Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Tool List & Tightening Torque

Caricato da

ShivamGargCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Tool List & Tightening Torque

Caricato da

ShivamGargCopyright:

Formati disponibili

TATA 697 TCIC CEV BS III

1. GENERAL INFORMATION

1.1 TECHNICAL SPECIFICATIONS

Model

TATA 697 TCIC BS III ( CEV)

Type

High speed water cooled, Turbo charged inter cooled, high pressure

direct injection diesel engine

No. of cylinders

6 Inline

Bore / stroke

97 / 128 mm

Capacity

5.6 lit.

Max. Engine output

101 Ps @ 2300 rpm

130 Ps @ 2400 rpm

Max. Torque

46 mkg for 130 Ps and 35 mkg for 101 Ps

Compression Ratio

17.5 : 1

Firing Order

1-5-3-6-2-4

Engine oil capacity

Minimum 12 liter

Maximum 14 liter

Oil filter

Spin on type

Fuel Filter

Fuel filter with water separator, spin on type

Fuel injection pump

Rotary for 130 Ps / Inline for 101 Ps

Governor

Centrifugal type variable speed (RSV)

Weight of engine

470 Kg. (Dry)

Inlet valve clearance

0.20 mm

Exhaust valve clearance

0.30 mm

Max. Permissible variation in

injection nozzles pressure

5 bar

Cooling water temperature

90-95 C

Oil filter capacity

1 Liter

TATA 697 TCIC CEV BS III

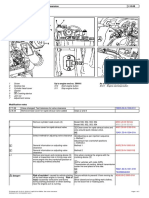

1.2 SPECIAL TOOLS AND EQUIPMENTS

SR.

NO.

DESCRIPTION

TML PART NO.

Adaptor for checking engine

compression for BS-II & BS-III

2652 5840 26 01

Locking screw for injection

timer (Where timer is mounted

on F.I.P.)

000 589 01 13

Puller for removing injectors

000 589 01 19

Spanner for fitment/removal of

pressure screw

000 589 02 09

Socket for protective sleeve

000 589 03 09

TOOL IMAGE

000 589 00 19

000 589 01 19

TATA 697 TCIC CEV BS III

SR.

NO.

DESCRIPTION

TML PART NO.

Socket wrench for tightening

cap nuts of high pressure lines

on injection pump

0005890509

Crow foot spanner for cylinder

head nut

0005890603

Drift for valve guide removal

(inlet)

1365890039

Assy. Adjusting fork for

injection lines

3125890085

10

Feeler strips for intake and

exhaust valves clearances

3125890123

11

Handles for lifting

cylinder head

3125890131

TOOL IMAGE

-----------

-----------

TATA 697 TCIC CEV BS III

SR.

NO.

DESCRIPTION

TML PART NO.

12

Universal joint socket wrench

for front engine mounting bolts

3125890209

13

Swan neck tube with nipple for

fuel timing

3125890223

14

Valve spring compressor

3125890231

TOOL IMAGE

TATA 697 TCIC CEV BS III

SR.

NO.

DESCRIPTION

TML PART NO.

15

Pliers for connecting nipple of

rocker arm shaft

3125890261

16

Support rail for valve spring

compressor

3125890331

17

Valve spring compressor with

rocker shaft in position

3125890431

TOOL IMAGE

TATA 697 TCIC CEV BS III

SR.

NO.

DESCRIPTION

TML PART NO.

18

Puller for oil pump gear

3125890633

19

Puller for crankshaft gear

3125890733

20

21

Drift for removal / installation

of camshaft bushing

Wrench for air compressor

exhaust valve

TOOL IMAGE

3125890739

3125890907

TATA 697 TCIC CEV BS III

SR.

NO.

DESCRIPTION

TML PART NO.

22

Puller for vibration damper

3125890933

23

Drift for installing oil seal in

timing gear valve

3125891239

24

Drift for pressing out piston pin

3125891339

25

Puller for generator pulley

3125892033

TOOL IMAGE

TATA 697 TCIC CEV BS III

SR.

NO.

DESCRIPTION

TML PART NO.

26

Sleeve for drift 3125890739

3125893339

27

Wrench for air compress

or inlet valve

325890207

28

GO-NOGO gauge for inlet

valve guide

6365890021

29

Reamer for new inlet valve

guides 9 dia.

6365890253

TOOL IMAGE

-----------

TATA 697 TCIC CEV BS III

SR.

NO.

30

DESCRIPTION

Drift for installing spigot

bearing in crankshaft

TML PART NO.

TOOL IMAGE

250658909902

Drift for installing

31

1) Injection pump drive gear

on engine camshaft

252358909902

2) Camshaft bore cover

32

33

Drift for installing crankshaft

gear

Drift for installing

oil pump gear

257458903503

257458909902

TATA 697 TCIC CEV BS III

SR.

NO.

DESCRIPTION

TML PART NO.

34

Spanner for turning

crankshaft

257658900201

35

Reamer for new exhaust

valve guides 10 dia.

251658900202

36

GO-NO GO gauge for

exhaust valve guides

257658900203

37

38

Angle indexing tool

Piston ring compressor main

pistons

257658900204

TOOL IMAGE

------------------

257658900206

10

TATA 697 TCIC CEV BS III

SR.

NO.

DESCRIPTION

TML PART NO.

39

Drift for installation and

removal of connecting Rod

bush

257658900207

40

Puller for Crankshaft spigot

bearing

257658900208

41

Piston ring compressor for

compressor piston

(3215890037 + 3215890137)

257658900209

TOOL IMAGE

Drift for removal of

i) Water pump shaft

42

ii) Small ball bearing of water

pump shaft

iii) For installing radial seal

ring in water pump housing.

257658900210

11

TATA 697 TCIC CEV BS III

SR.

NO.

DESCRIPTION

TML PART NO.

43

Sleeve for removal and

installation of water pump

shaft bearing

257658900211

44

Trolley for aggregate handling

257658900219

45

Tools for installing 7th main

bearing oil seal

257658900220

46

Drift for removal of exhaust

valve guide

257658900221

TOOL IMAGE

12

TATA 697 TCIC CEV BS III

SR.

NO.

DESCRIPTION

TML PART NO.

47

Adaptors stand for engine

removal from vehicle. To suite

trolley 2576 5890 0219.

257658900222

48

Drift with sleeve for installing

valve guides

257658900223

49

Guide bush for reaming

exhaust valve guides

257658900224

50

Guide bush for reaming inlet

valve guides

TOOL IMAGE

----------257658900225

13

TATA 697 TCIC CEV BS III

SR.

NO.

DESCRIPTION

TML PART NO.

51

Puller for water pump pulley

hub

257658900222

52

Adaptor bolt for camshaft

261058900304

53

Drift for removal of Liners

265158900201

54

Drift for installation of Liners

265158900202

TOOL IMAGE

14

TATA 697 TCIC CEV BS III

1.3 TIGHTENING TORQUE TABLE

Sr.

No

.

Description

Torque kgfM

Main Bearing Cap Bolts MI5

Screw Plug M30X 1.5 in Cylinder Head

Pressure Lock in Cylinder Head M24X 1.5

5-6

Nozzle in Nozzle Holter

3-4

Cylinder Head Cover Bolts M8

2.5

Screw Plug MI8 on Cylinder Crankcase

Push Rod Chamber Cover Bolts M8

Oil Sump Screw M6

0.8

Oil Sump Screw M8

0.9

10

Timing Gear Housing Cover M6

11

Screw Plug for Oil Gallery, Front and Rear MI6 1.5

12

Timing Gear Housing on Crankcase MI0

4.5

13

Screw Plug M24X 1.5 in Cylinder Head

7-15

14

Oil Sump Drain Plug

5+1

15

Cooler Side Cover for Water Jacket

0.4 0.6

16

Relief Valve On Cylinder Block (Piston Cooling)

2.5 + 0.5

17

Vibration Damper Lock M24X 1.5

18

Con. Rod Bolt 2525 0315 MI4X 1.25

5+1 (90 + 20)

19

Flywheel Mounting Bolts MI2, SW, 22

10

20

Con Rod Bolts MI2X 1.5 (Serrated)

21

Rocker Arm Support Bolts MI2

22

Camshaft Gear to drive gear(Inj. Pump) M8

23

Camshaft Thrust Washer To Cylinder Block

2.5 3.0

24

Camshaft Centre Pin (Timer on Camshaft)

30.0

25

Timing Gear Nut MI4x1.5

26

Capnuts on High Pressure Line

27

28

Banjo Bolt of leak Oil Line

Fuel Filter Mounting Bolts MI2x1.5

5+1 (90 + 20)

10-20

8

0.4 0.6

0.8 + 0.1

6

50-55

4+1 (90 + 10)

10-11

8

2 2.5

0.5 0.7

2

15

TATA 697 TCIC CEV BS III

29

Con. Rod Bolts

30

Cylinder Sleeve and Cylinder Head to Block M8 ( 94)

31

Delivery Valves In Cylinder Head ( 94 Air Compressor) M6

1 0.1

32

Section Valve In Cylinder Head ( 94 Air Compressor) M40X 1.5

18 2

33

Exhaust Manifold on Cylinder Head, Nut with Stud or bolt M10

34

Starter Motor on Flywheel Housing M10

35

Clamping Bolt for alternate M10

36

Nut for Pulley on Alternate MI4X 1.5

37

Oil Cooler Bolt On Cylinder Crankcase M8

38

Oil Pump cover Cylinder on Oil Pump M8

39

Oil Filter on Cylinder Crankcase M10

40

Screw Plug M24X 1.5 Oil Pressure Relief Valve (Shorter)

41

Assy. Suction Tube with Strainer to Oil Pump Cover (Shorter

Version)

42

Oil Filter Bowl (Center Pin) To Oil Filter Cover

43

Fan on Water Pump Hub M8

For Water Pump Thermostat Housing and Upper

Cooling Water Line

44

1.5 + 0.2

3.75

3.5

3.5 + 1

1.5 + 1

3.5

M6

1 1.5

M8

M10

45

Engine Support Arm Front MI4X 1.5

16

46

Pulley On Power Steering Pump

47

Clamping Bolts For Power Steering Pump

48

Clutch Housing On Flywheel Housing M10

49

Clutch Housing On Cylinder Crankcase M12

Cylinder Head Tightening Sequence: 1st stage - 4 mkg, 2nd stage 5mkg & 3rd stage - 90 + 10

16

TATA 697 TCIC CEV BS III

LPT-1613 Service schedule

Engine

Change Engine oil. Clean engine breather

Check condition of all drive belts (except timing belt) & rollers

Clean intercooler , radiator , AC condensor (if fitted)

Check condition of air intake system hoses / pipes / clamps

Check tappet clearance

Change engine coolant

Check red band at air filter indicator

Check stored errors in ECU

Fuel system

Drain water sediments in fuel filter

Change secondary / main fuel filter

Clutch

Change clutch fluid

Gear box

Change gearbox oil

Propeller shaft

Check propeller shaft condition

Tyres

Check tyre pressures

Rotate tyres

Check for tyre wear

Brakes

Check service , parking & exhaust brakes

Drain water sediments from air tanks

Overhaul air brake components

Change air drier desicant

Suspension

Check suspension condition

Steering system

Change steering oil

Check steering linkage condition

Electrical

Check functioning of switches / gauges / lights

Check battery

Check headlamp focus

Check health of electrical system

Grease all grease nipples

Check pipes & hoses of engine lubrication / fuel / coolant / air

conditioning (If fitted) / wind shield washing system / pneumatic

& hydraulic system

Conduct road test for vehicle for Customer complaints / to detect

any other issue

40,000

40,000

40,000

40,000

40,000

2,00,000 / 2 yrs

40,000

40,000

Auto drain

40,000

80,000

First at 80,000 & there

after every 1,20,000

40,000

Monthly

40,000

40,000

40,000

40,000

2,00,000 / 2 yrs

Every 2 yrs

40,000

80,000

40,000

40,000

40,000

40,000

Every 1 yrs

40,000

40,000

40,000

17

TATA 697 TCIC CEV BS III

1.4 ASSEMBLY CLEARANCES

Sr.

No

.

Values

(mm)

Description

1.

Main bearing diametral clearance

0.05 0.9

2.

Main bearing axial play

3.

Injector tip from bottom surface of cylinder

4.

Connecting rod diametral clearance

0.5 0.95

5.

Connecting rod axial play

0.1 0.4

6.

Piston play clearance on skirt (Escorts mahle) Linered

7.

Piston projection on cylinder block

8.

Camshaft bearing radial play

0.030 0.079

9.

Camshaft bearing axial play

0.111- 0.39

10.

Valve clearance (Cold.), Inlet

0.2 0.05

11.

Valve clearance (Cold.), Exhaust

0.3 0.05

12.

Valve steam clearance, Inlet

0.05 0.087

13.

Valve steam clearance, Exhaust

0.060 0.097

14.

Piston clearance aluminum

0.068 0.092

15.

Connecting rod radial play

0.02 0.066

16.

Connecting rod axial play

0.065 0.317

17.

Piston projection out of sleeve

Thrust Bearing

2.5 +0.6

697NA

0.11 0.12

Ambient

Percentage

temperature

up to C

Percentage

Summer

grade

Supplementary

fuel

697 TC

0.11

0.12

-0.4 / +0.31

0.25 0.70

1.5 FUEL, LUBRICANT AND COOLANTS

Fuels:

At very low temperature the fluidity of the diesel

becomes insufficient due to paraffin separation.

Care should be taken that the diesel and

supplementary fuels are thoroughly mixed before

filling. The fuel filters are to be drained out

thoroughly before refilling. The ratios for mixing of

supplementary fuel and diesel fuel are shown in

the table:

0.144 0.336

up to 0

0 to -10

-10 to -15

diesel

100

70

50

Ambient

Percentage

temperature

up to C

Up to 0 -15

-15 to -20

-20 and above

30

50

Percentage

Winter

grade

diesel

100

70

50

Supplementary

fuel

0

30

50

At low temperature, the correct mixture has better

flow properties. In order to achieve good engine

18

TATA 697 TCIC CEV BS III

operation, the entire fuel system should be drained

and filled with the recommended mixture. Care

should be taken that the diesel and supplementary

fuels are thoroughly mixed before filling. The fuel

filters should be drained out thoroughly before

refilling.

HS-Diesel oils recommended for use on TATA

diesel engines conform to following specifications

IS 1460, DIN 51601 or equivalent.

Do not mix kerosene with diesel as a cost reducing

measure. This mixture has poor lubricating

properties. It causes faster wear and tear of fuel

injection equipment components under normal

operating conditions. Cleanliness of the fuel

influences the efficiency and life of the fuel filters

and fuel injection equipment.

It is, therefore, more economical to fill clean fuel

into the tank. All precautions should be taken to

ensure that no dirt enters the tank while filling the

fuel.

Lubricants:

The lubrication oils for engine are required to be of

lower viscosity. Recommendations for the same

are as under. The recommended types of engine

oils and the range of ambient temperatures at

which these can be used are given in the following

table.

Engine oil grade

SAE 15W 40

Ambient Temperature C

-10 and above

SAE 10W 30

SAE 5W

-20 to 0

20 -10 and below

Please use only recommended brands of oil for

getting optimum engine performance and life.

There are several brands of lubricating oils in the

market. Only some of these oils have been

approved by us for use in TATA 697 TCIC engine.

The lubricating oils approved by us conform to

following specifications: SAE API CH4 and MB

228.3 engine oils.

The recommended oils have certain vital properties

that help to reduce the wear and tear of the

components.

We have tested these oils for thousands of hours

in similar conditions, your equipment is likely to

encounter.

The optimum period of use for each oil filling has

been carefully determined. Therefore, always use

only the approved oil. Strictly adhere to the engine

oil and oil filter cartridge change period specified

by us. The engine oil should be replaced at every

500 hours of operation along with the engine oil

filter. The oils of two different specifications should

not be mixed. Do not use reclaimed oils even for

topping up. They have already lost their vital

properties. The adverse effect using reclaimed oil

will not be seen immediately, but the life of the

components will be greatly reduced. It is difficult to

recognize poor quality oil. Therefore, buy the

recommended brands in sealed tins only from

authorized dealers.

Coolants:

Presence of dirt in coolant chokes-up radiator,

water passages in cylinder head and crankcase,

thereby causing overheating of engine. To prevent

rust formation and freezing of water inside water

jackets of crankcase and cylinder head mix

antifreeze agent as recommended. Use the

mixture of clean soft water and antifreeze agent in

the ratio of 50:50 for changing coolant in the

cooling system and also for topping up.

Recommended antifreeze agents

Tata Motors Super Kool (Bharat Petroleum)

Castrol Long Life Coolant (Castrol)

Certain precautions have to be taken to enable the

cooling system to function properly at very low

ambient temperatures. To attain the recommended

working temperature of the engine faster, it is

necessary to use a radiator blind. In view of the

grave risk of damage due to frost, the cooling

system of the engine should be filled with

recommended quantity of antifreeze agent. Use

the mixture of clean soft water and antifreeze

agent in the ratio of 50:50 for changing coolant in

the cooling system and also for topping up.

Recommended antifreeze agents

Servo Kool (IOC)

Long life Coolant (Castrol)

Golden Cruiser Coolant - GC 1200

(Sunstar - CCI (India) Pvt. Ltd.)

Koolguard (HPCL)

Purocool (Ansysco)

Chemcool (Chemoleums)

Please insure following before adding

antifreeze agent into the cooling system,

the

i. Inspect the cooling system for leakages and clean

it thoroughly.

19

TATA 697 TCIC CEV BS III

ii. Inspect the thermostat and replace if found

defective. It is advisable to attach a warning

sign to the radiator neck reading.

Antifreeze Solution is effective up to 40 C. Do

not drain off cooling system. It is recommended

that the entire cooling system should be drained

and filled with fresh mixture of antifreeze agent and

water in the ratio of 50:50 for ambient temperature

of up to 40 C. Coolant should be drained and

replenished in the recommended ratio at every two

years or 2400 hours, whichever is earlier.

1.6 ENGINE NAME PLATE

The Engine is provided with engine number plate.

It is located at rear side of engine, just above the

engine flywheel housing.

Engine identification Information

20

TATA 697 TCIC CEV BS III

21

Potrebbero piacerti anche

- Ashok LeylandDocumento33 pagineAshok LeylandVasikar Vasi80% (5)

- AL BS 2 EngineDocumento75 pagineAL BS 2 Enginemohanan100% (4)

- 697 Na Engine For Excavator Ex-110: (Parts List)Documento58 pagine697 Na Engine For Excavator Ex-110: (Parts List)SUMAN SURJIT BISWAL0% (2)

- Leyland HA6ETI Service ManualDocumento72 pagineLeyland HA6ETI Service ManualPolavarapu Sreedhar100% (4)

- Hino Ha6eti2 Bs II EngineDocumento77 pagineHino Ha6eti2 Bs II EngineMohan CharanchathNessuna valutazione finora

- Tata 407 Bs-Iii - 1Documento184 pagineTata 407 Bs-Iii - 1Niten Gupta100% (2)

- Cummin's Engine Tappet & FIP TimingDocumento12 pagineCummin's Engine Tappet & FIP TimingAtanu DubeNessuna valutazione finora

- 6WG1 TQA Workshop Manual N2223 Ex PDFDocumento3 pagine6WG1 TQA Workshop Manual N2223 Ex PDFmasakp75% (8)

- 6DTI - Service ManualDocumento20 pagine6DTI - Service ManualRakshit60% (5)

- Crankshaft Main Bearing Bolts Torque (Converted)Documento5 pagineCrankshaft Main Bearing Bolts Torque (Converted)Nasser Ayoub100% (3)

- LPK 2516C BS Ii CatDocumento550 pagineLPK 2516C BS Ii CatSukhmeet Bhatia50% (4)

- Ashok Leyland 6DTI Engine Service ManualDocumento20 pagineAshok Leyland 6DTI Engine Service ManualFLORES SANTIAGO CESAR MIGUELNessuna valutazione finora

- Engine Torque Wrench SettingsDocumento2 pagineEngine Torque Wrench SettingsDNessuna valutazione finora

- Hino Ef750 Engine PDFDocumento2 pagineHino Ef750 Engine PDFvadim vadim60% (5)

- Set Valve ClearanceDocumento3 pagineSet Valve ClearancerudiNessuna valutazione finora

- 002-004 Cylinder Head Cummins 6BTA5.9 G2Documento10 pagine002-004 Cylinder Head Cummins 6BTA5.9 G2AleksaNessuna valutazione finora

- 2012-06-29 052659 Om403 Adjustment of The V... La, 403, 421, 422, 422 A PDFDocumento5 pagine2012-06-29 052659 Om403 Adjustment of The V... La, 403, 421, 422, 422 A PDFcommoril50% (2)

- 6R1080T Spare Parts PDFDocumento86 pagine6R1080T Spare Parts PDFSamir Khan100% (1)

- HA6ETI Service ManualDocumento72 pagineHA6ETI Service ManualRakshit83% (18)

- BA OM 904, 906, 926 LA BlueTec A 09-11, 1, en-GB PDFDocumento3 pagineBA OM 904, 906, 926 LA BlueTec A 09-11, 1, en-GB PDFLuisangelDueñasNessuna valutazione finora

- 6h.5255-6k1080ta Engine For Power Generation 125kvaDocumento118 pagine6h.5255-6k1080ta Engine For Power Generation 125kvanilesh asthana67% (3)

- TATA 407 SpecificationDocumento10 pagineTATA 407 Specificationbaisankit100% (2)

- BS VI Training Phase 1Documento57 pagineBS VI Training Phase 1siva kumar100% (4)

- B Series Head Torque DataDocumento21 pagineB Series Head Torque DataSpectrumRaijin100% (1)

- NGT 520 - Transmission PDFDocumento56 pagineNGT 520 - Transmission PDFihsan67% (12)

- 4HF1 4HG1Documento5 pagine4HF1 4HG1Arifin Arif100% (2)

- 1AL 485 - G1 TG2 TAG3 EngineDocumento30 pagine1AL 485 - G1 TG2 TAG3 Engineajay67% (3)

- Piston and Rings 3126BDocumento3 paginePiston and Rings 3126BGerardo100% (1)

- 9-Speed ManualDocumento214 pagine9-Speed ManualFusoTech93% (15)

- Service Manual Engine Mitsubishi Canter 4d34Documento1 paginaService Manual Engine Mitsubishi Canter 4d34Stif B. Marengo50% (2)

- Mdi Nef Service Manual - EnglishDocumento99 pagineMdi Nef Service Manual - EnglishUday Bhanu100% (4)

- Workshop Manual 2.2 L Dicor Engine: Customer Support International Business - PCBUDocumento48 pagineWorkshop Manual 2.2 L Dicor Engine: Customer Support International Business - PCBUPhillip van Dalen100% (7)

- SL90 Engine Workshop Manual Specification DataDocumento110 pagineSL90 Engine Workshop Manual Specification Datafreddy yagual88% (17)

- Dicor EngineDocumento8 pagineDicor Enginepkhurana22Nessuna valutazione finora

- Bosch Nozzles PDFDocumento11 pagineBosch Nozzles PDFAnonymous wpUyixsj100% (1)

- Connecting Rod Bolts Torque (Converted)Documento4 pagineConnecting Rod Bolts Torque (Converted)Nasser Ayoub100% (1)

- Isuzu Diesel Engine (4HK1, 6HK1) PDFDocumento11 pagineIsuzu Diesel Engine (4HK1, 6HK1) PDFtin tunlin100% (2)

- Parts Catalogue - MDIDocumento47 pagineParts Catalogue - MDIsengottaiyan83% (6)

- Electronic Unit Injector - Install: Disassembly and AssemblyDocumento5 pagineElectronic Unit Injector - Install: Disassembly and AssemblysxturboNessuna valutazione finora

- WWW - Incar.tw-Mitsubishi Engine 8dc9 Service ManualDocumento5 pagineWWW - Incar.tw-Mitsubishi Engine 8dc9 Service ManualRian100% (5)

- Illustrated Spare Parts List for 4R1040 EngineDocumento86 pagineIllustrated Spare Parts List for 4R1040 Enginejaxxx14360% (5)

- AL NEW PLATFORM TRUCKS WITH IGEN6 TECHNOLOGYDocumento102 pagineAL NEW PLATFORM TRUCKS WITH IGEN6 TECHNOLOGYAnkur MestryNessuna valutazione finora

- Diagnostic Cods Nem - For Problem PDFDocumento406 pagineDiagnostic Cods Nem - For Problem PDFMd MunnaNessuna valutazione finora

- 04 Cummins Engine Oil ConsumtionDocumento5 pagine04 Cummins Engine Oil ConsumtionOdlanier José Mendoza100% (1)

- Koel Engine, Ha Operation and Maintenance Manual (Ha - SR)Documento89 pagineKoel Engine, Ha Operation and Maintenance Manual (Ha - SR)Karthik K Raja75% (12)

- 6bt Valve Lash PDFDocumento7 pagine6bt Valve Lash PDFmilNessuna valutazione finora

- Caterpillar Wheel Loader TroubleshootingDocumento26 pagineCaterpillar Wheel Loader TroubleshootingNezar Amin100% (3)

- BS4 Pocket Guide New - 4.4.17Documento63 pagineBS4 Pocket Guide New - 4.4.17Ranjit0% (1)

- AL4DTG3/4 Parts CatalogDocumento82 pagineAL4DTG3/4 Parts Catalogsengottaiyan100% (4)

- TELCOLINE 2.2L DICOR LHD PARTLISTDocumento312 pagineTELCOLINE 2.2L DICOR LHD PARTLISTpescarul20175% (4)

- ZF S5 S6 and S6 OD Gear Box PDFDocumento58 pagineZF S5 S6 and S6 OD Gear Box PDFMohan Charanchath75% (4)

- Tightening Torque - EngineDocumento3 pagineTightening Torque - Enginencthanhck81% (27)

- C11 Valve Lash Settings (Tappet Settings)Documento6 pagineC11 Valve Lash Settings (Tappet Settings)Hari Hara Suthan100% (3)

- Mahindra XD3P BOLERO PDFDocumento107 pagineMahindra XD3P BOLERO PDFMamta Raybage100% (6)

- Eicher Pro 1000 Series Models - Self Study Module Presentation in PDF Format PDFDocumento93 pagineEicher Pro 1000 Series Models - Self Study Module Presentation in PDF Format PDFShaik SajithNessuna valutazione finora

- Tuning Valve ClearanceDocumento3 pagineTuning Valve ClearanceShimmer Crossbones100% (1)

- C100 Service Training Manual: Engine Mechanical (2.4L DOHC) : Participant's HandoutDocumento32 pagineC100 Service Training Manual: Engine Mechanical (2.4L DOHC) : Participant's Handoutsertex_joNessuna valutazione finora

- General Engine Spec'sDocumento3 pagineGeneral Engine Spec'sfuzzylollipopNessuna valutazione finora

- C7Documento72 pagineC7victorhernandezrega94% (35)

- Payroll SchemaDocumento34 paginePayroll SchemaShivamGargNessuna valutazione finora

- Sappress Practical Sap Us Payroll 2.Documento72 pagineSappress Practical Sap Us Payroll 2.kajay050167% (3)

- NIH Public Access: Author ManuscriptDocumento14 pagineNIH Public Access: Author ManuscriptShivamGargNessuna valutazione finora

- B School RankingsDocumento1 paginaB School RankingsShivamGargNessuna valutazione finora

- Wage Types PDFDocumento1 paginaWage Types PDFShivamGargNessuna valutazione finora

- Mounting Design, Fitting Practice, Setting and Installation: Spherical and Cylindrical Roller BearingsDocumento1 paginaMounting Design, Fitting Practice, Setting and Installation: Spherical and Cylindrical Roller BearingssureshNessuna valutazione finora

- Query Result 2023-10-12T16 19 41.042062+07 00Documento102 pagineQuery Result 2023-10-12T16 19 41.042062+07 00monanglgaolNessuna valutazione finora

- Revised - Semester 6 Elective Subject Selection Form (AY 2023-24, Even) Nov 23R (1-126)Documento2 pagineRevised - Semester 6 Elective Subject Selection Form (AY 2023-24, Even) Nov 23R (1-126)Hariom TiwariNessuna valutazione finora

- Ssang Yong Korando New Actyon 2010 2013 Engine Assambly Service Repair ManualDocumento20 pagineSsang Yong Korando New Actyon 2010 2013 Engine Assambly Service Repair Manualscott100% (35)

- 1.2 - Comparison of Slow Medium and High Speed EnginesDocumento6 pagine1.2 - Comparison of Slow Medium and High Speed EnginesDhruveshNessuna valutazione finora

- MECHANICAL TRANSPORTATION SYSTEM IN A BUILDING: ELEVATOR INTRODUCTIONDocumento21 pagineMECHANICAL TRANSPORTATION SYSTEM IN A BUILDING: ELEVATOR INTRODUCTIONShubhaNessuna valutazione finora

- Direct Drive Starting Motor Maintenance and OverhaulDocumento12 pagineDirect Drive Starting Motor Maintenance and OverhaulQuality DepartmentNessuna valutazione finora

- 2124 Knuckleboom Loader - PRSL-0408Documento6 pagine2124 Knuckleboom Loader - PRSL-0408Supriyo AdiNessuna valutazione finora

- FEBRUARY 2021 Surplus Record Machinery & Equipment DirectoryDocumento714 pagineFEBRUARY 2021 Surplus Record Machinery & Equipment DirectorySurplus RecordNessuna valutazione finora

- Self Drive Car Rentals in LudhianaDocumento1 paginaSelf Drive Car Rentals in LudhianaeagleeyecarrentalsNessuna valutazione finora

- Steering System 2Documento20 pagineSteering System 2Jonnathan SpringNessuna valutazione finora

- Parts Manual Motor KM 178fDocumento2 pagineParts Manual Motor KM 178fWilmer Lance Estupiñan90% (10)

- Bharat Benz 1215r bs6 BrochureDocumento2 pagineBharat Benz 1215r bs6 BrochureNipun SharmaNessuna valutazione finora

- IGG Detailed TroubleshootingDocumento13 pagineIGG Detailed TroubleshootingElder Franco100% (4)

- Goodyear GP-4D BrochureDocumento2 pagineGoodyear GP-4D BrochureMaria Teresa VergaraNessuna valutazione finora

- Neon Skies Playtest 05Documento83 pagineNeon Skies Playtest 05bumble blick crumplestickNessuna valutazione finora

- Battery VEN Bombardier Electrostar: Electrical Multiple UnitDocumento3 pagineBattery VEN Bombardier Electrostar: Electrical Multiple UnitEzana EzanaNessuna valutazione finora

- Manual de Partes RT-160Documento622 pagineManual de Partes RT-160leogerguzNessuna valutazione finora

- REPORTDocumento42 pagineREPORTgirnar solutionsNessuna valutazione finora

- Inspection Through Scavenge PortsDocumento1 paginaInspection Through Scavenge PortsValeriy DomashenkoNessuna valutazione finora

- Total Experience:-6 Years (5 Years in Die Casting.) : Deepak A Jagzap Diploma IN Mechanical EnggDocumento3 pagineTotal Experience:-6 Years (5 Years in Die Casting.) : Deepak A Jagzap Diploma IN Mechanical EnggSmart TradingNessuna valutazione finora

- How to Use Cookies and Privacy Settings on This SiteDocumento145 pagineHow to Use Cookies and Privacy Settings on This SiteBota NicusorNessuna valutazione finora

- Surface Vehicle Recommended PracticeDocumento4 pagineSurface Vehicle Recommended Practicewilian_coelho3309Nessuna valutazione finora

- TNB Hydraulic Breaker ManualDocumento54 pagineTNB Hydraulic Breaker ManualKadir Koray BozyelNessuna valutazione finora

- Adolf Hitler and The VolkswagenDocumento4 pagineAdolf Hitler and The VolkswagenmmNessuna valutazione finora

- LegacyXLOpManual ngjwvGU2p9ZVj5K1wDocumento96 pagineLegacyXLOpManual ngjwvGU2p9ZVj5K1wearlvbNessuna valutazione finora

- 6EY18 (A) L (0CH10-M35901 - En)Documento221 pagine6EY18 (A) L (0CH10-M35901 - En)fendynovapamelaNessuna valutazione finora

- Timing Belt: Service and Repair Timing Belt Removal and InstallationDocumento4 pagineTiming Belt: Service and Repair Timing Belt Removal and InstallationJosé Carlos da silvaNessuna valutazione finora

- 2021 Equipment Blades Catalog - EMAILDocumento32 pagine2021 Equipment Blades Catalog - EMAILjose miguelNessuna valutazione finora

- Basics of Hydraulics and Hydraulic SystemsDocumento7 pagineBasics of Hydraulics and Hydraulic SystemsIbrahima DioufNessuna valutazione finora