Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Road Pavement QA-QC Audit Manual - Appendixes A & B

Caricato da

freanne_0527Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Road Pavement QA-QC Audit Manual - Appendixes A & B

Caricato da

freanne_0527Copyright:

Formati disponibili

ASHGHAL - PUBLIC WORKS AUTHORITY

QA/QC PAVEMENT CONSULTANCY SERVICES

PROJECT ID: IA/10 11/S013/G

APPENDIX A: COLLECTION OF PROJECT INFORMATION

OPERATING

PROCEDURE

OP - 01

Revision Number:

Collection of Project Information

Prepared By:

Position:

Mohammed Anshasi

Quality Auditor

Issue Date:

Reviewed By:

Position:

23/10/2014

Alfredo Marques

Quality Expert Assistant

Mohammed Anshasi

Quality Auditor

Davide Lioi

Pavement Expert Assistant

Effective Date:

Approved By:

Position:

23/10/2014

Hussain Bahia

Leading Pavement Expert

Revision History:

Revision

Number

Revision

Date

Description of changes

Requested by

13-02-2014

Initial Release

Leading Pavement Expert

17-02-2014

Minor Changes

Leading Pavement Expert

09-06-2014

Changes in Terms, Definitions and Acronyms

and Responsibilities

Leading Pavement Expert

13-09-2014

Expanding the list of required project information

Leading Pavement Expert

19-10-2014

Revise the list of required project information

Leading Pavement Expert

23-10-2014

Revise the list of required project information and

the schedule templates/ID Coding Updating

Leading Pavement Expert

APPENDIX A: OPERATING PROCEDURE OP01 REV5

COLLECTION OF PROJECT INFORMATION

PAGE A-1

AQB-T03-QMSDS-PRO-MOA-231014-0-5

ASHGHAL - PUBLIC WORKS AUTHORITY

QA/QC PAVEMENT CONSULTANCY SERVICES

PROJECT ID: IA/10 11/S013/G

TABLE OF CONTENTS

APPENDIX A: COLLECTION OF PROJECT INFORMATION ..................................................................... A-1

A.1

POLICY .............................................................................................................................. A-3

A.2

SCOPE / FIELD OF APPLICATION........................................................................................... A-3

A.3

TERMS, DEFINITIONS AND ACRONYMS ................................................................................. A-3

A.4

RESPONSIBILITIES .............................................................................................................. A-5

A.5

PROCEDURE ...................................................................................................................... A-5

A.5.1 INFORMATION REQUIRED FOR A NEW PROJECT ................................................................. A-5

A.5.2 NAME & CONTACT DETAILS REQUIREMENT ...................................................................... A-5

A.5.3 INITIAL MEETING AND PROJECT INFORMATION REQUEST ................................................... A-6

A.5.4 AP BRIEFING AND PROJECT AUDIT PROPOSAL ................................................................. A-8

A.5.5 PROJECT CONSTRUCTION INFORMATION REQUEST ........................................................... A-8

A.5.6 INFORMATION TRANSMISSION .......................................................................................... A-9

A.5.7 PROCEDURE EFFECTIVENESS CRITERIA ........................................................................... A-9

A.5.8 FORMS/ RECORDS ........................................................................................................ A-10

APPENDIX A: OPERATING PROCEDURE OP01 REV5

COLLECTION OF PROJECT INFORMATION

PAGE A-2

AQB-T03-QMSDS-PRO-MOA-231014-0-5

ASHGHAL - PUBLIC WORKS AUTHORITY

QA/QC PAVEMENT CONSULTANCY SERVICES

PROJECT ID: IA/10 11/S013/G

A.1

POLICY

Project Information that will be collected following this procedure will be accurate,

reliable and always up to date, according to the PWA official contractual documents

for the project.

A.2

SCOPE / FIELD OF APPLICATION

The scope of this activity is to obtain all relevant project information for projects

audited by ANAS.

This procedure outlines the set of documents that are required by ANAS at the

commencement and during audit activities on projects. It also outlines the expected

channels of communication to keep project information updated.

A.3

TERMS, DEFINITIONS AND ACRONYMS

Auditee: Organization, area, task, function, or department being audited.

Auditor: Individual who carries out an audit. A person qualified and authorized to

perform all or part of an audit by way of training and experience.

Key Supply Chain Partners (KSCP): The entities that affect directly or indirectly,

inside or outside Qatar, the construction of roads for the PWA contracts.

Leading Pavement Expert (LPE): ANAS Resource responsible for directing the

technical activities of the project, responsible for the development of technical plans,

preparation of technical reports, briefs and circulars and make technical

presentations to the PWA and other stakeholders.

Quality Auditor: ANAS Resource, responsible for the overall management and

monitoring of the information, performed under progress or planned for the future, for

a specific project.

Programme Lead: The PWA Resource responsible for the management and

supervision of the QA/QC Pavement Consultancy Services Contract.

QA/QC Project: The Quality Assurance / Quality Control Pavement Consultancy

Services project, awarded to ANAS S.p.A.

Quality Management System (QMS): Ordered, well-documented quality system,

the primary goal of which is a quality product / service.

Task 3 Leader: ANAS Resource responsible for the overall management of the

Task 3 Auditing activities both internally (planning, executing, monitoring and

controlling and reporting) and externally (communicating with the PWA and Key

Supply Chain Partners of the roads construction industry).

APPENDIX A: OPERATING PROCEDURE OP01 REV5

COLLECTION OF PROJECT INFORMATION

PAGE A-3

AQB-T03-QMSDS-PRO-MOA-231014-0-5

ASHGHAL - PUBLIC WORKS AUTHORITY

QA/QC PAVEMENT CONSULTANCY SERVICES

PROJECT ID: IA/10 11/S013/G

Task 3 Audit Planner (AP): Activity performed by a nominated ANAS Resource in

the Task 3 team, responsible for the elaboration, continuous update, monitoring and

controlling of the planning of Task 3 auditing activities.

ANAS: ANAS S.p.A Qatar Branch

ANCR: Audit Non Conformance Report

AP: Task 3 Audit Planner

CAR: Corrective Action Report

CP: Construction Practices

CPAP: Construction Practices Audit Plan

DC: Document Controller

GEC: General Engineering Consultant

KSCP: Key Supply Chain Partners

ITP: Inspection Testing Plan

LA: Lead Auditor

LPE: Leading Pavement Expert

PAP: Project Auditing Proposal

PL: Programme Lead

PWA: Public Work Authority

PMC: Programme Management Consultant

PQMA: Project Quality Management Audit

QA/QC Project: QA/QC Pavement Consultant Services Project

QM: ANAS S.p.A. Qatar Branch Quality System Manager

QMS: Quality Management System

RE: Resident Engineer

SC: Supervision Consultant

WBS: Work Breakdown Structure

APPENDIX A: OPERATING PROCEDURE OP01 REV5

COLLECTION OF PROJECT INFORMATION

PAGE A-4

AQB-T03-QMSDS-PRO-MOA-231014-0-5

ASHGHAL - PUBLIC WORKS AUTHORITY

QA/QC PAVEMENT CONSULTANCY SERVICES

PROJECT ID: IA/10 11/S013/G

A.4

RESPONSIBILITIES

The Audit Planner (AP) reports to the Task 3 Leader or Leading Pavement Expert

(LPE) and is responsible for:

Planning of all necessary activities in order to obtain timely and accurate

project information for each PWA project to be audited by ANAS;

Communicating with the PWA and the KSCPs (as necessary) in order to

request and receive the project information;

Delivering all the project information to the Document Controller (DC), with

clear instructions regarding the storage, display and distribution;

Evaluating the effectiveness of the project information regarding the planning

and executing of the auditing activities;

Implementation this procedure; and

Providing feedback to the QM for continuous improvement.

The Task 3 Leader reports to LPE and is responsible for:

Addressing all the issues / problems that might arise while the project

information is being collected; and

Organizing relevant kick-off meetings with the KSCPs of each project

(participants, timing etc.).

A.5

A.5.1

PROCEDURE

INFORMATION REQUIRED FOR A NEW PROJECT

The PWA will request ANAS to consider a new project for auditing. ANAS will review

the request and compare to the criteria it established for projects that need to be

audited. ANAS will respond to PWA with the recommendations to audit or not audit

the specific project. If the Project to be audited by ANAS is approved by PWA for

auditing, PWA sends a formal request to ANAS including the expected starting date

for the project. The PWA instructions can be delivered to ANAS either by an official

letter or by e-mail. ANAS proceeds to collect all relevant Project Information, as

listed below.

A.5.2

NAME & CONTACT DETAILS REQUIREMENT

ANAS is to collect the names and contact details of all relevant parties involved

within the Project contract:

PWA Project Manager;

PMC Project Manager;

Supervision Consultant (SC) / General Engineering consultant (GEC):

o Senior Resident Engineer;

o Road Resident Engineer;

o Material Engineer;

o Site Road Inspector;

APPENDIX A: OPERATING PROCEDURE OP01 REV5

COLLECTION OF PROJECT INFORMATION

PAGE A-5

AQB-T03-QMSDS-PRO-MOA-231014-0-5

ASHGHAL - PUBLIC WORKS AUTHORITY

QA/QC PAVEMENT CONSULTANCY SERVICES

PROJECT ID: IA/10 11/S013/G

o Quality Manager;

Construction Contractor:

o Project Manager;

o Construction Manager;

o Quality Manager

A.5.3

INITIAL MEETING AND PROJECT INFORMATION REQUEST

Within one week of receiving the request from PWA for auditing a project, ANAS

responsible Engineer/Auditor schedules (AP) an initial meeting with PWA and

PMC/SC Project Managers, collecting / requiring the following information:

1. Project contractual information:

1.1. GEC contract technical submission;

1.2. Contractor Project technical submission;

1.3. Quality Manual (Quality Assurance and Quality Control plans) for:

1.3.1. PMC/GEC/SC;

1.3.2. Contractor;

1.3.3. Subcontractor/Supplier;

1.3.4. Third Party Laboratory.

2. General Project information

2.1 Brief project description:

2.1.1. Project location GIS Map;

2.1.2. General drawing layout with Chainages;

2.1.3. Road layers cross sections;

2.1.4. Interchanges / bridges, carriageway type, number of lanes;

2.1.5. Site accesses layout and traffic management plan if applicable.

2.2. Project Contact details

2.2.1 PMC (Project Manager)

2.2.2 SC (Senior RE, RE Roads, Senior Materials Engineer, Inspectors)

2.2.3 Contractor (Project Manager, QA/QC Manager, Plant Manager)

2.3. Project Detailed Design information;

2.3.1. Pavement design report

2.3.2. Materials and Mix design submittals as applicable:

2.3.2.1. Unbound Materials;

2.3.2.2. Cement Bound Materials;

2.3.2.3. Asphalt Courses.

APPENDIX A: OPERATING PROCEDURE OP01 REV5

COLLECTION OF PROJECT INFORMATION

PAGE A-6

AQB-T03-QMSDS-PRO-MOA-231014-0-5

ASHGHAL - PUBLIC WORKS AUTHORITY

QA/QC PAVEMENT CONSULTANCY SERVICES

PROJECT ID: IA/10 11/S013/G

2.4. Project Planning and Scheduling

2.4.1. Project baseline Schedule, to include (WBS, Project calendars and work

periods, activities definitions, duration and sequencing);

2.4.2. Three months look-ahead of pavement activities schedule

(last

Thursday of the Month on or before 2:00pm);

2.4.3. Biweekly look-ahead of pavement activities schedule (every Thursday

on or before 2:00pm);

2.4.4. Daily notification of pavement activities (one day before the planned

activity on or before 2:00pm).

2.5. Project Quantities and Physical Progress

2.5.1. Quantities Calculations (For all Different Pavement Structures in the

Project)

2.5.2. Areas calculations according to WBS;

2.5.3. Volumes calculations for each layer according to design drawing

with related cross section;

2.5.4. Tonnage calculations for each layer according to design drawing

with related cross section;

2.5.5. Biweekly Physical progress for each pavement layer (every

Thursday on or before 2:00pm);

2.5.6. Daily progress and activities completed (daily on or before 2:00pm).

2.6. Material Sources and Suppliers:

2.6.1. Subgrade Suppliers and Crusher;

2.6.2. Aggregate bases Suppliers, Crusher and Wet Mix Plant;

2.6.3. CBM Suppliers, Crusher and Plant/s;

2.6.4. Asphalt Mixtures aggregates source, binder source, PMB Suppliers,

Plant/s.

2.7. Pavement, material production, construction and quality control documents

2.7.1. Stockpile management plan

2.7.2. Approved Method Statement for pavement layers production and

construction;

2.7.3. Approved ITPs for pavement layers;

3. Materials Testing Laboratory and Contacts:

3.1. Contact details of the third party laboratory (legal name, Laboratory Manager

Name).

4. Materials Specification Requirements (QCS 2010, PWA Guides, etc.).

5. Materials testing results (Summary Logs) for all pavement layers from Third-Party

Laboratories to be sent on Biweekly basis (every other Thursday on or before

2:00pm).

APPENDIX A: OPERATING PROCEDURE OP01 REV5

COLLECTION OF PROJECT INFORMATION

PAGE A-7

AQB-T03-QMSDS-PRO-MOA-231014-0-5

ASHGHAL - PUBLIC WORKS AUTHORITY

QA/QC PAVEMENT CONSULTANCY SERVICES

PROJECT ID: IA/10 11/S013/G

6. Any Change and/or new instructions regarding the specification requirements

officially given to the contractor shall also be provided to ANAS within Two

working days.

The above Project Information shall be provided to ANAS within one week from initial

meeting with PWA/PMC Project Managers or as noted for periodical information

requested during project execution phase, i.e. look-ahead schedules, physical

progress and summary logs of material testing results.

Once the documents requested are obtained, the AP will check the information

against the Project Initial Information Checklist OP-01-F01. In case information is

not complete, the check list with the missing documents highlighted will be issued to

the PWA/PMC Project Managers.

A.5.4

AP BRIEFING AND PROJECT AUDIT PROPOSAL

Within one week of receiving the required information, a specific briefing will be given

by the AP to ANAS Project Manager and LPE. AP is also required to prepare and

present to PWA the Project Auditing Proposal (PAP).

PWA will review the PAP and give feedback for approval or rejection to ANAS within

one week of receipt of the PAP.

A.5.5

PROJECT CONSTRUCTION INFORMATION REQUEST

Upon receiving notification of Project commencement, the AP will request the

following information regarding the pavement layers construction on periodic basis

during the project as shown below. The request will be from SC/GEC for Legacy,

Local Roads & Drainage and Expressways projects, and from PWA project manager

for RIW Projects.

Information

3 months activities and production look

ahead schedule

Biweekly activities and production look

ahead schedule

Daily activity look ahead schedule

Daily progress and activities completed

QC Records

Updated site access and traffic

management plan

Time Limit of delivering to ANAS

Last Thursday of every Month by 2:00

PM

On Thursday of every Week by 2:00 PM

The day before the activities by 2:00 PM

Every day by 2:00 PM

Every three months

If necessary

Action

SC/GEC has

to send

through Email

to AP, DC

In case information is not received as indicated in the table above, or is incomplete,

Unacceptable Observation according to OP-21-F06 (Operating Procedure

Management of Non-Conformances) will be issued to the relevant Party.

APPENDIX A: OPERATING PROCEDURE OP01 REV5

COLLECTION OF PROJECT INFORMATION

PAGE A-8

AQB-T03-QMSDS-PRO-MOA-231014-0-5

ASHGHAL - PUBLIC WORKS AUTHORITY

QA/QC PAVEMENT CONSULTANCY SERVICES

PROJECT ID: IA/10 11/S013/G

A.5.6

INFORMATION TRANSMISSION

The information listed in Sections 5.1 through 5.5 is transmitted by the relevant

Parties via email to the ANAS AP and to the Document Controller using the following

email: admin.docs@anas.com.qa

The information received is recorded in ANAS system. Document recording storage

and retrieval will be according to ANAS Procedure QP-01 Document Control, and

distributed throughout the ANAS Audit Team via email.

A.5.7

PROCEDURE EFFECTIVENESS CRITERIA

Timely collection and delivery of information;

Clarity of the Project Audit Proposal and effective implementation;

Timely recording of information in ANAS system.

APPENDIX A: OPERATING PROCEDURE OP01 REV5

COLLECTION OF PROJECT INFORMATION

PAGE A-9

AQB-T03-QMSDS-PRO-MOA-231014-0-5

ASHGHAL - PUBLIC WORKS AUTHORITY

QA/QC PAVEMENT CONSULTANCY SERVICES

PROJECT ID: IA/10 11/S013/G

A.5.8

FORMS/ RECORDS

Form / Record

Form/ Record Name

Satisfies

IS0

9001 Clause

Required by ISO 9001:2008

Other Forms/ Records

OP-01-F01

Project Initial Information Checklist

OP-01-F02*

Three Monthly Schedule

OP-01-F03*

Biweekly Schedule

OP-01-F04*

Daily Schedule

OP-01-F05*

Biweekly

Schedule

Pavement

Materials

Production

(*): The formats of these forms are optional for use by contractors or consultants, but information is required.

Excel Spreadsheets of the same are available and can be requested from ANAS AP or DC.

APPENDIX A: OPERATING PROCEDURE OP01 REV5

COLLECTION OF PROJECT INFORMATION

PAGE A-10

AQB-T03-QMSDS-PRO-MOA-231014-0-5

ASHGHAL - PUBLIC WORKS AUTHORITY

QA/QC PAVEMENT CONSULTANCY SERVICES

PROJECT ID: IA/10 11/S013/G

Table A.5-1 OP-01-F01

Project Initial Information Checklist

NOTE

( Received, not

received, or

incomplete)

Project Code

Project Name

Project contractual information:

1.1

GEC contract technical submission;

1.2

Contractor Project technical submission;

1.3

Quality Manual (Quality Assurance and Quality Control

plans) for:

1.3.1

PMC/GEC/SC;

1.3.2

Contractor;

1.3.3

Subcontractor/Supplier;

1.3.4

Third Party Laboratory.

General Project information

2.1

Brief project description

2.1.1

Project location GIS Map;

2.1.2

General drawing layout with Chainages;

2.1.3

Road layers cross sections;

2.1.4

2.1.5

2.2

2.2.2

2.2.3

2.3

Interchanges / bridges, carriageway type, number of

lanes;

Site accesses layout and traffic management plan if

applicable.

Project Contact details

2.2.1

PMC (Project Manager)

SC (Senior RE, RE Roads, Senior Materials

Engineer, Inspectors)

Contractor (Project Manager, QA/QC Manager, Plant

Manager)

Project Detailed Design information;

Pavement design report

2.3.2

Materials and Mix design submittals as applicable:

2.3.2.1

Unbound Materials;

2.3.2.2

Cement Bound Materials;

2.3.2.3

Asphalt Courses.

2.4

Project Planning and Scheduling

2.4.1

2.4.2

2.3.1

Project baseline Schedule, to include (WBS, Project

calendars and work periods, activities definitions,

duration and sequencing);

Three months look-ahead of pavement activities

schedule (last Thursday of the Month on or before

APPENDIX A: OPERATING PROCEDURE OP01 REV5

COLLECTION OF PROJECT INFORMATION

PAGE A-11

AQB-T03-QMSDS-PRO-MOA-231014-0-5

ASHGHAL - PUBLIC WORKS AUTHORITY

QA/QC PAVEMENT CONSULTANCY SERVICES

PROJECT ID: IA/10 11/S013/G

Project Initial Information Checklist

NOTE

( Received, not

received, or

incomplete)

Project Code

Project Name

2:00pm);

2.4.3

2.4.4

2.5

Project Quantities and Physical Progress

2.5.1

2.5.2

Areas calculations according to WBS;

2.5.4

2.5.5

2.5.6

2.6

Quantities Calculations (For all Different Pavement

Structures in the Project)

2.5.3

Biweekly look-ahead of pavement activities schedule

(every Thursday on or before 2:00pm);

Daily notification of pavement activities (one day

before the planned activity on or before 2:00pm).

Volumes calculations for each layer according to

design drawing with related cross section;

Tonnage calculations for each layer according to

design drawing with related cross section;

Biweekly Physical progress for each pavement layer

(every Thursday on or before 2:00pm);

Daily progress and activities completed (daily on or

before 2:00pm).

Material Sources and Suppliers:

2.6.1

Subgrade Suppliers and Crusher;

2.6.2

Aggregate bases Suppliers, Crusher and Wet Mix

Plant;

2.6.3

CBM Suppliers, Crusher and Plant/s;

2.7

Asphalt Mixtures aggregates source, binder source,

2.6.4

PMB Suppliers, Plant/s.

Pavement material production construction and quality

control documents

2.7.1

Stockpiles management plans

2.7.2

Approved Method Statement for pavement layers

production and construction;

2.7.3

Approved ITPs for pavement layers;

Materials Testing Laboratory and Contacts:

3.1

Contact details of the third party laboratory (legal name,

Laboratory Manager Name).

Materials Specification Requirements (QCS 2010, PWA Guides,

etc.).

Materials testing results (Summary Logs) for all pavement layers

from Third-Party Laboratories to be sent on Biweekly basis (every

other Thursday on or before 2:00pm).

APPENDIX A: OPERATING PROCEDURE OP01 REV5

COLLECTION OF PROJECT INFORMATION

PAGE A-12

AQB-T03-QMSDS-PRO-MOA-231014-0-5

ASHGHAL - PUBLIC WORKS AUTHORITY

QA/QC PAVEMENT CONSULTANCY SERVICES

PROJECT ID: IA/10 11/S013/G

Project Initial Information Checklist

NOTE

( Received, not

received, or

incomplete)

Project Code

Project Name

Any Change and/or new instructions regarding the specification

requirements officially given to the contractor shall also be

provided to ANAS within Two working days.

APPENDIX A: OPERATING PROCEDURE OP01 REV5

COLLECTION OF PROJECT INFORMATION

PAGE A-13

AQB-T03-QMSDS-PRO-MOA-231014-0-5

ASHGHAL - PUBLIC WORKS AUTHORITY

QA/QC PAVEMENT CONSULTANCY SERVICES

PROJECT ID: IA/10 11/S013/G

Table A.5-2 OP-01-F02 Three Monthly Schedule

APPENDIX A: OPERATING PROCEDURE OP01 REV5

COLLECTION OF PROJECT INFORMATION

PAGE A-14

AQB-T03-QMSDS-PRO-MOA-231014-0-5

ASHGHAL - PUBLIC WORKS AUTHORITY

QA/QC PAVEMENT CONSULTANCY SERVICES

PROJECT ID: IA/10 11/S013/G

Table A.5-3 OP-01-F03 Biweekly Schedule

APPENDIX A: OPERATING PROCEDURE OP01 REV5

COLLECTION OF PROJECT INFORMATION

PAGE A-15

AQB-T03-QMSDS-PRO-MOA-231014-0-5

ASHGHAL - PUBLIC WORKS AUTHORITY

QA/QC PAVEMENT CONSULTANCY SERVICES

PROJECT ID: IA/10 11/S013/G

Table A.5-4 OP-01-F04 Daily Schedule

APPENDIX A: OPERATING PROCEDURE OP01 REV5

COLLECTION OF PROJECT INFORMATION

PAGE A-16

AQB-T03-QMSDS-PRO-MOA-231014-0-5

ASHGHAL - PUBLIC WORKS AUTHORITY

QA/QC PAVEMENT CONSULTANCY SERVICES

PROJECT ID: IA/10 11/S013/G

Table A.5-5 OP-01-F05 Biweekly Pavement Materials Production Schedule

APPENDIX A: OPERATING PROCEDURE OP01 REV5

COLLECTION OF PROJECT INFORMATION

PAGE A-17

AQB-T03-QMSDS-PRO-MOA-231014-0-5

ASHGHAL - PUBLIC WORKS AUTHORITY

QA/QC PAVEMENT CONSULTANCY SERVICES

PROJECT ID: IA/10 11/S013/G

Page intentionally left blank

APPENDIX A: OPERATING PROCEDURE OP01 REV5

COLLECTION OF PROJECT INFORMATION

PAGE A-18

AQB-T03-QMSDS-PRO-MOA-231014-0-5

ASHGHAL - PUBLIC WORKS AUTHORITY

QA/QC PAVEMENT CONSULTANCY SERVICES

PROJECT ID: IA/10 11/S013/G

APPENDIX B: INTEGRATED AUDITING PROCEDURE

Revision Number:

Prepared By:

Position:

Mohammed Anshasi

Quality Auditor

Romolo Neri

Quality Auditor

Issue Date:

Reviewed By:

Position:

31/08/2014

James Maina

Pavement Expert

Davide Lioi

Pavement Expert Assistant

Effective Date:

Approved By:

Position:

04/11/2014

Hussain Bahia

Leading Pavement Expert

Revision History:

Revision

Number

Revision

Date

Description of changes

Requested by

26-06-2014

Initial Release

Leading Pavement Expert

11/08/2014

Identification of required skills for each audit

activities

Leading Pavement Expert

31/08/2014

Replacing QMS Audits with PQMA Audits and

make them part of other Audits

Leading Pavement Expert

04/11/2014

ID Coding Updating

Leading Pavement Expert

APPENDIX B INTEGRATED AUDITING PROCEDURE REV 3

INTEGRATED AUDITING PROCEDURE

PAGE B-1

AQB-T03-QMSDS-PRO-JAM-110414-0-3

ASHGHAL - PUBLIC WORKS AUTHORITY

QA/QC PAVEMENT CONSULTANCY SERVICES

PROJECT ID: IA/10 11/S013/G

TABLE OF CONTENTS

APPENDIX B: INTEGRATED AUDITING PROCEDURE............................................................................ B-1

B.1

PURPOSE ........................................................................................................................... B-3

B.2

BACKGROUND .................................................................................................................... B-4

B.3

AUDIT SCOPE AND OBJECTIVES .......................................................................................... B-4

B.4

REVIEW OF PAVEMENT DESIGN ........................................................................................... B-5

B.4.1 AUDIT TEAM: REQUIRED SKILLS, ROLES AND ACTIVITIES .................................................. B-5

B.4.2 AUDIT ITEMS/ACTIVITIES .................................................................................................. B-5

B.4.3 LINKS ............................................................................................................................. B-5

B.4.4 REPORTING AND OUTCOME ............................................................................................. B-6

B.4.5 APPLICABLE AUDITING PROCEDURE ................................................................................ B-6

B.5

AUDIT OF MATERIAL SUPPLIERS AND PRODUCTION FACILITIES AND LABORATORY AT-PLANT ... B-7

B.5.1 AUDIT TEAM: REQUIRED SKILLS, ROLES AND ACTIVITIES .................................................. B-7

B.5.2 AUDIT ITEMS/ACTIVITIES .................................................................................................. B-8

B.5.3 LINKS ........................................................................................................................... B-10

B.5.4 REPORTING AND OUTCOME ........................................................................................... B-10

B.5.5 APPLICABLE AUDITING PROCEDURE .............................................................................. B-10

B.6

CONSTRUCTION PRACTICE AUDITS ........................................................................ B-11

B.6.1 AUDIT TEAM: REQUIRED SKILLS, ROLES AND ACTIVITIES ................................................ B-11

B.6.2 AUDIT ITEMS/ACTIVITIES, EXTENT AND FREQUENCIES ...................................................... B-12

B.6.3 LINKS ........................................................................................................................... B-14

B.6.4 REPORTING AND OUTCOME ........................................................................................... B-14

B.6.5 APPLICABLE AUDITING PROCEDURE .............................................................................. B-15

B.7

AUDIT OF THIRD PARTY LABORATORY .............................................................................. B-16

B.7.1 AUDIT TEAM: REQUIRED SKILLS, ROLES AND ACTIVITIES ................................................ B-16

B.7.2 AUDIT ITEMS/ACTIVITIES................................................................................................ B-16

B.7.3 LINKS ........................................................................................................................... B-17

B.7.4 REPORTING AND OUTCOME ........................................................................................... B-17

B.7.5 APPLICABLE AUDITING PROCEDURE .............................................................................. B-17

B.8

AUDIT OF CONSTRUCTED PAVEMENT (POST-CONSTRUCTION) ............................................ B-18

B.8.1 AUDIT TEAM: REQUIRED SKILLS, ROLES AND ACTIVITIES ................................................ B-18

B.8.2 AUDIT ITEMS/ACTIVITIES ................................................................................................ B-18

B.8.3 LINKS ........................................................................................................................... B-18

B.8.4 REPORTING AND OUTCOME ........................................................................................... B-18

B.8.5 APPLICABLE AUDITING PROCEDURE .............................................................................. B-19

B.9

INTEGRATED AUDIT PROGRAM/SCHEDULE ......................................................................... B-20

B.9.1 RESOURCE PLAN FOR INTEGRATED AUDITING................................................................. B-21

B.10

INTEGRATED AUDIT REPORTS AND PERIODIC UPDATES ...................................................... B-23

B.11

MATERIALS SAMPLING AND TESTING FREQUENCIES ........................................................... B-24

APPENDIX B INTEGRATED AUDITING PROCEDURE REV 3

INTEGRATED AUDITING PROCEDURE

PAGE B-2

AQB-T03-QMSDS-PRO-JAM-110414-0-3

ASHGHAL - PUBLIC WORKS AUTHORITY

QA/QC PAVEMENT CONSULTANCY SERVICES

PROJECT ID: IA/10 11/S013/G

B.1

PURPOSE

The purpose of this document is to define the objectives of the Integrated Audits to

cover all Key Supply Chain Partners (KSCPs) involved in the delivery of a road

construction project for PWA. The integrated audit described in this procedure

represents the audit execution phase of the overall auditing plan shown in Figure 1.

The document also defines the audit activities, extents and frequencies, audit teams,

schedule for each type of audits. \

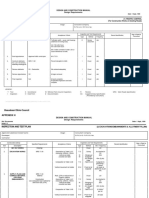

Figure 1. Project Audit and Testing Procedures

APPENDIX B INTEGRATED AUDITING PROCEDURE REV 3

INTEGRATED AUDITING PROCEDURE

PAGE B-3

AQB-T03-QMSDS-PRO-JAM-110414-0-3

ASHGHAL - PUBLIC WORKS AUTHORITY

QA/QC PAVEMENT CONSULTANCY SERVICES

PROJECT ID: IA/10 11/S013/G

B.2

BACKGROUND

Based on the critical review of the auditing conducted during the first year of the

QA/QC project, during which individual disconnected audits of various production

and construction activities were conducted, ANAS agreed with PWA that conducting

integrated project audits is a better approach to monitor quality. Integrated audits

include linking all required audit activities related to a project and covering larger

project audit area. The audits require spending more time analyzing projects,

preparing and conducting the audits, and integrating the results from auditing

activities of all KSCPs.

B.3

AUDIT SCOPE AND OBJECTIVES

The Integrated Audit spans across the supply chain related to road construction for

PWA Projects. The Supply Chain can be grouped into four major categories:

Pavement design

Materials Supplier and Production Facilities

o Material Supplier1(Aggregate and Asphalt Binder),

o Mixtures/Materials Production

Crusher plants;

Wet mix plants;

Asphalt plants.

Site Laboratories

Construction Practices and Project Quality Management

o Program Management Consultants;

o Supervision Consultants;

o Construction Contractors and Sub-Contractors;

o Third Party Laboratories.

Post construction

o International Roughness Index (IRI) as per project requirements.

The Integrated Audit activities include the following Steps:

1.

2.

3.

4.

5.

Review the Pavement Design Report and project construction layout;

Auditing the materials handling, storage and transportation (*);

Production Facilities and Laboratory at-Plant;

Construction Practices;

Third Party Laboratory (material sampling, testing and QC records) - For

planning the PQMA audits and collecting QC data;

6. Quality Management protocols for all KSCPs - For auditing of project quality

management procedures as related to technical matters.

1

Audits on bitumen sources/Suppliers (i.e. refineries, WOQOD) will be confirmed upon finalization of materials

importation framework

Audits on aggregates sources/crushers outside state of Qatar (UAE) to be confirmed upon finalization of

materials importation framework

APPENDIX B INTEGRATED AUDITING PROCEDURE REV 3

INTEGRATED AUDITING PROCEDURE

PAGE B-4

AQB-T03-QMSDS-PRO-JAM-110414-0-3

ASHGHAL - PUBLIC WORKS AUTHORITY

QA/QC PAVEMENT CONSULTANCY SERVICES

PROJECT ID: IA/10 11/S013/G

B.4

REVIEW OF PAVEMENT DESIGN

This audit is the first to be performed on a project. The objective is to review the

complete process that was followed in the pavement design to ensure its

conformance to the required design method.

B.4.1

AUDIT TEAM: REQUIRED SKILLS, ROLES AND ACTIVITIES

Required Skills

Job Title

(Knowledge of)

Pavement Design methods

QHDM

AASHTO 1993

M-E Pavement design

Number of staff

required per

Audit team

Leading

Pavement

Expert

Pavement

Expert

Pavement materials

properties and behaviours

B.4.2

Participate and

approve the review

done by Pavement

Expert.

PV.1 to PV.6

(See B.4.2)

Perform review of

pavement design

reports. Fill out the

Design Review Sheet

(DRS) and draft

Certificate of

approval.

PV.1 to PV.6

AUDIT ITEMS/ACTIVITIES

Audit Item/Activity

PV Pavement Design Check

PV.1 General Check- Pavement Design

Report (PDR) Content

PV.2 Geotechnical Investigation

PV.3 Design Traffic

PV.4 Pavement Design Inputs - AASHTO

1993 Method

PV.5 Pavement Design Inputs - M-E Design

Method

PV.6 Pavement Design Inputs - QHDM

B.4.3

Activities

Review and sign the

Certificate.

Pavement materials

properties and behaviours

Pavement Design methods

QHDM

AASHTO 1993

M-E Pavement design

General Roles and

Responsibilities

Audit Extent

Variable frequency

Three days for each project.

The review of pavement

design reports for the

following design stages:

Concept

Preliminary

Detailed

In case of Rejection

LINKS

Review of pavement design reports will identify pavement layers and materials

quantities. This information is used to determine:

Pavement material types, layer thicknesses and quantities

Audit activities

Audit frequencies

APPENDIX B INTEGRATED AUDITING PROCEDURE REV 3

INTEGRATED AUDITING PROCEDURE

PAGE B-5

AQB-T03-QMSDS-PRO-JAM-110414-0-3

ASHGHAL - PUBLIC WORKS AUTHORITY

QA/QC PAVEMENT CONSULTANCY SERVICES

PROJECT ID: IA/10 11/S013/G

B.4.4

REPORTING AND OUTCOME

Report of the review of pavement design report will include:

Completed Design Review Sheet (DRS)

Pavement design certificate

Pavement material types, layer thicknesses, and quantities

B.4.5

APPLICABLE AUDITING PROCEDURE

Operating procedure for the Review of Pavement Design Report (OP-14)

Appendix C3 in the Audit Manual.

APPENDIX B INTEGRATED AUDITING PROCEDURE REV 3

INTEGRATED AUDITING PROCEDURE

PAGE B-6

AQB-T03-QMSDS-PRO-JAM-110414-0-3

ASHGHAL - PUBLIC WORKS AUTHORITY

QA/QC PAVEMENT CONSULTANCY SERVICES

PROJECT ID: IA/10 11/S013/G

B.5

AUDIT OF MATERIAL SUPPLIERS AND PRODUCTION

FACILITIES AND LABORATORY AT-PLANT

The scope of this audit covers verification of the systems and processes in material

handling and storage, mixtures and their productions - at-plant. In addition, materials

testing facilities are also included in this audit.

B.5.1

AUDIT TEAM: REQUIRED SKILLS, ROLES AND ACTIVITIES

Required Skills

Job Title

(Knowledge of)

Mixture design

specifications and

requirements

Materials

Engineer

Plant operations

visit the Plant only

when necessary)

Materials storage

and transportation

Number of

staff

required per

Audit team

1

General Roles and

Responsibilities

Activities

Confirm audit schedule

PF.A.11

PF.A.18

(See B.6.2)

Implementation and compliance

with applicable standards and

ANAS procedures.

(This resource will

PF.C.7-PF.C.12

PF.D.2

Perform audit on process and

materials.

Technical review of QC

document and records

Training for

personnel

Communicate with Key Supply

chain partners.

Prepare unacceptable

observations, ANCR

Make recommendation for

ongoing improvement.

Production plant,

equipment and

operating

procedure

Plant Specialist

(Quality Auditor

Junior)

Control system

and software

Testing

procedure,

equipment and

maintenance

Verify the adequacy and

condition of plant equipment and

process

PF.A.1

Report any fault/malfunction to

the quality auditor

PF.C.1

PF.B.1 - PF.B.3

Prepare the audit form

Laboratory

Supervisor

Materials

handling, storage

and transportation

ISO 17025

requirements

Conduct Audits on plant and site

laboratories

Verify laboratory equipment

availability and compliance with

the standards

PF.A.18

PF.D.1

PF.D.3

Verify QC sampling and testing

procedures and frequency in

the plant and laboratory

Complete laboratory audit form

for the equipment and the

witnessed testing procedure

Report any laboratory nonconformance and deviation to

ANAS senior laboratory

manager

APPENDIX B INTEGRATED AUDITING PROCEDURE REV 3

INTEGRATED AUDITING PROCEDURE

PAGE B-7

AQB-T03-QMSDS-PRO-JAM-110414-0-3

ASHGHAL - PUBLIC WORKS AUTHORITY

QA/QC PAVEMENT CONSULTANCY SERVICES

PROJECT ID: IA/10 11/S013/G

Required Skills

Job Title

(Knowledge of)

Materials

sampling

procedures and

requirements

Number of

staff

required per

Audit team

Technician

(Sampling

Supervisor)

General Roles and

Responsibilities

Activities

Manage and supervise sampling

teams

PF.A.18

(See B.6.2)

Assure compliance with

procedures and frequency

according to specifications.

Materials

handling, storage

and transportation

PF.B.4

PF.C.12

Communicate with SC materials

engineer and QC third party

laboratory

ISO 17025

requirements

Assure samples are marked,

identified and properly sealed

Materials

sampling

procedures

Sampling

Technicians

Conduct sampling according to

standards

Make sure sampling tools and

equipment

are

properly

maintained

and

in

good

condition

Insure proper handling

transporting of the sample

ISO 19011

requirements

Quality Expert

Assistant

Project Quality

Plan (PQP)

PF.A.18

PF.B.4

PF.C.12

and

Perform PQMA audits on

production facilities

PF.D

Verify quality document,

procedures and records related

to material stockpiling

Training for staff

Verify quality document,

procedures and records related

to material sampling and testing

Verify personnel training and

certification

B.5.2

AUDIT ITEMS/ACTIVITIES

Audit Item/Activity

Audit Extent*

Variable Frequency*

PF.A Verify asphalt plant

Up to 300t of

materials

Once every 15,000t for base course

PF.A.1

PF.A.2

Equipment and process

Cold feeding system (bins and

conveyors)

PF.A.3 Dryer and hot elevator

PF.A.4 Mineral filler feeding and weighing

PF.A.5 Plant screens

PF.A.6 Hot bins

PF.A.7 Bitumen storage tanks (heating

and agitation) and feeding lines

PF.A.8 Plant scales

PF.A.9 Plant mixer/pug mill

PF.A.10 Plant

control

system

(mix

proportioning against JMF)

PF.A.11 Verify materials and process

PF.A.12 Visual verification of materials,

storage and handling

APPENDIX B INTEGRATED AUDITING PROCEDURE REV 3

INTEGRATED AUDITING PROCEDURE

See B.13 for testing

details

OR

10,000t when 2 consecutive

ANCRs or 3 different ANCRs are

generated.

PAGE B-8

AQB-T03-QMSDS-PRO-JAM-110414-0-3

ASHGHAL - PUBLIC WORKS AUTHORITY

QA/QC PAVEMENT CONSULTANCY SERVICES

PROJECT ID: IA/10 11/S013/G

Audit Item/Activity

Audit Extent*

PF.A.13 Transportation equipment

PF.A.14 Verifying materials delivery and

traceability

from

the

Supplier/source

PF.A.15 Verify materials (aggregates,

binder and asphalt mix), QC test

records, quality control charts and

testing frequency.

PF.A.16 Verify plant ES&H provisions

PF.A.17 Communicate/co-ordinate

with

plant Manager and Supervision

Consultant

PF.A.18 Sampling and testing (aggregates

stockpiles, binder, hot bins and

asphalt mix)

PF.B

Verify Subbase/ Subgrade crusher

equipment and process

PF.B.1

PF.B.2

PF.B.3

PF.B.4

Receiving hoppers condition

Grizzly/Screen condition

Clay extractor condition

Sampling and testing

PF.C Verify Sub-base / CBM central mixing

plant

PF.C.1

PF.C.2

PF.C.3

PF.C.4

PF.C.5

PF.C.6

PF.C.7

Plant scales

Weighing hoppers

Control cabin

Plant mixer

Ticketing system

Plant control system

Visual verification of materials,

storage and handling

PF.C.8 Verifying materials delivery and

traceability from the

Supplier/source

PF.C.9 Verify materials, QC test records

PF.C.10 ES&H provisions

PF.C.11 Communicate/coordinate with

plant Manager and Supervision

Consultant

PF.C.12 Sampling and testing (aggregate

stockpiles and mix)

PF.D PQMA of plant/site laboratory.

PF.D.1

PF.D.2

PF.D.3

PF.D.4

PF.E

PF.E.1

PF.E.2

PF.E.3

PF.E.4

PF.E.5

Up to 500 m of

materials

See B.13 for testing

details

Up to 500 m of

materials

See B.13 for testing

details

One day

Verify sampling and testing

process (aggregates, binder and

mix)

Verify QC records

Verify

laboratory

equipment

(availability and calibration)

Verify laboratory

technicians

competency and certification

Visual inspection

stockpile

of

aggregates

Proper separation between

different sizes

Stockpile marking and signage

No segregation or contamination

Stockpile building and shape

Delivery tickets

APPENDIX B INTEGRATED AUDITING PROCEDURE REV 3

INTEGRATED AUDITING PROCEDURE

Variable Frequency*

Once every 20,000 m , or

OR

3

15,000 m when 2 consecutive

ANCRs or 3 different ANCRs are

generated.

3

Once every 15,000 m ,

OR

3

10,000 m when 2 consecutive

ANCRs or 3 different ANCRs are

generated.

Once at the beginning of the project

Once every three months to be

performed at the same time as

other audit activities, OR

within one month after the previous

audit in case of Unacceptable

Observation.

One day

Once at the beginning of the project

Once every six months to be

performed at the same time as

other audit activities, OR

within one month after the previous

audit in case of Unacceptable

Observation.

PAGE B-9

AQB-T03-QMSDS-PRO-JAM-110414-0-3

ASHGHAL - PUBLIC WORKS AUTHORITY

QA/QC PAVEMENT CONSULTANCY SERVICES

PROJECT ID: IA/10 11/S013/G

Notes *: The figures used in this Table are indicative only, productivity will be monitored and the variable frequency will be

adjusted accordingly

B.5.3

B.5.4

LINKS

As part of the Audit, the plant will be required to provide a list of suppliers of

their raw materials

The plant will also be required to provide a list of projects and/or KSCPs that

they have or intend to supply.

This list will be cross-checked with the reports of Pavement design and

Construction Practices for consistency.

The QC testing results, if available, will be analysed in conjunction with the

materials testing from Task 5.

REPORTING AND OUTCOME

Report of the audit of production facilities will include:

Completed Audit Forms and narrative of critical and unacceptable

observations

Summary of QC results

IDs of samples and locations of sampling

ANCRs, MUOs and UOs

B.5.5

APPLICABLE AUDITING PROCEDURE

Task 7 Plant Prequalification Procedure (OPT07-01)

Audit on Production Facilities (T3PF-02) Appendix C8 of the Audit Manual

Sampling procedure (AnnexOP-21-A3) - Appendix C6 of the Audit Manual

Technical audit for third party laboratories (OP-22) Appendix C10 of the

Audit Manual.

APPENDIX B INTEGRATED AUDITING PROCEDURE REV 3

INTEGRATED AUDITING PROCEDURE

PAGE B-10

AQB-T03-QMSDS-PRO-JAM-110414-0-3

ASHGHAL - PUBLIC WORKS AUTHORITY

QA/QC PAVEMENT CONSULTANCY SERVICES

PROJECT ID: IA/10 11/S013/G

B.6

CONSTRUCTION PRACTICE AUDITS

As for any process, pavement construction has inputs and outputs. Identifying,

monitoring, controlling, and improving the process inputs will directly affect the

quality of the process outputs. The scope of this audit covers the verification of all

the major process inputs directly related to pavement construction practices, which

are expected to impact on the quality of the constructed pavement.

B.6.1

AUDIT TEAM: REQUIRED SKILLS, ROLES AND ACTIVITIES

Required Skills

Job Title

(Knowledge of)

Construction process

and management

Quality Auditor

Number of staff

required per

Audit team

1

Construction

equipment

Materials behaviour

during construction

Influence of

environment

General Roles and

Responsibilities

Activities

Confirm audit

schedule

CP.A.1

CP.A.10

to

Implementation and

compliance with

applicable standards

and ANAS

procedures.

CP.B.1

CP.B.9

to

CP.C.1

CP.C.6

to

(See B.7.2)

Perform audit on

process.

Training of personnel

Technical review of

QC document and

records

Communicate with

Key Supply chain

partners.

Prepare unacceptable

observations, ANCR

Recommendation for

ongoing

improvement.

Construction

equipment

Materials behaviour

during construction

Quality

Auditor

Junior

(Construction

Equipment

Expert)

Verify the adequacy

and condition of

construction

equipment.

CP.A.3, CP.B.3

and CP.C.3

Report any

fault/malfunction to

the quality auditor

Initiate the audit form

Sampling procedures

and requirements

ISO 17025

requirements

Technician

(Sampling

Supervisor)

APPENDIX B INTEGRATED AUDITING PROCEDURE REV 3

INTEGRATED AUDITING PROCEDURE

Manage and

supervise sampling

teams

CP.A.9,

CP.A.11,

CP.B.8,

Assure compliance

with procedures and

frequency according

to specifications.

CP.B.10,

CP.C5, CP.C.7

PAGE B-11

AQB-T03-QMSDS-PRO-JAM-110414-0-3

ASHGHAL - PUBLIC WORKS AUTHORITY

QA/QC PAVEMENT CONSULTANCY SERVICES

PROJECT ID: IA/10 11/S013/G

Required Skills

Job Title

Number of staff

required per

Audit team

(Knowledge of)

General Roles and

Responsibilities

Activities

(See B.7.2)

Communicate with

SC materials

engineer and QC

third party laboratory

Assure samples are

marked, identified

and properly sealed

Verify QC sampling

procedure and

frequency.

Sampling procedures

ISO 17025

requirements

Sampling

Technicians

Conduct

according

standards

sampling

to

Make sure sampling

tools and equipment

tools and equipment

are

properly

maintained and in

good condition

Insure

handling

transporting

sample

ISO 19011

requirements

Quality

Assistant

Expert

CP.B.10,

PF.C.7

proper

and

of the

Perform PQMA audits

on contractors and

supervision

consultants

Project Quality Plan

(PQP)

CP.A.11,

CP.D.1

CP.D.9

to

CP.E.1

CP.E.7

to

Verify quality

document,

procedures and

records related to

pavement production

and testing

Training for staff

Verify equipment

calibration and

certificates

Verify personnel

training and

certification

B.6.2

AUDIT ITEMS/ACTIVITIES, EXTENT AND FREQUENCIES

Audit Item/Activity

Verifying pavement layers construction equipment

and process.

CP.A Asphalt courses auditing activities

CP.A.1 Verify the SC approval on underlying

layers (signed RFIs) in conjunction with

APPENDIX B INTEGRATED AUDITING PROCEDURE REV 3

INTEGRATED AUDITING PROCEDURE

Audit Extent

Variable Frequency

Up to 500t of

materials

See B.13 for

testing details

Once every 15,000t for base

course

OR

10,000t when 2 consecutive

ANCRs or 3 different ANCRs

are generated

PAGE B-12

AQB-T03-QMSDS-PRO-JAM-110414-0-3

ASHGHAL - PUBLIC WORKS AUTHORITY

QA/QC PAVEMENT CONSULTANCY SERVICES

PROJECT ID: IA/10 11/S013/G

Audit Item/Activity

QC reports.

CP.A.2 Verify the construction process according

to approved design drawing, method

statement and trial section

CP.A.3 Verify paving, rolling equipment,

condition and adequacy

CP.A.4 Prime and Tack Coat visual inspection

CP.A.5 Visual verification of asphalt mix

delivered to site (delivery tickets,

aggregate coating, segregation, delivery

temperature)

CP.A.6 Visual verification of mat surface (i.e.

screed marks, segregation, auger

shadows, waviness, temperatures prior

to compaction)

CP.A.7 Verify placing and compaction

temperature QC log

CP.A.8 Identify potential non-conforming

material and call for sampling

CP.A.9 Verify contractor QC sampling process

and frequency

CP.A.10 Communicate with SC/PMC

Representative for Construction Practice

audits observation and/or nonconformance and other issues related to

site coordination

CP.A.11 Sampling and Testing(Loose Asphalt

Mix, Asphalt temperature and FDT)

CP.B Subbase / CBM

CP.B.1 Verify the SC approval on underlying

layers (signed RFIs) in conjunction with

QC reports.

CP.B.2 Verify the construction process according

to approved design drawing method

statement and trial section

CP.B.3 Paving, rolling equipment, condition and

adequacy

CP.B.4 Visual verification of mix delivered to site

(delivery tickets, segregation)

CP.B.5 Visual verification of laid surface (i.e.

segregation, waviness and construction

joints condition)

CP.B.6 Verify mixing vs. placing time of CBM

Contractor QC log

CP.B.7 Identify

potential

non-conforming

material and call for sampling

CP.B.8 Verify contractor QC sampling process

and frequency

CP.B.9 Communicate

with

SC/PMC

Representative for Construction Practice

audits

observation

and/or

nonconformance and other issues related to

site coordination

CP.B.10 Sampling and testing(Loose material and

FDT)

CP.C Subgrade

CP.C.1 Verify the SC approval for laying (signed

RFIs) in conjunction with QC reports.

CP.C.2 Verify the construction process according

to approved design drawing method

statement and trial section

APPENDIX B INTEGRATED AUDITING PROCEDURE REV 3

INTEGRATED AUDITING PROCEDURE

Audit Extent

Variable Frequency

Random

inspection

See B.13 for

testing details

10000 t When 2 consecutive

ANCRs or 3 different ANCRs

are generated.

Random

inspection

See B.13 for

testing details

10000 t When 2 consecutive

ANCRs or 3 different ANCRs

are generated.

PAGE B-13

AQB-T03-QMSDS-PRO-JAM-110414-0-3

ASHGHAL - PUBLIC WORKS AUTHORITY

QA/QC PAVEMENT CONSULTANCY SERVICES

PROJECT ID: IA/10 11/S013/G

Audit Item/Activity

Audit Extent

Variable Frequency

CP.C.3 Grading, rolling equipment, condition and

adequacy

CP.C.4 Visual inspection of Subgrade materials

delivered to site (visually unsuitable

material),Identify

potential

nonconforming material and call for sampling

CP.C.5 Verify contractor QC sampling process

and frequency

CP.C.6 Communicate

with

SC/PMC

Representative for Construction Practice

audits

observation

and/or

nonconformance and other issues related to

site coordination

CP.C.7 Sampling and testing (Loose materials

and FDT)

One day

CP.D PQMA for Construction Contractors

The quality system

verification are:

CP.D.1

CP.D.2

CP.D.3

CP.D.4

CP.D.5

CP.D.6

CP.D.7

CP.D.8

CP.D.9

components

selected

for

Once at the beginning of the

project

Once every three months to be

performed at the same time as

other audits, OR

Method Statements (MSs)

Inspection and Test Plans (ITPs)

Product Identification and Traceability

Control of Inspection, Measuring and

Testing Equipment

Owner Supplied Product

Procurement of Services, Equipment

and Materials

Procedure for Control of Nonconforming

Work, Corrective and Preventive Action

System and Compliance Audits

Training (Human Resources)

within one month after the

previous audit in case of

Unacceptable Observation

One day

CP.E PQMA for Supervision Consultant

The quality system

verification are:

components

selected

for

CP.E.1 Approval of Method Statements (MSs)

CP.E.2 Approval of Inspection and Test Plans

(ITPs)

CP.E.3 Procedure for Control of Nonconforming

Work, Corrective and Preventive Action

CP.E.4 Approval of Equipment and Materials

CP.E.5 System and Compliance Audits

CP.E.6 Training (Human Resources)

CP.E.7 Third Party Laboratories Supervision

B.6.3

B.6.4

Once at the beginning of the

project

Once every three months to be

performed at the same time as

other audits, OR

within one month after the

previous audit in case of

Unacceptable Observation

LINKS

As part of the Audit, the contractor will be required to provide a list of suppliers

of their raw materials and mixes

This list will be cross-checked with the reports of Supplier/Source materials

and Production Facilities for consistency.

The equipment maintenance and personnel training will be analysed in

conduction with the PQMA audits for contractor.

REPORTING AND OUTCOME

Report of the audit of production facilities will include:

APPENDIX B INTEGRATED AUDITING PROCEDURE REV 3

INTEGRATED AUDITING PROCEDURE

PAGE B-14

AQB-T03-QMSDS-PRO-JAM-110414-0-3

ASHGHAL - PUBLIC WORKS AUTHORITY

QA/QC PAVEMENT CONSULTANCY SERVICES

PROJECT ID: IA/10 11/S013/G

B.6.5

Completed Audit Forms and narrative of critical and unacceptable

observations

Summary of QC results

IDs of samples and locations of sampling

ANCRs, MUOs and/or UOs

APPLICABLE AUDITING PROCEDURE

Auditing of Construction Practices (T3CP-01) Appendix C7 of the Audit

Manual

Sampling procedure (Annexure OP-21-A3) - Appendix C6 of the Audit Manual

APPENDIX B INTEGRATED AUDITING PROCEDURE REV 3

INTEGRATED AUDITING PROCEDURE

PAGE B-15

AQB-T03-QMSDS-PRO-JAM-110414-0-3

ASHGHAL - PUBLIC WORKS AUTHORITY

QA/QC PAVEMENT CONSULTANCY SERVICES

PROJECT ID: IA/10 11/S013/G

B.7

AUDIT OF THIRD PARTY LABORATORY

The objective of this activity is to perform technical and management audit of the

third party laboratory used by contractor on the project to ensure that the laboratory

is capable of successfully performing tests of the pavement materials. This Audit is

conducted on the main laboratories, not on the project site laboratory.

B.7.1

AUDIT TEAM: REQUIRED SKILLS, ROLES AND ACTIVITIES

Required Skills

Job Title

Number of staff

required per

Audit team

(Knowledge of)

ISO 17025

requirements

Training for staff

Laboratory

Manager/

Supervisor

Testing

procedures

General Roles and

Responsibilities

Responsibilities

Verify laboratory

equipment availability and

compliance with the

standards

TL.A.1, TL.A.2

and TL.A.4

(See B.8.2)

Verify QC sampling and

testing procedures and

frequency

Equipment

requirements,

calibration and

maintenance

Complete laboratory audit

form for the equipment and

the witnessed testing

procedure

Report any laboratory nonconformance and deviation

to ANAS senior laboratory

manager

ISO 17025

requirements

Quality

Assistant

Expert

Training for staff

Perform PQMA audits on

laboratories

TL.B

Verify quality procedures

and records related to

pavement production and

testing

Testing

procedures

Verify equipment

calibration and certificates

Verify personnel training

and certification

B.7.2

AUDIT ITEMS/ACTIVITIES

Audit Item/Activity

Audit Extent

Variable Frequency

TL.A.1 Verify laboratory equipment

(availability, calibration)

TL.A.2 Verify sampling and testing

process/procedure (aggregates,

binder and mix)

TL.A.3 Verify laboratory technicians

competency and certification

TL.A.4 Verify asphalt testing QC records

One day

At the beginning of the project

Once every six months, or

within one month after the previous

audit in case of Unacceptable

Observation.

TL.B PQMA of Third Party Laboratories.

TL.B.1

TL.B.2

Verify sampling and testing process

(aggregates, binder and mix)

Verify QC records

APPENDIX B INTEGRATED AUDITING PROCEDURE REV 3

INTEGRATED AUDITING PROCEDURE

One day

Once at the beginning of the project

Once every three months to be

performed at the same time as

other audits,

PAGE B-16

AQB-T03-QMSDS-PRO-JAM-110414-0-3

ASHGHAL - PUBLIC WORKS AUTHORITY

QA/QC PAVEMENT CONSULTANCY SERVICES

PROJECT ID: IA/10 11/S013/G

TL.B.3

TL.B.4

B.7.3

B.7.4

Verify

laboratory

equipment

(availability and calibration)

Verify laboratory

technicians

competency and certification

OR within one month after the

previous

audit

in

case

of

Unacceptable Observation.

LINKS

As part of the Audit, the Third Party Laboratory will be required to provide a

list of Contractors/Plant for which testing of raw materials and mixes have

been conducted.

This list will be cross-checked with the reports of Production Facilities and

Construction Practices for consistency.

The QC testing results, if available, will be analysed in conjunction with the

materials testing from Task 5.

The QC data entered in the PEMS in Task 2 will be verified.

REPORTING AND OUTCOME

Report of the audit of production facilities will include:

Completed Audit Forms and narrative of critical and unacceptable

observations

ANCRs and/or UOs

B.7.5

APPLICABLE AUDITING PROCEDURE

External Audits of Third party laboratories (OP-20) Appendix C5 of the Audit

Manual

Technical audit for third party laboratories (OP-22) Appendix C10 of the

Audit Manual

APPENDIX B INTEGRATED AUDITING PROCEDURE REV 3

INTEGRATED AUDITING PROCEDURE

PAGE B-17

AQB-T03-QMSDS-PRO-JAM-110414-0-3

ASHGHAL - PUBLIC WORKS AUTHORITY

QA/QC PAVEMENT CONSULTANCY SERVICES

PROJECT ID: IA/10 11/S013/G

B.8

AUDIT OF CONSTRUCTED PAVEMENT

(POST-CONSTRUCTION)

This Audit of the constructed pavement is the last audit performed on the final

pavement structure being delivered to the road agency. The objective of this activity

is to review the complete process that was followed by the Supervision Consultant to

ensure that the as-built pavement conforms to the project specifications and the

quality requirements of PWA. The Audit process will identify as-built information such

as the different pavement cross-sections in a project, layer thicknesses and material

types. This information will be compared to the materials testing report and

construction practices findings.

B.8.1

AUDIT TEAM: REQUIRED SKILLS, ROLES AND ACTIVITIES

Required Skills

Job Title

(Knowledge of)

As-built drawings

Non-destructive testing

ground penetrating radar

(GPR) and Falling Weight

Deflectometer (FWD)

Pavement roughness

Pavement skid resistance

B.8.2

Leading

Pavement

Expert

PC.1

PC.2

PC.3

PC.4

B.8.4

General Roles and

Responsibilities

Participate and

approve the review

done by Quality Audit

(Constructed

pavement expert).

Activities

(See B.9.2)

PC.1 to PC.4

Perform review of

constructed

pavement reports.

AUDIT ITEMS/ACTIVITIES

PC Constructed pavement check

Pavement

Expert

(Constructed

pavement

expert)

Audit Item/Activity

B.8.3

Number of

staff required

per Audit

team

As-built plans/drawings

Non-destructive testing

Pavement roughness

Pavement skid resistance

Audit Extent

Variable frequency

Once within one-month

after

completion

of

construction.

In case of Unacceptable

Observation or ANCR

LINKS

Review of pavement design reports will identify pavement as-built information

such as layer thicknesses and materials;

This information will be linked to the review of pavement design report for

consistency between the design requirements and constructed pavement

This information will also be linked to the materials testing report for

consistency between the design requirements and constructed pavement

REPORTING AND OUTCOME

Report of the audit of constructed pavement (post-construction) will include:

Completed Audit Forms and narrative of critical and unacceptable

observations

APPENDIX B INTEGRATED AUDITING PROCEDURE REV 3

INTEGRATED AUDITING PROCEDURE

PAGE B-18

AQB-T03-QMSDS-PRO-JAM-110414-0-3

ASHGHAL - PUBLIC WORKS AUTHORITY

QA/QC PAVEMENT CONSULTANCY SERVICES

PROJECT ID: IA/10 11/S013/G

B.8.5

ANCRs and/or UOs

APPLICABLE AUDITING PROCEDURE

Operating procedure for the Audit of As-Built Plans (OP-18) Appendix C9 in

the Audit Manual.

APPENDIX B INTEGRATED AUDITING PROCEDURE REV 3

INTEGRATED AUDITING PROCEDURE

PAGE B-19

AQB-T03-QMSDS-PRO-JAM-110414-0-3

ASHGHAL - PUBLIC WORKS AUTHORITY

QA/QC PAVEMENT CONSULTANCY SERVICES

PROJECT ID: IA/10 11/S013/G

B.9

INTEGRATED AUDIT PROGRAM/SCHEDULE

The auditing activities will be carried out at different times. The following list includes

the timing, location and resource for each audit.

No.

Audit Type

Location

Timing

1.

Pavement design report review

ANAS/PWA Office

During the PWA design

acceptance stage.

2.

Development of Project Auditing

Proposal for the Project

ANAS/PWA office

No later than 2 months

before start of the project.

Laboratory facility

Material Supplier

Crusher/Central mixing

plant sites

Construction site

Contractor site office

Plant office

Plant site

PMCs offices

SC offices

The auditing of the

construction practice and

production facility will include

PQMA and will be conducted

at the same time and at the

required frequency.

Third Party Laboratory

office

One month after start of

project and every six months

thereafter.

3.

4.

5.

Construction Project Auditing

Construction Practices

Materials Suppliers, Production

Facilities and Site Labs

Third Party Laboratories

Project Quality Management Audits

SCs and PMCs

Production Facilities

Contractors

Third Part Laboratories

Technical and Project Quality

Management Audits of Third

Party laboratories

Post-Construction (Constructed

Pavement)

APPENDIX B INTEGRATED AUDITING PROCEDURE REV 3

INTEGRATED AUDITING PROCEDURE

Constructed Pavement

Within one month after

completion of the

construction project.

PAGE B-20

AQB-T03-QMSDS-PRO-JAM-110414-0-3

ASHGHAL - PUBLIC WORKS AUTHORITY

QA/QC PAVEMENT CONSULTANCY SERVICES

PROJECT ID: IA/10 11/S013/G

B.9.1

RESOURCE PLAN FOR INTEGRATED AUDITING

Quality Expert assistant 2

Quality Auditor Junior1

Construction Practices

Quality Auditor Junior2

Plant Expert

Senior Technicians 1

Senior Technicians 2

Activity

Project 6: Audit Report

Weekly Summary

reporting and preparing

for following week

Weekly Summary

Reporting

Final reporting and

preparing for following

week

Activity

Project 3

CP.A.1 to CP.A.10

CP.B.1 to CP.B.9

CP.C.1 to CP.C.6

Project 3: Audit Report

Project 5: Audit

Preparation

Project 5

CP.A.1 to CP.A.10

CP.B.1 to CP.B.9

CP.C.1 to CP.C.6

Project 5: Audit Report

28

0.63

Other Tasks

28

0.63

45

0.63

45

0.63

45

1.04

45

1.04

23.8

0.7

45

0.7

Afternoon/Nig

ht Shift

5

Project 6

CP.A.1 to CP.A.10

CP.B.1 to CP.B.9

CP.C.1 to CP.C.6

Morning Shift

2

Project 4: Audit Report

Project 6: Audit

Preparation

Project 1: Audit Report

Project 3: Audit

Preparation

Afternoon/Nig

ht Shift

5

Project 4

CP.A.1 to CP.A.10

CP.B.1 to CP.B.9

CP.C.1 to CP.C.6

Morning Shift

Afternoon/Nig

ht Shift

2

Project 2: Audit Report

Project 4: Audit

Preparation

Total recourse

Available as per

contract

5

Project 2

CP.A.1 to CP.A.10

CP.B.1 to CP.B.9

CP.C.1 to CP.C.6

Project 1

CP.A.1 to CP.A.10

CP.B.1 to CP.B.9

CP.C.1 to CP.C.6

TOTAL HOURS

Quality Expert assistant 1

Morning Shift

2

Project 1: Audit

Preparation

Hours

Other Tasks

Day5

Day4

Afternoon/Nig

ht Shift

Quality Auditor 2

Day3

Hours

Morning Shift

Day2

Afternoon/Nig

ht Shift

Quality Auditor 1

Working

Hours/

Activities*

Morning Shift

Resource/Staff

Audit Team

Week

Day1

Hours

14

Activity

Project 1: Collaboration

of Audit Preparation

From Project 2

CP.D.1 to CP.D.9

CP.E.1 to CP.E.7

Project 2: Prepare PQMA

Audit reports

From Project 4

CP.D.1 to CP.D.9

CP.E.1 to CP.E.7

Project 4: Prepare PQMA

Audit reports

From Project 6

CP.D.1 to CP.D.9

CP.E.1 to CP.E.7

Project 6: Prepare PQMA

Audit reports

Receive, compile project quality records required for audits from projects ,

maintain project information folders

Hours

Activity

From Project 1

CP.D.1 to CP.D.9

CP.E.1 to CP.E.7

Project 1: Prepare PQMA

Audit reports

From Project 3

CP.D.1 to CP.D.9

CP.E.1 to CP.E.7

Project 3: Prepare PQMA

Audit reports

From Project 5

CP.D.1 to CP.D.9

CP.E.1 to CP.E.7

Hours

4.5

4.5

4.5

4.5

4.5

Activities

18

Project 5: Prepare PQMA Receive, compile project quality records required for audits from projects , maintain project information

folders

Audit reports

4.5

Project 1

Project 2

Project 3

Project 4

Project 5

Project 6

CP.A.3, CP.B.3 & CP.C.3 CP.A.3, CP.B.3 & CP.C.3 CP.A.3, CP.B.3 & CP.C.3 CP.A.3, CP.B.3 & CP.C.3 CP.A.3, CP.B.3 & CP.C.3 CP.A.3, CP.B.3 & CP.C.3

Hours

4.5

4.5

4.5

4.5

4.5

4.5

Activities

Project 1

PF.A.1

PF.B.1 to PF.B.3

& PF.C.1

Project 2

PF.A.1

PF.B.1 to PF.B.3

& PF.C.1

Project 3

PF.A.1

PF.B.1 to PF.B.3

& PF.C.1

Project 4

PF.A.1

PF.B.1 to PF.B.3

& PF.C.1

Project 5

PF.A.1

PF.B.1 to PF.B.3

& PF.C.1

Project 6

PF.A.1

PF.B.1 to PF.B.3

& PF.C.1

4.5

4.5

4.5

Audits Follow Up

Reporting and preparing

for following week

4.5

4.5

Audit Follow Up

Reporting and preparing

for following week

4.5

4.5

4.5

4.5

4.5

1.3

Activities

Project 1

PF.A.18, PF.D.1

& PF.D.3

Project 1 - Audit Report

Preparation

Project 3 - Audit Planning

Project 3

PF.A.18, PF.D.1

& PF.D.3

Project 3 - Audit Report

Preparation

Project 5 - Audit Planning

Project 5

PF.A.18, PF.D.1

& PF.D.3

Project 5 - Audit Report

Preparation

Hours

Project 2 - Audit Planning

Project 2

PF.A.18, PF.D.1

& PF.D.3

Project 2 - Audit Report

Preparation

Project 4 - Audit Planning

Project 4

PF.A.18, PF.D.1

& PF.D.3

Project 4 - Audit Report

Preparation

Project 6 - Audit Planning

Project 6

PF.A.18, PF.D.1

& PF.D.3

Project 5 - Audit Report

Preparation

Final Reporting

Activity

APPENDIX B INTEGRATED AUDITING PROCEDURE REV 3

INTEGRATED AUDITING PROCEDURE

Gathering and compiling Project information

required for audit planning and conducting

4.5

Hours

4.5

4.5

Gathering and compiling Project information

required for audit planning and conducting

Other Tasks

Audits on External laboratories

PAGE B-21

AQB-T03-QMSDS-PRO-JAM-110414-0-3

ASHGHAL - PUBLIC WORKS AUTHORITY

QA/QC PAVEMENT CONSULTANCY SERVICES

PROJECT ID: IA/10 11/S013/G

Hours

Laboratory

Supervisor/Material

Engineer Junior

Technicians 1

(Sampling Supervisor)

1&2

1&2

Activity

NA

NA

NA

2

Project 4

PF.A.11PF.A.18

PF.C.7-PF.C.12

PF.D.2

2

Project 5

PF.A.11PF.A.18

PF.C.7-PF.C.12

PF.D.2

2

Project 6

PF.A.11PF.A.18

PF.C.7-PF.C.12

PF.D.2

2

Other Tasks

Collaboration on Audit

Report Preparation

4.5

4.5

4.5

4.5

4.5

4.5

4.5

4.5

4.5

4.5

Activity

Project 2

PF.A.18, PF.B.4

& PF.C.12

CP.A.9, CP.A.11,

CP.B.8,

CP.B.10,

CP.C5, CP.C.7

Project 3

PF.A.18, PF.B.4

& PF.C.12

CP.A.9, CP.A.11,

CP.B.8,

CP.B.10,

CP.C5, CP.C.7

Project 4

PF.A.18, PF.B.4

& PF.C.12

CP.A.9, CP.A.11,

CP.B.8,

CP.B.10,

CP.C5, CP.C.7

Project 5

PF.A.18, PF.B.4

& PF.C.12

CP.A.9, CP.A.11,

CP.B.8,

CP.B.10,

CP.C5, CP.C.7

Project 6

PF.A.18, PF.B.4

& PF.C.12

CP.A.9, CP.A.11,

CP.B.8,

CP.B.10,

CP.C5, CP.C.7

Sampling 25% of QCS

Sampling 25% of QCS

Sampling 25% of QCS

Weekly meeting

Sampling 25% of QCS

Sampling 25% of QCS

Sampling 25% of QCS

Sampling 25% of QCS

Sampling 25% of QCS