Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Formwork Costing

Caricato da

Shikhin GargDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Formwork Costing

Caricato da

Shikhin GargCopyright:

Formati disponibili

LARSEN & TOUBRO LIMITED

FCCE

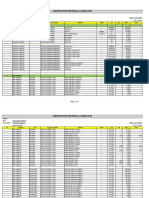

FORM WORK COSTING

ESTIMATING COST OF FORM WORK

The cost of formwork consists of the cost of

Materials

Labour for making Formwork

Labour for erection and dismantling

Repair of formwork

Labour for transporting, shifting materials

Plant and equipment used for making, erection, dismantling, repair and

transport

Cleaning and storage costs

Transportation costs

MATERIALS

Usually this is a major component of the total cost of formwork. Material can be

classified as

Direct materials

They are the main component of form work eg. Timber, steel etc.

Consumables

Nails, shuttering oils etc. are treated as consumables.

The cost can be computed in two ways

Cost of materials scrap value

Cost of material per use

=

Number of repetitions

FORM WORK COSTING

LARSEN & TOUBRO LIMITED

Cost of material for an

item in the project

FCCE

Cost of material scrap value x period of use

}=

Life of material

Usually the first method is used for materials with short life like timber and

plywood and second method is used for materials with long life like steel and metal

components.

COST REDUCTION

The key areas of the cost reduction are

Right system for the right job

Considerable savings result when the appropriate system is used for the job in

hand. Several times the system best suited for the job is not selected and hence the project

may not be completed profitably.

Planning for maximum reuse

Specification or local code requirements for stripping and reshoring are an

important factor in planning form reuse. Maximum investment in forms is achieved by

constructing the least number of forms required for a smooth workflow and then reusing

these forms as often as necessary until the job is completed.

Economical form construction

When non - reusable forms are to be built in position on the job, the planning

should be such that inexpensive materials are used which are easy to transport, handle

and shape in the field.

Reusable forms must be more durable, made of strong materials that can

withstand continuing and usually must have added features that make them easy to

handle and to assemble.

In choosing ties or inserts, the initial cost is not as important as the labour

involved in their installation and form striping.

FORM WORK COSTING

LARSEN & TOUBRO LIMITED

FCCE

Efficient setting and stripping practice

The full benefit of a plan for reuse of forms can only be realized if the forms can

be stripped and re-erected without too much lost time and if the form is not wrecked in

the process. Therefore, designing for easy handling and disassembly is essential.

OTHER COSTS AFFECTED BY FORMWORK PLAN

Crew efficiency

Advance planning eliminates confusion and delay in the field, where it is most

costly. Where maximum reuse of forms if emphasized every operation must be

scheduled precisely to sustain effective continuity of employment of craftsmen on site.

Concreting

The ease and speed of placing concrete is related to the planned sequence and to

some extent to the choice of form design.

Bar setting

If form design can enable the reinforcement to be pre-assembled before installing,

it may enable the reinforcing crew to work under more favorable conditions.

Cranes and hoists

One object of planning should be to use cranes and hoists efficiently so that there

are just enough on a project to keep the work going smoothly.

FORM WORK COSTING

Potrebbero piacerti anche

- Void Engineers (Convention: Mage The Ascension)Documento6 pagineVoid Engineers (Convention: Mage The Ascension)Beth0% (1)

- Penetron - Ceo - Sonasea - Waterproofing Details and SpecsDocumento7 paginePenetron - Ceo - Sonasea - Waterproofing Details and SpecsNguyễn ThanhNessuna valutazione finora

- 1 - Construction Material List - 20191021Documento10 pagine1 - Construction Material List - 20191021SokHeang ButhNessuna valutazione finora

- Guide To Standards and Tolerances 2019 - WA - 17521Documento72 pagineGuide To Standards and Tolerances 2019 - WA - 17521RuwiniNessuna valutazione finora

- Super Structure ConstructionDocumento53 pagineSuper Structure ConstructionInformation Techn. HODNessuna valutazione finora

- Turbine Start-Up SOPDocumento17 pagineTurbine Start-Up SOPCo-gen ManagerNessuna valutazione finora

- Design For Disassembly GuidelinesDocumento8 pagineDesign For Disassembly GuidelinesMalvika KulkarniNessuna valutazione finora

- Probability Theory - VaradhanDocumento6 pagineProbability Theory - VaradhanTom HenNessuna valutazione finora

- Formwork Based On: Structural ComponentsDocumento20 pagineFormwork Based On: Structural ComponentsPatrick Jake DimapilisNessuna valutazione finora

- Example Checklist For Piping and HVAC Drawings in Interiour Design ProjectsDocumento2 pagineExample Checklist For Piping and HVAC Drawings in Interiour Design Projectskhanh123ctmNessuna valutazione finora

- Non Structural Cracking of ConcreteDocumento4 pagineNon Structural Cracking of ConcreteMinh LinhTinhNessuna valutazione finora

- Lecture 5 Ground Slab ConstDocumento85 pagineLecture 5 Ground Slab Constkriti shuklaNessuna valutazione finora

- Pouring Concrete 1floorDocumento2 paginePouring Concrete 1floorNimas AfinaNessuna valutazione finora

- CTC's Milestone Schedule For Coordination - Rev 00 Dated 16.04.2018Documento7 pagineCTC's Milestone Schedule For Coordination - Rev 00 Dated 16.04.2018ThanhNessuna valutazione finora

- Form WorkDocumento35 pagineForm Workcdnaveen100% (4)

- Temperature Control in Mass ConcreteDocumento34 pagineTemperature Control in Mass ConcreteIrvebry Ayu Wulandary100% (1)

- 160007-SWP-QS-CostPlanB-140318 Rev02 BNDocumento163 pagine160007-SWP-QS-CostPlanB-140318 Rev02 BNMinh TanNessuna valutazione finora

- WBS Name Activity Name PredecessorDocumento55 pagineWBS Name Activity Name Predecessorjules_gwapoNessuna valutazione finora

- SD-NOC-MAR-202 - Rev00 Transfer of Personnel at Offshore FacilitiesDocumento33 pagineSD-NOC-MAR-202 - Rev00 Transfer of Personnel at Offshore Facilitiestho03103261100% (1)

- Construction ManualDocumento13 pagineConstruction ManualGuransh SinghNessuna valutazione finora

- Geto Aluminium Formwork User ManualDocumento35 pagineGeto Aluminium Formwork User ManualbsudhareddyNessuna valutazione finora

- Jump Form MethodologyDocumento30 pagineJump Form MethodologyyusufuNessuna valutazione finora

- Slope Stability AnalysisDocumento2 pagineSlope Stability AnalysisdantevariasNessuna valutazione finora

- KUMKANG LOAD CAL - 1500KVA - 19.03.26 (3차)Documento70 pagineKUMKANG LOAD CAL - 1500KVA - 19.03.26 (3차)Phạm Đức HoằngNessuna valutazione finora

- Plastic Water BottleDocumento25 paginePlastic Water BottleShikhin GargNessuna valutazione finora

- GP 09-04-01Documento31 pagineGP 09-04-01Anbarasan Perumal100% (1)

- BIM For Construction MGT and Planning - Student Manual PDFDocumento21 pagineBIM For Construction MGT and Planning - Student Manual PDFTuấn AnhNessuna valutazione finora

- CS E10:2014: Guidelines on Design Loads for Skyrise GreeneryDa EverandCS E10:2014: Guidelines on Design Loads for Skyrise GreeneryNessuna valutazione finora

- Precast Concrete ConstructionDocumento71 paginePrecast Concrete ConstructionMahad AbdiNessuna valutazione finora

- Akbar Great Mogul 100 S Mitu of TDocumento554 pagineAkbar Great Mogul 100 S Mitu of TShikhin GargNessuna valutazione finora

- Alternative Technologies in Building ConstructionDocumento24 pagineAlternative Technologies in Building ConstructionMuskan ChoudharyNessuna valutazione finora

- Hsa FTM 2012-09Documento19 pagineHsa FTM 2012-09Thang VoNessuna valutazione finora

- Tiếng Anh Trong Xây Dựng: Bài GiảngDocumento50 pagineTiếng Anh Trong Xây Dựng: Bài GiảngTrọng NghĩaNessuna valutazione finora

- Tim Hieu Qua Trinh Loc Tach Dau KhiDocumento838 pagineTim Hieu Qua Trinh Loc Tach Dau KhiNem Chua RánNessuna valutazione finora

- CE5301 Construction Processes and Technology: Tall BuildingsDocumento27 pagineCE5301 Construction Processes and Technology: Tall BuildingsImalka Priyadarshani100% (1)

- Design of Slab FormsDocumento27 pagineDesign of Slab FormsZevanyaRolandTualaka100% (1)

- 4 Estimating Labour Plant Material CostsDocumento17 pagine4 Estimating Labour Plant Material CostsSarah HaiderNessuna valutazione finora

- 1999 - Anaiysis of Construction Loads On Concrete FormworkDocumento210 pagine1999 - Anaiysis of Construction Loads On Concrete FormworkbobbynguyenNessuna valutazione finora

- Explanatory Information FM Table 3.1 TR34 4th Edition 2013Documento10 pagineExplanatory Information FM Table 3.1 TR34 4th Edition 2013jay76123123Nessuna valutazione finora

- Concrete Polishing & Laser Screed FlooringDocumento7 pagineConcrete Polishing & Laser Screed FlooringLamba Techno Flooring SolutionsNessuna valutazione finora

- WB Offshore Wind Development Program Offshore Wind Roadmap For Vietnam DVToanDocumento227 pagineWB Offshore Wind Development Program Offshore Wind Roadmap For Vietnam DVToanNam Hoai LeNessuna valutazione finora

- Unit-3Documento22 pagineUnit-3Vijay VNessuna valutazione finora

- Slideshare - VN Bai Tap Lon Ki Thuat Thi Cong Tim Hieu Ve Van Khuon Truot Van Khuon LeoDocumento33 pagineSlideshare - VN Bai Tap Lon Ki Thuat Thi Cong Tim Hieu Ve Van Khuon Truot Van Khuon LeoThang Tran VietNessuna valutazione finora

- ĐỊNH GIÁ SO SÁNHDocumento6 pagineĐỊNH GIÁ SO SÁNHAn HoaiNessuna valutazione finora

- Formwork in HighriseDocumento21 pagineFormwork in HighriseAmrutha PavithranNessuna valutazione finora

- Checklist For Hse Day EventsDocumento2 pagineChecklist For Hse Day EventsJani AceNessuna valutazione finora

- AssignmentDocumento60 pagineAssignmentArdiniNessuna valutazione finora

- Basics of Project Planning PDFDocumento12 pagineBasics of Project Planning PDFanwar abdullah qabajaNessuna valutazione finora

- Logisvalley Bac Ninh - Vietnam VersionDocumento17 pagineLogisvalley Bac Ninh - Vietnam VersionvulinhquocNessuna valutazione finora

- M16 - Report Mockup PDFDocumento34 pagineM16 - Report Mockup PDFTheAnh TranNessuna valutazione finora

- Acrow SpanDocumento2 pagineAcrow SpangattaiahNessuna valutazione finora

- IPC No 10-Rev 1 (Check)Documento80 pagineIPC No 10-Rev 1 (Check)Nguyen Hoành QuảngNessuna valutazione finora

- 2010 10 OnlineDocumento72 pagine2010 10 OnlineSanja RadovicNessuna valutazione finora

- Geotechnical PracticalDocumento24 pagineGeotechnical PracticalTshepiso NthiteNessuna valutazione finora

- 3D BIM 2D Plan Submission (Sanitary)Documento29 pagine3D BIM 2D Plan Submission (Sanitary)Ko NandaNessuna valutazione finora

- Basics of Post Installed Rebar Connections: 1 ApplicationsDocumento33 pagineBasics of Post Installed Rebar Connections: 1 ApplicationsHaitham KayyaliNessuna valutazione finora

- Analysis of The Static Tests of Boring Piles Through FDP (Full Displacement Pile) TechnologyDocumento4 pagineAnalysis of The Static Tests of Boring Piles Through FDP (Full Displacement Pile) TechnologyJohn STCNessuna valutazione finora

- Ringlock Vs BS1139Documento22 pagineRinglock Vs BS1139dam van tuyen100% (1)

- 8-IWRE 416-Formwork and FalseworkDocumento41 pagine8-IWRE 416-Formwork and Falseworkally IsayaNessuna valutazione finora

- Doremon ProjectDocumento18 pagineDoremon ProjectXiao LynnNessuna valutazione finora

- TV (1) .TD.C23 Volume 1+2Documento124 pagineTV (1) .TD.C23 Volume 1+2Nguyen Phuc PhamNessuna valutazione finora

- QC 222 - Building Construction Iii: Formwork and False WorkDocumento10 pagineQC 222 - Building Construction Iii: Formwork and False Workkefapaul21Nessuna valutazione finora

- Cost EfficientDocumento14 pagineCost EfficientYigezu YehombaworkNessuna valutazione finora

- Seminar Summary: Title Lecturer Date/Place Organizer Confirmation of Attendance Contents Summary Composite TechnologyDocumento4 pagineSeminar Summary: Title Lecturer Date/Place Organizer Confirmation of Attendance Contents Summary Composite Technologywandee2393Nessuna valutazione finora

- Plastic Formworks For ConcreteDocumento12 paginePlastic Formworks For ConcreteNarlyn TevesNessuna valutazione finora

- CUR96 Full Paper Template Madrid2014Documento8 pagineCUR96 Full Paper Template Madrid2014martin_calmonNessuna valutazione finora

- Design For Additive Manufacturing: by 20M153 - V.RahulDocumento13 pagineDesign For Additive Manufacturing: by 20M153 - V.Rahul20M130 - MUKUNTH A GNessuna valutazione finora

- HeadstoneMarkerMedallion BrochureDocumento2 pagineHeadstoneMarkerMedallion BrochureShikhin GargNessuna valutazione finora

- Volume 1091 I 16743 English PDFDocumento122 pagineVolume 1091 I 16743 English PDFShikhin GargNessuna valutazione finora

- Marine Debris Neutral 2018 WebDocumento5 pagineMarine Debris Neutral 2018 WebShikhin GargNessuna valutazione finora

- ChyawanprashDocumento5 pagineChyawanprashShikhin GargNessuna valutazione finora

- Traffic SignsDocumento4 pagineTraffic SignsShikhin GargNessuna valutazione finora

- How To Reach Sjmsom, Iit Bombay: Public TransportDocumento2 pagineHow To Reach Sjmsom, Iit Bombay: Public TransportShikhin GargNessuna valutazione finora

- Tal Eem: WI Nter 2016 Issue - IDocumento4 pagineTal Eem: WI Nter 2016 Issue - IShikhin GargNessuna valutazione finora

- 09 Han PDFDocumento15 pagine09 Han PDFShikhin GargNessuna valutazione finora

- Placement Brochure 2016-17 PDFDocumento20 paginePlacement Brochure 2016-17 PDFShikhin GargNessuna valutazione finora

- Mladen Oska 2007Documento5 pagineMladen Oska 2007Shikhin GargNessuna valutazione finora

- Roads Sensitive Habitats and WildlifeDocumento231 pagineRoads Sensitive Habitats and WildlifeShikhin GargNessuna valutazione finora

- JR YamunaExpressway enDocumento8 pagineJR YamunaExpressway enShikhin GargNessuna valutazione finora

- 2016 Community Cultural Activity in TaipeiDocumento1 pagina2016 Community Cultural Activity in TaipeiShikhin GargNessuna valutazione finora

- Hsinchu Bus 182 ScheduleDocumento1 paginaHsinchu Bus 182 ScheduleShikhin GargNessuna valutazione finora

- C&C Construction LTD - New-June14Documento1 paginaC&C Construction LTD - New-June14Shikhin GargNessuna valutazione finora

- CKRE Lab (CHC 304) Manual - 16 May 22Documento66 pagineCKRE Lab (CHC 304) Manual - 16 May 22Varun pandeyNessuna valutazione finora

- Drilling Jigs Italiana FerramentaDocumento34 pagineDrilling Jigs Italiana FerramentaOliver Augusto Fuentes LópezNessuna valutazione finora

- Hume 100 ReviewerDocumento7 pagineHume 100 ReviewerShai GaviñoNessuna valutazione finora

- Moc3040 MotorolaDocumento3 pagineMoc3040 MotorolaBryanTipánNessuna valutazione finora

- Myers Briggs Type Indicator-2Documento1 paginaMyers Briggs Type Indicator-2api-261818438Nessuna valutazione finora

- The Data Driven AuditDocumento34 pagineThe Data Driven AuditMon compte Mon compteNessuna valutazione finora

- S25580 MSDS Corn Starch FisherchiDocumento6 pagineS25580 MSDS Corn Starch FisherchiProcurement ProlineNessuna valutazione finora

- Evidence MODULE 1 Evidence DefinitionDocumento8 pagineEvidence MODULE 1 Evidence Definitiondave BarretoNessuna valutazione finora

- Most Dangerous City - Mainstreet/Postmedia PollDocumento35 pagineMost Dangerous City - Mainstreet/Postmedia PollTessa VanderhartNessuna valutazione finora

- Problems: C D y XDocumento7 pagineProblems: C D y XBanana QNessuna valutazione finora

- Fiedler1950 - A Comparison of Therapeutic Relationships in PsychoanalyticDocumento10 pagineFiedler1950 - A Comparison of Therapeutic Relationships in PsychoanalyticAnca-Maria CovaciNessuna valutazione finora

- Application Letter For Promotion T2 T3Documento24 pagineApplication Letter For Promotion T2 T3FGacadSabadoNessuna valutazione finora

- TOEFL-Reading Question Type Definitions and ExplanationDocumento5 pagineTOEFL-Reading Question Type Definitions and ExplanationSamara SampaioNessuna valutazione finora

- Thesis - A Surlyn® Ionomer As A Self-Healing and Self-Sensing Composite - 2011 - UKDocumento194 pagineThesis - A Surlyn® Ionomer As A Self-Healing and Self-Sensing Composite - 2011 - UKAhmedNessuna valutazione finora

- CS3501 Compiler Design Lab ManualDocumento43 pagineCS3501 Compiler Design Lab ManualMANIMEKALAINessuna valutazione finora

- 2011 Burris CatalogDocumento56 pagine2011 Burris CatalogMario Lopez100% (1)

- Manitou 1350RDocumento4 pagineManitou 1350RcandlaganNessuna valutazione finora

- MidsemDocumento6 pagineMidsemAravind SomasundaramNessuna valutazione finora

- World English 2ed 1 WorkbookDocumento80 pagineWorld English 2ed 1 WorkbookMatheus EdneiNessuna valutazione finora

- Control System PPT DO1Documento11 pagineControl System PPT DO1Luis AndersonNessuna valutazione finora

- Scan WV1DB12H4B8018760 20210927 1800Documento6 pagineScan WV1DB12H4B8018760 20210927 1800Sergio AlvarezNessuna valutazione finora

- Concept of Lokmitra Kendra in Himachal PradeshDocumento2 pagineConcept of Lokmitra Kendra in Himachal PradeshSureshSharmaNessuna valutazione finora

- ERP Solution in Hospital: Yangyang Shao TTU 2013Documento25 pagineERP Solution in Hospital: Yangyang Shao TTU 2013Vishakh SubbayyanNessuna valutazione finora

- ANNEXESDocumento6 pagineANNEXESKyzer Calix LaguitNessuna valutazione finora

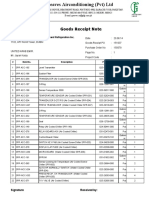

- Goods Receipt Note: Johnson Controls Air Conditioning and Refrigeration Inc. (YORK) DateDocumento4 pagineGoods Receipt Note: Johnson Controls Air Conditioning and Refrigeration Inc. (YORK) DateSaad PathanNessuna valutazione finora