Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

09 Motor Protection Relay CAT

Caricato da

Miguel RodriguezDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

09 Motor Protection Relay CAT

Caricato da

Miguel RodriguezCopyright:

Formati disponibili

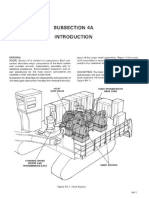

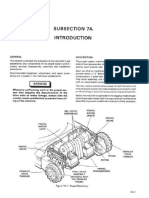

Hydraulic Mining Excavators

CAMP/ SIL Electric System CAT-6040FS AC

Motor Protection Relay

Sebastian Fillinger - 2014

Motor Protection Relay - MPR

Service Training

The MPR evaluates the actual operating conditions of the electric motor

against stored limit values.

The MPR data is displayed by the BCS

Overcurrent

Indication and trip

Voltage

Alarm and trip on undervoltage

Unbalance

Alarm and trip on slope load (wrong load)

Frequency

Alarm and trip

Overload

Indication and trip when the the motor bearings and windings overheats

Ground Fault

Indication and trip

Motor Protection

Indication and trip

MPR - Front Panel

Service Training

RUN / ERROR LED

Lit when the relay is operational

or not

Vacuum Fluorescent Display

View real-time and historic

information; view relay settings

Front Panel Push Buttons

Control the front panel display and

enter relay settings.

Trip Target LEDs

Target LEDs flash to indicate

alarm conditions; steady on to

indicate the cause of the latest

trip

Trip reset / Lamp test Button

Reset a trip or check the Lamps

Close / Trip Buttons

Not used

USB Port

Access all relay data, control

and setting functions quickly

using a PC, USB cable and

SIEMENS Digsi software

3

MPR - Front Panel Screen 1

Current Phases

Service Training

Voltage Phases

Phase 1 to Phase 2

Phase 2 to Phase 3

Phase 3 to Phase 1

Leakage Current

Frequency

ESC Button

to enter the Menu

ENTER Button

to enter the Menu

UP / DOWN Buttons

to jump into the next screen

MPR - Front Panel Screen 2

Service Training

Current Phase1

Voltage Phase1 to Ground

Active Power

Reactive Power

Apparent Power

Power Factor

ESC Button

to enter the Menu

ENTER Button

to enter the Menu

UP / DOWN Buttons

to jump into the next screen

MPR - Front Panel Screen 3

Service Training

Active Power

Voltage Phases

Reactive Power

Phase 1 to Phase 2

Phase 2 to Phase 3

Phase 3 to Phase 1

Apparent Power

Current Phases

Frequency

Power Factor

ESC Button

to enter the Menu

ENTER Button

to enter the Menu

UP / DOWN Buttons

to jump into the next screen

MPR - Front Panel Screen 4

Current Phases

Service Training

MAX. Current during lifetime

Leakage Current

Frequency

ESC Button

to enter the Menu

ENTER Button

to enter the Menu

UP / DOWN Buttons

to jump into the next screen

MPR - Front Panel Screen 5

Service Training

Current Phases

Leakage Current

Frequency

ESC Button

to enter the Menu

ENTER Button

to enter the Menu

UP / DOWN Buttons

to jump into the next screen

MPR - Front Panel Menu

Service Training

Annuniation

Check error messages etc.

Measurement

Check Min/Max data; winding

temperatures etc.

Control

Cannot be changed without

Code

Settings

Cannot be changed

ESC Button

to enter Screen 1

ENTER Button

to enter an application level

UP / DOWN Buttons

to select an application level

MPR - Front Panel Menu

Service Training

Test/ Diagnosis

Cannot entered without Code

ESC Button

to enter Screen 1

ENTER Button

to enter an application level

UP / DOWN Buttons

to select an application level

10

MPR - Front Panel Target Leds

Service Training

11

Safety Temperature Relay for Board Transformer

Board transformer with one

thermo couple (PT100) for

each winding

Safety Temperature Relay

Service Training

Motor Protection Relay

to motor protection

relay

If the winding temperature from the board transformer exceeds 150C, the Safety temperature Relay gives a signal to the

motor protection relay.

The motor protection relay is disconnecting the main switch.

(The transformer temperature you can see on the screen from the temperature relay which is located in the 400V-cabinet)

12

How to program the Safety Temperature Relay?

1.

Turn the rotary switch on sensor type and push the

UP/DOWN buttons until the number 100 for PT100 comes

up on screen.

2.

Turn the rotary switch on Sensor NO and push the

UP/DOWN buttons until the number 3 for 3 sensors comes

up on screen.

3.

Turn the rotary switch on 1 and push the UP/DOWN

buttpns until the number 150 for 150C comes up on

screen.

4.

Turn the rotary switch on 2 and push the UP/DOWN

buttons until the number 150 for 150C comes up on

screen.

5.

Turn the rotary switch on run

6.

The relay is ready when green lamp flashes.

Screen

UP/DOWN

Buttons

Rotary

Switch

Service Training

13

MPR - Tripping Configuration

Service Training

Overvoltage

Undervoltage

Overcurrent

Slope Load

OR

Motor Stop

Frequency

Overload

Winding Temperature

Rotating Field

Failure

14

MPR - Tripping Configuration

Ground Fault

Service Training

OR

Main Switch interruption

Temperatur Board

Transformer

Failure

15

Questions?

Service Training

Questions are free of charge!!!

16

Potrebbero piacerti anche

- Microelectronic Systems N2 Checkbook: The Checkbook SeriesDa EverandMicroelectronic Systems N2 Checkbook: The Checkbook SeriesNessuna valutazione finora

- Canon EOS R6: Pocket Guide: Buttons, Dials, Settings, Modes, and Shooting TipsDa EverandCanon EOS R6: Pocket Guide: Buttons, Dials, Settings, Modes, and Shooting TipsNessuna valutazione finora

- 09 - Motor Protection Relay - CATDocumento16 pagine09 - Motor Protection Relay - CATMiguel Angel RodriguezNessuna valutazione finora

- PW & 1002T Control Systems Intermediate PDFDocumento62 paginePW & 1002T Control Systems Intermediate PDFbagus100% (4)

- 12.0 - CAT-6040 - E-Drive - Electric Training MPR RH170-B Eng (Print in A4 Colour)Documento18 pagine12.0 - CAT-6040 - E-Drive - Electric Training MPR RH170-B Eng (Print in A4 Colour)WilliamNessuna valutazione finora

- Controlador Asco 4000 7000Documento32 pagineControlador Asco 4000 7000larousse14Nessuna valutazione finora

- 09 - Motor Protection Relay - CATDocumento16 pagine09 - Motor Protection Relay - CATMiguel Angel RodriguezNessuna valutazione finora

- 09 Motor Protection Relay CATDocumento16 pagine09 Motor Protection Relay CATMiguel Angel RodriguezNessuna valutazione finora

- MU250 3-Phase Voltage Relay User's Guide: 7. Technical Data Brief OverviewDocumento2 pagineMU250 3-Phase Voltage Relay User's Guide: 7. Technical Data Brief OverviewVan Huynh NguyenNessuna valutazione finora

- Diagnostic Trouble CodesDocumento6 pagineDiagnostic Trouble CodesTaras KNessuna valutazione finora

- Generator ControllerDocumento21 pagineGenerator ControllerBrianHazeNessuna valutazione finora

- ICM 450 InstallationDocumento2 pagineICM 450 InstallationRay RavelNessuna valutazione finora

- Guida - Mitsubishi ENDocumento15 pagineGuida - Mitsubishi ENHan MoreyraNessuna valutazione finora

- Service Thermostat MCH2Documento4 pagineService Thermostat MCH2ИлияИвановNessuna valutazione finora

- Benshaw Motor StarterDocumento228 pagineBenshaw Motor Starterhennry_8307Nessuna valutazione finora

- Dkg-207 Amf and Remote Start Unit Installation and Operating InstructionsDocumento4 pagineDkg-207 Amf and Remote Start Unit Installation and Operating InstructionsBambang Ardiansyah SetiadyNessuna valutazione finora

- Eco490n - enDocumento20 pagineEco490n - enVictor VargasNessuna valutazione finora

- XL CodesDocumento3 pagineXL CodesAntonioPalloneNessuna valutazione finora

- Aircon TroubleshootingDocumento11 pagineAircon TroubleshootingpropessorsergioNessuna valutazione finora

- Manual Calibrado Monitor Excav. 320 330 CATDocumento8 pagineManual Calibrado Monitor Excav. 320 330 CAThyromec95% (59)

- DataKom 116 - USERDocumento4 pagineDataKom 116 - USERKhaleel KhanNessuna valutazione finora

- Dse5510 Installation InstDocumento2 pagineDse5510 Installation Instricardo_dionisi2700Nessuna valutazione finora

- CMD 2 ManualDocumento30 pagineCMD 2 ManualAbdul Manan60% (5)

- AlptecDocumento15 pagineAlpteczakiNessuna valutazione finora

- AirMaster P1ÄÜÆ® Ñ (¿ ®) PDFDocumento10 pagineAirMaster P1ÄÜÆ® Ñ (¿ ®) PDFkaduz800% (1)

- TtaDocumento2 pagineTtaJorge Andres UrraNessuna valutazione finora

- Bla Power Pvt. LTD: Woodward 505 Governor Valve / Actuator Calibration &testDocumento23 pagineBla Power Pvt. LTD: Woodward 505 Governor Valve / Actuator Calibration &testWilliam Will Controle WoodwardNessuna valutazione finora

- Regulateur ALPTECDocumento15 pagineRegulateur ALPTECCris_eu09Nessuna valutazione finora

- Robojax XY-SEP4 DatasheetDocumento14 pagineRobojax XY-SEP4 DatasheetFelixJgrNessuna valutazione finora

- PowerWizard Training PresentationDocumento27 paginePowerWizard Training PresentationJorge100% (17)

- 820B enDocumento12 pagine820B enSaif Ali100% (1)

- 116 UserDocumento4 pagine116 UserMohamed Yahya100% (1)

- Lago Basic 0101 1001 GBDocumento28 pagineLago Basic 0101 1001 GBavouzikisNessuna valutazione finora

- Mh6n Mh12n ManualDocumento4 pagineMh6n Mh12n ManualMelissa Porter100% (3)

- Alarms Programmed Through Code ForDocumento2 pagineAlarms Programmed Through Code ForAbdul Manan75% (4)

- Inverter Manual Operation in Silver Rev - 1Documento5 pagineInverter Manual Operation in Silver Rev - 1firasalthiyabyNessuna valutazione finora

- L 120 E 302. Instrument Control Unit I-ECU, Error SymptomDocumento56 pagineL 120 E 302. Instrument Control Unit I-ECU, Error SymptomAstrit StratiNessuna valutazione finora

- EMS98R3 User GuideDocumento22 pagineEMS98R3 User GuideAnas BasarahNessuna valutazione finora

- ELK38-240-C-R-2R DataSheetDocumento14 pagineELK38-240-C-R-2R DataSheetAnna PopaNessuna valutazione finora

- Microprocessor-Based Digital Electronic Controller: Operating Instructions Tecnologic S.P.ADocumento14 pagineMicroprocessor-Based Digital Electronic Controller: Operating Instructions Tecnologic S.P.Apgomberg1982Nessuna valutazione finora

- AlptecDocumento15 pagineAlptecdabic_zoranNessuna valutazione finora

- Electronic Control ModuleDocumento5 pagineElectronic Control ModuleRamiro Toledo RamírezNessuna valutazione finora

- AT2000 PCS QuickDocumento18 pagineAT2000 PCS QuickJuan Carlos ZavalaNessuna valutazione finora

- Carbolite MC18-GB v1'04 - 3216Documento20 pagineCarbolite MC18-GB v1'04 - 3216thexsamNessuna valutazione finora

- User'S Manual: Larsen & Toubro LimitedDocumento8 pagineUser'S Manual: Larsen & Toubro LimitedRa HulNessuna valutazione finora

- UDC3300 HoneywellDocumento92 pagineUDC3300 HoneywellCarlos VivasNessuna valutazione finora

- Technical Data Sheet 3RW33 Soft Starter For Carrier NGC Iv: DangerDocumento9 pagineTechnical Data Sheet 3RW33 Soft Starter For Carrier NGC Iv: DangervickersNessuna valutazione finora

- IGC700 Series: Ngine Overning YstemsDocumento6 pagineIGC700 Series: Ngine Overning YstemsRamon Thales DomeniconiNessuna valutazione finora

- Motor Testing Procedure On Test Bench (By Sohail)Documento1 paginaMotor Testing Procedure On Test Bench (By Sohail)Imran HaqNessuna valutazione finora

- RG-T en A2936 R2Documento4 pagineRG-T en A2936 R2Noureddine LingburgNessuna valutazione finora

- Manual Informacion Tecnica-Operacion y Servicio Te 804Documento38 pagineManual Informacion Tecnica-Operacion y Servicio Te 804Miguel Angel Pavon CarbonellNessuna valutazione finora

- Benshaw Softstart MX2 Quickstart Reference Sheet PDFDocumento2 pagineBenshaw Softstart MX2 Quickstart Reference Sheet PDFCesar RodriguezNessuna valutazione finora

- TE804Documento38 pagineTE804byronsmart100% (2)

- EE-FT-01-Filtre Timer Manual-Tran-EngDocumento4 pagineEE-FT-01-Filtre Timer Manual-Tran-EngbobyalfredoNessuna valutazione finora

- User Manual ELK38Documento14 pagineUser Manual ELK38Krl Krl GnzalzNessuna valutazione finora

- Fujifilm X-T5: Pocket Guide: Buttons, Dials, Settings, Modes, and Shooting TipsDa EverandFujifilm X-T5: Pocket Guide: Buttons, Dials, Settings, Modes, and Shooting TipsNessuna valutazione finora

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Da EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Nessuna valutazione finora

- OM System "Olympus" OM-1: Pocket Guide: Buttons, Dials, Settings, Modes, and Shooting TipsDa EverandOM System "Olympus" OM-1: Pocket Guide: Buttons, Dials, Settings, Modes, and Shooting TipsNessuna valutazione finora

- Introduction to the simulation of power plants for EBSILON®Professional Version 15Da EverandIntroduction to the simulation of power plants for EBSILON®Professional Version 15Nessuna valutazione finora

- Canon EOS R6 II: Pocket Guide: Buttons, Dials, Settings, Modes, and Shooting TipsDa EverandCanon EOS R6 II: Pocket Guide: Buttons, Dials, Settings, Modes, and Shooting TipsNessuna valutazione finora

- Esquema Hidráulico AtualizadoDocumento3 pagineEsquema Hidráulico AtualizadoMiguel RodriguezNessuna valutazione finora

- Manufacturing Operating Procedure: Appendix "B" Deviation Requests (MRB)Documento3 pagineManufacturing Operating Procedure: Appendix "B" Deviation Requests (MRB)Miguel RodriguezNessuna valutazione finora

- 014 CAT-6060 AC 60Hz E-Drive CAMP + SIL + BCS4 FS Legend H-Schematic Canada No New AvailableDocumento13 pagine014 CAT-6060 AC 60Hz E-Drive CAMP + SIL + BCS4 FS Legend H-Schematic Canada No New AvailableMiguel RodriguezNessuna valutazione finora

- 3 Zone Lincoln PDFDocumento1 pagina3 Zone Lincoln PDFMiguel RodriguezNessuna valutazione finora

- 13 - Drive Controller - Operation ManualDocumento14 pagine13 - Drive Controller - Operation ManualMiguel RodriguezNessuna valutazione finora

- Manufacturing Operating Procedure: Recommended Filler Material and Preheat/Interpass TemperaturesDocumento5 pagineManufacturing Operating Procedure: Recommended Filler Material and Preheat/Interpass TemperaturesMiguel Rodriguez100% (1)

- NDT-PQ PDFDocumento7 pagineNDT-PQ PDFMiguel RodriguezNessuna valutazione finora

- Diagrama de Bloque de 3 Zonas PDFDocumento1 paginaDiagrama de Bloque de 3 Zonas PDFMiguel RodriguezNessuna valutazione finora

- Diagrama de Bloque de 4 Zonas PDFDocumento1 paginaDiagrama de Bloque de 4 Zonas PDFMiguel RodriguezNessuna valutazione finora

- Nondestructive Test Procedure: Acceptance Criteria For Nondestructive Testing of P&H ProductDocumento3 pagineNondestructive Test Procedure: Acceptance Criteria For Nondestructive Testing of P&H ProductMiguel RodriguezNessuna valutazione finora

- Section 9 Maintenance WeldingDocumento4 pagineSection 9 Maintenance WeldingMiguel RodriguezNessuna valutazione finora

- Bypass Kit Hoist FilterDocumento2 pagineBypass Kit Hoist FilterMiguel RodriguezNessuna valutazione finora

- Bronze Bushing Shrinkage On Diameter PDFDocumento1 paginaBronze Bushing Shrinkage On Diameter PDFMiguel RodriguezNessuna valutazione finora

- Extension - Cable Grease SystemDocumento3 pagineExtension - Cable Grease SystemMiguel RodriguezNessuna valutazione finora

- Tarjetas 2800XPBDocumento3 pagineTarjetas 2800XPBMiguel RodriguezNessuna valutazione finora

- 004 - Cat-6040AC - CAMP-SIL-BCS4 - E-Motor and Powertrain PDFDocumento12 pagine004 - Cat-6040AC - CAMP-SIL-BCS4 - E-Motor and Powertrain PDFMiguel RodriguezNessuna valutazione finora

- Table of Contents:: User InstructionsDocumento2 pagineTable of Contents:: User InstructionsMiguel RodriguezNessuna valutazione finora

- Section 10 LubricationDocumento16 pagineSection 10 LubricationMiguel RodriguezNessuna valutazione finora

- Section 4 Hoist SystemDocumento32 pagineSection 4 Hoist SystemMiguel RodriguezNessuna valutazione finora

- Section 7 Propel SystemDocumento50 pagineSection 7 Propel SystemMiguel RodriguezNessuna valutazione finora

- Section 3 Swing SystemDocumento35 pagineSection 3 Swing SystemMiguel RodriguezNessuna valutazione finora

- Sis Web User Guide v3-5-1Documento60 pagineSis Web User Guide v3-5-1Miguel RodriguezNessuna valutazione finora

- NPR & Kits PDFDocumento11 pagineNPR & Kits PDFMiguel RodriguezNessuna valutazione finora

- Service Technician Workbench: What's New in 2004BDocumento53 pagineService Technician Workbench: What's New in 2004BMiguel RodriguezNessuna valutazione finora

- IC EnginesDocumento2 pagineIC EnginesVinay Korekar0% (1)

- Regulations and Guidelines: District Heating of BuildingsDocumento84 pagineRegulations and Guidelines: District Heating of BuildingsKhoi LeNessuna valutazione finora

- The Philosophy of Mass in Modern PhysicsDocumento8 pagineThe Philosophy of Mass in Modern Physicsinoydevil2100% (1)

- The Crises of The European Imagination: Denise Ferreira Da SilvaDocumento7 pagineThe Crises of The European Imagination: Denise Ferreira Da SilvaSamonaMartinsNessuna valutazione finora

- Major ProjectDocumento8 pagineMajor ProjectDevansh SinghNessuna valutazione finora

- Activity 12Documento8 pagineActivity 12Shawn LeeNessuna valutazione finora

- Calorific Value Course Using Boys CalorimeterDocumento7 pagineCalorific Value Course Using Boys CalorimeterJOHANAN OROKNessuna valutazione finora

- Ee9al Ee5d Del Rosario Ramosa. File 3Documento3 pagineEe9al Ee5d Del Rosario Ramosa. File 3jenixson tamondongNessuna valutazione finora

- Revisi Presentasi KPK HAZOP - Ida (102) - JosephineDocumento8 pagineRevisi Presentasi KPK HAZOP - Ida (102) - JosephineJosephine TdnNessuna valutazione finora

- Renewable Energy ResourcesDocumento83 pagineRenewable Energy ResourcesVivek Sharma100% (5)

- What Are Circuit Breakers Different Types of Circuit BreakersDocumento18 pagineWhat Are Circuit Breakers Different Types of Circuit BreakersnellaiNessuna valutazione finora

- System Loss Process and ResultsDocumento42 pagineSystem Loss Process and ResultsAlvin Garcia PalancaNessuna valutazione finora

- M Pact MPro Air CircuitBreakersDocumento6 pagineM Pact MPro Air CircuitBreakersdejanoski_aNessuna valutazione finora

- Gas Engine Technical Data: Load 100% 75% 50% Rating and EfficiencyDocumento3 pagineGas Engine Technical Data: Load 100% 75% 50% Rating and EfficiencyEzequiel Juarez BenítezNessuna valutazione finora

- CHEM2122 General Chemistry Week 11 - 19 by Querubin Cabalida GR12Documento14 pagineCHEM2122 General Chemistry Week 11 - 19 by Querubin Cabalida GR12Cesar TuñacaoNessuna valutazione finora

- Coal Fired Power PlantsDocumento17 pagineCoal Fired Power PlantsSahil Sankalp PatelNessuna valutazione finora

- Resume 4may2022Documento7 pagineResume 4may2022raghvendraprasadNessuna valutazione finora

- ESS Design and Installation Manual-EnDocumento32 pagineESS Design and Installation Manual-EnAnthony ObiNessuna valutazione finora

- G4-276 (7-18b) 48RCLB (KG6208) SpecDocumento4 pagineG4-276 (7-18b) 48RCLB (KG6208) SpecService Brags & Hayes, Inc.Nessuna valutazione finora

- F4 Final Exam 2122Documento19 pagineF4 Final Exam 21225B04 CHOW HOI LAMNessuna valutazione finora

- Pmi Rda-Rdat Series Batterycharger Userbook - enDocumento44 paginePmi Rda-Rdat Series Batterycharger Userbook - enYudhiSaputraIsman100% (1)

- 35 Quantum ChemistryDocumento9 pagine35 Quantum ChemistryJagannath PandaNessuna valutazione finora

- 4 s3 Sabir Shah BHC PresentationDocumento19 pagine4 s3 Sabir Shah BHC PresentationsaadNessuna valutazione finora

- Smart Grid Policy Framework and Roadmap For The Philippines: Redentor E. DelolaDocumento47 pagineSmart Grid Policy Framework and Roadmap For The Philippines: Redentor E. DelolaJonathan SantiagoNessuna valutazione finora

- Welcome To::: Class 12Documento14 pagineWelcome To::: Class 12Amarnath K VNessuna valutazione finora

- Cable SelectionDocumento1 paginaCable SelectionMAYUR GENSETNessuna valutazione finora

- Presentation On Industrial Training at NTPC, Anta Gas Power PlantDocumento18 paginePresentation On Industrial Training at NTPC, Anta Gas Power PlantsunilkumarmeenaNessuna valutazione finora

- Battery-Assisted Low-Cost H2 Production From Solar Energy - Cost AnalysisDocumento15 pagineBattery-Assisted Low-Cost H2 Production From Solar Energy - Cost Analysisfrancisco NeiraNessuna valutazione finora

- WECC Second Generation Wind Turbine Models 012314Documento36 pagineWECC Second Generation Wind Turbine Models 012314SaeedAhmedKhanNessuna valutazione finora

- Enersys DataSafe HX 12V Telecom Battery Range SummaryDocumento2 pagineEnersys DataSafe HX 12V Telecom Battery Range Summaryingchester24Nessuna valutazione finora