Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Rohit Pandey Ashish Ambar

Caricato da

Rohit RaiCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Rohit Pandey Ashish Ambar

Caricato da

Rohit RaiCopyright:

Formati disponibili

ISSN 2320 6020

IJBSTR REVIEW PAPER VOL 1 [ISSUE 9] SEPTEMBER 2013

A Review of Relation between Cube Strength and Core Strength of

Hardened Concrete in the Light of IS456:2000and IS516:1959

Rohit Rai1, Ambareesh Kumar2, Ashish Singh3, and Kanhaiya Lal Pandey4

ABSTRACT- This paper presents the relation between core compressive strength and cube compressive in polynomial form and this

relation was developed with the help of software MATLAB .This relation was found to be in much agreement with that of relation in

is code IS 516:1959. In this experiment 15 beams and cubes were casted of M25 and cores were taken out from beams with the help of

core cutter machine of core diameter 75mm. and compression testing machine was used to test the strength. These all specimens were

tested in structural and concrete laboratory of MMMEC, Gorakhpur (UP).

KEY WORDS: Cube, Core, Compressive Strength, Ultrasonic Pulse Velocity.

INTRODUCTION

The main purpose of the determination of strength of concrete

standard specimens is to ensure that the potential strength of

the concrete in actual structure is satisfactory .Now, if the

strength of the standard compression test specimens is below

the specified values then either the concrete in the actual

structure is unsatisfactory ,or else the specimens are not truly

representative of the concrete in the structure .The latter

possibility should not be ignored in the disputes of the

acceptance ,or otherwise of a doubtful part of the structure the

test specimens may have been in correctly prepared, handled

or cured, or the testing machine could be at fault. The

argument is often resolved by testing cores of hardened

concrete taken from the suspected part of the structure in order

to estimate the potential strength of concrete in the structure.

Potential strength equivalent to 28-day strength of the standard

test specimens. In translating the core strength into potential

strength we take into account differences in the type of

specimen and in curing conditions, age and degree of

compaction between the core and the standard test specimen.

In other situations, we may want to assess the actual strength

of concrete in a structure because we suspect, for instance,

frost damage at a very early age or we are not sure that the

correct concrete was used and no standard specimens were

made.

Author 1,2,3 and 4 is currently pursuing master

of technology program in Department of civil

engineering Madan Mohan Malaviya

Engineering College Gorakhpur Uttar Pradesh 273010

Email-rohit.rai2609@gmail.com

We should remember, however that core taking damages or

mars the structure, so that test cores should be taken only

when other, non-destructive methods, are inadequate.

2.1 Testing Of Hardened Concrete

There exists various method of testing the strength of

hardened concrete. They can be broadly classified into 2

types:

1. Mechanical tests

Specimens are tested to the point of destruction. The purpose

of this is to determine the maximum loading a concrete

structure can take before collapse. A common mechanical test

widely used is the compressive strength test.

2. Non-destructive tests

These tests can be carried out on specimens as well as on the

actual structure. As the specimen / structure is intact after

testing, such tests are good for monitoring the change of

properties in the structure over time. One such test is the

Ultrasonic Pulse Velocity (UPV) Test.

It is important to know the influence of each test method on

the measured property of the concrete as different methods

and techniques are used in different countries.

2.2 Compressive Strength Tests

Compressive strength tests are most commonly used and are

simple to perform. As concrete is often designed to take

compressive loads, the compressive strength of concrete is

therefore an important property. In Great Britain, Germany

and other European countries, cube specimens of 100 mm and

150 mm are used. During testing, cubes are placed

perpendicular to their as-cast positions. In the United States,

France, Canada, Australia and New Zealand, cylinders are the

9

ijbstr.org

ISSN 2320 6020

IJBSTR REVIEW PAPER VOL 1 [ISSUE 9] SEPTEMBER 2013

typical specimens. 2 common cylinder sizes are 100 mm in

diameter X 200 mm in length and 150 mm in diameter X 300

mm in length. During testing, the top surface of the cylinder is

in contact with the platens. Hence they need to be grinded or

capped to ensure that they are sufficiently flat.

2.3 Ultrasonic Pulse Velocity (UPV) Tests

The UPV test consists of the measurement of the time taken

by an ultrasonic pulse to travel the distance of the length of the

specimen. The ultrasonic wave velocity is then related to the

density of the concrete. Generally, a higher value of UPV

implies higher compressive strength when moisture conditions

are kept constant. This is because the pulse usually travels

faster through a water-filled void than an air-filled one.

from the mean dimensions of the section and shall be

expressed to the nearest kg per sq. cm. Average of three values

shall be taken as the representative of the batch provided the

individual shall be taken as the representative of the batch

provided the individual variation is not more than 15 percent

of the average. Otherwise repeat tests shall be made.

A correction factor according to the height/diameter ratio of

specimen after capping shall be obtained from the curve

shown in Fig. The product of this correction factor and the

measured compressive strength shall be known as the

corrected compressive strength, this being the equivalent

strength of a cylinder having a height/diameter ratio of two.

The equivalent cube strength of the concrete shall be

determined by multiplying the corrected cylinder strength by

5/4.

2.4 Comparison of strength of standard cubes and

standard cylinders

Standard Cubes (L/D = 1) and standard cylinders (L/D = 2)

derived from the same batch of concrete display differences in

compressive strength. This is because of the difference in

influence of the platens restraining effects. According to BS

8110: Part 120:1983, the strength of a cylinder is

approximately 0.8 that of a cube. Nonetheless, research has

shown that the ratio of strength of a cylinder vs. cube

increases as the strength of concrete increases. At strengths of

more than 100 MPa, the ratio approaches 1.

2.5 Effect of Length / Diameter (L/D) ratio on the strength

of cylinders

Standard cylinders cast in moulds have a L/D ratio of 2, while

cored cylinders depend on the size of the coring tool and the

thickness or width of the slab or beam it is derived from.

Cylindrical cores of L/D ratio lesser than 2 tend to give higher

measured strength as compared to those with larger L/D ratio.

Table A1 in the appendix shows the correction factors for

strength of cylinders with different L/D ratio as provided by

ASTM C 42-90 and BS 1881:Part 120:1983. Higher strength

concrete however are less affected by the L/D ratio as found

by Murdock and Kesler (1957) (Figure A1). Neville (1998)

infers that there is comparatively little difference between the

strengths of cube and cylinder with h/d ratio of 1.

2.6 CODAL PROVSIONS

This method for determining the compressive strength of cores

are prescribed by BS EN 12504-1:2000, ASTM C 42-04 and

IS-516-1959.All are essentially similar .In the UK, the

preferred diameter of the core is 150mm, and the ratio of

diameter to diameter to the maximum size of aggregate should

not be less than 3; the length should be between 1 and 2 times

the diameter. Grinding is the preferred method of end

preparation but capping material may also be used. The

measured compressive strength of the specimen shall be

calculated by dividing the maximum load applied to the

specimen during the test by the cross-sectional area, calculated

3. METHODOLGY

In this 15 cubes and 15 beams of sizes 150mm x150mm x150

mm

were

casted

and

size

of

beams

were

150mm150mm750mm each from same batch of concrete of

M25 .Cubes and beams were cured for 28 days. And after that

cubes were taken out from moulds and beams were taken out

.The cores were taken out from beams from core cutter of size

75mm. Edges of the core are smoothened using grinding and

cutting wheels and epoxy motors is applied on both sides of

capping. This ensures the ends approximately 90 percent to the

axis and is within 0.05mm planeness. The core then subjected

to compression force on compression testing machine the

breaking point is observed. And cubes were also tested in

compression testing up to full fracture.

10

ijbstr.org

ISSN 2320 6020

IJBSTR REVIEW PAPER VOL 1 [ISSUE 9] SEPTEMBER 2013

4. EXPERIMENTAL OBSERVATION

4.3Core strength table:-

4.1 Observation Table of cube tested:-

4.2Observation table of core strength:-

5. ANALYSIS WITH COMPUTER SOFTWARE

5.1Matlab analysis program-

11

ijbstr.org

ISSN 2320 6020

IJBSTR REVIEW PAPER VOL 1 [ISSUE 9] SEPTEMBER 2013

6. RESULT

7. CONCLUSION

By using MATLAB we can find out the best fit curve

equation.

It is seen that with the help of experiment and software

we got a polynomial relation that could be used for

correlation between core strength and cube strength.

f(x) = p1*x^3 + p2*x^2 + p3*x + p4

Coefficients (with 95% confidence bounds):

8. REFERENCES

p1 = 0.0002494 (-0.00199, 0.002489)

[1] A.M Neville and J. J. Brooks, Properties of concrete, 2th

p2 = -0.01314 (-0.1686, 0.1423)

edition PEARSON publisher 2010.

p3 =1.45 (-2.104, 5.003)

[2] Unnikrishan Pillai & Devdas Menon, Design of RCC by

p4 = -0.7792 (-27.51, 25.95)

So, we have this final expression for the relation between core

strength and cube strength

3

Core Strength=.0002494(Cube Strength) -0.01314(Cube

Strength)2 + 1.45 (Cube Strength) -0.7792

GRAPHICAL INTERPRETATION OF RESULTS

Graph showing relation between core strength and core

strength.

3rd edition TMH publisher 2009.

[3] IS 456 (part 1):2000-Plain and reinforced concrete code

of practice (4threvision), BIS, New

Delhi, 2000.

[4] IS 516-1959 methods of tests for strength of concrete.

[5] IS 1199-1959 methods of sampling and analysis of

concrete.

12

ijbstr.org

Potrebbero piacerti anche

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- A Review of Relation Between Cube Strength and Core Strength of Hardened Concrete in The Light of IS456:2000and IS516:1959Documento4 pagineA Review of Relation Between Cube Strength and Core Strength of Hardened Concrete in The Light of IS456:2000and IS516:1959Rohit RaiNessuna valutazione finora

- Maulana Azad National Institute of Technology, Bhopal-462003Documento10 pagineMaulana Azad National Institute of Technology, Bhopal-462003Rohit RaiNessuna valutazione finora

- Office of The Chief Engineer-Regional Office, Lucknow Ministry of Road Transport & Highways, Government of IndiaDocumento1 paginaOffice of The Chief Engineer-Regional Office, Lucknow Ministry of Road Transport & Highways, Government of IndiaRohit RaiNessuna valutazione finora

- ह रयाणा कमचारी चयन आयोग Haryana Staff Selection Commission, Government of HaryanaDocumento1 paginaह रयाणा कमचारी चयन आयोग Haryana Staff Selection Commission, Government of HaryanaRohit RaiNessuna valutazione finora

- Government Eprocurement System: Decrypted Bid Openers ListDocumento1 paginaGovernment Eprocurement System: Decrypted Bid Openers ListRohit RaiNessuna valutazione finora

- SIP Plus One Pager InvestorDocumento2 pagineSIP Plus One Pager InvestorRohit RaiNessuna valutazione finora

- Bill of Quantities: Retaining Wall "A+B" L 340 M (110+230) H 3.6 MDocumento2 pagineBill of Quantities: Retaining Wall "A+B" L 340 M (110+230) H 3.6 MRohit RaiNessuna valutazione finora

- Comprative Analysis of Highway DesignDocumento55 pagineComprative Analysis of Highway DesignRohit RaiNessuna valutazione finora

- B.TECH 7th TunnelDocumento2 pagineB.TECH 7th TunnelRohit RaiNessuna valutazione finora

- Course: Diploma CIVIL ENGINEERING Academic Year: 2018-19 Year /semester: 3 / 5 Assignment No: 5 SubjectDocumento1 paginaCourse: Diploma CIVIL ENGINEERING Academic Year: 2018-19 Year /semester: 3 / 5 Assignment No: 5 SubjectRohit RaiNessuna valutazione finora

- Analysis of Finite Element Mesh Spacing Influence On Modeling Results 14augDocumento4 pagineAnalysis of Finite Element Mesh Spacing Influence On Modeling Results 14augRohit RaiNessuna valutazione finora

- Orientation Program 30-AUG-2017: Presented By:-Rohit RaiDocumento27 pagineOrientation Program 30-AUG-2017: Presented By:-Rohit RaiRohit RaiNessuna valutazione finora

- Maharishi University of Information Technology, Lucknow Presents A Training Program On STAAD - ProDocumento1 paginaMaharishi University of Information Technology, Lucknow Presents A Training Program On STAAD - ProRohit RaiNessuna valutazione finora

- Staad. Pro. A Tool For Civil Engineer'S: Presented By:-Rohit Rai, (Assistant Professor Muit, LucknowDocumento12 pagineStaad. Pro. A Tool For Civil Engineer'S: Presented By:-Rohit Rai, (Assistant Professor Muit, LucknowRohit RaiNessuna valutazione finora

- Rohit Rai Research PaperDocumento11 pagineRohit Rai Research PaperRohit RaiNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- AIATS Schedule (2011, 2012)Documento7 pagineAIATS Schedule (2011, 2012)goelbharatNessuna valutazione finora

- Indian Standard: Code of Practice For Design in Tunnels Conveying WaterDocumento29 pagineIndian Standard: Code of Practice For Design in Tunnels Conveying WaterswabrightNessuna valutazione finora

- Sampling Procedure For Impact Testing of Structural SteelDocumento5 pagineSampling Procedure For Impact Testing of Structural Steelrodrigo nuñezNessuna valutazione finora

- Becogur enDocumento2 pagineBecogur enRui Felizardo0% (1)

- Interpretation Guide: Salmonella Express SystemDocumento6 pagineInterpretation Guide: Salmonella Express SystemDavid Alexander AcevedoNessuna valutazione finora

- Ls Series Washer Extractors: Designed To LastDocumento4 pagineLs Series Washer Extractors: Designed To LastTom DavidcsNessuna valutazione finora

- 12th Grade Chemical Kinetics WorhshhetDocumento1 pagina12th Grade Chemical Kinetics WorhshhetAmen RaipurNessuna valutazione finora

- Volker Hoenig Stanford 2008 UploadDocumento28 pagineVolker Hoenig Stanford 2008 Uploadjason1989Nessuna valutazione finora

- Section A: Multiple Choice Questions (Compulsory)Documento19 pagineSection A: Multiple Choice Questions (Compulsory)ivyNessuna valutazione finora

- Bc20122lnh-1 Assay Sheet (For Bc-30 Vet Research Use Only)Documento1 paginaBc20122lnh-1 Assay Sheet (For Bc-30 Vet Research Use Only)Subodh SahuNessuna valutazione finora

- Phar 1205L Activity 2Documento6 paginePhar 1205L Activity 2Draco PhoenixNessuna valutazione finora

- Compozitia Smaltului Si DemineralizareaDocumento10 pagineCompozitia Smaltului Si DemineralizareaMadalina Elena TapeleaNessuna valutazione finora

- 19 Heat of Combustion MGDocumento5 pagine19 Heat of Combustion MGmanuelscribdgonzalesNessuna valutazione finora

- Herb-Modle Peptide in Anaerobic Titration and Reduce-05032013Documento4 pagineHerb-Modle Peptide in Anaerobic Titration and Reduce-05032013陳育孝Nessuna valutazione finora

- Heat and Mass Transfer Study in The Spray Drying of Tomato JuiceDocumento6 pagineHeat and Mass Transfer Study in The Spray Drying of Tomato Juicefatemeh afariNessuna valutazione finora

- Experiment #1 / Unit 10 Solubility Curve of Potassium NitrateDocumento2 pagineExperiment #1 / Unit 10 Solubility Curve of Potassium Nitrateapi-368121935100% (1)

- Instruction Manual: 2700 Series Benchtop MetersDocumento60 pagineInstruction Manual: 2700 Series Benchtop Meterssebastian florez sernaNessuna valutazione finora

- PG Brochure 2014Documento59 paginePG Brochure 2014ParinitaSahooNessuna valutazione finora

- Mrex - Brochure 0810 PDFDocumento12 pagineMrex - Brochure 0810 PDFGyörgy BernáthNessuna valutazione finora

- A Sustainable Bioplastic Obtained From Rice StrawDocumento12 pagineA Sustainable Bioplastic Obtained From Rice StrawNovrynda Eko SatriawanNessuna valutazione finora

- Simulation Report TemplateDocumento11 pagineSimulation Report TemplateFahmi FahreziNessuna valutazione finora

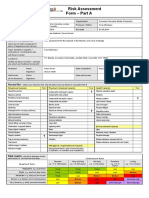

- Risk AssessmentDocumento2 pagineRisk AssessmentFaraiMbudaya0% (1)

- XXI Paper 044Documento9 pagineXXI Paper 044RICARDO3454Nessuna valutazione finora

- Practice Exam 2.4Documento6 paginePractice Exam 2.4jamalNessuna valutazione finora

- Chemistry Paper 1Documento17 pagineChemistry Paper 1printdaddyNessuna valutazione finora

- KLEN 2207 Cream CleanerDocumento3 pagineKLEN 2207 Cream CleanerSneha Nagaokar100% (1)

- Work WsDocumento5 pagineWork Wsapi-261954479Nessuna valutazione finora

- Astm C 171-07Documento2 pagineAstm C 171-07jun floresNessuna valutazione finora

- AAK Dairy Fat PDFDocumento20 pagineAAK Dairy Fat PDFa4rarhim100% (2)

- Safety Data Sheet: 3M Brand Fire Barrier CP-25WB+Documento12 pagineSafety Data Sheet: 3M Brand Fire Barrier CP-25WB+ErickoNessuna valutazione finora