Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Daily Work Management Sheet

Caricato da

Balachandar SathananthanTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Daily Work Management Sheet

Caricato da

Balachandar SathananthanCopyright:

Formati disponibili

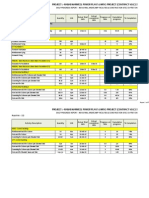

Sundaram Brake Linings Limited

Plant :

Date :

For the date :

Daily Work Management Sheet

Cell Incharge

Cell Technician

Maintenance Engineer

Review Yesterdays

output

Collect data for the day

Quality Engineer

Caluculate Availability,

Performance & Quality

rates

KK Representative

Analyse each losses

Output Log

Countermeasure &

Preventive action

Plan counter measure &

preventive action

CELL :

SUB CELL :

Reason for Gap

OUTPUT PLANNED :

OUTPUT ACHIEVED :

GAP:

TOTAL AVAILABLE TIME

SHIFT 1

B

C

D

E

F

G

H

I

J

K

L

SHIFT 2

SHIFT 3

JH TIME

PLANNED DOWN TIME(WANT OF MATL,PM etc..)

PROCESS SCRAP(PROCESSING TIME IN MTS)

ACTUAL AVAILABLE TIME (A-B)

DOWNTIME(B/D, SETUP,ADJUSTMENT)

ACTUAL UPTIME (C-D)

EQUIPMENT AVAILABILITY IN %(E/C)X100)

QUANTITY PRODUCED

THEORITICAL CYCLE TIME IN MTS

PERFORMANCE RATE((HXG)/E X 100))

QUANTITY REJECTED

QUALITY RATE ((G-J)/G X 100))

OVERALL EQUIPMENT EFFECTIVENESS

AVAILABILITY =

TARGET = 95%

GAP=

LOSSES IN MTS

SET UP =

ADJUSTMENT =

BREAKDOWN =

PERFORMANCE =

TARGET = 90%

GAP =

LOSSES IN MTS

STARTUP DELAY =

MINOR STOPPAGE =

REDUCED SPEED =

QUALITY =

TARGET = 99%

GAP =

LOSSES

SCRAP IN NOS

PHENOMENA

Sundaram Brake Linings Ltd

Padi Plant

WHY WHY ANALYSIS SHEET

WW.C5:NO:

EQUIPMENT / MACHINE

Date

Time

Shift

1 2 3

Breakdown / Physical Phenomenon

What is your final action ?

( Part Replacement )

Describe Countermeasure:

In case of spare part replacement

( Adjustment )

In case of spare-part no replacement

Why did you take above action ?

Due to

Why 1

Why 2

Why 3

Why 4

Why 5

Root cause :

Root cause is one of the following 5 items.

(1)

Poor Basic Condition

(2)

Poor Operating Condition

(3)

Deterioration

(4)

Weak Design

(5)

Poor Skill

(Note: Please fill up this form in pencil immediately after machine is started)

Kaizen Idea and Schedule.

JH

PM

Design

E&T Skill

ABNORMALITIES REGISTER FOR CELL-5

Potrebbero piacerti anche

- Sep'18 SPM SectionDocumento143 pagineSep'18 SPM SectionPatrick AndriesNessuna valutazione finora

- Annexure Vi - Quality Objectives: Measurement Criteria TypeDocumento5 pagineAnnexure Vi - Quality Objectives: Measurement Criteria Typemuthuswamy77Nessuna valutazione finora

- Machine CapacityDocumento3 pagineMachine CapacitycaturNessuna valutazione finora

- Tiao Him - Perimeter FenceDocumento54 pagineTiao Him - Perimeter FenceBert EngNessuna valutazione finora

- Use of Oee Coefficient For Identification of Bottlenecks For Pressure Die Casting ProcessesDocumento6 pagineUse of Oee Coefficient For Identification of Bottlenecks For Pressure Die Casting ProcessesIonut EduardNessuna valutazione finora

- Premium Reduction & Delivery Improvement: Champion - SponsorDocumento40 paginePremium Reduction & Delivery Improvement: Champion - Sponsorjitendrasutar1975Nessuna valutazione finora

- Oee Exercise Result: Please Perform This Analysis For All Key ProcessesDocumento1 paginaOee Exercise Result: Please Perform This Analysis For All Key ProcessesBalu RaviNessuna valutazione finora

- Rich Downey PresentationDocumento31 pagineRich Downey Presentationskywalk189Nessuna valutazione finora

- ICAS Initial-Capacity-Assessment-Sheet 2010-12-09Documento15 pagineICAS Initial-Capacity-Assessment-Sheet 2010-12-09Fitzi ShadyNessuna valutazione finora

- VSM 27janDocumento21 pagineVSM 27janShweta SinghNessuna valutazione finora

- CapacityDocumento7 pagineCapacityPatryk RączyNessuna valutazione finora

- ICAS Initial Capacity Assessment Sheet 2010-12-09Documento15 pagineICAS Initial Capacity Assessment Sheet 2010-12-09kannan_pillai_4Nessuna valutazione finora

- ICAS - Initial Capacity Assessment Sheet - 2010 12 09Documento15 pagineICAS - Initial Capacity Assessment Sheet - 2010 12 09Musa GürsoyNessuna valutazione finora

- JLR PSF-010 Capacity Analysis ReportDocumento7 pagineJLR PSF-010 Capacity Analysis ReporttruongngvNessuna valutazione finora

- Op-3-72. Checklist For Draft Subsurface Investigation Factual ReportDocumento5 pagineOp-3-72. Checklist For Draft Subsurface Investigation Factual Reportjinwook75Nessuna valutazione finora

- Project:-Rabab Harweel Power Plant & HRSG Project (Contract No.C311530)Documento7 pagineProject:-Rabab Harweel Power Plant & HRSG Project (Contract No.C311530)Nadim JilaniNessuna valutazione finora

- Dynamic Control Plan - DCPDocumento2 pagineDynamic Control Plan - DCPGabriel Caicedo RussyNessuna valutazione finora

- Computer: Manufacturing SystemsDocumento39 pagineComputer: Manufacturing SystemsJeganNessuna valutazione finora

- Six Sigma Sample QuestionsDocumento2 pagineSix Sigma Sample Questionsbreezeee100% (1)

- Monitoring LogsheetDocumento2 pagineMonitoring LogsheetDominic CabaloNessuna valutazione finora

- Application of Smed Single Minutes Exchange of Die For Production OptimizationDocumento7 pagineApplication of Smed Single Minutes Exchange of Die For Production OptimizationRellan YbanezNessuna valutazione finora

- Thesis On OEE of WeldingDocumento6 pagineThesis On OEE of WeldingAbdullah Al MahmudNessuna valutazione finora

- Faizal AhmedDocumento5 pagineFaizal AhmedEngineer - E&INessuna valutazione finora

- KBR Standard Project: Ipms Chains Safety EngineeringDocumento13 pagineKBR Standard Project: Ipms Chains Safety EngineeringkamlNessuna valutazione finora

- Schedule 03Documento70 pagineSchedule 03Tarek HassanNessuna valutazione finora

- Plant Layout Design & Material Handling: Ir. Florida Butarbutar, MTDocumento9 paginePlant Layout Design & Material Handling: Ir. Florida Butarbutar, MTfridynaintanNessuna valutazione finora

- MDRF FormatDocumento1 paginaMDRF FormatSamsung NetworksNessuna valutazione finora

- CANELAR ELEM. SCHOOL - by AdminDocumento31 pagineCANELAR ELEM. SCHOOL - by AdminBert EngNessuna valutazione finora

- On Mixed Integer Programming Formulations For The Unit Commitment ProblemDocumento92 pagineOn Mixed Integer Programming Formulations For The Unit Commitment ProblemEduards Moises Triviño VildósolaNessuna valutazione finora

- II. Capacity Planning: I. Key InformationDocumento7 pagineII. Capacity Planning: I. Key Informationqzm74lNessuna valutazione finora

- E - III.3. Kanban Parameters CalculationDocumento37 pagineE - III.3. Kanban Parameters CalculationMohamed Emam MohamedNessuna valutazione finora

- Ford Capacity Analysis ReportDocumento7 pagineFord Capacity Analysis Reportss2mrattriNessuna valutazione finora

- Maintenance Engineer PDFDocumento4 pagineMaintenance Engineer PDFMasroor RasoolNessuna valutazione finora

- 004-MS For Erection of Equipment Platforms, Handrails, Gratings, Stairways PDFDocumento9 pagine004-MS For Erection of Equipment Platforms, Handrails, Gratings, Stairways PDFKöksal Patan100% (1)

- Monthly Performance Review For The Month of April 2012Documento10 pagineMonthly Performance Review For The Month of April 2012Shoaib RathoreNessuna valutazione finora

- Measurement of Overall Equipment Effectiveness Oee of A Manufacturing Industry An Effective Lean ToolDocumento8 pagineMeasurement of Overall Equipment Effectiveness Oee of A Manufacturing Industry An Effective Lean ToolEko MaulidiNessuna valutazione finora

- Overall Equipment Effectiveness Analyse For PerforDocumento9 pagineOverall Equipment Effectiveness Analyse For PerforLjubomir FilipovskiNessuna valutazione finora

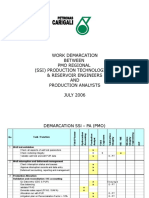

- Work Demarcation Between Pmo Regional (Ssi) Production Technologists & Reservoir Engineers AND Production Analysts JULY 2006Documento5 pagineWork Demarcation Between Pmo Regional (Ssi) Production Technologists & Reservoir Engineers AND Production Analysts JULY 2006ronelbarafaeldiegoNessuna valutazione finora

- Diseno Simulacion y Optimizacion de Un Circuito SAG Utilizando JKsimmetDocumento16 pagineDiseno Simulacion y Optimizacion de Un Circuito SAG Utilizando JKsimmetRommel Heredia TejadaNessuna valutazione finora

- Payroll Remittance Six Sigma Case StudyDocumento2 paginePayroll Remittance Six Sigma Case StudySteven BonacorsiNessuna valutazione finora

- Maint Philsp N Devlp ProgrDocumento47 pagineMaint Philsp N Devlp Progrhatach100% (1)

- Draft Kpi Report Presentation - 250109Documento71 pagineDraft Kpi Report Presentation - 250109S.m. Al-AmoudiNessuna valutazione finora

- MydocDocumento3 pagineMydocghatevinod9360Nessuna valutazione finora

- GE6 SigmaDocumento44 pagineGE6 SigmaFisher1987Nessuna valutazione finora

- Body ModelDocumento145 pagineBody ModelDipika PandaNessuna valutazione finora

- Department Flow ChartDocumento5 pagineDepartment Flow ChartsazzadNessuna valutazione finora

- SRU Offplot - Process - Phase 3 - Class 3 TIC Estimate (FEED)Documento86 pagineSRU Offplot - Process - Phase 3 - Class 3 TIC Estimate (FEED)GPNessuna valutazione finora

- Generation Reliability: C&I System ManagementDocumento13 pagineGeneration Reliability: C&I System ManagementcmcNessuna valutazione finora

- WSAD Course SummaryDocumento16 pagineWSAD Course SummaryAbdulwahab AlmaimaniNessuna valutazione finora

- Basic Productivity Improvement Techniques-Anil and Rahul SinghDocumento15 pagineBasic Productivity Improvement Techniques-Anil and Rahul Singhmohit vatsNessuna valutazione finora

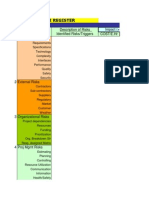

- Risk RegisterDocumento34 pagineRisk RegisterMohamedMoideenNagoorMeeran33% (3)

- Computer: Manufacturing SystemsDocumento39 pagineComputer: Manufacturing SystemsRajueswarNessuna valutazione finora

- Tugas Pemrogaman NC Job 7 ErvianDocumento3 pagineTugas Pemrogaman NC Job 7 Erviananjay0336Nessuna valutazione finora

- Worksheet 4 1Documento2 pagineWorksheet 4 1barmarwanNessuna valutazione finora

- 001-MS For Structural Steel Assembly and Erection PDFDocumento28 pagine001-MS For Structural Steel Assembly and Erection PDFKöksal Patan100% (1)

- Aide Memoire: Subject: DEL EGC Project, QatarDocumento5 pagineAide Memoire: Subject: DEL EGC Project, QatarRanish P. KurianNessuna valutazione finora

- Maintenance PhilosophyDocumento40 pagineMaintenance PhilosophySam100% (1)

- Daily Progress Report of Pipeline ConstructionDocumento58 pagineDaily Progress Report of Pipeline ConstructionMintu Choudhury46% (13)

- ICPM BurgessDocumento27 pagineICPM BurgessJacob Jack YoshaNessuna valutazione finora

- Bla BlaDocumento24 pagineBla BlamclorenzNessuna valutazione finora

- Job Instruction How To InstructDocumento2 pagineJob Instruction How To InstructBalachandar SathananthanNessuna valutazione finora

- 7 Types of AbnormalitiesDocumento23 pagine7 Types of AbnormalitiesBalachandar SathananthanNessuna valutazione finora

- FJMJDocumento1 paginaFJMJBalachandar SathananthanNessuna valutazione finora

- Standards Requirement Sheet: FunctionDocumento16 pagineStandards Requirement Sheet: FunctionBalachandar SathananthanNessuna valutazione finora

- Standards Requirement Sheet: FunctionDocumento16 pagineStandards Requirement Sheet: FunctionBalachandar SathananthanNessuna valutazione finora

- Granulation Area: Tablet ManufacturingDocumento5 pagineGranulation Area: Tablet ManufacturingBalachandar SathananthanNessuna valutazione finora

- Standards Requirement Sheet: FunctionDocumento16 pagineStandards Requirement Sheet: FunctionBalachandar SathananthanNessuna valutazione finora

- EtfwreDocumento2 pagineEtfwreBalachandar SathananthanNessuna valutazione finora

- Tolerance Analysis: Norbert Jagodzinski Rochester Institute of TechnologyDocumento30 pagineTolerance Analysis: Norbert Jagodzinski Rochester Institute of TechnologyBalachandar SathananthanNessuna valutazione finora

- Wdvvwcwqcwe 2 EcwcwcDocumento2 pagineWdvvwcwqcwe 2 EcwcwcBalachandar SathananthanNessuna valutazione finora

- And Reliability (Documento1 paginaAnd Reliability (Balachandar SathananthanNessuna valutazione finora

- Centre of Excellence in TQM: SRM School of ManagementDocumento2 pagineCentre of Excellence in TQM: SRM School of ManagementBalachandar SathananthanNessuna valutazione finora

- One Day Experience Sharing Session by Deming Prize and Deming Grand Prize Winners in 2012Documento4 pagineOne Day Experience Sharing Session by Deming Prize and Deming Grand Prize Winners in 2012Balachandar SathananthanNessuna valutazione finora

- 1 BHK Good Condition Flat For Sale at Very Good Locality at Nasik Details. Address Narsinha Nagar, Gangapur Road, Nasik. Interested PL May ContactDocumento1 pagina1 BHK Good Condition Flat For Sale at Very Good Locality at Nasik Details. Address Narsinha Nagar, Gangapur Road, Nasik. Interested PL May ContactBalachandar SathananthanNessuna valutazione finora

- SBL Flow EfeqfqqDocumento2 pagineSBL Flow EfeqfqqBalachandar SathananthanNessuna valutazione finora

- Financial Bid For Engine Parts Cluster - GCCE 1 - AurangabadDocumento7 pagineFinancial Bid For Engine Parts Cluster - GCCE 1 - AurangabadBalachandar SathananthanNessuna valutazione finora

- JDVHCF ASDRKDocumento1 paginaJDVHCF ASDRKBalachandar SathananthanNessuna valutazione finora

- OneWay Cab - Invoice No. - 13175Documento1 paginaOneWay Cab - Invoice No. - 13175Balachandar SathananthanNessuna valutazione finora

- EfqwfqxDocumento5 pagineEfqwfqxBalachandar SathananthanNessuna valutazione finora

- Kaizen Idea - Sheet: Measurement & Adjustment LossDocumento1 paginaKaizen Idea - Sheet: Measurement & Adjustment LossBalachandar SathananthanNessuna valutazione finora

- To Reduce Cycle Time Variation in GANG PRESSES 5,6,7,8,16&17Documento1 paginaTo Reduce Cycle Time Variation in GANG PRESSES 5,6,7,8,16&17Balachandar SathananthanNessuna valutazione finora

- Description Before After: Key Words To Be Used in Setting Time Projects Smed MethodolgyDocumento1 paginaDescription Before After: Key Words To Be Used in Setting Time Projects Smed MethodolgyBalachandar SathananthanNessuna valutazione finora

- ELGI Dexterity Plan: SR - No 1 2 3 4 5 6 7 8 9 10 11 12Documento8 pagineELGI Dexterity Plan: SR - No 1 2 3 4 5 6 7 8 9 10 11 12Balachandar SathananthanNessuna valutazione finora

- SR - No Phase: Content of Dexterity ImplimentationDocumento2 pagineSR - No Phase: Content of Dexterity ImplimentationBalachandar SathananthanNessuna valutazione finora

- Eticket: Chennai Salem Sunday, July 3, 2016Documento1 paginaEticket: Chennai Salem Sunday, July 3, 2016Thalapathy VenkatNessuna valutazione finora

- Dexterity TrainingDocumento6 pagineDexterity TrainingBalachandar SathananthanNessuna valutazione finora

- Dex. School Items: Pratice BenchDocumento4 pagineDex. School Items: Pratice BenchBalachandar SathananthanNessuna valutazione finora

- Dexterity Instructor Selection Should Be Done On Following Points SR - No 1 2 3 4 5 6 7 8 9 10 11 12 13 14Documento5 pagineDexterity Instructor Selection Should Be Done On Following Points SR - No 1 2 3 4 5 6 7 8 9 10 11 12 13 14Balachandar SathananthanNessuna valutazione finora