Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Fem For Inclined Pressure Vessel

Caricato da

Prayas SubediTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Fem For Inclined Pressure Vessel

Caricato da

Prayas SubediCopyright:

Formati disponibili

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 1 Issue 3, May - 2012

Structural Analysis of Inclined Pressure vessel Using FEM

Imran M.Jamadara, Prof.R.M.Tayade b , Mr.Vinay Patilc

a

PG Student Mechanical Engineering Depart ment, Veermata Jijabai Technological Institute(VJTI),

Matunga,Mumbai, Maharashtra, Mumbai,India

b

Prof.R.M.Tayade, Mechanical Engineering Depart ment, Veermata Jijabai Technological Institute(VJTI),

Matunga, Mumbai ,Maharashtra,India

c

Mr.Vinay Patil, FEA Consultant, VAFTSY CAE, Hadapsar,

Pune, Maharashtra,India

Abstract: Inclined pressure vessel (IPV) study

using finite element analysis using ANSYS to find

out stresses in the vessel for its structural stability

is done in this paper. Inclined pressure vessel is

used for production of nitrous oxide by ammoniu m

nitrate pyrolysis reaction by passing the steam at

around 2000 C and 1.37895 Mpa over the

ammon iu m nit rate contained in the cylindrical

vessel. Here design challenge is inclined nature of

vessel as, ASME code enables design of Horizontal

or a Vertical vessel but there is no provision for an

Inclined Vessel in it.

Keywords-IPV, stress anal ysis, structural

stability.

1. Introducti on

Vessels, tanks, and pipelines that carry, store, or

receive flu ids are called pressure vessels. A

pressure vessel is defined as a container with a

pressure differential between inside and outside.

The inside pressure is usually higher than the

outside, except for some isolated situations. The

flu id inside the vessel may undergo a change in

state as in the case of steam boilers, or may

combine with other reagents as in the case of a

chemical reactor. Pressure vessels often have a

combination of high pressures together with high

temperatures, and in some cases flammable fluids

or highly radio- act ive materials. Because of such

hazards it is imperative that the design be such that

no leakage can occur.

Designing, thus, involves estimation of stresses and

deformations of the components at different critical

points of a component for the specified loads and

boundary conditions, so as to satisfy operational

constraints .Design is associated with the

calculation of dimensions of a component to

withstand the applied loads and perform the desired

function. Analysis is associated with the estimat ion

of displacements or stresses in a component of

assumed dimensions so that adequacy of assumed

dimensions is validated .

2. Material selection

We are doing analysis of inclined pressure vessel

for which ASM E codes are not applicable. To

overcome this firstly we have done analysis of

horizontal vessel and its results are utilized to do

further inclined vessel analysis. This section

discusses the primary factors that influence

material selection for pressure vessels and the

maximu m allo wable material stresses specified by

the ASME Code [9]. The mechanical design of a

pressure vessel can proceed only after the materials

have been specified. The ASME Code does not

state what materials must be used in each

application. It specifies what materials may be used

for ASM E Code vessels, plus rules and limitations

on their use. But, it is up to the end user to specify

the appropriate materials fo r each applicat ion

considering various material selection factors in

conjunction with ASME Code requirements.

Accordingly, structural steel is selected as a

material for vessel the properties of which are

tabulated .

3. Modeling

The detailed 3D modeling of pressure vessel

was done using CATIA V5R17.

4. Meshing

The accuracy of the FE model is highly dependent

on the mesh employed, especially if h igher order

(cubic, quadratic etc.) elements are not used. In

general, a finer mesh will produce more accurate

results than a coarser mesh. At some point, one

reaches a point of diminishing returns, where the

increased mesh density fails to produce a

significant change in the results. At this point the

mesh is said to be converged. This process of

refining the mesh and evaluating the results is

normally referred to as a mesh convergence

study or analysis. Although many FE codes contain

error estimates of one sort or another, mesh

convergence remains the most reliab le means of

judging model accuracy. Coarse meshes almost

always under-report the stresses in a model. It is

not uncommon to have maximu m reported stresses

on the order of less than 50% of the converged

www.ijert.org

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 1 Issue 3, May - 2012

stresses on a coarsely meshed model. Thus, without

consideration of mesh convergence, gross errors in

stress estimates are quite possible. If higher order

elements are used, good results can be obtained

with fewer elements. Either mesh convergence

analysis or a reliable error estimate is absolutely

necessary to quantify the analysis results.

Typically, an increase of less than 5% in the stress

levels after a doubling of mesh density or an error

estimate of less than 0.05 will ensure that the

indicated stresses are within 5-10% of the

converged values [2]. So me FE codes employ an

adaptive process to automatically refine the mesh

and/or increase the order of the elements to reach

the desired degree of accuracy. When available,

these processes can save a lot of manual effort.

They do not, however, completely relieve the

engineer of the need to check the results.

5. Boundary conditi ons

One of the most significant sources of errors in FE

modeling is the inaccurate (or inappropriate)

modeling of the loads and restraints on a model.

For example, fully fixing (restrain ing) all of the

nodes on the end of a pressure vessel do not

represent the same condition as does a normal

head. With any normal head, the radial stiffness is

not infinite, thus radial expansion under pressure

loading will occur. This cannot be the case when

the node is fixed. The symmetrical boundary

condition always restrains translations normal to

the plane of symmetry and the rotations in the

plane of symmetry. In this case, we would have

restrained translation in the X direction and the

rotations about the Y and Z axes. Fo rces and

mo ments may be applied to a model in a number of

different ways. The particular method chosen is

often a function of the pre-processor used to

generate the model. So me pre-processors will

automatically distribute a force or mo ment along a

line or surface, such as the end of the nozzle. Even

though we are using a modern computer-based

tool, the sum of the forces and moments about each

axis must remain equal to zero when the body is at

rest.

6. Stress Anal ysis

Stress analysis is the determination of the

relationship between external and internal forces

applied to a vessel and the corresponding stress.

The emphasis is not how to do stress analysis in

particular, but rather how to analyze vessels and

their component parts in an effort to arrive at an

economical and safe design-the difference being

that we analyze stresses where necessary to

determine thickness of material and sizes of

members. It is not necessary to find every stress but

rather to know the governing stresses and how they

relate to the vessel or its respective parts,

attachments, and supports [4].

The starting place for stress analysis is to determine

all design conditions for a given problem and then

determine all the related external forces. We must

then relate these external forces to the vessel parts

which must resist them to find the corresponding

stresses. By isolating the causes (loadings), the

effects (stress) can be more accurately determined.

The designer must also be keenly aware of the

types of loads and how they relate to the vessel as a

whole. Are the effects long or short term? Do they

apply to a localized portion of the vessel or are they

uniform throughout? How these stresses are

interpreted and combined, what significance they

have to the overall safety of the vessel, and what

allo wable stresses are applied will be determined

by three things:

1. The strength failure theory utilized.

2. The types and categories of loadings.

3. The hazard the stress represents to the vessel

The basic intent of design by analysis is to

determine the stress conditions in a pressure vessel

under load for each load condition for the vessels

entire operational life. In order to meet the intent

and specifications of Section VIII, Div ision 2, the

designer must carry out a sufficiently detailed

stress analysis of the vessel to show compliance

with the stress limitations imposed by the Code for

the material fro m which the vessel is to be

fabricated. The designer may specify any manner

by which to determine the stresses in the vessel

under load, so long as use of the methodologies

emp loyed.

This investigation primarily deals with the

probable causes of in-service damage of IPV with

approximate estimat ion of stresses . The design

temperature and pressure of vessel 1490 C and

1.3789Mpa, respectively. There were four nu mbers

of openings, Viz.entry and exit of steam, Exit of

Nitrous oxide and drain. The vessel thickness was

around 9.65mm. Stress analysis was carried out by

fin ite element method using ANSYS 13.0 code.

Structural Elements Used for the Analysis: The

higher order hexahedron element is used for

meshing [8].

Boundary Constraints (figure 4): The whole vessel

is supported on two saddle supports. The upper

saddle was fixed while to the lower saddle

cylindrical support was provided. Vessel was

analyzed using ANSYS code on the basis of

strength for internal pressure 1.38 Mpa, plus Self

Weight considering portions of the drum of

1275.55 mm length with inside diameter of dru m

304.8 mm, thickness of the shell 9.65mm.

Considering the symmetry of the unit, one half of

the unit was analyzed for stress calculations. The

fin ite element model of the co mponent under

investigation is shown in Fig. 1

www.ijert.org

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 1 Issue 3, May - 2012

Fig.1 3DModel

Fig.2 Meshing

Fig.3 Axis-symmetric model

Fig.4B oundry Conditions

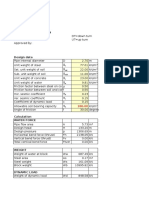

Material

Modulus of Elasticity in Mpa

Poisson's Ratio

Density Kg/m 3

Tensile Yield Strength Mpa

Tensile Ultimate Steel Mpa

Allowable Hoop Stress Mpa

Allowable Equivalent Stress By PV

Elite Software Code,Mpa

Structural steel

2e5

0.3

7850

250

460

23.13

117

Table.1 Materi al Properties

www.ijert.org

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 1 Issue 3, May - 2012

Fig.5 Equi valent Von-Mises Stress Plot

Fig.6 Total Deformati on Plot

Angle

Nodes

Elements

Stress(Equi valent

Von-Mises)Mpa

Total

Deformation(mm)

0

4

8

12

16

20

24

28

32

512863

514642

512896

521004

512635

532145

541236

532147

512347

214566

216241

215012

228791

213650

246531

250169

246545

203651

116.07

116.10

116.6

116.96

117.05

117.16

117.32

117.50

117.88

0.17523

0.17520

0.17516

0.17514

0.17512

0.17501

0.17499

0.17497

0.17494

Linearised

Equi valent

Membrane

stress

across

vessel

thickness

32.741

32.615

32.577

32.845

32.954

33.126

33.469

33.611

33.805

Table.2 Stress and deformati on val ues at various angles

Graphs:

Fig.7 Inclination V/s Equi valent Stress

Fig.8 Inclination V/s Linearised Stress

www.ijert.org

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 1 Issue 3, May - 2012

7.Discussion and Conclusions

Fro m above analysis it was observed that

maximu m equivalent stress observed in the vessel

around the cylindrical support

was about

117.88Mpa for vessel angle 320 , it is exceeding

allo wable limits but it is less than yield strength

and ultimate tensile strength .so failure will not be

observed in this condition but to provide sufficient

factor of safety and reduce stress below allo wable

limits some modification in this area are necessary.

The deformation was observed to be maximu m

around nozzle vessel intersection 0.17494mm for

320 inclinations. The deformation was observed to

be minimu m around fixed support.

Partially

superimposed weld heat affected zones of nozzle

weld caused localized adverse non liner condition

and high load that facilitated initiat ion and

propagation of cracks. From fig.8 and Fig..9 it is

concluded that the equivalent Von-Mises Stress

and linearised membrane stress along vessel

thickness are increasing with inclination of vessel.

References

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

www.ijert.org

CHEN Ru-xun, Structure analysis for filament -wound

cylinder pressure vessel. Journal of Solid Rocket

Technology. Vol.27 No.2, 2004, 105-107(3).

Jaroslav Mackerle Finite Elements in the analysis of

pressure vessel and piping.,1996 Elsevier

publicationPp279-339

Heckman, David: Finite element analysis of pressure

vessels, MBARI 1998 Pp 1-7

Dong-xia Liu et.al /Nonlinear Finite Element Analysis of

Mechanical Characteristics on CFRP Composite Pressure

Vessels IOP Conf. Series: Materials Science and

Engineering 10 (2010) 012098

P. V. Marcal, Elastic-plastic analysis of pressure vessel

components Paper presented at 1st Pressure Vessel and

Piping Conference Use of the Computer in Pressure Vessel

Analysis ASME Computer Seminar Dallas, Texas,

September 20, 1968

J.L. Otegui et.al/Common root causes of recent failures of

flanges in pressure vessels subjected to dynamic loads

Elsevier -Engineering Failure Analysis 16 (2009) Pp1825

1836

Young, W. (1989). Roarks Formulas for Stress & Strain.

McGraw-Hill, New York, New York.

ANSYS (2004), Structural Analysis Guide, ANSYS

Inc., Canonsburg USA.

ASME Boiler and Pressure Vessel Code. Am Soc Mech

Eng; 1999

Potrebbero piacerti anche

- Analysis of Dished Head and Skirt Joint of Pressure Vessel Using FEA MethodDocumento4 pagineAnalysis of Dished Head and Skirt Joint of Pressure Vessel Using FEA MethodIJSTENessuna valutazione finora

- Determination of Modification Factor R For Seismic Design of Pressure Vessels Using ASME and EurocodesDocumento11 pagineDetermination of Modification Factor R For Seismic Design of Pressure Vessels Using ASME and Eurocodesoscargon19Nessuna valutazione finora

- Design, Analysis and Optimization of Non Standard Weld Neck Body Flange in Small Pressure VesselDocumento7 pagineDesign, Analysis and Optimization of Non Standard Weld Neck Body Flange in Small Pressure VesselGRD JournalsNessuna valutazione finora

- Stress Analysis of Thin Walled Pressure Vessel by Ibrahim Et. Al.Documento10 pagineStress Analysis of Thin Walled Pressure Vessel by Ibrahim Et. Al.Ivan Ernest TomagosNessuna valutazione finora

- Fatigue Assessment IJETT-V13P205Documento4 pagineFatigue Assessment IJETT-V13P205MehdiNessuna valutazione finora

- Annex B2-Recommendations For Linearization of Stress Results ForDocumento20 pagineAnnex B2-Recommendations For Linearization of Stress Results ForMarlon VillarrealNessuna valutazione finora

- Ccopps WebinarDocumento36 pagineCcopps WebinarAkenathon71Nessuna valutazione finora

- Applied Thermal Engineering: Farhad Nemati Taher, Sirous Zeyninejad Movassag, Kazem Razmi, Reza Tasouji AzarDocumento7 pagineApplied Thermal Engineering: Farhad Nemati Taher, Sirous Zeyninejad Movassag, Kazem Razmi, Reza Tasouji AzarememNessuna valutazione finora

- Fatigue Life For ASME VII-DIV2Documento23 pagineFatigue Life For ASME VII-DIV2Muhammad Abd El KawyNessuna valutazione finora

- Safety ValvesDocumento62 pagineSafety Valveslifemillion2847Nessuna valutazione finora

- Design by Rule-Design by Analysis PDFDocumento18 pagineDesign by Rule-Design by Analysis PDFChandra ClarkNessuna valutazione finora

- A Comparison Study of Pressure Vessel Design Using Different Standards PDFDocumento319 pagineA Comparison Study of Pressure Vessel Design Using Different Standards PDFJM100% (1)

- Jun 97Documento349 pagineJun 97homer hullezaNessuna valutazione finora

- Maximum Allowable Stress: Mechanical Design of Pressure VesselsDocumento17 pagineMaximum Allowable Stress: Mechanical Design of Pressure Vesselsfauzi100% (1)

- 16 Preiss Study en 13445 Asme ViiiDocumento26 pagine16 Preiss Study en 13445 Asme ViiiDubaiHMARNessuna valutazione finora

- Analytical Considerations The Code Qualification Piping SystemsDocumento17 pagineAnalytical Considerations The Code Qualification Piping SystemsMahendra RathoreNessuna valutazione finora

- Stress Corrosion Cracking of A723 Steel Pressure Vessel Two Case StudiesDocumento38 pagineStress Corrosion Cracking of A723 Steel Pressure Vessel Two Case Studieslitao2314Nessuna valutazione finora

- Questions Flange Breaking ContainmentDocumento2 pagineQuestions Flange Breaking ContainmentMicky PlumbNessuna valutazione finora

- Stress Analysis of Different Reinforcement Pad For Nozzle Opening in Pressure VesselDocumento7 pagineStress Analysis of Different Reinforcement Pad For Nozzle Opening in Pressure VesselIJSTENessuna valutazione finora

- ASME e EN STDDocumento23 pagineASME e EN STDmatteo2009Nessuna valutazione finora

- WRC Load AnalysisDocumento5 pagineWRC Load Analysisyogacruise100% (1)

- Effect of Poorly Shaped ElementsDocumento5 pagineEffect of Poorly Shaped ElementsShamik ChowdhuryNessuna valutazione finora

- TSG R0004 2009Documento76 pagineTSG R0004 2009bikobelloNessuna valutazione finora

- Fea NozzelsDocumento2 pagineFea NozzelsRomner CordovaNessuna valutazione finora

- ASMEDocumento25 pagineASMEAnonymous bENWheBNessuna valutazione finora

- Fatigue Design of Process EquipmentDocumento94 pagineFatigue Design of Process EquipmentGuillermo CorderoNessuna valutazione finora

- 3D Stress CriteriaDocumento5 pagine3D Stress CriteriaFernando DiezNessuna valutazione finora

- Pressure Vessel Selection, Sizing and Troubleshooting Kolmetz Handbook of Process Equipment DesignDocumento26 paginePressure Vessel Selection, Sizing and Troubleshooting Kolmetz Handbook of Process Equipment Designazmil hadyNessuna valutazione finora

- Class 1 Vs Class 2 Pressure Vessels - Hedderman ConsultingDocumento3 pagineClass 1 Vs Class 2 Pressure Vessels - Hedderman ConsultinglorenzoNessuna valutazione finora

- Improve Evaluation of Brittle-Fracture Resistance For VesselsDocumento6 pagineImprove Evaluation of Brittle-Fracture Resistance For VesselsHieuNessuna valutazione finora

- Elevated Temperature Fatigue of Pressure Vessel SteelsDocumento6 pagineElevated Temperature Fatigue of Pressure Vessel SteelsJohnNessuna valutazione finora

- Pressure Points: Ask The EngineerDocumento5 paginePressure Points: Ask The EngineerMario MolinaNessuna valutazione finora

- Credit For Internal Cladding-RevDocumento3 pagineCredit For Internal Cladding-RevAhmedNessuna valutazione finora

- Weld Misalignment Influence On Structural Integrity of Cylindrical Pressure VesselDocumento7 pagineWeld Misalignment Influence On Structural Integrity of Cylindrical Pressure VesselyuriNessuna valutazione finora

- Optimization of Tubesheet Thickness of Shell and Tube Heat ExchangerDocumento6 pagineOptimization of Tubesheet Thickness of Shell and Tube Heat Exchangersagar1503Nessuna valutazione finora

- Improved Analysis of External Loads On Flanged JointsDocumento1 paginaImproved Analysis of External Loads On Flanged JointsTiHoRNessuna valutazione finora

- Pvp2010-25092-Lower Bound Buckling Load of A Floating Roof PontoonDocumento9 paginePvp2010-25092-Lower Bound Buckling Load of A Floating Roof PontoonAnonymous wWOWz9UnWNessuna valutazione finora

- Comparison of Design and Analysis of Tube Sheet Thickness by Using Uhx Code-2/comparison of Design and Analysis of Tube Sheet Thickness by Using Uhx Code-2 PDFDocumento13 pagineComparison of Design and Analysis of Tube Sheet Thickness by Using Uhx Code-2/comparison of Design and Analysis of Tube Sheet Thickness by Using Uhx Code-2 PDFruponline1Nessuna valutazione finora

- Linearizing StressDocumento6 pagineLinearizing Stressbo cambellNessuna valutazione finora

- What Is Design Interpretation?Documento17 pagineWhat Is Design Interpretation?Qaisir MehmoodNessuna valutazione finora

- Design and Finite Element Assessment of Mounded Bullet PDFDocumento14 pagineDesign and Finite Element Assessment of Mounded Bullet PDFc0g100% (1)

- Brittle Fracture and Reporting OverviewDocumento38 pagineBrittle Fracture and Reporting OverviewRaja HoneNessuna valutazione finora

- 11110d-2 Obround Nozzle Revised DesignDocumento1 pagina11110d-2 Obround Nozzle Revised DesignSivateja NallamothuNessuna valutazione finora

- Paulin Research Group - FE107 Experimental ValidationDocumento5 paginePaulin Research Group - FE107 Experimental ValidationNikunj KNessuna valutazione finora

- Strength of Materials - Stresses in Thin Walled Cylinder - Hani Aziz AmeenDocumento13 pagineStrength of Materials - Stresses in Thin Walled Cylinder - Hani Aziz AmeenHani Aziz Ameen100% (1)

- Comparative Study EN 13445 / ASME Section VIII Div. 1 & 2Documento48 pagineComparative Study EN 13445 / ASME Section VIII Div. 1 & 2Anand PatelNessuna valutazione finora

- Me 42 PDFDocumento5 pagineMe 42 PDFMohamed Rafeek0% (1)

- Jacketed PipingDocumento4 pagineJacketed Pipingbinukumar100Nessuna valutazione finora

- Technical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionDa EverandTechnical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionNessuna valutazione finora

- Nanofluid in Heat Exchangers for Mechanical Systems: Numerical SimulationDa EverandNanofluid in Heat Exchangers for Mechanical Systems: Numerical SimulationNessuna valutazione finora

- Industrial Engineer: Passbooks Study GuideDa EverandIndustrial Engineer: Passbooks Study GuideNessuna valutazione finora

- Proceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988Da EverandProceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988R. G. ScurlockNessuna valutazione finora

- Nonlinear Finite Element Analysis and Adina: Proceedings of the 4th ADINA ConferenceDa EverandNonlinear Finite Element Analysis and Adina: Proceedings of the 4th ADINA ConferenceNessuna valutazione finora

- A Suggested Stress Analysis Procedure For Nozzle To Head Shell Element Model - A Case StudyDocumento7 pagineA Suggested Stress Analysis Procedure For Nozzle To Head Shell Element Model - A Case StudyLincs lincolnNessuna valutazione finora

- Design and Analysis of Crane HookDocumento6 pagineDesign and Analysis of Crane HookOSHI JAINNessuna valutazione finora

- E 08Documento16 pagineE 08João PauloNessuna valutazione finora

- SW NewDocumento1 paginaSW NewPrayas SubediNessuna valutazione finora

- Tunnel Lenth 3500 M Tunnel Diameter Inside Area (m2) Wetted Perimeter (M)Documento26 pagineTunnel Lenth 3500 M Tunnel Diameter Inside Area (m2) Wetted Perimeter (M)Prayas SubediNessuna valutazione finora

- Stability Sheet For Various RWDocumento14 pagineStability Sheet For Various RWPrayas SubediNessuna valutazione finora

- Spring Constant Calculation1Documento3 pagineSpring Constant Calculation1DipeshNessuna valutazione finora

- Wind Load CalculationsDocumento1 paginaWind Load CalculationsPrayas SubediNessuna valutazione finora

- Stability-Bulk Head Gate NewDocumento1 paginaStability-Bulk Head Gate NewPrayas SubediNessuna valutazione finora

- Typ RW FinishedDocumento18 pagineTyp RW FinishedPrayas SubediNessuna valutazione finora

- T-Beam Design-BMPDocumento1 paginaT-Beam Design-BMPPrayas SubediNessuna valutazione finora

- T-Beam Design-BMPDocumento1 paginaT-Beam Design-BMPPrayas SubediNessuna valutazione finora

- Typ RW FinishedDocumento18 pagineTyp RW FinishedPrayas SubediNessuna valutazione finora

- RW With Relieving Platform - NewDocumento9 pagineRW With Relieving Platform - NewPrayas SubediNessuna valutazione finora

- Spacing of ReinforcementDocumento4 pagineSpacing of ReinforcementPrayas SubediNessuna valutazione finora

- Ses Coeff - UthpDocumento4 pagineSes Coeff - UthpPrayas SubediNessuna valutazione finora

- Type of Soil Support Zone, Z Importance Factor, IDocumento7 pagineType of Soil Support Zone, Z Importance Factor, IPrayas SubediNessuna valutazione finora

- Chapter 6 SEISMIC DESIGN - SP-17 - 09-07Documento28 pagineChapter 6 SEISMIC DESIGN - SP-17 - 09-07Prayas SubediNessuna valutazione finora

- Steel Corbel Design Based On AISC-ASD 9th, Appendix F Design CriteriaDocumento3 pagineSteel Corbel Design Based On AISC-ASD 9th, Appendix F Design CriteriaPrayas SubediNessuna valutazione finora

- Diff BWT Is 800 101Documento96 pagineDiff BWT Is 800 101tops123Nessuna valutazione finora

- WEIRS Design1Documento46 pagineWEIRS Design1June CruzNessuna valutazione finora

- Seismic Analysis of Water TankDocumento4 pagineSeismic Analysis of Water TankhungNessuna valutazione finora

- Gravity Dam StabilityDocumento14 pagineGravity Dam StabilityHarilal Kishan67% (3)

- Autodesk Land Desktop 2007Documento4 pagineAutodesk Land Desktop 2007Prayas SubediNessuna valutazione finora

- Feasibility Study-MoroccoDocumento215 pagineFeasibility Study-MoroccoPrayas SubediNessuna valutazione finora

- Stresses in Support PipeDocumento20 pagineStresses in Support PipePrayas SubediNessuna valutazione finora

- General Principles EQRDDocumento5 pagineGeneral Principles EQRDPrayas SubediNessuna valutazione finora

- Appendix D - Existing Conditions Bridge Assessment Report ADocumento44 pagineAppendix D - Existing Conditions Bridge Assessment Report APrayas SubediNessuna valutazione finora

- ABDocumento4 pagineABPrayas Subedi100% (1)

- Approved Welding Procedures-Rebar Indirect Butt Joint With Splice AngleDocumento8 pagineApproved Welding Procedures-Rebar Indirect Butt Joint With Splice Anglecipele12Nessuna valutazione finora

- Dynamic Tests of Large Reinforcing Bar SplicesDocumento185 pagineDynamic Tests of Large Reinforcing Bar SplicesPrayas SubediNessuna valutazione finora

- 12.design Problems in Lap Welded Joints of Reinforcing Steel BarsDocumento7 pagine12.design Problems in Lap Welded Joints of Reinforcing Steel BarsHalil DemirNessuna valutazione finora

- Lecture Notes 12Documento26 pagineLecture Notes 12tnvishNessuna valutazione finora

- Thermal Stress Intensity Factors For A Cracked Cylinder Under Transient Thermal LoadingDocumento11 pagineThermal Stress Intensity Factors For A Cracked Cylinder Under Transient Thermal Loading882636013Nessuna valutazione finora

- D198 PDFDocumento20 pagineD198 PDFArnold RojasNessuna valutazione finora

- Torsion of Thin-Walled Tube - Strength of Materials ReviewDocumento4 pagineTorsion of Thin-Walled Tube - Strength of Materials ReviewJethro RubiaNessuna valutazione finora

- Design and Fabrication of Centrifugal Air Blower Test RigDocumento8 pagineDesign and Fabrication of Centrifugal Air Blower Test RigIAEME PublicationNessuna valutazione finora

- STRUCTURAL - Chapter 2 - Structural Static Analysis (UP19980818)Documento36 pagineSTRUCTURAL - Chapter 2 - Structural Static Analysis (UP19980818)Rory Cristian Cordero RojoNessuna valutazione finora

- Ansys ManualDocumento36 pagineAnsys ManualSaras ChandraNessuna valutazione finora

- Parametric Study of Beams With Externally Bonded FRP ReinforcementDocumento9 pagineParametric Study of Beams With Externally Bonded FRP ReinforcementpicottNessuna valutazione finora

- Intro To BHJDocumento38 pagineIntro To BHJRajni SharmaNessuna valutazione finora

- Hilti Webinar - Anchor Design Influencing Factors PDFDocumento57 pagineHilti Webinar - Anchor Design Influencing Factors PDFDoug WeirNessuna valutazione finora

- Flexible vs. Rigid Wall PressuresDocumento6 pagineFlexible vs. Rigid Wall PressuresSeth ReddyNessuna valutazione finora

- Chapter 2 Mechanics of Metal CuttingDocumento36 pagineChapter 2 Mechanics of Metal CuttingAvinash Ganesan67% (3)

- Lec 5 - Rock PropertiesDocumento29 pagineLec 5 - Rock PropertiesSyed HammadNessuna valutazione finora

- Femap Neutral File FormatDocumento81 pagineFemap Neutral File FormatMSC Nastran BeginnerNessuna valutazione finora

- Filigree Slabs TestingDocumento6 pagineFiligree Slabs Testingmulti5torpeNessuna valutazione finora

- A General Solution For The Stress Around Internally Pressurized Circular Hole in Symmetric LaminatesDocumento5 pagineA General Solution For The Stress Around Internally Pressurized Circular Hole in Symmetric LaminatesIoan-Lucian StanNessuna valutazione finora

- 2012 - Hou - Experimental Study On Yield Behavior of Daqing Crude Oil - Rheologica ActaDocumento5 pagine2012 - Hou - Experimental Study On Yield Behavior of Daqing Crude Oil - Rheologica ActaGéssica PalaoroNessuna valutazione finora

- Index: 2 / Supplier Information Modelling and CalculationDocumento15 pagineIndex: 2 / Supplier Information Modelling and CalculationCanan DönmezNessuna valutazione finora

- ST01 Bending Stress in A BeamDocumento6 pagineST01 Bending Stress in A BeamAnh HoàngNessuna valutazione finora

- Design of A Stair Climbing WheelchairDocumento40 pagineDesign of A Stair Climbing WheelchairSupratim Naskar88% (8)

- Mast2014 Avalanche and Landslide Simulation Using The Material Point MethodDocumento14 pagineMast2014 Avalanche and Landslide Simulation Using The Material Point MethodlinoficNessuna valutazione finora

- MAAE 3202 Mid Term Assignment 2014Documento11 pagineMAAE 3202 Mid Term Assignment 2014Moustafa SohdyNessuna valutazione finora

- Volume Changes of ConcreteDocumento17 pagineVolume Changes of ConcreteAljawhara AlnadiraNessuna valutazione finora

- Unit - 1: General Features of Reinforced ConcreteDocumento36 pagineUnit - 1: General Features of Reinforced ConcretemdaashuNessuna valutazione finora

- Prestressed ConcreteDocumento2 paginePrestressed ConcreteAmit ThoriyaNessuna valutazione finora

- Creep and FatigueDocumento20 pagineCreep and Fatiguecheveresan123100% (2)

- 2 Stress Strain Curve - WebDocumento28 pagine2 Stress Strain Curve - WebJeevanantham KannanNessuna valutazione finora

- Uppcl 2016Documento7 pagineUppcl 2016bigboss0086Nessuna valutazione finora

- A320 Structure Ata 51-57Documento267 pagineA320 Structure Ata 51-57Sufiyan Khan100% (1)

- Analysis and Design of Box Type Major BridgeDocumento8 pagineAnalysis and Design of Box Type Major BridgeIJRASETPublicationsNessuna valutazione finora

- Structural Analysis of Turbine Blade Disc Fir-Tree Root Using ANSYSDocumento4 pagineStructural Analysis of Turbine Blade Disc Fir-Tree Root Using ANSYSRahul VermaNessuna valutazione finora