Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

21 CFR 158-170 Frozen Peas PDF

Caricato da

ngoc98Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

21 CFR 158-170 Frozen Peas PDF

Caricato da

ngoc98Copyright:

Formati disponibili

158.

21 CFR Ch. I (4116 Edition)

Subpart BRequirements for Specific

Standardized Frozen Vegetables

158.170

(g) Acceptable quality level (AQL). The

maximum percent of defective sample

units permitted in a lot that will be accepted approximately 95 percent of the

time.

Frozen peas.

AUTHORITY: 21 U.S.C. 321, 341, 343, 348, 371.

[42 FR 14461, Mar. 15, 1977]

Subpart AGeneral Provisions

158.3 Definitions.

For the purposes of this part the following definitions shall apply:

(a) Lot. A collection of primary containers or units of the same size, type

and style manufactured or packed

under similar conditions and handled

as a single unit of trade.

(b) Lot size. The number of primary

containers or units (pounds when in

bulk) in the lot.

(c) Sample size. The total number of

sample units drawn for examination

from a lot.

(d) Sample unit. A container, a portion of the contents of a container, or

a composite mixture of product from

small containers that is sufficient for

the examination or testing as a single

unit.

(e) Defective. Any sample unit shall

be regarded as defective when the sample unit does not meet the criteria set

forth in the standards.

(f) Acceptance number. The maximum

number of defective sample units permitted in the sample in order to consider the lot as meeting the specified

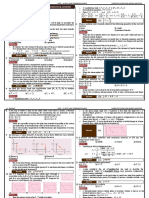

requirements. The following acceptance numbers shall apply:

Size container

Lot size (primary container)

n1

NET WEIGHT EQUAL TO OR LESS THAN

4,800 or less ......................................

4,801 to 24,000 .................................

24,001 to 48,000 ...............................

48,001 to 84,000 ...............................

84,001 to 144,000 .............................

144,001 to 240,000 ...........................

Over 240,000 .....................................

lpowell on DSK54DXVN1OFR with $$_JOB

NET WEIGHT GREATER THAN

Number of Pounds

20,000 or less ....................................

More than 20,000 to 100,000 ............

More than 100,000 to 200,000 ..........

More than 200,000 to 400,000 ..........

More than 400,000 to 600,000 ..........

More than 600,000 to 1,000,000 .......

More than 1,000,000 .........................

1n

2c

c2

1 KG (2.2 LB)

13

21

29

48

84

126

200

2

3

4

6

9

13

19

1 KG (2.2 LB)

13

21

29

48

84

126

200

2

3

4

6

9

13

19

= number of sample units.

= acceptance number.

Subpart BRequirements for Specific

Standardized

Frozen

Vegetables

158.170 Frozen peas.

(a) Identity(1) Product definition.

Frozen peas is the food in package

form as that term is defined in 1.20 of

this chapter, prepared from the succulent seed of the pea plant of the species Pisum sativum L. Any suitable variety of pea may be used. It is blanched,

drained, and preserved by freezing in

such a way that the range of temperature of maximum crystallization is

passed quickly. The freezing process

shall not be regarded as complete until

the product temperature has reached

18 C (0 F) or lower at the thermal

center, after thermal stabilization.

Such food may contain one, or any

combination of two or more, of the following safe and suitable optional ingredients:

(i) Natural and artificial flavors.

(ii) Condiments such as spices and

mint leaves.

(iii) Dry nutritive carbohydrate

sweeteners.

(iv) Salt.

(v) Monosodium glutamate and other

glutamic acid salts.

(2) Size specifications. If size graded,

frozen peas shall contain not less than

80 percent by weight of peas of the size

declared or of smaller sizes. The sample unit may not contain more than 20

percent by weight of peas of the next

two larger sizes, of which not more

than one quarter by weight of such

peas may be of the larger of these two

sizes, and may contain no peas larger

than the next two larger sizes, if such

there be. The following sizes and designations shall apply:

Size designation

Round hole sieve size through

which peas will pass

Millimeters

Extra small .....................

Very small ......................

Small ..............................

Up to 7.5 .......................

Up to 8.2 .......................

Up to 8.75 .....................

640

VerDate Sep<11>2014

17:31 May 24, 2016

Jkt 238071

PO 00000

Frm 00650

Fmt 8010

Sfmt 8010

Q:\21\21V2.TXT

31

Inch

0.295

.32

.34

Food and Drug Administration, HHS

Size designation

Round hole sieve size through

which peas will pass

Millimeters

lpowell on DSK54DXVN1OFR with $$_JOB

Medium ..........................

Large ..............................

158.170

Up to 10.2 .....................

Over 10.2 ......................

Inch

.40

.40

(3) Labeling. The name of the product

is peas. The term early, June,

or early June shall precede or follow

the name in the case of smooth-skin or

substantially smooth-skin peas, such

as Alaska-type peas. Where the peas

are of sweet green wrinkled varieties,

the name may include the designation

sweet, green, wrinkled, or any

combination thereof. The label shall

contain the words frozen or quick

frozen. The name of the food shall include a declaration of any flavoring

that characterizes the product as specified in 101.22 of this chapter and a declaration of any condiment such as

spices and mint leaves that characterizes the product, e.g., Spice added.

Where a statement of pea size is made,

such statement shall indicate either

the size designation as specified in

paragraph (a)(2) of this section or the

applicable sieve size. However, the optional descriptive words petite or

tiny may be used in conjunction

with the product name when an average of 80 percent or more of the peas

will pass through a circular opening of

a diameter of 8.75 mm (0.34 in) or less

for sweet green wrinkled peas and 8.2

mm (0.32 in) for smooth-skin or substantially smooth-skin peas, such as

Alaska-type peas.

(4) Label declaration. Each of the ingredients used in the food shall be declared on the label as required by the

applicable sections of parts 101 and 130

of this chapter.

(b) Quality. (1) The standard of quality for frozen peas is as follows:

(i) Not more than 4 percent by weight

blond peas, i.e., yellow or white but edible peas;

(ii) Not more than 10 percent by

weight blemished peas, i.e., slightly

stained or spotted peas;

(iii) Not more than 2 percent by

weight seriously blemished peas, i.e.,

peas that are hard, shrivelled, spotted,

discolored or otherwise blemished to an

extent that the appearance or eating

quality is seriously affected.

(iv) Not more than 15 percent by

weight pea fragments, i.e., portions of

peas,

separated

or

individual

cotyledons, crushed, partial or broken

cotyledons and loose skins, but excluding entire intact peas with skins detached;

(v) Not more than 0.5 percent by

weight, or more than 12 sq cm (2 sq in)

in area, extraneous vegetable material,

i.e., vine or leaf or pod material from

the pea plant or other such material

per sample unit as defined in paragraph

(b) of this section.

(vi) The sum of the pea material described in paragraphs (b)(1) (i), (ii),

(iii), and (iv) of this section shall not

exceed 15 percent.

(vii) For peas that meet the

organoleptic and analytical characteristics of sweet green wrinkled varieties:

(a) The alcohol-insoluble solids may

not be more than 19 percent based on

the procedure set forth in paragraph

(b)(3) of this section.

(b) Not more than 15 percent by

count of the peas may sink in a solution containing 16 percent salt by

weight according to the brine flotation

test set forth in paragraph (b)(4) of this

section;

(viii) For smooth-skin or substantially smooth-skin varieties the alcohol insoluble solids may not be more

than 23 percent based on the procedure

set forth in paragraph (b)(3) of this section.

(ix) The quality of a lot shall be considered acceptable when the number of

defectives does not exceed the acceptance number in the sampling plans set

forth in 158.3(f).

(2) The sample unit for determining

compliance with the requirements of

paragraph (b)(1) of this section other

than those of paragraphs (b)(1)(vii)(a)

and (b)(1)(viii) of this section, shall be

500 g (17.6 oz). For the determination of

alcohol-insoluble solids as specified in

paragraph (b)(3) of this section, the

container may be the sample unit.

(3) Alcohol-insoluble solids determination. (i) Extracting solutions:

(a) One hundred parts of ethanol denatured with five parts of methanol

volume to volume (formula 3A denatured alcohol), or

641

VerDate Sep<11>2014

17:31 May 24, 2016

Jkt 238071

PO 00000

Frm 00651

Fmt 8010

Sfmt 8010

Q:\21\21V2.TXT

31

lpowell on DSK54DXVN1OFR with $$_JOB

Pt. 160

21 CFR Ch. I (4116 Edition)

(b) A mixture of 95 parts of formula

3A denatured alcohol and five parts of

isopropanol v/v.

(ii) Eighty percent alcohol (8 liters of

extracting solutions, specified in paragraph (b)(3)(i) (a) or (b) of this section,

diluted to 9.5 liters with water).

(iii) Drying disha flat-bottom dish

with a tight fitting cover.

(iv) Drying ovena properly ventilated oven thermostatically controlled

at 1002 C.

(v) ProcedureTransfer frozen contents of package to plastic bag; tie bag

securely and immerse in water bath

with continuous flow at room temperature. Avoid agitation of bag during

thawing by using clamps or weights.

When sample completely thaws, remove bag, blot off adhering water, and

transfer peas to U.S. No. 8 sieve, using

(20 cm.) size for container of less than

3 lb. net weight and (30.5 cm.) for larger

quantities. Without shifting peas, incline sieve to aid drainage, drain 2 minutes. With cloth wipe surplus water

from lower screen surface. Weigh 250 g.

of peas into high-speed blender, add 250

g. of water and blend to smooth paste.

For less than 250 g. sample, use entire

sample with equal weight of water.

Weight 20 g.10 mg. of the paste into

250 ml. distillation flask, add 120 ml. of

extracting solutions specified in paragraph (b)(3)(i) (a) or (b) of this section,

and reflux 30 minutes on steam or

water bath or hotplate. Fit into a

buchner funnel a filter paper of appropriate size (previously prepared by drying in flatbottom dish for 2 hours in

drying oven, covering, cooling in desiccator, and weighing). Apply vacuum to

buchner funnel and transfer contents of

beaker so as to avoid running over edge

of paper. Aspirate to dryness and wash

material on filter with 80 percent alcohol until washings are clear and colorless. Transfer paper and alcohol-insoluble solids to drying dish used to prepare paper, dry uncovered for 2 hours

in drying oven, cover, cool in desiccator, and weigh at once. From this

weight deduct weight of dish, cover,

and paper. Calculate percent by weight

of alcohol-insoluble solids.

(4) Brine flotation test. (i) ExplanationThe brine flotation test utilizes salt solutions of various specific

gravities to separate the peas accord-

ing to maturity. The brine solutions

are based on the percentage by weight

of pure salt (NaCl) in solution at 20 C.

In making the test the brine solutions

are standardized to the proper specific

gravity equivalent to the specified

percent of salt solutions at 20 C by

using a salometer spindle accurately

calibrated at 20 C. A 250 ml glass beaker or similar receptacle is filled with

the brine solution to a depth of approximately 50 mm. The brine solution

and sample (100 peas per container)

must be at the same temperature and

should closely approximate 20 C.

(ii) ProcedureAfter carefully removing the skins from the peas, place

the peas into the solution. Pieces of

peas and loose skins should not be used

in making the brine flotation test. If

cotyledons divide, use both cotyledons

in the test and consider the two separated cotyledons as 1 pea; and, if an

odd cotyledon sinks, consider it as one

pea. Only peas that sink to the bottom

of the receptacle within 10 seconds

after immersion are counted as peas

that sink.

(5) If the quality of the frozen peas

falls below the standard prescribed in

paragraph (b)(1) of this section, the

label shall bear the general statement

of substandard quality specified in the

Code of Federal Regulations but in lieu

of the words prescribed in the second

line of the rectangle the following

words may be used where the frozen

peas fall below the standard in only

one respect: Below standard in quality lll, the blank to be filled in

with the specific reason for substandard quality as listed in the standard.

[42 FR 14461, Mar. 15, 1977, as amended at 42

FR 15673, Mar. 22, 1977; 58 FR 2883, Jan. 6,

1993]

PART 160EGGS AND EGG

PRODUCTS

Subpart A [Reserved]

Subpart BRequirements for Specific

Standardized Eggs and Egg Products

Sec.

160.100

160.105

160.110

160.115

Eggs.

Dried eggs.

Frozen eggs.

Liquid eggs.

642

VerDate Sep<11>2014

17:31 May 24, 2016

Jkt 238071

PO 00000

Frm 00652

Fmt 8010

Sfmt 8010

Q:\21\21V2.TXT

31

Potrebbero piacerti anche

- Ketchup: Methods of Manufacture; Microscopic ExaminationDa EverandKetchup: Methods of Manufacture; Microscopic ExaminationNessuna valutazione finora

- Dal Analogue - An Economic and Healthy Option From Soy To Bridge The Pulses Supply-Demand GapDocumento5 pagineDal Analogue - An Economic and Healthy Option From Soy To Bridge The Pulses Supply-Demand Gapsitapu0% (1)

- Optimization of The Process of Drying of Corn Seeds With The Use of MicrowavesDocumento10 pagineOptimization of The Process of Drying of Corn Seeds With The Use of MicrowavesShania GintingNessuna valutazione finora

- Indian Dairy Product Market PDFDocumento5 pagineIndian Dairy Product Market PDFharisankar sureshNessuna valutazione finora

- Banana Plantation: Geographic DistributionDocumento7 pagineBanana Plantation: Geographic DistributionJebjeb C. BrañaNessuna valutazione finora

- Micro Propagation of Banana Musa SP CV Agnishwar by in Vitro Shoot Tip CultureDocumento6 pagineMicro Propagation of Banana Musa SP CV Agnishwar by in Vitro Shoot Tip Cultureadididi33Nessuna valutazione finora

- Philippine Dried Fruit Marketing Plan PDFDocumento9 paginePhilippine Dried Fruit Marketing Plan PDFJordy Verdadero0% (1)

- The Effects of Oils and Frying Temperatures On The Texture and FatDocumento5 pagineThe Effects of Oils and Frying Temperatures On The Texture and FatAgus SupriatnaNessuna valutazione finora

- Fertigrow Business Plan Group 3Documento69 pagineFertigrow Business Plan Group 3Elaiza May PatigayonNessuna valutazione finora

- Mango Pulp Manufacturing Unit: Group 7 Ashwin - Madhumitha - Neha - Seshadri - VimalDocumento16 pagineMango Pulp Manufacturing Unit: Group 7 Ashwin - Madhumitha - Neha - Seshadri - VimalVimal AnbalaganNessuna valutazione finora

- Using Virgin Coconut Oil Waste Products For Chicken and Pig FeedDocumento4 pagineUsing Virgin Coconut Oil Waste Products For Chicken and Pig FeedAmalia RahmahNessuna valutazione finora

- Corn Flour (Intro and Profile)Documento3 pagineCorn Flour (Intro and Profile)Michele RogersNessuna valutazione finora

- My Project New EditDocumento38 pagineMy Project New Editmuhammad m butuNessuna valutazione finora

- Production of Spray-Dried CoconutDocumento4 pagineProduction of Spray-Dried CoconutIin YahyaNessuna valutazione finora

- AloeVera BPDocumento26 pagineAloeVera BPdivyaNessuna valutazione finora

- Centuries BP 2Documento50 pagineCenturies BP 2Dadon4uNessuna valutazione finora

- Peanut Processing PlantDocumento19 paginePeanut Processing PlantfaizkauNessuna valutazione finora

- Kwon 2014Documento11 pagineKwon 2014restyayuyo50% (2)

- Papaya Feasibility Study IndiaDocumento4 paginePapaya Feasibility Study IndiaHarbest Hydrobest100% (2)

- Intro To Pineapple Unit 10 - CompressedDocumento40 pagineIntro To Pineapple Unit 10 - CompressedKin LeNessuna valutazione finora

- Cereal Production in PakistanDocumento24 pagineCereal Production in PakistananamNessuna valutazione finora

- Ayurvet HPonics DubaiDocumento28 pagineAyurvet HPonics DubaidrgsainiNessuna valutazione finora

- The Agriculturalist Newspaper (Denbigh) - August 2014Documento24 pagineThe Agriculturalist Newspaper (Denbigh) - August 2014Patrick MaitlandNessuna valutazione finora

- Lecture - 1: Scope and Importance of Post Harvest Technology in Horticultural CropsDocumento17 pagineLecture - 1: Scope and Importance of Post Harvest Technology in Horticultural CropsAGRI KUDUMIYANMALAINessuna valutazione finora

- Food Chemistry: Maruf Ahmed, Mst. Sorifa Akter, Jong-Bang EunDocumento7 pagineFood Chemistry: Maruf Ahmed, Mst. Sorifa Akter, Jong-Bang EunFibra NurainyNessuna valutazione finora

- SteviaDocumento7 pagineSteviaRavi KumarNessuna valutazione finora

- Barley Sprout and Fodder Solutions System (Jakarta)Documento33 pagineBarley Sprout and Fodder Solutions System (Jakarta)Zakaria YahayaNessuna valutazione finora

- Fermented Fish ProcessingDocumento35 pagineFermented Fish ProcessingAlexine Cartin100% (1)

- Aquaculture Big Numbers PDFDocumento80 pagineAquaculture Big Numbers PDFAnonymous xv5fUs4AvNessuna valutazione finora

- AIC Organic Fertilizer For CacaoDocumento4 pagineAIC Organic Fertilizer For CacaoGene Gregorio100% (1)

- Agribusiness MGTDocumento2 pagineAgribusiness MGTyajuvendrasinhNessuna valutazione finora

- Feed MillDocumento10 pagineFeed MillRai Abid Abbas RabairaNessuna valutazione finora

- CIP Annual Report 1989Documento201 pagineCIP Annual Report 1989cip-libraryNessuna valutazione finora

- Model Project Report On Fruit & Vegetable Processing UnitDocumento24 pagineModel Project Report On Fruit & Vegetable Processing UnitSuhas Ninghot100% (1)

- Pakistan Feedstuffs Database 2020 - Final-1Documento40 paginePakistan Feedstuffs Database 2020 - Final-1Jawad JamilNessuna valutazione finora

- Formulation of Value Added Low-Calorie, High Fibre Biscuits Using Flax Seeds and Stevia RebaudianaDocumento8 pagineFormulation of Value Added Low-Calorie, High Fibre Biscuits Using Flax Seeds and Stevia Rebaudianascience worldNessuna valutazione finora

- To Study Effect of Drought On Coriander (Coriandrum Sativum) For Morpho-Physiological TraitsDocumento67 pagineTo Study Effect of Drought On Coriander (Coriandrum Sativum) For Morpho-Physiological TraitsrahulNessuna valutazione finora

- Starting A Guava FarmDocumento22 pagineStarting A Guava FarmMarlyn RichardsNessuna valutazione finora

- Dabar ChyawanprashDocumento11 pagineDabar ChyawanprashVipulNessuna valutazione finora

- Marketing Plan Khalis Chali Atta by MubeenDocumento11 pagineMarketing Plan Khalis Chali Atta by MubeenKalhoro Ali ArslanNessuna valutazione finora

- NAmkeen PPRDocumento46 pagineNAmkeen PPRFăÍż SăįYąð100% (1)

- 10 Postharvest ManagementDocumento58 pagine10 Postharvest ManagementDans DansNessuna valutazione finora

- Safal Report FinalDocumento25 pagineSafal Report FinalNatasha PandeyNessuna valutazione finora

- Fufu Flour: Process Flow Chart For FufuDocumento10 pagineFufu Flour: Process Flow Chart For FufuDotun AdesinaNessuna valutazione finora

- Rapid Mass Propagation TechniquesDocumento8 pagineRapid Mass Propagation TechniquesEJ Corpuz SalvadorNessuna valutazione finora

- General Standard For Food Additives PDFDocumento107 pagineGeneral Standard For Food Additives PDFMercyNessuna valutazione finora

- Ready To Eat VegetablesDocumento7 pagineReady To Eat VegetablesMita TannaNessuna valutazione finora

- SMART AGRICULTURE MONITORING SYSTEM USING IoTDocumento57 pagineSMART AGRICULTURE MONITORING SYSTEM USING IoTsukantakundu11Nessuna valutazione finora

- Black UreaDocumento20 pagineBlack UreaMacarthur B. Monsanto0% (1)

- The Complete Book On Cultivation and Manufacture of TeaDocumento30 pagineThe Complete Book On Cultivation and Manufacture of TeaAmy SNessuna valutazione finora

- Production of Cultured Milk by FAODocumento9 pagineProduction of Cultured Milk by FAOChevronelle100% (1)

- World: Cashew Nuts - Market Report. Analysis and Forecast To 2020Documento9 pagineWorld: Cashew Nuts - Market Report. Analysis and Forecast To 2020IndexBox Marketing100% (2)

- Supply and Demand Trend of Tropical Fruits in IndonesiaDocumento38 pagineSupply and Demand Trend of Tropical Fruits in IndonesiaeugeniaviviNessuna valutazione finora

- Technical Program - Horticulture 2005-06Documento19 pagineTechnical Program - Horticulture 2005-06Dr.Eswara Reddy SiddareddyNessuna valutazione finora

- Variety of Black PepperDocumento9 pagineVariety of Black PepperbharatNessuna valutazione finora

- CHAPTER I of Plant DesignDocumento8 pagineCHAPTER I of Plant DesignRehinaNessuna valutazione finora

- BrinjalDocumento31 pagineBrinjalraphaelagroNessuna valutazione finora

- Packaging Trends in Organized Food Retail: Reliance Industries LimitedDocumento38 paginePackaging Trends in Organized Food Retail: Reliance Industries LimitedAditi SarkarNessuna valutazione finora

- Production Technology For Cumbu Napier GrassDocumento20 pagineProduction Technology For Cumbu Napier GrassOVIYA M JNessuna valutazione finora

- Post-Harvest Management of Mango: (Mangifera indica L.)Da EverandPost-Harvest Management of Mango: (Mangifera indica L.)Nessuna valutazione finora

- Gupta, R.B., Kompella U.B., Nanoparticle Technology For Drug DeliveryDocumento42 pagineGupta, R.B., Kompella U.B., Nanoparticle Technology For Drug DeliverytaufikNessuna valutazione finora

- Why Are Cells So Small MyDocumento2 pagineWhy Are Cells So Small Myapi-521781723Nessuna valutazione finora

- Oxidation Reduction ReactionsDocumento40 pagineOxidation Reduction ReactionsLock SeriesNessuna valutazione finora

- Conservacion de Motores CaterpillarDocumento26 pagineConservacion de Motores CaterpillarRamón José Aponte Franco100% (1)

- Water Clarification Using Moringa Oleifera SeedsDocumento4 pagineWater Clarification Using Moringa Oleifera SeedsGreen Action Sustainable Technology GroupNessuna valutazione finora

- Manual For GASBOARD-6010 Opacity Meter Components Smoke HeadDocumento10 pagineManual For GASBOARD-6010 Opacity Meter Components Smoke HeadJOSEPH CAJOTENessuna valutazione finora

- MH Catalog Fuel Filters enDocumento42 pagineMH Catalog Fuel Filters enerwerwerwerwewytiygNessuna valutazione finora

- G11 Phy CH-8 Study MaterialDocumento29 pagineG11 Phy CH-8 Study MaterialPrasanna VijayakumarNessuna valutazione finora

- Design and Analysis of Liquid Cooled Cold Plates Using CAD ModelingDocumento5 pagineDesign and Analysis of Liquid Cooled Cold Plates Using CAD ModelingEditor IJTSRDNessuna valutazione finora

- Chemistry The Central Science 14th Edition Brown Test Bank 1Documento36 pagineChemistry The Central Science 14th Edition Brown Test Bank 1jaclynsanchezphdgrocpaiysj100% (18)

- 11 Physics Imp ch6 Marks 2Documento20 pagine11 Physics Imp ch6 Marks 2Anmol AgrawalNessuna valutazione finora

- Original Articles / / /: Home Archives Diyala Journal of Engineering Sciences Vol.15, No 3, September 2022Documento7 pagineOriginal Articles / / /: Home Archives Diyala Journal of Engineering Sciences Vol.15, No 3, September 2022Celvin SamNessuna valutazione finora

- Nodia and Company: Gate Solved Paper Chemical Engineering 2011Documento17 pagineNodia and Company: Gate Solved Paper Chemical Engineering 2011vijendra mauryaNessuna valutazione finora

- Chemical Effects of Electric Current: C E E CDocumento9 pagineChemical Effects of Electric Current: C E E CSonal AgarwalNessuna valutazione finora

- Chemistry - Copy of Lesson 6.6 - Theories of The AtomDocumento19 pagineChemistry - Copy of Lesson 6.6 - Theories of The AtomarielNessuna valutazione finora

- Mil-B-007883 Brazing - Cancelled - See Cancellation NoteDocumento26 pagineMil-B-007883 Brazing - Cancelled - See Cancellation NoteChris NenovNessuna valutazione finora

- Volatile Constituents of Centaurea Pelia DC., C. Thessala Hausskn. Subsp. Drakiensis (Freyn & Sint.) Georg. and C. Zuccariniana DC. From GreeceDocumento5 pagineVolatile Constituents of Centaurea Pelia DC., C. Thessala Hausskn. Subsp. Drakiensis (Freyn & Sint.) Georg. and C. Zuccariniana DC. From GreeceРусланNessuna valutazione finora

- Pharmaceutics 13 00919 v2Documento45 paginePharmaceutics 13 00919 v24n4n4sNessuna valutazione finora

- One-Part Epoxy ResinDocumento10 pagineOne-Part Epoxy ResinyangboNessuna valutazione finora

- Liquid Analysis v3 Powell-Cumming 2010 StanfordgwDocumento28 pagineLiquid Analysis v3 Powell-Cumming 2010 StanfordgwFebrianto MangopoNessuna valutazione finora

- Surtec 680: Protection UpgradedDocumento7 pagineSurtec 680: Protection Upgradedyudhien4443Nessuna valutazione finora

- Tutorial Questions 1111Documento6 pagineTutorial Questions 1111Fahmy Muhd100% (1)

- MSDS CRDocumento6 pagineMSDS CRReid KirbyNessuna valutazione finora

- Sample Paper Ftre 2022 Class Viii p2 PCBMDocumento27 pagineSample Paper Ftre 2022 Class Viii p2 PCBMNandini Saha50% (2)

- V.1. MAT Chart BrochureDocumento4 pagineV.1. MAT Chart BrochurekhaledallouchNessuna valutazione finora

- Customs and Border Protection: Keeping The Public Safe-And Commerce Moving - With Handheld Checkpoint SolutionsDocumento2 pagineCustoms and Border Protection: Keeping The Public Safe-And Commerce Moving - With Handheld Checkpoint SolutionsWacel HamaniNessuna valutazione finora

- Gas Laws LabDocumento4 pagineGas Laws LabBrady DeNioNessuna valutazione finora

- Ch. 3 Molecules of Life Review-2008Documento3 pagineCh. 3 Molecules of Life Review-2008Nopporn SaSaNessuna valutazione finora

- ICTON - Cristiana Grigorescu Paper ICTON 2020Documento4 pagineICTON - Cristiana Grigorescu Paper ICTON 2020CristianaNessuna valutazione finora

- Industry AbbreviationsDocumento39 pagineIndustry Abbreviationsrafik1995Nessuna valutazione finora