proportion of concrete shall be

1:4:8 as cement : sand course aggregate by volume centering shuttering shall

be provided as required as per specification. Concrete shall be laid gently in

layer of 15mm thick and compacted by roads and tempering with wooden

timbers after about 2 hours layering in concrete the surfaces should be kept

we with water.

Dept of Civil Engineering

College, Palakkad

Govt Polytechnic

Project Report 2012

44

Mini Civil Station at Chittur

3. RANDOM RUBBLE MASONRY FOR FOUNDATION AND

BASEMENT.

The stones shall be of hard, sound and durable of provoked quarry stone

shall be hammer dressed to secure close joint. So the stones when laid will

come in to close proximity. Stones shall be fairly equally in size, mortar shall

be of cement mortar 1:5 materials of mortar shall be standard specification

and joint shall not be thicker than 20mm the masonry shall be kept wet for

10 days. The measurement shall be taken in cubic metre.

4. BRICK WORK FOR SUPER STRUCTURE.

All bricks shall be first class for standard specifications made of good

brick, earth thoroughly burnt and shall be deep every red or copper colour.

Brick shall be regular in shape and their edge should be square and shall emit

clear ringing sound on being stuck and shall be free from cracks, chips flows

and lumps any kind. Bricks shall not absorb water more than sixth of their

weight. After one hour of snaking by immersing in water bricks shall have a

minimum crushing strength of 150 kg/cm2 mortar shall be specified be

bonded and laid in English bond wall shall be truly in plump. Vertical joints

of consecutive courses not come over one another. Brick shall be kept wet

for a period of 10 days after lay. Measurement taken in cubic meter.

5. CENTERING AND SHUTTERING OF R.C.C. WORK.

Shuttering shall be either of hard wooden plant 30mm thick or the steel

plates shifted by angle iron. The shuttering shall be supported on batten,

beams etc to make a rigid form work. Beam for centering shall be carried out

and supported on the walls with double wedges underneath and supported at

interval with props, prop shall consist of brick pillars. The shuttering shall

have smooth uneven surfaces and joints shall close tight centering and

Dept of Civil Engineering

College, Palakkad

Govt Polytechnic

Project Report 2012

45

Mini Civil Station at Chittur

shuttering shall not be removed before 14 days in general and shall be

removed slowly and carefully without any snack. Centering and shuttering

shall be measured in square meters.

6. REINFORCED CEMENT CONCRETE FOR ROOF SLAB, FLOOR

SLAB, BEAM, LINTEL ETC.

Steel reinforcement bars shall be of mild seal of standard specifications

and shall be free from corrosion, rose rust scales, oils, grease, paints etc. The

steel bars shall be round and capable of being bend without fracture. Bars

shall be looked and bend accurately and placed in position as for design and

drawing. Cement concrete shall be 1:2:4 proportion by volume for slabs,

beams, lintels and column. Sand and broken stone shall be of standard

specifications. Mixing done by means of machine or manually. Laying of

concrete is done after the steel reinforcement placed in position. The

concrete shall be compacted by mechanical vibrating machine. Laying the

concrete surfaces should be kept wet with water. Measurement is done in

cubic metres.

7. DOORS AND WINDOWS.

Timber shall be of the kind specified may be teak, sal, anjaly, decodar etc.

The timber shall be best qualities, well seasoned and free from raps, knots,

warps, cracks and other defects. All wood work shall be planed and neatly

and correctly finished to the exact dimensions. All joints shall be neat and

strong and truly and accurately filled and glould before filled together.

The shutters may be parallel as specified the thickness of shuutte shall be

3cms 5cms as specified. All doors have handless on inner slab. The

necessary linges and bolts shall be provided. The chock lots shall be

measured in cubic metres and the shuttering shall be measured in square

metre.

Dept of Civil Engineering

College, Palakkad

Govt Polytechnic

Project Report 2012

46

Mini Civil Station at Chittur

8. GLASS FOR SHUTTERS.

Glass shall be of the best quality and free from the defects. The thickness

of glass shall be of 3mm or as specified. The rebate shall be painted be for

glass is fixed.

9. CEMENT MORTAR.

The proportion of cement and sand shall be as specified may be 1:3 to

1:6 the materials shall be done first dryb on an platform and them mixed

with water, cement and shall be measured with boxes to have the required

proportion. First sand is spread on the platform and the required quantity of

cement is spread on the top of the sand and the whole mixed dry. The

mixture shall be then formed roughly in to a cone shape and water is added

slowly and then the hole mixed thoroughly to have a uniform colour and

consistency.

10. POINTING.

The joint of brick work shall be rocked out to a depth of 20mm and the

surface of the wall washed and cleaned and kept wet for 2 day before

pointing. The materials of mortar shall be of standard specification. Mortar

shall be applied in the joints slightly in excess and pressed by a proper tool

of the required shape. Extra mortar of any is removed and surface is finished.

The measurements shall be taken in the square meters.

11. WHITE WASHING.

Fresh white lime should be mixed with sufficient water to make a thin

cream, the quantity of water shall be 5 liters of water percent Kg of lime, the

surface should be clean from dust and dirt. After cleaning white wash shall

be applied two coats. For final coat, base pigment powder should be mixed

Dept of Civil Engineering

College, Palakkad

Govt Polytechnic

Project Report 2012

47

Mini Civil Station at Chittur

to give bright white surface. The measurement shall be kept in square

meters.

12. PAINTING.

The branch of paint shall be an readymade of the required colours should

be coated. For new work are primary coated and two coats of paint shall be

used. The paint shall be applied with brushes. The measurement shall be

taken in square metres. Each coat should be perfectly dry before next coat is

applied.

Dept of Civil Engineering

College, Palakkad

Govt Polytechnic

Project Report 2012

48

Mini Civil Station at Chittur

8. DESIGN OF SEPTIC TANK

Number of user

= 100

Assume rate of water supply

= 1000ml / head / day

Assume detention period as 24 hours and twice of cleaning the

Sludge as 24 hours.

Space required for setting

= 100 x 100/ 1000

= 10m2

Space required for dig stone

= 100 x 0.425

= 4.25 m2

Space required for storage of sludge

= 100 x 0.085

= 8.5 m2

Total space required

= 10 + 4.25 + 8.5

= 22.75m3

Assume liquid depth

= 2m

Plan area of septic tank

= 22.75 / 2

Assume length

= 4.5m

Breadth

= 11.375 / 4.5

Provide free board

= 50cm

Total depth

= 2 + 0.50

Size of tank

= 4.5 x 2.5 x 2.5m

= 11.375 m2

= 2.5m

= 2.50m

9. DESIGN OF SOAKPIT

Dept of Civil Engineering

College, Palakkad

Govt Polytechnic

49

Project Report 2012

Mini Civil Station at Chittur

Sewage to soak pit

= 100 x 60

Assume the depth of soak pit as

= 2.5 m

= 6000 liters = 6m3

= d2 x 2.5 = 6

4

d2

= 6 x 4/2.5 = 3.05

= 1.75m

Design of c.c projection,

Assume overall depth, D

= 100mm

D

= 100 15 8/2

= 81mm

Effective span

= 1000 mm

Load

Live load

= 1.5KN/m

Need load

= 1 x 0.1 x 25

= 2.5 KN/m

Total

= 4 KN/m

B.M & S.F

Maximum B.M at support

= Wl /2

=4x

= 2 KN/m

Shear force

= Wl

=4x1

= 4KN

Maximum B.M at support

= Wl /2

=4x

= 2 KN/m

Shear force

= Wl

=4x1

= 4KN

Check for effective depth

D req.

= M

Rb

2 x 106

0.914 x 100

= 46.77mm

46.77 <81 mm, Hence O.K

Assuming 8mm bars

Ast =

M

st x jd

Spacing

2 x 106

230 x 0.904 x 100

= 50 x 1000 /120

= 96.19mm2

= 416.6mm

= Say 40s0mmc/c

Dept of Civil Engineering

College, Palakkad

Govt Polytechnic

Project Report 2012

Item

Description

Dept of Civil Engineering

College, Palakkad

50

No Length

Mini Civil Station at Chittur

Breadth

Height

Quantity

Remarks

Govt Polytechnic

51

Project Report 2012

No.

Mini Civil Station at Chittur

.

SEPTIC

TANK

1.

Earth work excavation

5.40

3.40

2.70

49.57m3

2.

P.C.C 1:3:6

5.40

3.40

0.20

3.672m3

3.

First class brick work

First footing

15.20

0.30

1.50

6.84m3

Second footing

14.80

0.20

1.00

2.96m3

Cover slab

4.90

2.90

0.10

1.421

Buffle wall

2.60

0.05

0.60

0.078

(3.14/4x

0.502)

0.01

0.02

4.

R.C.C work

Deduction

Manhole

1.479m3

5.

20 mm thick plastering

6.

50 cm dia cast iron

14.00

2.45

@ 56 kg

34.3m2

manhole cover with frame

56 kg

7.

100 mm dia S.W.Tee

2 Nos

8.

A.C ventilation cowl

1 No.

9.

100 mm dia S.W pipe

2 Nos.

SOAKPIT

1.

Earth work

( x 2.752

/4)

2.875

17.85m3

2.

P.C.C

( x 1.752

/4)

0.30

0.72m3

3.

Brick work

( x 2.152

/4)

2.80

10.17m3

4.

Brick aggregate

( x 2.452

/4)

2.00

9.43m3

5.

Course sand

( x 2.752

/4)

0.075

11.88m3

6.

R.C.C 1:2:4

( x 2.152 /4)

0.27m3

7.

Plastering

( x 1.75

13.74m2

Sl no.

Quantity

Dept of Civil Engineering

College, Palakkad

Description of work

x 2.5)

Unit

Rate

Amount

Govt Polytechnic

52

Project Report 2012

Mini Civil Station at Chittur

SEPTIC TANK

1

49.57m3

Earth work excavation

10 m3

2125.20

10534.62

4.297m3

P.C.C 1:4:8 for foundation

m3

4009.61

17229.29

980m3

Brick work in cm 1:5

m3

2695.37

36214.63

103.293

R.C.C work

10d m3

59.11

6088.33

34.30m3

Plastering

10 dm3

1590.89

5456.75

56 kg

6588.98

3688.70

Nos.

170

140.00

Total =

79352.32

50mm dia cast iron man hole

cover

2 Nos

100 mm S.W pipe

SOAK PIT

1

17.03 m3

Earth work excavation

10 m3

2125.20

3619.21

0.72 m3

Plain cement concrete

m3

4009.61

2886.91

10.17 m3

Brick work

m3

3695.37

7581.92

9.43 m3

Brick aggregate

m3

591.00

5573.13

11.88 m3

Coarse sand

m3

1860.00

22096.80

0.273 m3

R.C.C 1:2:4

10d m3

59.11

1613.70

13.74 m2

Plastering

10 m2

1590.89

2185.88

Total =

75557.85

10. DETAILED ESTIMATE

GROUND FLOOR

Item

Description

Dept of Civil Engineering

College, Palakkad

No.

Length

Breadth

Height

Quantity

Remarks

Govt Polytechnic

53

Project Report 2012

Mini Civil Station at Chittur

No

1.

2.

3.

4.

Item

Clearing and leveling

the site including

uprooting of trees up

to 30 cm grith etc.

Earth work excavation

in hard soil and

deposited on bank

with initial lead up to

50m and lift up to

1.5m including

breaking clouds water

remaining etc.

complete.

For

foundations(walls)

for pillars

Plain cement concrete

1:4:8 using nominal

size broken stone for

base concrete

for walls

For pillars

R.R masonry in c.m

1:6 for foundation and

basement for

foundation

Foundation

for walls

for pillars

Basement

For walls

For pillars

Description

L.S

45.00

25.00

1125

=1125m2

1

11

205.24

1.20

1.20

1.20

1.20

1.20

295.65

19.01

=314.56m3

1

11

205.24

1.20

1.20

1.20

0.20

0.20

49.26

3.168

=52.43m3

1

11

210.34

0.90

0.90

0.90

1.00

1.00

189.306

8.91

1

11

217.14

0.50

0.50

0.50

0.50

0.50

54.285

1.375

=253.93m3

No.

Length

Breadth

Height

Quantity

Remarks

No

5.

Earth filling inside

the basement.

Dept of Civil Engineering

College, Palakkad

Govt Polytechnic

54

Project Report 2012

6.

Taluk industry

Taluk supply

Computer room

Rest room

A.R Co-op (A)

Verandah

Toilet verandah

1

1

1

1

1

1

1

8.98

10.14

5.50

5.22

9.24

36.18

9.48

4.74

9.24

2.74

3.24

8.24

2.24

2.74

0.50

0.50

0.50

0.50

0.50

0.50

0.50

21.28

46.84

7.535

8.456

38.06

40.52

12.98

=175.67m3

First class brick work

c.m 1:6 for

superstructure and

steps

24 cm walls

10 cm wall

for pillars

Steps

1st

2nd

3rd

1

1

11

180.10

43.0

0.45

0.24

0.10

0.45

3.60

3.60

3.60

155.60

15.48

8.019

1

1

1

4.00

4.00

4.00

0.30

0.30

0.30

0.17

0.34

0.50

0.20

0.408

0.60

=180.23

2.50

0.24

3.10

4.32

7

3

8

13

11

3

1.00

0.90

0.80

1.50

1.00

0.50

0.24

0.10

0.10

0.24

0.24

0.24

2.10

2.00

2.00

1.50

1.50

0.50

3.52

0.54

1.28

7.02

3.96

0.48

92.34

0.24

0.15

3.34

Length

Breadth

Height

Quantity

Deduction

For opening

(Balcony)

Doors & windows

D

D1

D2

W

W1

W3

Lintels

All round

Item

Mini Civil Station at Chittur

Description

No.

Remarks

No

Above doors and

windows (inside)

Above D1

Dept of Civil Engineering

College, Palakkad

1

3

30.96

1.20

0.24

0.10

0.15

0.10

1.114

0.036

Govt Polytechnic

55

Project Report 2012

Above W1

Above D2

Opening

Portico entrance

open

7.

Item

Mini Civil Station at Chittur

4

8

9

1

1.30

1.10

5.46 (are

4.50

0.10

0.10

a)

0.24

0.10

0.10

0.24

3.00

0.052

0.088

11.79

3.24

=41.988

=138.75m3

1

1

1

Qua

1

36.92

11.60

62.36

ntity sa

4.97

12.72

10.4

0.60

me as th

4.48

0.135

0.135

0.060

at for ite

0.11

63.39

16.28

2.24

m no.6 4.63

2.44

Stair case

Landing slab

Waist slab

Steps

1

2

22

3.24

3.76

(1/2x0.1

1.74

1.62

5x0.3)

0.110

0.110

1.20

0.620

1.340

0.594

Beams

Beam 1

Beam 2

Beam 3

Beam 4

Beam 5

Beam 6

Beam 7

Under portico slab 1

2

Above pillar

1

2

1

2

9

1

1

1

1

3

3

5.00

9.52

8.50

3.00

2.50

4.58

5.34

4.97

4.60

11.36

10.18

0.24

0.24

0.24

0.24

0.24

0.24

0.24

0.30

0.30

0.40

0.40

0.30

0.30

0.30

0.30

0.30

0.30

0.30

0.30

0.30

0.40

0.40

0.36

1.368

0.612

0.43

1.62

0.329

0.384

0.447

0.36

5.45

4.88

R.C.C 1:2:4 using

20mm broken stone

for slab, lintel

sunshade etc.

Slab

Main all round

Above pillars

Sunshade

Lintel

Portico slab

Description

No.

Length

Breadth

Height

Quantity

Rise=0.15

Tread=0.3

=105.34

Remarks

No

Deduction

Landing slab

opening in

stair area

Dept of Civil Engineering

College, Palakkad

4.92

3.10

0.135

2.05

=20.05

=103.25m3

Govt Polytechnic

56

Project Report 2012

8.

9.

DPC 2.5cm with c.c

24cm wall

12 cm wall

1

1

Reinforcement tie

and place in position

etc. complete at

0.85% by volume of

concrete

Mini Civil Station at Chittur

217.66

70.14

0.50

0.50

0.85/100

x 103.25

108.83

35.07

=143.90m2

x 78.5

68.12

=68.92 q

1

99.28

14x4 0.45

3.60

3.60

357.41

90.72

3

3

2

4.00

4.00

0.303

0.17

0.3

2.04

3.60

0.61

2x2

2x1

4.97

4.97

0.30

0.30

5.964

5.964

1x3

4.00

0.30

3.60

No.

Length

Breadth

Beam 3

Beam 4

9

9

11.36

10.18

0.40

0.40

40.896

36.452

Sunshade

Top & bottom

62.36

0.60

37.42

10.

Plastering with c.m

1:5

12mm thick on

exposed surface of

wall and inside

surface of wall and

steps.

Out side plastering

Main wall all round

Pillar

Steps

Face

Tread

Sides

Beams

Beam 1 side

Face

(area)

Beam 2

Item

Description

Height

Quantity

Remarks

No

Dept of Civil Engineering

College, Palakkad

Govt Polytechnic

57

Project Report 2012

Mini Civil Station at Chittur

Face

62.36

0.06

3.74

=635.23

Deduction

Balcony open

Opening

2

9

2.50

5.46(area)

3.60

18.00

49.14

=67.14

=568.09m2

1

1

1

1

1

1

1

1

1X2

29.00

39.8

17.52

17.48

36.00

68.04

17.52

7.76

44.1

3.60

3.60

3.60

3.60

3.60

3.60

3.60

3.60

3.60

104.4

143.25

63.07

62.93

129.60

244.94

63.07

27.94

317.52

1X2

1X1

1

70.92

70.92

16.12

0.30

0.24

16.12

42.55

17.02

Inside plastering

Taluk industry

Taluk supply

Stair room

Rest room

Toilet verandah

Verandah

Computer room

Wall

10 cm wall

Beams

Side

Bottom

Stair

=1313.08

Deduction

D

1.00

2.10

14.70

D1

0.90

2.00

5.40

D2

0.80

2.00

12.8

No.

Length

Breadth

13

1.50

1.50

29.25

11

1.00

1.50

16.50

0.50

0.50

2.00

Item

Description

Height

Quantity

Remarks

No

W

W1

V

=80.65

Dept of Civil Engineering

College, Palakkad

Govt Polytechnic

58

Project Report 2012

Mini Civil Station at Chittur

=1232.42m2

11.

Wood work for the

frames of doors and

windows

Doors

D

6.20

0.07

0.10

0.303

D1

6.00

0.07

0.10

0.126

D2

5.80

0.07

0.10

0.32

13

9.00

0.07

0.10

0.819

W1

11

7.50

0.07

0.10

0.577

2.00

0.07

0.10

0.112

Windows

12.

13.

Item

=2.257m3

Wood work for the

shutters of fully

paneled doors

D

1.98

0.88

12.19

D1

1.88

0.78

4.39

D2

1.88

0.68

10.22

=26.80m2

13X3

0.427

1.38

W1

11X2

0.415

1.38

8X1

0.38

0.38

22.98

12.60

1.155

=36.73m2

Length

Breadth

Shutters of fully

glazed windows

Description

No.

Height

Quantity

Remarks

No

14.

Painting for doors

and windows two

coats over one coat

wooden primer used

over approved quality

Dept of Civil Engineering

College, Palakkad

Govt Polytechnic

59

Project Report 2012

15.

in cement paint

D

1.00

2.10

2.25

33.07

D1

0.90

2.00

2.25

12.15

D2

0.80

2.00

2.25

28.8

13

1.50

1.50

1.00

29.25

W1

11

1.00

1.50

1.00

16.50

0.50

0.50

1.00

2.00

Flooring c.c 1:3:6,

75mm thick using

40mm nominal

broken stone and

plastered over with

12mm thick c.m 1:3

one coat

Taluk industry

Taluk supply office

Stair room

Computer room

Rest room

A.R.CO.OP

Verandah (toilet side)

Verandah

Deduction

10 cm wall inside the

office

Item

Mini Civil Station at Chittur

Description

=121.77m2

1

1

1

1

1

1

1

1

5.00

10.40

3.10

5.24

3.50

8.50

3.00

2.50

9.50

9.50

9.50

5.76

5.24

9.50

9.70

36.44

47.50

98.8

29.45

30.18

18.34

80.75

29.10

91.10

=425.22

44.10

0.10

4.41

=420.81m2

No.

Length

Breadth

1

11

100.22

2.00

Height

Quantity

0.50

0.50

50.11

11.00

=61.11m2

Remarks

No

16.

Pointing the

exposed faces of

basement using c.m

1:3

Main wall all round

Pillar basement

Dept of Civil Engineering

College, Palakkad

Govt Polytechnic

60

Project Report 2012

17.

18.

White washing 2

coats only on out

side wall and

ceilings

Outside area

Ceiling area

Ceiling plastering

in c.m 1:3 12mm

thick under side of

slab

Taluk industries

Taluk supply office

Stair room

Rest room

Computer room

A.R.CO.

Verandah (Toilet)

Verandah

19.

Colour washing

two coats only on

inside walls

Inside area

Item

Description

Same

Same

as item

as item

1

1

1

1

1

1

1

1

5.00

10.40

4.82

3.50

5.24

8.50

3.00

36.44

area

same as

Mini Civil Station at Chittur

no. 10

no. 18

582.49

410.74

993.20m2

9.50

9.50

3.10

5.24

5.76

9.50

9.70

2.50

47.50

98.80

14.94

18.34

30.18

80.75

29.10

91.10

=410.74m2

that of it

em no.10

1232.42

=1232.42m2

No.

Length

Breadth

Height

Quantity

Supplying and fixing

10mm iron hinges

For doors

18

4 Nos/

1 door

72

For windows W

13

9 Nos/

1 window

117

11

6 Nos

Remarks

No

20.

W1

Dept of Civil Engineering

College, Palakkad

66

Govt Polytechnic

61

Project Report 2012

V

21.

22.

23.

Mini Civil Station at Chittur

2 Nos

16

=271Nos

Supplying and fixing

75mm iron tower bolt

Doors

18

3 Nos/

54

1 door

= 54Nos

Fixing 75mm iron

hookes

For windows W

13

6 Nos/

78

W1

11

4 Nos

44

1 Nos

1 window

=130Nos

Providing 150 mm

aluminium door

handle

24.

Doors

18

2 Nos/

36

=36 Nos

Providing flat iron

hold fast size

350x50x6 for doors

windows etc.

Doors

18

4 Nos/

Windows

24

2 Nos

48

Ventilators

2 Nos

16

1 door

72

1 door

=136Nos

FIRST FLOOR

Item

Description

No.

Length

Breadth

Height

Quantity

First class brick

work c.m 1:6 for

super structure and

steps

24 cm walls

10 cm walls

1

1

217.66

70.14

0.24

0.10

3.60

3.60

188.06

25.25

=213.31

Remarks

No

1.

Dept of Civil Engineering

College, Palakkad

Govt Polytechnic

62

Project Report 2012

Deductions

For opening

(Balcony)

Opening

Doors & Windows

D

D1

D2

W

W1

W3

Lintels

All round

24 cm wall

D1

D2

W1

3

8

2.50

5.46(area)

0.24

3.10

0.24

6.48

10.48

1.00

0.24

2.10

4.03

0.90

0.10

2.00

1.08

10

0.80

0.10

2.00

1.60

19

1.50

0.24

1.50

10.26

12

1.00

0.24

1.50

3.06

10

0.50

0.24

0.50

0.60

121.52

0.24

0.15

4.37

31.90

0.24

0.15

1.15

1.20

0.10

0.10

0.072

10

1.10

0.10

0.10

0.11

1.30

0.10

0.10

0.078

=43.38

R.C.C 1:2:4 using

20 mm broken

stone for slab,

lintel sunshade etc.

Slab

Main all round

Above pillars

Sunshade

Lintel

Item

Mini Civil Station at Chittur

Description

=169.93m3

1

36.92

1

11.60

1

76.70

Quan tity same

No.

Length

12.72

10.4

0.60

0.135

0.135

0.060

as that for

item no.1

Breadth

63.39

16.28

2.76

5.76

Height

Quantity

0.110

0.110

1.20

0.620

1.340

0.594

0.30

0.36

Remarks

No

Stair case

Landing slab

Waist slab

Steps

1

2

22

3.24

1.74

3.76

1.62

(1/2x0.15 x0.3)

Beams

Beam 1

Dept of Civil Engineering

College, Palakkad

5.00

0.24

Govt Polytechnic

63

Project Report 2012

Mini Civil Station at Chittur

Beam 2

9.52

0.24

0.30

1.368

Beam 3

8.50

0.24

0.30

0.612

Beam 4

5.24

0.24

0.30

0.377

Beam 5

3.00

0.24

0.30

0.22

Beam 6

2.5

0.24

0.30

0.18

Beam 7

2.50

0.24

0.30

1.62

Beam 8

3.10

0.24

0.30

0.22

Beam 9

2.50

0.24

0.30

0.36

Beam 10

7.18

0.24

0.30

1.033

=97.12

Landing slab opening

4.92

3.10

0.135

2.06

=2.06

3.

=95.06m3

Reinforcement tie and

place in position etc.

complete at 0.85% by

volume of concrete

0.85/100

x95.06x

63.43

=63.43 q

4.

Plastering with c.m

1:5 12mm thick on

exposed surface of

wall and inside

surface of wall and

steps.

Out side plastering

122.48

3.60

440.93

Main wall all round

Item

Description

No.

Length

Breadth

Height

Quantity

Sunshade

Top & bottom

Face

1

1

76.50

76.70

0.60

0.06

46.02

4.60

=491.55

Deduction

Balcony open

Opening

3

8

2.50

5.46(area)

3.60

27.00

43.68

=70.68

=420.87m2

Remarks

No

Dept of Civil Engineering

College, Palakkad

Govt Polytechnic

64

Project Report 2012

Inside plastering

Town employment

Soil conservation

Stair room

A.E.NH

Food inspector

Verandah

10 cm wall

Beams

Side

Bottom

Stair

1

1

1

1

1

1

1X2

29.00

39.8

17.52

36.00

29.48

68.04

71.64

88.92

1X2

88.92

1X1

1

16.12(area)

Deduction

D

D1

D2

10

19

W1

12

10

1.00

0.90

0.80

1.50

1.50

0.50

Mini Civil Station at Chittur

3.60

3.60

3.60

3.60

3.60

3.60

3.60

104.4

143.25

63.07

129.60

106.13

244.94

555.82

0.30

52.95

0.24

21.17

16.12

2.10

=1478.08

16.80

2.00

10.80

2.00

16.00

1.50

42.75

1.50

18.00

0.50

2.50

=106.85

=1371.23m2

Item

Description

No.

Length

Breadth

Height

Quantity

6.20

0.07

0.10

0.347

D1

6.00

0.07

0.10

0.252

Remarks

No

5.

Wood work for the

frames of doors and

windows

Doors

Dept of Civil Engineering

College, Palakkad

Govt Polytechnic

65

Project Report 2012

D2

Mini Civil Station at Chittur

10

5.80

0.07

0.10

0.406

19

9.00

0.07

0.10

1.970

W1

12

7.50

0.07

0.10

0.630

10

2.00

0.07

0.10

0.140

Windows

6.

=2.972m3

Wood work for the

shutters of fully

paneled doors

D

1.98

0.88

13.94

D1

1.88

0.78

8.79

D2

10

1.88

0.68

12.78

=35.51m2

Shutters of fully

7.

8.

glazed window

W

19X3

0.427

1.38

33.59

W1

12X2

0.415

1.38

13.74

10X1

0.38

0.38

1.44

Painting for goods

and window two

coats over one coat

wooden primer used

over approved

quality in cement

paint

D

=44.77m2

1.00

2.10

2.25

37.80

0.90

2.00

2.25

24.30

No.

Length

Breadth

Height

Quantity

D2

10

0.80

2.00

2.25

36.00

19

1.50

1.50

1.00

42.75

W1

12

1.00

1.50

1.00

18.00

10

0.50

0.50

1.00

2.50

D1

Item

Description

Remarks

No

=161.35m2

9.

White washing 2

Dept of Civil Engineering

College, Palakkad

Govt Polytechnic

66

Project Report 2012

Mini Civil Station at Chittur

coats only on out

side walls and

ceiling

same

as item

no.4

420.87

Out side area

same

as item

no.11

493.65

=914.52m2

Ceiling area

10.

Ceiling plastering in

c.m 1:3 12mm thick

under side of slab

Town employment

5.00

9.50

47.50

Soil conservation

10.40

9.50

98.80

Stair room

4.82

3.10

14.94

Food inspector

5.24

9.50

49.78

A.E

8.50

9.50

80.75

Verandah (Toilet)

3.00

9.70

29.10

Verandah

36.44

2.50

91.10

A.E.O

7.18

11.36

81.56

=493.65m2

11.

Colour washing two

coats only on inside

walls

Inside area

area

same as th

at of item

no.4

1126.29

=1126.29m2

Item

Description

No.

Length

Breadth

Height

Quantity

For doors

24

4Nos/

1 door

96

For windows W

19

9Nos/ 1

window

171

12

6Nos

Remarks

No

12.

Supplying and fixing

10mm iron hinges

W1

Dept of Civil Engineering

College, Palakkad

72

Govt Polytechnic

67

Project Report 2012

V

10

Mini Civil Station at Chittur

2Nos

20

=359Nos

13.

Supplying and fixing

75mm iron tower bolt

Doors

24

3Nos/

1 door

72

=72Nos

14.

Fixing 75 mm iron

hookes

For windows W

19

6Nos/1

window

114

W1

12

4Nos

48

10

1Nos

10

=172Nos

15.

Providing 150 mm

aluminium door

handle

Doors

16.

24

2Nos/

1 door

48

Providing flat iron

hold fast size

350x50x6 for doors

widows etc.

Doors

=48Nos

24

4Nos/

Windows

31

2Nos

62

Ventilators

10

2Nos

20

1 door

46

=178Nos

SECOND FLOOR

Item

Description

No.

Length

Breadth

Height

Quantity

First class brick work

c.m 1:6 for

superstructure and

steps

24 cm walls

10 cm wall

Parapet wall

1

1

1

217.66

47.74

124.10

0.24

0.10

0.10

3.60

3.60

0.60

188.06

25.25

7.45

Remarks

No

1.

Dept of Civil Engineering

College, Palakkad

Govt Polytechnic

68

Project Report 2012

Mini Civil Station at Chittur

Head room

16.00

0.24

3.00

Deductions

For opening

18.84

=231.51

2.50

0.24

3.10

6.48

(Balcony)

5.46(area)

0.24

10.48

8

4

8

19

13

8

1.00

0.90

0.80

1.50

1.00

0.50

0.24

0.10

0.10

0.24

0.24

0.24

2.10

2.00

2.00

1.50

1.50

0.50

4.03

0.72

1.28

10.26

3.31

0.48

121.52

0.24

0.15

4.37

31.90

0.24

0.15

1.15

1.20

0.10

0.10

0.048

1.10

0.10

0.10

0.088

1.30

0.10

0.10

0.078

Opening

Doors & windows

D

D1

D2

W

W1

W3

Lintels

All round

24 cm wall

D1

D2

W1

R.C.C 1:2:4 using 20

mm broken stone for

slab, lintel sunshade

etc.

Slab

=42.78

=188.74m3

Main all round

Front portion

Item

Description

37.32

13.32

0.125

62.14

11.60

10.80

0.125

15.66

No

Length

Breadth

Height

Quantity

Remarks

No

Sunshade

Lintel

Stair case

Landing slab

Waist slab

Steps

Beams

Beam 1

Dept of Civil Engineering

College, Palakkad

76.70

0.60

0.060

Qu

an

tity same a

s that for

it

em no.1

2.76

5.76

0.110

0.110

1.20

0.620

1.340

0.594

0.30

0.36

1

2

22

1

3.24

3.76

(1/2x0.15

5.00

1.74

1.62

x0.3)

0.24

Rise=0.15

Tread=0.3

Govt Polytechnic

69

Project Report 2012

Mini Civil Station at Chittur

Beam 2

9.52

0.24

0.30

1.368

Beam 3

8.50

0.24

0.30

0.612

Beam 4

5.24

0.24

0.30

0.377

Beam 5

3.00

0.24

0.30

0.22

Beam 6

2.50

0.24

0.30

0.18

Beam 7

2.50

0.24

0.30