Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Verif EPI Casques PRO Procedure EN PDF

Caricato da

DimasDianaFerreiraDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Verif EPI Casques PRO Procedure EN PDF

Caricato da

DimasDianaFerreiraCopyright:

Formati disponibili

PPE Inspection

Inspection procedure

In addition to routine checks for each use, PPE should regularly undergo a detailed inspection by a competent

person. Petzl recommends an inspection every 12 months and after any exceptional event in the life of the product.

PPE inspection should be conducted with the manufacturer's Instructions for Use.

Download the instructions at PETZL.COM.

HELMETS

1. Known product history

Any PPE showing unexpected degradation should be quarantined, pending a detailed inspection.

The user should:

- Provide precise information on the usage conditions.

- Report any exceptional event regarding his PPE.

(Examples: fall or fall arrest, use or storage at extreme temperatures, modification outside manufacturer's

facilities...).

2. Preliminary observations

Verify the presence and legibility of the serial number and the CE mark.

Verify that the product lifetime has not been exceeded.

Compare with a new device to verify there are no modifications or missing parts.

3. Checking the shell

Check the condition of the outside of the shell (marks, impacts,

deformation, cracks, burns, wear, signs of chemical products...).

Check the condition of the inside of the shell (marks, deformation, cracks,

missing parts...). WARNING: do not remove the liner that is attached to the

shell.

Remember: personalizing or marking the helmet must not be done with

chemical products. Use water-based adhesives for any marking.

PPE INSPECTION - Inspection procedure - HELMETS (271114)

1/6

Check the condition of the slots and holes for

mounting accessories (deformation, cracks...).

Check the condition and function of the ventilation

shutters (for VERTEX VENT, ELIOS...).

4. Checking the liner

Check the condition of the liner (marks, deformation, cracks, missing parts...).

Remove the comfort parts to inspect the hidden areas.

WARNING: do not remove the liner that is attached to the shell.

Note: depending on the helmet model, the shell and liner can be:

SIRROCO

SIRROCO

SIRROCO

METEOR

one and the same piece

PPE INSPECTION - Inspection procedure - HELMETS (271114)

METEOR

METEOR

VERTEX, ALVEO...VERTEX, ALVEO... VERTEX, ALVEO...

two pieces glued together

two pieces assembled

together

2/6

5. Checking the cradle (webbing head harness)

Check the condition of the straps and their attachments to the shell (wear,

cuts, burns, deformation of plastic pieces).

Note: most helmets that have a liner do not

have a webbing harness.

6. Checking the headband

Check the condition of the headband and its attachments to the shell (wear,

deformation, missing parts...).

If necessary, remove the foams or comfort parts to inspect the hidden areas.

Note: certain helmets such as the METEOR or the

SIROCCO have no headband.

7. Checking the adjustment system

Check the condition of the adjustment system and its attachments to

the shell (wear, deformation, missing parts...).

PPE INSPECTION - Inspection procedure - HELMETS (271114)

3/6

Check the function of the adjustment system.

Operate the adjustment system in both directions. Pull on the system to verify that it does not lose its adjustment

setting.

8. Checking the chin strap

Check the condition of the chin strap and the adjustment parts (wear,

cuts, burns, deformation of plastic pieces).

Move the keepers and plastic pieces to inspect any hidden areas on the

straps.

PPE INSPECTION - Inspection procedure - HELMETS (271114)

Check the condition of the chin strap

buckle (wear, deformation, breakage). Test

the reliability of the fastening by pulling gently

on the chin strap.

4/6

9. Checking the comfort foams

Check the condition of the comfort foams. If necessary, remove them

for washing or replacement.

10. Checking the headlamp clips

Check the condition of the headlamp clips (wear, deformation,

missing parts...).

11. Checking accessories

If accessories are mounted on the helmet, check their condition and

make sure they are working properly (face shield, headlamp...).

PPE INSPECTION - Inspection procedure - HELMETS (271114)

5/6

Appendix 1. Examples of helmets that are worn out, or that should be retired

Broken buckle

Broken buckle

Broken buckle

Impact on the shell

Chemical product on the shell

Chemical product on the shell

Deep scratch on the shell

Marks on the shell and broken clip

Cracked liner

Cracked liner

Cracked liner

Liner marked and deformed

Cracked shell

Broken adjustment system

Deformed shell

Impact on the shell

Cracked shell

Cracked shell

Deformed shell

Deformed shell

Worn out comfort foam

Torn comfort foam

PPE INSPECTION - Inspection procedure - HELMETS (271114)

6/6

Potrebbero piacerti anche

- Verif EPI Harnais PRO Procedure EN PDFDocumento6 pagineVerif EPI Harnais PRO Procedure EN PDFDimasDianaFerreiraNessuna valutazione finora

- Handbook of Adhesive Bonded Structural RepairDa EverandHandbook of Adhesive Bonded Structural RepairValutazione: 5 su 5 stelle5/5 (1)

- Verif EPI Harnais PRO Procedure enDocumento6 pagineVerif EPI Harnais PRO Procedure enDimasDianaFerreiraNessuna valutazione finora

- PPE Inspection GuideDocumento5 paginePPE Inspection GuideDarwin AndyNessuna valutazione finora

- Verif EPI Harnais PRO Suivi EN PDFDocumento1 paginaVerif EPI Harnais PRO Suivi EN PDFDimasDianaFerreiraNessuna valutazione finora

- Inspection Form: Frame-Loaded Rope ClampDocumento1 paginaInspection Form: Frame-Loaded Rope ClampDimasDianaFerreiraNessuna valutazione finora

- PPE Inspection - 12-step rope clamp checkDocumento5 paginePPE Inspection - 12-step rope clamp checkDimasDianaFerreiraNessuna valutazione finora

- Tecnical Notice Avao Bod Bodfast 1 C715010eDocumento24 pagineTecnical Notice Avao Bod Bodfast 1 C715010eEdgar Barrientos VilcasNessuna valutazione finora

- Fsra 5 Step ChecklistDocumento9 pagineFsra 5 Step ChecklistDhifani Hayu FadhilahNessuna valutazione finora

- PETZL - William Screw-LockDocumento22 paginePETZL - William Screw-LockForbez3Nessuna valutazione finora

- Inspection Procedure: Grillon LanyardDocumento5 pagineInspection Procedure: Grillon LanyardUlviyye ElesgerovaNessuna valutazione finora

- A Manual Valve 4 02Documento11 pagineA Manual Valve 4 02Robbi FerdianNessuna valutazione finora

- Harness (And Body Belt) Inspection: WebbingDocumento3 pagineHarness (And Body Belt) Inspection: WebbingUlviyye ElesgerovaNessuna valutazione finora

- Verif EPI Casque PRO Suivi enDocumento1 paginaVerif EPI Casque PRO Suivi eneastNessuna valutazione finora

- Installation and Care Guide for Stop ValveDocumento14 pagineInstallation and Care Guide for Stop ValveVijay DaeNessuna valutazione finora

- Swing Check Valve: Installation, Operation and Maintenance ManualDocumento13 pagineSwing Check Valve: Installation, Operation and Maintenance ManualaftabNessuna valutazione finora

- Longdar SM906 InspectionDocumento2 pagineLongdar SM906 InspectionLê Anh MinhNessuna valutazione finora

- كيفية فحص ادوات الحمايه من السقوط من الارتفاعاتDocumento20 pagineكيفية فحص ادوات الحمايه من السقوط من الارتفاعاتMohamedSaidNessuna valutazione finora

- Inspecting Fall Arrest Equipment Made From Webbing or RopeDocumento6 pagineInspecting Fall Arrest Equipment Made From Webbing or RopePieterNessuna valutazione finora

- Method Statement Form - Diaphragm ValveDocumento6 pagineMethod Statement Form - Diaphragm ValveSmith SuwanNessuna valutazione finora

- Installation and Care Manual for Constant Flow ValvesDocumento16 pagineInstallation and Care Manual for Constant Flow ValvesQuỳnh GermanNessuna valutazione finora

- BuWa SZF Manual Globe-Valves EN-1Documento11 pagineBuWa SZF Manual Globe-Valves EN-1Diego VerlyNessuna valutazione finora

- Diaphragm Valve Type 72: Installation, Operation and Maintenance ManualDocumento17 pagineDiaphragm Valve Type 72: Installation, Operation and Maintenance Manualshinchan1112Nessuna valutazione finora

- Harness Insp. and Maint. Daily ChecklistDocumento3 pagineHarness Insp. and Maint. Daily ChecklistSarojini VeeraraghavanNessuna valutazione finora

- Inspection and Testing of Personal Protective EquipmentDocumento11 pagineInspection and Testing of Personal Protective EquipmentMohan RajNessuna valutazione finora

- Selecting A Safety HarnessDocumento4 pagineSelecting A Safety HarnessStevien HendryanNessuna valutazione finora

- B16 CrollDocumento24 pagineB16 CrollJuan Manuel Rodriguez ArbelaezNessuna valutazione finora

- Measuring Rubber Goods IrregularitiesDocumento34 pagineMeasuring Rubber Goods IrregularitiesKelt NoltuNessuna valutazione finora

- Flowvalves KSB Va Pn16Documento11 pagineFlowvalves KSB Va Pn16JavierNessuna valutazione finora

- Technical Notice CORDES SEMI STATDocumento26 pagineTechnical Notice CORDES SEMI STATJuan Reyes GomezNessuna valutazione finora

- V Belt Replacement Work Instructions - ENDocumento24 pagineV Belt Replacement Work Instructions - ENfendy_wu100% (1)

- Tips For Protecting Your Equipment RopesDocumento5 pagineTips For Protecting Your Equipment RopesLuis Ernesto Del Rio MurilloNessuna valutazione finora

- Inspection Ppe FallDocumento6 pagineInspection Ppe FallAnonymous GfPSYi4nNessuna valutazione finora

- Technical Notice OMNI TRIACTLOCK 1Documento22 pagineTechnical Notice OMNI TRIACTLOCK 1DistribuidorIBoolPedregalDeSantoDomingoNessuna valutazione finora

- The Full Body HarnessDocumento3 pagineThe Full Body HarnessroelNessuna valutazione finora

- Webbing SlingDocumento3 pagineWebbing Slingmoha19841Nessuna valutazione finora

- Admin 4 2 R0Documento2 pagineAdmin 4 2 R0Stephen MalobaNessuna valutazione finora

- Technical Notice ABSORBICA - CE 1 PDFDocumento17 pagineTechnical Notice ABSORBICA - CE 1 PDFJhoan FlorezNessuna valutazione finora

- Lukas LS Series User ManualDocumento15 pagineLukas LS Series User ManualBoris Enrique Chandia LibbrechtNessuna valutazione finora

- Competent Inspector ManualDocumento123 pagineCompetent Inspector Manualnothingnothing76Nessuna valutazione finora

- Fall Arrest: Product CatalogueDocumento60 pagineFall Arrest: Product CatalogueBorislav VulićNessuna valutazione finora

- Checklist - Backup Device - Petzl ASAP-LOCKDocumento1 paginaChecklist - Backup Device - Petzl ASAP-LOCKMax BeeksNessuna valutazione finora

- Petzl b18 Ascensor BasicDocumento26 paginePetzl b18 Ascensor BasicVictor FdezNessuna valutazione finora

- Technical Notice OMNI SCREWLOCK 1Documento20 pagineTechnical Notice OMNI SCREWLOCK 1DistribuidorIBoolPedregalDeSantoDomingoNessuna valutazione finora

- Fall ProtectionDocumento57 pagineFall ProtectionDonna Diaz CantilloNessuna valutazione finora

- Guide For The Repairs Excavator Structures by Welding: Print No. 604.07.189.01 - EnglishDocumento32 pagineGuide For The Repairs Excavator Structures by Welding: Print No. 604.07.189.01 - EnglishАнатолій ГуменюкNessuna valutazione finora

- HABONIMDocumento18 pagineHABONIMHema IbraNessuna valutazione finora

- 2012 Ol1 1.7 UDocumento14 pagine2012 Ol1 1.7 UalexedamalaNessuna valutazione finora

- Installation, Operation and Maintenance Manual: Type II Type IDocumento32 pagineInstallation, Operation and Maintenance Manual: Type II Type IMauro Calahorrano CárdenasNessuna valutazione finora

- Newton Newton Fast JakDocumento24 pagineNewton Newton Fast JakEmba_ShehilaNessuna valutazione finora

- Muller CoDocumento12 pagineMuller CoRamSalunkheNessuna valutazione finora

- Caa Inspections and Safe Use of Lifting Equipment March 2022Documento66 pagineCaa Inspections and Safe Use of Lifting Equipment March 2022rubalcava_70Nessuna valutazione finora

- Cooker Hood Instruction Manual: Important: Retain For Future ReferenceDocumento28 pagineCooker Hood Instruction Manual: Important: Retain For Future ReferenceAnkurNessuna valutazione finora

- Essential Guide to Installation, Use and Maintenance of Air Handling UnitsDocumento28 pagineEssential Guide to Installation, Use and Maintenance of Air Handling UnitsTr3mbl3Nessuna valutazione finora

- Checklist - Ascenders - Petzl Hand & Chest - 050717Documento1 paginaChecklist - Ascenders - Petzl Hand & Chest - 050717Max BeeksNessuna valutazione finora

- Camilla Nest S61Documento13 pagineCamilla Nest S61viboralunaNessuna valutazione finora

- Body Belts InspectionDocumento4 pagineBody Belts InspectionI LucianaNessuna valutazione finora

- Snap SOP - 27 Feb 2022Documento38 pagineSnap SOP - 27 Feb 2022Suresh KumarNessuna valutazione finora

- Protecting Equipment Tips enDocumento22 pagineProtecting Equipment Tips enoliveirajpazNessuna valutazione finora

- Verif EPI IDS IDL RIG Procedure enDocumento5 pagineVerif EPI IDS IDL RIG Procedure enDimasDianaFerreiraNessuna valutazione finora

- Z33 Petzl Tactical Solutions 2016 enDocumento16 pagineZ33 Petzl Tactical Solutions 2016 enDimasDianaFerreiraNessuna valutazione finora

- Steel GuitarDocumento1 paginaSteel GuitarDimasDianaFerreiraNessuna valutazione finora

- Yearly Injury Report SummaryDocumento1 paginaYearly Injury Report SummaryDimasDianaFerreiraNessuna valutazione finora

- Workplace Hazardous Material Information System - WHMIS Employee Training/instructionDocumento1 paginaWorkplace Hazardous Material Information System - WHMIS Employee Training/instructionDimasDianaFerreiraNessuna valutazione finora

- Working at Heights Rescue ProcedureDocumento6 pagineWorking at Heights Rescue ProcedureBea Mok0% (1)

- Whitepaper NFPA 2013 Standards Update HS 7440 enDocumento4 pagineWhitepaper NFPA 2013 Standards Update HS 7440 enDimasDianaFerreiraNessuna valutazione finora

- WWW Cmcrescue Com Equipment Stainless Steel Rescue LitterDocumento2 pagineWWW Cmcrescue Com Equipment Stainless Steel Rescue LitterDimasDianaFerreiraNessuna valutazione finora

- Witness Statement FormDocumento1 paginaWitness Statement FormDimasDianaFerreiraNessuna valutazione finora

- What About Rescue Response For Fallen Workers at HeightDocumento3 pagineWhat About Rescue Response For Fallen Workers at HeightDimasDianaFerreiraNessuna valutazione finora

- Webpage of Dennis Havlena - W8mi Mackinac Straits, MiDocumento10 pagineWebpage of Dennis Havlena - W8mi Mackinac Straits, MiDimasDianaFerreiraNessuna valutazione finora

- Verif Epi Ids Idl Rig Suivi enDocumento1 paginaVerif Epi Ids Idl Rig Suivi enDimasDianaFerreiraNessuna valutazione finora

- 2 Ways To Record PowerpointDocumento5 pagine2 Ways To Record PowerpointDimasDianaFerreiraNessuna valutazione finora

- Plectrum Technique For Bass GuitarDocumento1 paginaPlectrum Technique For Bass GuitarDimasDianaFerreira0% (1)

- Bass Guitar Technique Guide - Alternate Picking, String Crossing & MoreDocumento1 paginaBass Guitar Technique Guide - Alternate Picking, String Crossing & MoreDimasDianaFerreira0% (3)

- Boss Catalog 2012Documento17 pagineBoss Catalog 2012Daniel MiceliNessuna valutazione finora

- PPE Inspection - 12-step rope clamp checkDocumento5 paginePPE Inspection - 12-step rope clamp checkDimasDianaFerreiraNessuna valutazione finora

- Alternate Picking - Part 1Documento1 paginaAlternate Picking - Part 1DimasDianaFerreiraNessuna valutazione finora

- Asp2 2 GB PDFDocumento42 pagineAsp2 2 GB PDFclaudipakalNessuna valutazione finora

- Exercise 129Documento1 paginaExercise 129DimasDianaFerreiraNessuna valutazione finora

- 3893 BOSS Prod Cat2005 72Documento19 pagine3893 BOSS Prod Cat2005 72moodiomemoNessuna valutazione finora

- Pure Pi - Control Custom Stompbox Effects On A Raspberry Pi With A Smartphone PDFDocumento5 paginePure Pi - Control Custom Stompbox Effects On A Raspberry Pi With A Smartphone PDFDimasDianaFerreiraNessuna valutazione finora

- 2009-10 KIPP Academy Elementary Family HandbookDocumento22 pagine2009-10 KIPP Academy Elementary Family HandbookKaya StoneNessuna valutazione finora

- S3 - Lesson 22 Summarizing)Documento8 pagineS3 - Lesson 22 Summarizing)Muhammad Harist MurdaniNessuna valutazione finora

- Assignment On Intercultural Communication 4421Documento10 pagineAssignment On Intercultural Communication 4421hoanglanhou100% (2)

- Arts Grade 7Documento22 pagineArts Grade 7IMELDA TORRESNessuna valutazione finora

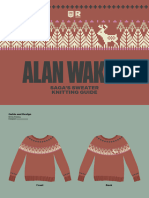

- AW2 Saga Knittingguide 2Documento6 pagineAW2 Saga Knittingguide 2jinterryNessuna valutazione finora

- BR 222 RepairDocumento32 pagineBR 222 RepairSerkanAlNessuna valutazione finora

- Cute Crochet Teddy Bear Amigurumi Toy Free PatternDocumento6 pagineCute Crochet Teddy Bear Amigurumi Toy Free PatternAndreea Elena Caba100% (1)

- Macbeth by Shakespeare - "Fair is foul and foul is fairDocumento19 pagineMacbeth by Shakespeare - "Fair is foul and foul is fairPamela Alvarez100% (1)

- 500 Short Stories 2 PDFDocumento209 pagine500 Short Stories 2 PDFmdecarneri100% (4)

- Modul SMK Kelas Xii Semester 2Documento21 pagineModul SMK Kelas Xii Semester 2Anonymous DSPDrcT100% (1)

- Improving Belt Conveyor Safety With Better Procedures and TrainingDocumento6 pagineImproving Belt Conveyor Safety With Better Procedures and TrainingcdkueaNessuna valutazione finora

- Resume: Mobile No - 9600477781 Coimbatore - 641 105Documento3 pagineResume: Mobile No - 9600477781 Coimbatore - 641 105chitrabalrajNessuna valutazione finora

- Body Bio MethodsDocumento2 pagineBody Bio Methodsapi-432999648Nessuna valutazione finora

- Present Perfect Vs SimpleDocumento6 paginePresent Perfect Vs SimpleAna SánchezNessuna valutazione finora

- Banjara Embroidery - HyderabadDocumento35 pagineBanjara Embroidery - HyderabadForum Majithia67% (3)

- High converse shoes shopping guideDocumento1 paginaHigh converse shoes shopping guideKherss Ann Joy EspinosaNessuna valutazione finora

- Natural Rubber WikiDocumento9 pagineNatural Rubber WikiMyra Wardati SNessuna valutazione finora

- Adidas Case StudyDocumento2 pagineAdidas Case StudyBarnik GoswamiNessuna valutazione finora

- Small Scale Industry Auroville IndiaDocumento34 pagineSmall Scale Industry Auroville IndiaIsabell Fringer100% (1)

- Plan, Elevation and End ElevationDocumento136 paginePlan, Elevation and End ElevationGraham LeesNessuna valutazione finora

- Upstream Pre B1 Unit Test 5Documento2 pagineUpstream Pre B1 Unit Test 5Biljana NestorovskaNessuna valutazione finora

- Royson Hat: Free Knitting PatternDocumento3 pagineRoyson Hat: Free Knitting Patternhello hiNessuna valutazione finora

- FormulasDocumento20 pagineFormulasRishit MevadaNessuna valutazione finora

- Name: - Date: - : English Year 2 Unit 7: Get Dressed Match The Picture CorrectlyDocumento12 pagineName: - Date: - : English Year 2 Unit 7: Get Dressed Match The Picture CorrectlySHANMUGA MALAR A/P KANDIPAN MoeNessuna valutazione finora

- Traditional EmbroideryDocumento38 pagineTraditional EmbroiderySabrina SuptiNessuna valutazione finora

- There are hospitals and cafesDocumento2 pagineThere are hospitals and cafesGonzaloNessuna valutazione finora

- Industrial ReportDocumento64 pagineIndustrial Reportfuad ullahNessuna valutazione finora

- ComparativeDocumento5 pagineComparativenindyaariniNessuna valutazione finora

- Redacted Complaint Against Utah County Commissioner Greg GravesDocumento104 pagineRedacted Complaint Against Utah County Commissioner Greg GravesThe Salt Lake TribuneNessuna valutazione finora

- Tom Sawyer Summary Based ActivitiesDocumento15 pagineTom Sawyer Summary Based ActivitiesRuth SanchezNessuna valutazione finora