Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Timing Belt Chery QQ PDF

Caricato da

08088338100%(4)Il 100% ha trovato utile questo documento (4 voti)

3K visualizzazioni2 pagineTitolo originale

timing belt chery qq.pdf

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

100%(4)Il 100% ha trovato utile questo documento (4 voti)

3K visualizzazioni2 pagineTiming Belt Chery QQ PDF

Caricato da

08088338Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 2

Timing System

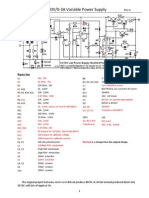

Shown as Fig. 2-51

c amshaf t timin g gear ( rim diameter :54. 65-+0 0.7

m m

.13

timing to othed

belt(wide : 25.3mm

t iming c over

wa ter pum p pulley

tension wheel

(wide :2 7.0mm

outer diamet er:50 mm

torsion shock absorber

toot hed bel t guard

cra nkshaf t timin g gear

+ 0.1

(rim diameter :110.7- 0 .2

Fig. 2-51 Timing Me chanism Con figuration

Check and maintenance of the timing device

Check and maintenance of tensioner

Removal

1Carry out the operation at the upper thrust point of compression of the first cylinder piston

2 After removing the timing cover cap, turn the bolt and rotate the timing gear clockwise with wrench,

align timing mark of camshaft timing gear with the cam mark

of camshaft cover cap;

Attention: You can rotate the engine clockwise only, after

installing the pulley;

Before removal, make a arrow mark on the position of timing

mark, assemble according to original state.

3 Make sure that the crankshaft timing pulley wheel

mark is aligned with the mark of the oil pump.

4 Remove the tensioner bolt, and take off the tensioner

Install

Install the timing belt

1 Ensure the upper thrust point of the first cylinder

compression

Place the camshaft timing gear around the front end of the

air exhaust camshaft so as to make the positioning groove on the

gear be aligned with the positioning pin on the end surface of the

camshaft. Then use screws to fix the clockwise gear, with the

torque of 100 5N.m.

2Make sure that the punched mark on the crankshaft

5m m

2030N

Fig. 2-52 check of the flexibility

clockwise pulley is aligned with the mark of the oil pump.

Adjust the tension of the timing belt

1Use a screwdriver to swing the stretcher toward the right so as to make the space between the edge of the

stretching wheel and the water pump case arc to be about 8mm;

2Tighten the bolt of the stretching wheel with a torque of 25 3N.m.

3Turn the crankshaft for two circles towards the engine rotating direction, so that the camshaft pulley and

the crankshaft pulley matches the clockwise marks respectively.

4 Press down the right centre for about 5mm. The force for pressing the clockwise belt is about 2030 N.

Shown as figure 2-52.

Notice: When the deflection of the timing belt fails to meet the specifications, the key is to adjust the

above-mentioned stretcher fastening bolt by widening the spacing.

Potrebbero piacerti anche

- Ignition Igniter For Suzuki GS1000GT 1980Documento17 pagineIgnition Igniter For Suzuki GS1000GT 1980migNessuna valutazione finora

- Y270 Ewl 101Documento6 pagineY270 Ewl 101Luis AlfonsoNessuna valutazione finora

- Volvo D13H Shop Armed Vol2Documento34 pagineVolvo D13H Shop Armed Vol2Juan José AldanaNessuna valutazione finora

- V6 Auto TransDocumento9 pagineV6 Auto Trans08088338Nessuna valutazione finora

- Automatic Transaxle: SectionDocumento754 pagineAutomatic Transaxle: SectionElias SerranoNessuna valutazione finora

- How To Test The Fuel Injectors1Documento7 pagineHow To Test The Fuel Injectors1ElliAbatziNessuna valutazione finora

- How To Read Electrical Wiring DiagramDocumento3 pagineHow To Read Electrical Wiring DiagramRiahi RezegNessuna valutazione finora

- SQR 472 Engine: Service Manual For Mechanical PartDocumento57 pagineSQR 472 Engine: Service Manual For Mechanical PartjamesmotuvNessuna valutazione finora

- Rebuilding The Yamaha Vision Motorcycle TCI Electronic Igniter Module / Electronic Ignition / Transistor Controlled IgnitionDocumento11 pagineRebuilding The Yamaha Vision Motorcycle TCI Electronic Igniter Module / Electronic Ignition / Transistor Controlled Ignitionxplod11Nessuna valutazione finora

- Amibios CodesDocumento12 pagineAmibios CodesmigbonNessuna valutazione finora

- Panasonic 2007 LCD Models TV Service Guide PDFDocumento109 paginePanasonic 2007 LCD Models TV Service Guide PDFOakkar OrgNessuna valutazione finora

- Insulated Gate Bipolar Transistor With Ultrafast Soft Recovery DiodeDocumento16 pagineInsulated Gate Bipolar Transistor With Ultrafast Soft Recovery DiodeSalah Al-AbsiNessuna valutazione finora

- Subaru WRX 97 To 98 Full PinoutsDocumento1 paginaSubaru WRX 97 To 98 Full Pinouts08088338Nessuna valutazione finora

- Dell Latitude E7440 Compal LA-9591P Rev 0.4 SchematicsDocumento58 pagineDell Latitude E7440 Compal LA-9591P Rev 0.4 SchematicsconradoNessuna valutazione finora

- 13 ToyotaDocumento105 pagine13 Toyota0808833867% (3)

- Ford BTR Transmission Repair Manual PDFDocumento100 pagineFord BTR Transmission Repair Manual PDF08088338100% (2)

- What Is An Electric Circuit Diagram and How Does It WorkDocumento11 pagineWhat Is An Electric Circuit Diagram and How Does It WorkjackNessuna valutazione finora

- Ac Compressor ServicingDocumento25 pagineAc Compressor Servicingsonny1234100% (1)

- Microwave InfoDocumento36 pagineMicrowave InforamjoceNessuna valutazione finora

- 1996 Toyota Corolla Owners Manual PDFDocumento195 pagine1996 Toyota Corolla Owners Manual PDFhanzhio elNessuna valutazione finora

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementDa EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNessuna valutazione finora

- Integrated Circuit TutorialDocumento12 pagineIntegrated Circuit Tutorialdim PakoNessuna valutazione finora

- Masterpiece OvensDocumento33 pagineMasterpiece OvensplasmapeteNessuna valutazione finora

- MOTHERBOARD INFO Biw1bDocumento64 pagineMOTHERBOARD INFO Biw1bshawnrodNessuna valutazione finora

- Technical Guide: Microwave Ovens With InvertersDocumento46 pagineTechnical Guide: Microwave Ovens With InvertersdavidNessuna valutazione finora

- Opel Astra H Radiator Fan Failure Engine OverheatsDocumento2 pagineOpel Astra H Radiator Fan Failure Engine OverheatsAnonymous OFfJVrQY6Nessuna valutazione finora

- DEP StructureDocumento23 pagineDEP StructureishaharomNessuna valutazione finora

- Computer POST and Beep Codes PDFDocumento18 pagineComputer POST and Beep Codes PDFSavaKrstic100% (1)

- Cylinder Clearance-Head Gaskets: (TABLE 11.1 REF. U)Documento3 pagineCylinder Clearance-Head Gaskets: (TABLE 11.1 REF. U)heroskNessuna valutazione finora

- Microwave Oven E BookDocumento23 pagineMicrowave Oven E BookgkavosNessuna valutazione finora

- Step by Step To Repair MainboardDocumento21 pagineStep by Step To Repair MainboardfabiobonadiaNessuna valutazione finora

- Beeps CodeDocumento7 pagineBeeps CodeMaqsood Ahmed PathanNessuna valutazione finora

- Testing Mother Board For FailureDocumento7 pagineTesting Mother Board For FailureJayanta ChakrabartiNessuna valutazione finora

- Laptop SpecificationsDocumento124 pagineLaptop SpecificationsAbhishek Majumdar100% (1)

- Panasonic NN Cs596a NN Cs596sDocumento64 paginePanasonic NN Cs596a NN Cs596sAsrulNessuna valutazione finora

- How To Read Wiring Diagramed (EMS 400)Documento19 pagineHow To Read Wiring Diagramed (EMS 400)Mahmoud Abd El Lateef100% (1)

- Repairing Faulty EMV Backlight Inverter.: Table 1 Parts Required For RepairDocumento11 pagineRepairing Faulty EMV Backlight Inverter.: Table 1 Parts Required For RepairJulian SchmitzNessuna valutazione finora

- Maneurop NTZ Low Temp - Refrigeration CompressorsDocumento32 pagineManeurop NTZ Low Temp - Refrigeration CompressorsMacSparesNessuna valutazione finora

- Hybrid+batteryDocumento5 pagineHybrid+batterylitieuduyNessuna valutazione finora

- Fe04a PDFDocumento32 pagineFe04a PDFvette512Nessuna valutazione finora

- Training Program Day2 RAKESHDocumento56 pagineTraining Program Day2 RAKESHtansnvarmaNessuna valutazione finora

- Acer Aspire 3 A315-22 NB8607 Rev1.0Documento55 pagineAcer Aspire 3 A315-22 NB8607 Rev1.0Carlos Yuvini Hernandez100% (1)

- Samsung MO1650xx Service ManualDocumento29 pagineSamsung MO1650xx Service ManualBrent SmithNessuna valutazione finora

- Typical LED SymbolDocumento4 pagineTypical LED Symbolthy thy thyNessuna valutazione finora

- Modified 0-30V - 0-3A Variable Power Supply - Rev.2Documento2 pagineModified 0-30V - 0-3A Variable Power Supply - Rev.2Manuel Cereijo NeiraNessuna valutazione finora

- How To Reset An Acer BIOS Password PDFDocumento5 pagineHow To Reset An Acer BIOS Password PDFrahul2222222Nessuna valutazione finora

- LG 32ls3500-Ud 32ls3510-Ua Chassis La25a mfl67454202Documento42 pagineLG 32ls3500-Ud 32ls3510-Ua Chassis La25a mfl67454202noguri25Nessuna valutazione finora

- How To Calculate Resistors in Series and ParallelDocumento4 pagineHow To Calculate Resistors in Series and ParallelGeoff HampsonNessuna valutazione finora

- Power Supply Unit (PSU)Documento18 paginePower Supply Unit (PSU)robeecalNessuna valutazione finora

- 5 Engine and Its ComponentsDocumento16 pagine5 Engine and Its ComponentsMoisés MartinezNessuna valutazione finora

- Thread-Cutting Tools and Procedures: Session 9Documento22 pagineThread-Cutting Tools and Procedures: Session 9Rodel M. VasquezNessuna valutazione finora

- 555 TimerDocumento76 pagine555 TimerSai Krishna KodaliNessuna valutazione finora

- Kirisun PT260-Service-ManualDocumento29 pagineKirisun PT260-Service-ManualRobertinoNessuna valutazione finora

- Plasma TV: Service ManualDocumento37 paginePlasma TV: Service ManualTobias LehenbergerNessuna valutazione finora

- PWM Off-Line Switching Regulator Ics: Str-A6000H SeriesDocumento13 paginePWM Off-Line Switching Regulator Ics: Str-A6000H SeriesAnonymous Lfgk6vygNessuna valutazione finora

- Panasonic Th-42py80p th-42pz80 PDFDocumento143 paginePanasonic Th-42py80p th-42pz80 PDFNsb El-kathiriNessuna valutazione finora

- Repair of Broken Power Supply in Apple Time CapsuleDocumento4 pagineRepair of Broken Power Supply in Apple Time Capsulepethei100% (2)

- Product Introduction Product Introduction: LEXUS LS600h/LS600hL Hybrid System Power Control Unit (PCU)Documento4 pagineProduct Introduction Product Introduction: LEXUS LS600h/LS600hL Hybrid System Power Control Unit (PCU)Вячеслав ГлушакNessuna valutazione finora

- Samsung F33a Ps42c91hxDocumento85 pagineSamsung F33a Ps42c91hxfaroltekNessuna valutazione finora

- Samsung Gt-p1000 Service Manual r1Documento80 pagineSamsung Gt-p1000 Service Manual r1Alfred Vivien BossonNessuna valutazione finora

- Diesel Fuel Injector Pump: Factsheet Updated 3 October 2008Documento8 pagineDiesel Fuel Injector Pump: Factsheet Updated 3 October 2008anshel100% (1)

- Timing BeltDocumento8 pagineTiming BeltSteve FosterNessuna valutazione finora

- 924F 3114 3116 Engine Valve Lash - InspectAdjustDocumento3 pagine924F 3114 3116 Engine Valve Lash - InspectAdjustReymundo Enrique Dominguez HernandezNessuna valutazione finora

- 1988 Tomos A3 Workshop ManualDocumento30 pagine1988 Tomos A3 Workshop ManualcerubdzijaNessuna valutazione finora

- Technical Service Bulletin: Sorento Digital Clock Losing TimeDocumento4 pagineTechnical Service Bulletin: Sorento Digital Clock Losing Time08088338Nessuna valutazione finora

- g3 Air System AbaDocumento15 pagineg3 Air System Aba08088338Nessuna valutazione finora

- Kia Sorento 2.4 ChargerDocumento1 paginaKia Sorento 2.4 Charger08088338Nessuna valutazione finora

- Technical Service Bulletin: - DescriptionDocumento4 pagineTechnical Service Bulletin: - Description08088338Nessuna valutazione finora

- Water Pump Cleaning and InspectionDocumento1 paginaWater Pump Cleaning and Inspection08088338Nessuna valutazione finora

- Evaporative Emission Control System DescriptionDocumento1 paginaEvaporative Emission Control System Description08088338Nessuna valutazione finora

- Engine Coolant Fan Replacement 1 0l LMT 1 19l Lc5 and 1 2l LmuDocumento1 paginaEngine Coolant Fan Replacement 1 0l LMT 1 19l Lc5 and 1 2l Lmu08088338Nessuna valutazione finora

- 2005 Audi A6 / Quattro (4F) : Submodel: Engine Type: Liters: Fuel Delivery: FuelDocumento1 pagina2005 Audi A6 / Quattro (4F) : Submodel: Engine Type: Liters: Fuel Delivery: Fuel08088338Nessuna valutazione finora

- Data Link Communications Description and OperationDocumento1 paginaData Link Communications Description and Operation08088338Nessuna valutazione finora

- General Body Construction Unibody DescriptionDocumento3 pagineGeneral Body Construction Unibody Description08088338Nessuna valutazione finora

- S53 Manual TransaxleDocumento2 pagineS53 Manual Transaxle08088338Nessuna valutazione finora

- Ford 30 V600Documento7 pagineFord 30 V60008088338Nessuna valutazione finora

- 307-01 - Digital Transmission Range (TR) SensorDocumento6 pagine307-01 - Digital Transmission Range (TR) Sensor08088338Nessuna valutazione finora

- 231Documento4 pagine23108088338Nessuna valutazione finora

- Circuit Diagram: Luggage Compartment Light Ceiling LampDocumento1 paginaCircuit Diagram: Luggage Compartment Light Ceiling Lamp08088338Nessuna valutazione finora

- Circult DiagramDocumento1 paginaCircult Diagram08088338Nessuna valutazione finora

- Xtunter-E3 User Manual v8.4Documento62 pagineXtunter-E3 User Manual v8.408088338Nessuna valutazione finora