Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

AKS F05c Initial Audrep 9k2k (Rev1)

Caricato da

Jamil VoraTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

AKS F05c Initial Audrep 9k2k (Rev1)

Caricato da

Jamil VoraCopyright:

Formati disponibili

International Standards Certifications Pty. Ltd.

Report No

A.B.N. 45 071 810 949

Page No.

The Quality Centre, Suite 32/7 Anella Ave, Castle Hill, Sydney, NSW 2154, Australia

Audit

Date(s)

A/91/312/104

1

of

28th April2001

INITIAL AUDIT REPORT

COMPANY:

AKS Bearings Ltd.,

AUDITED

A-87 (B), road no. 9 (C), V. K. I. Area, Jaipur 302 013., Rajasthan, India.

SITE(S):

STANDARD:

ISO 9001:2000

CLIENT:

As Above

SCOPE OF AUDIT

/ CAPABILITY:

Scope : - Manufacturing, Marketing & Supply of Bearings (Excluding Design & Development)

ANZSIC CODE

NUMBER OF EMPLOYEES

: 19

: C 2869

Report By....N. Bhattacharya .......Signature.................................................Date.....30.04.2001

FORM 05 AUDREP 1

ISSUE 1 REV

1

Report No

International Standards Certifications Pty. Ltd.

A.B.N. 45 071 810 949

Page No.

The Quality Centre, Suite 32/7 Anella Ave, Castle Hill, Sydney, NSW 2154, Australia

Audit

Date(s)

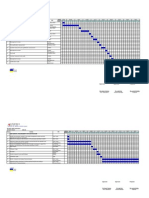

Clause

ISO

9001

Clause Title

4.2

Documentation Requirements

Mi

28th April2001

Car no. 01/01 raised

Management Responsibility

Management Commitment

5.2

Customer Focus

5.3

Quality Policy

5.4

Planning

Mi

Car no. 01/02 raised

5.5

Responsibility, Authority, and communication

Mi

Car no. 01/03 raised

5.6

Management Review

Resource Management

S

6.1

Provision of resources

6.2

Human Resources

6.3

Infrastructure

6.4

Work Environment

Mi

Car no. 01/04 raised

Product Realization

7.1

Planning of Product realization

7.2

Customer related processes

7.3

S

Mi

Car no. 01/05 raised

Design and Development

Not Applicable

7.4

Purchasing

7.5

Production and service provision

Mi

Car no. 01/06 raised

7.6

Control of monitoring and measuring devices

Mi

Car no. 01/07 raised & Closed

CAR / NCR #. & Status

5.1

of

General Requirements

Quality Management System

4.1

Clause

Status

*

A/91/312/104

Measurement,

improvement

Analysis

and

8.1

General

8.2

Monitoring and Measurement

8.3

Control of nonconforming product

8.4

Analysis of data

8.5

Improvement

* Clause Status:

Mi

= Satisfactory,

Ma = Major,

Car no. 01/08 raised

Mi = Minor,

N/A = Not audited fully

FORM 05 AUDREP 1

ISSUE 1 REV

1

International Standards Certifications Pty. Ltd.

Report No

A.B.N. 45 071 810 949

Page No.

The Quality Centre, Suite 32/7 Anella Ave, Castle Hill, Sydney, NSW 2154, Australia

Audit

Date(s)

A/91/312/104

3

of

28th April2001

SUMMARY OF AUDIT

An audit of the AKS Bearings Ltd. jaipur, Quality System was conducted on the above date by

International Standards Certifications in accordance with the requirements outlined in ISO Standard

10011.1. The purpose of the audit was to verify compliance of the implemented system to the

requirements of the company quality manual, associated procedures and ISO 9001:2000.

NONCONFORMANCES IDENTIFIED

The system Audit Plan and the Audit Attendance Register identifying those Present during the entry and

exit meetings are provided as attachments.

The audit team observed that the Management and personnel of M/s. AKS Bearings Ltd. - jaipur, were

committed to the development of the quality system and appreciated the opportunities for

improvements identified during the audit. The details of CARs raised are as follows.

4.2 Documentation Requirement.

The System does not ensure that

Document of external origin such as DIN std, ISO std, Etc. indicated in the product category are

available and controlled.

5.4 Planning

The System does not ensure that

1) Quality Objective given by the top management, all are measurable Ex. Objective like

a) Up gradation and effective control of process at suppliers end.

b) Motivate and develop employee by training and education.

2) Objectives are available to support the quality policy like total customer satisfaction.

5.5 Responsibility, Authority & communication

The System does not ensure that

a) Appropriate communication processes are established for all interrelated function of the

Organization.

b) How the production planning process goes down below to production manager & Operator?

Other than daily planning and operation process M/C wise, no other related documents were

found.

6.2 Human Resources

FORM 05 AUDREP 1

ISSUE 1 REV

1

International Standards Certifications Pty. Ltd.

Report No

A.B.N. 45 071 810 949

Page No.

The Quality Centre, Suite 32/7 Anella Ave, Castle Hill, Sydney, NSW 2154, Australia

Audit

Date(s)

A/91/312/104

4

of

28th April2001

The System does not ensure that

a) The competence of personals carrying out calibration of instruments are defined.

Viz. During audit it was observed that the concern person is not very clearly aware of the

calibration method.

b) Appropriate need of skills are maintained for inspectors carrying out visual inspection.

Requirement of eye sight test is defined for visual inspectors but no record available.

7.2 Customer related processes

The System does not ensure that

Product catalogue clearly indicates about supply of Normal. Bearing in case customer has not

specified in their order other wise.

7.5 Production and service provision

The System does not ensure that

All internal processes are covered in the system as being done practically.

(Viz. A. Tendering process, b. Delivery Process &

B. Issue slip was not interlinked with the store process where as practically issue slip was used

for issuing material from stores.)

7.6 Control of monitoring and measuring devices

The System does not ensure that

All calibration records are identifiable through the I.D. No. provided in the Master list.

Viz. Slip gauge I. D. No. indicated in Master list found 3555 where as record indicates 3554.

8.5 Improvement

The System does not ensure that

Appropriate corrective action is initiated to eliminate root cause of product non conformity of the final

stage inspection on account of Hardness.

Viz. 5 non hardened pieces of Bearings 1838001 were found rejected/ re-graded form a lot due to their

soft nature (On examination it was found that 2 were okay)

No action has so far taken (Since such incidents are regular) to identify where the thing has gone

wrong. i.e. In raw material or in Heat treatment by the sub contractor?

OPPORTUNITIES FOR IMPROVEMENT

The Auditor observed that Corrective actions were immediately initiated. Car no. 01/07 were closed

before the close out meeting. Corrective action completion dates have been provided for the pending 7

CARs.

FORM 05 AUDREP 1

ISSUE 1 REV

1

International Standards Certifications Pty. Ltd.

Report No

A.B.N. 45 071 810 949

Page No.

The Quality Centre, Suite 32/7 Anella Ave, Castle Hill, Sydney, NSW 2154, Australia

Audit

Date(s)

A/91/312/104

5

of

28th April2001

CONCLUSION

The basic of the system were found to have been implemented. Future efforts will be required in coming

months to ensure the system development continues.

Based on the audit findings since no Major NCRs were found and corrective action plans against the

pending Minor NCRs have already been developed by the client, reviewed and accepted by ISC, a

recommendation for Certification of the Quality Management System (ISO 9001:2000) of M/s.

AKS Bearings Ltd. - Jaipur, will be made under the following provisions.

Verification of the planned corrective action will be undertaken by ISC during Surveillance Audit

N. Bhattacharya - Lead Auditor

International Standards Certifications

FORM 05 AUDREP 1

ISSUE 1 REV

1

Potrebbero piacerti anche

- Surveillance Audit Report: International Standards Certifications Pty. LTDDocumento3 pagineSurveillance Audit Report: International Standards Certifications Pty. LTDJamil VoraNessuna valutazione finora

- F05b Surv Audrep (Rev4)Documento4 pagineF05b Surv Audrep (Rev4)Jamil VoraNessuna valutazione finora

- ISO Certification Audit ReportDocumento5 pagineISO Certification Audit ReportJamil VoraNessuna valutazione finora

- ISO 9001 Certification Audit ReportDocumento3 pagineISO 9001 Certification Audit ReportJamil VoraNessuna valutazione finora

- F05a Initial Audrep (Rev4)Documento5 pagineF05a Initial Audrep (Rev4)Jamil VoraNessuna valutazione finora

- Second Surveillance Audit Report: Agrasen Engineering Industries LTD.Documento3 pagineSecond Surveillance Audit Report: Agrasen Engineering Industries LTD.Jamil VoraNessuna valutazione finora

- Surveillance Audit Report: International Standards Certifications Pty. LTDDocumento3 pagineSurveillance Audit Report: International Standards Certifications Pty. LTDJamil VoraNessuna valutazione finora

- Vital F05a Initial Audrep (Rev4)Documento4 pagineVital F05a Initial Audrep (Rev4)Jamil VoraNessuna valutazione finora

- First Surveillance Audit Report: Agrasen Engineering Industries LTD.Documento4 pagineFirst Surveillance Audit Report: Agrasen Engineering Industries LTD.Jamil VoraNessuna valutazione finora

- Corrective Action Request: R/91/072/011 Company: Agrasen Engineering Industries LTD.Documento3 pagineCorrective Action Request: R/91/072/011 Company: Agrasen Engineering Industries LTD.Jamil VoraNessuna valutazione finora

- Preliminary Audit Report: AKS Bearings LTDDocumento5 paginePreliminary Audit Report: AKS Bearings LTDJamil VoraNessuna valutazione finora

- Supplier Evaluation Questionnaire: InstructionsDocumento6 pagineSupplier Evaluation Questionnaire: Instructionsutpa8080Nessuna valutazione finora

- Name: - Place: - DateDocumento4 pagineName: - Place: - DateTariq AslamNessuna valutazione finora

- AR1 Audit - Report (Stage 2) MajikDocumento8 pagineAR1 Audit - Report (Stage 2) MajikRachel TangNessuna valutazione finora

- Preliminary Audit Report: Automotive Valves Pvt. LTD.Documento3 paginePreliminary Audit Report: Automotive Valves Pvt. LTD.Jamil VoraNessuna valutazione finora

- AC7140 Rev CDocumento73 pagineAC7140 Rev CRanga100% (1)

- Management System Certification Audit Summary ReportDocumento8 pagineManagement System Certification Audit Summary ReportLedo HoussienNessuna valutazione finora

- Process Effectiveness Assessment ReportDocumento2 pagineProcess Effectiveness Assessment Reportjohnoo7Nessuna valutazione finora

- 15-RCA-011 - Executive Summary November 03 2015Documento4 pagine15-RCA-011 - Executive Summary November 03 2015Kenaia AdeleyeNessuna valutazione finora

- Iso 9001 Audit Trail: A Practical Guide to Process Auditing Following an Audit TrailDa EverandIso 9001 Audit Trail: A Practical Guide to Process Auditing Following an Audit TrailValutazione: 5 su 5 stelle5/5 (3)

- QSP 05 Internal Audits REV 1Documento7 pagineQSP 05 Internal Audits REV 1kmvimal36Nessuna valutazione finora

- Aqc Middle East Fze: Stage 2 Audit ReportDocumento7 pagineAqc Middle East Fze: Stage 2 Audit ReporttriveshNessuna valutazione finora

- Internal Audit ISO 9001 (2008) Checklists (EJJV)Documento4 pagineInternal Audit ISO 9001 (2008) Checklists (EJJV)Abdul Hakam Mohamed YusofNessuna valutazione finora

- ISO Certification Audit Report SummaryDocumento3 pagineISO Certification Audit Report SummaryJamil VoraNessuna valutazione finora

- Cara ReportDocumento25 pagineCara ReportSurendharNessuna valutazione finora

- 1.4 Evidance ISO 9001-2015 On ProcessDocumento6 pagine1.4 Evidance ISO 9001-2015 On ProcessRaharjo YakinNessuna valutazione finora

- ISO 9001 Auditor Training Q&ADocumento10 pagineISO 9001 Auditor Training Q&AAli Zafar71% (7)

- IT Group Internal Audit Schedules and ReportsDocumento11 pagineIT Group Internal Audit Schedules and ReportsBhavin SukhadiyaNessuna valutazione finora

- Quality System Manual ISO 9001:2008 Internal Audit Check ListDocumento14 pagineQuality System Manual ISO 9001:2008 Internal Audit Check ListDivakar Panigrahi100% (1)

- Iso9001-As9100 Check ListDocumento19 pagineIso9001-As9100 Check ListJohn Rajesh100% (1)

- Pentair Noida ARG-407503 WI-820614 Audit ReportDocumento13 paginePentair Noida ARG-407503 WI-820614 Audit ReportHolly SmithNessuna valutazione finora

- Bureau Veritas Certification Management System Certification Audit Report For The Initial Audit of RENA Technical Services Co. Agency :689Documento8 pagineBureau Veritas Certification Management System Certification Audit Report For The Initial Audit of RENA Technical Services Co. Agency :689SAEEDNessuna valutazione finora

- Process Audit Check ListDocumento24 pagineProcess Audit Check ListSorin FrentoniNessuna valutazione finora

- 069 Audit Report RSUD Sekayu 9K St2 To ClientsDocumento11 pagine069 Audit Report RSUD Sekayu 9K St2 To ClientstutiarlyNessuna valutazione finora

- Internal Audit Check SheetDocumento14 pagineInternal Audit Check SheetJOAI BITANANessuna valutazione finora

- ExamDocumento6 pagineExamBWQ67% (3)

- Corrective Action Request: Company: Agrasen Engineering Industries LTDDocumento3 pagineCorrective Action Request: Company: Agrasen Engineering Industries LTDJamil VoraNessuna valutazione finora

- -tqm-sunum-3Documento18 pagine-tqm-sunum-3an7l7aNessuna valutazione finora

- Internal Audit Procedure 305Documento7 pagineInternal Audit Procedure 305Sayed AbbasNessuna valutazione finora

- Internal Audit Checklist Q1 - IsO 2015 - Final FormatDocumento30 pagineInternal Audit Checklist Q1 - IsO 2015 - Final FormatThee BouyyNessuna valutazione finora

- Preliminary Audit Report: Diamant Carbon & Graphite Products LTDDocumento3 paginePreliminary Audit Report: Diamant Carbon & Graphite Products LTDJamil VoraNessuna valutazione finora

- CS 4 Identifying NC - 2021 VILTDocumento3 pagineCS 4 Identifying NC - 2021 VILTDeepak AroraNessuna valutazione finora

- Internal Audit Exam For Auditors Getting Ready To Be QualifiedDocumento6 pagineInternal Audit Exam For Auditors Getting Ready To Be QualifiedYahya Chiguer75% (4)

- A00F207e Audit ReportDocumento8 pagineA00F207e Audit ReportMuhammad HashiNessuna valutazione finora

- Pedoman Audit InternalDocumento6 paginePedoman Audit Internalsamu bahri100% (1)

- Evaluate Supplier Quality QuestionnaireDocumento6 pagineEvaluate Supplier Quality Questionnairenithi_123100% (1)

- M. S. Khurana Engineering Pvt. LTD.,: Jay Tower, 3 Floor, Ankur Complex, Naranpura, Ahmedabad - 380 013 Gujarat, IndiaDocumento3 pagineM. S. Khurana Engineering Pvt. LTD.,: Jay Tower, 3 Floor, Ankur Complex, Naranpura, Ahmedabad - 380 013 Gujarat, IndiaJamil VoraNessuna valutazione finora

- Internal Audit ChecklistDocumento18 pagineInternal Audit ChecklistAkhilesh Kumar75% (4)

- ISO 9001 RecordsDocumento3 pagineISO 9001 RecordsganandmailNessuna valutazione finora

- CSL P5-007229 AuditReportDocumento5 pagineCSL P5-007229 AuditReportIdrus IsmailNessuna valutazione finora

- Iso 9001 Activity Plan '05Documento3 pagineIso 9001 Activity Plan '05jvenrqzNessuna valutazione finora

- LEAD AUDITOR COURSE WORKBOOK FOR ISO 9001 QUALITY MANAGEMENT SYSTEMSDocumento115 pagineLEAD AUDITOR COURSE WORKBOOK FOR ISO 9001 QUALITY MANAGEMENT SYSTEMSIsaiahNessuna valutazione finora

- Group Exercise Covering Audit Situations From P5, P6, P7Documento3 pagineGroup Exercise Covering Audit Situations From P5, P6, P7sankusi_rkflNessuna valutazione finora

- BMS Surveillance Audit ReportDocumento10 pagineBMS Surveillance Audit ReportrajarajanNessuna valutazione finora

- CASESTDUDIESDocumento13 pagineCASESTDUDIESmohanksebNessuna valutazione finora

- AC7101.1 Rev G 2Documento37 pagineAC7101.1 Rev G 2Namelezz ShadowwNessuna valutazione finora

- Like This Article?Documento3 pagineLike This Article?UnknownNessuna valutazione finora

- 2017 ISO9001 External Audit ReportDocumento19 pagine2017 ISO9001 External Audit ReportTata OdoyNessuna valutazione finora

- Centerwide System Level Procedure: ISO 9001 - Ames Research CenterDocumento8 pagineCenterwide System Level Procedure: ISO 9001 - Ames Research CenterKamal MulchandaniNessuna valutazione finora

- Cracking the Case of ISO 9001:2015 for Service: A Simple Guide to Implementing Quality Management in Service OrganizationsDa EverandCracking the Case of ISO 9001:2015 for Service: A Simple Guide to Implementing Quality Management in Service OrganizationsNessuna valutazione finora

- Heat Treatment Procedure Qualification ReportDocumento96 pagineHeat Treatment Procedure Qualification ReportrecnessNessuna valutazione finora

- 7.2.2 APQP Introduction 01 APR 2014Documento39 pagine7.2.2 APQP Introduction 01 APR 2014Jamil VoraNessuna valutazione finora

- New Order FormDocumento1 paginaNew Order FormJamil VoraNessuna valutazione finora

- Preliminary Audit Report: Future Vision Netlink LTD.Documento3 paginePreliminary Audit Report: Future Vision Netlink LTD.Jamil VoraNessuna valutazione finora

- Contract Review of MagnaDocumento4 pagineContract Review of MagnaJamil VoraNessuna valutazione finora

- Rev ReptDocumento3 pagineRev ReptJamil VoraNessuna valutazione finora

- Contract Review of MagnaDocumento1 paginaContract Review of MagnaJamil VoraNessuna valutazione finora

- 6D ClauseDocumento1 pagina6D ClauseJamil VoraNessuna valutazione finora

- Definition: "Combination of Internal and External Issues That Can Have An Effect On An Organization's Approach To Developing and Achieving Its Objectives"Documento4 pagineDefinition: "Combination of Internal and External Issues That Can Have An Effect On An Organization's Approach To Developing and Achieving Its Objectives"Jamil VoraNessuna valutazione finora

- International Standards Certifications: H.O.:-5/6, Shreyas, 2Documento2 pagineInternational Standards Certifications: H.O.:-5/6, Shreyas, 2Jamil VoraNessuna valutazione finora

- LEO Road Contract Review FormDocumento1 paginaLEO Road Contract Review FormJamil VoraNessuna valutazione finora

- Contract Review of MagnaDocumento1 paginaContract Review of MagnaJamil VoraNessuna valutazione finora

- Rev ReptDocumento3 pagineRev ReptJamil VoraNessuna valutazione finora

- Matching Anzsic Code Holder - MM & PS: Form FA/038 Rev 0Documento1 paginaMatching Anzsic Code Holder - MM & PS: Form FA/038 Rev 0Jamil VoraNessuna valutazione finora

- Banpal F31 Contract Review (Rev 2)Documento1 paginaBanpal F31 Contract Review (Rev 2)Jamil VoraNessuna valutazione finora

- ISO 9001 Certification Audit Details for Indian Bearings ManufacturerDocumento1 paginaISO 9001 Certification Audit Details for Indian Bearings ManufacturerJamil VoraNessuna valutazione finora

- CR VitalElectrocomp343Documento2 pagineCR VitalElectrocomp343Jamil VoraNessuna valutazione finora

- Declaration of Independence: ISC File No. R/91/312/207Documento1 paginaDeclaration of Independence: ISC File No. R/91/312/207Jamil VoraNessuna valutazione finora

- GoelDocumento1 paginaGoelJamil VoraNessuna valutazione finora

- M. S. Khurana Engineering Pvt. LTD.,: Jay Tower, 3 Floor, Ankur Complex, Naranpura, Ahmedabad - 380 013 Gujarat, IndiaDocumento3 pagineM. S. Khurana Engineering Pvt. LTD.,: Jay Tower, 3 Floor, Ankur Complex, Naranpura, Ahmedabad - 380 013 Gujarat, IndiaJamil VoraNessuna valutazione finora

- International Standards Certifications R/91/222/109: File Ref:-Item Audit Observations Car#Documento1 paginaInternational Standards Certifications R/91/222/109: File Ref:-Item Audit Observations Car#Jamil VoraNessuna valutazione finora

- Applicant) : File Number Customer SIC CodeDocumento1 paginaApplicant) : File Number Customer SIC CodeJamil VoraNessuna valutazione finora

- Corrective Action Request: A/91/222/010 Company: Suvik Electronics Pvt. LTD.Documento1 paginaCorrective Action Request: A/91/222/010 Company: Suvik Electronics Pvt. LTD.Jamil VoraNessuna valutazione finora

- Licence Agreement for Use of Quality Assurance TrademarkDocumento4 pagineLicence Agreement for Use of Quality Assurance TrademarkJamil VoraNessuna valutazione finora

- F04 Initial Audpln 1 (Iss1 Rev0)Documento1 paginaF04 Initial Audpln 1 (Iss1 Rev0)Jamil VoraNessuna valutazione finora

- Followup AuditplanDocumento2 pagineFollowup AuditplanJamil VoraNessuna valutazione finora

- Declaration of Independence: ISC File No. R/91/312/207Documento1 paginaDeclaration of Independence: ISC File No. R/91/312/207Jamil VoraNessuna valutazione finora

- ISO Certification Audit Plan for Suvik ElectronicsDocumento1 paginaISO Certification Audit Plan for Suvik ElectronicsJamil VoraNessuna valutazione finora

- Shifting The Focus From End-Of-Life Recycling To Continuous Product LifecyclesDocumento9 pagineShifting The Focus From End-Of-Life Recycling To Continuous Product LifecyclesDeneshVijayNessuna valutazione finora

- Solution Manual - RANTE COST ACCDocumento127 pagineSolution Manual - RANTE COST ACCray57% (7)

- COSMOPHANE Portfolio Film Types and ApplicationsDocumento2 pagineCOSMOPHANE Portfolio Film Types and ApplicationsSachin KothariNessuna valutazione finora

- Learning To LEED: Day 2 Materials & Resources QuizDocumento5 pagineLearning To LEED: Day 2 Materials & Resources Quizvico1982Nessuna valutazione finora

- Solid Waste Management of Dibrugarh Municipality BoardDocumento17 pagineSolid Waste Management of Dibrugarh Municipality BoardAnnesha Mech100% (1)

- IRIS Guideline 2 2012 FAIDocumento12 pagineIRIS Guideline 2 2012 FAI44abcNessuna valutazione finora

- Product Quality Plan Flow Chart: 1.0 Plan & Define The ProjectDocumento1 paginaProduct Quality Plan Flow Chart: 1.0 Plan & Define The ProjectmjapmgNessuna valutazione finora

- Topic 3 BPR in Manufaturing IndustryDocumento9 pagineTopic 3 BPR in Manufaturing Industryneyom bitvooNessuna valutazione finora

- To Pull or Not To PullDocumento17 pagineTo Pull or Not To PullJabri JuhininNessuna valutazione finora

- SolidCAM Imachining Getting StartedDocumento26 pagineSolidCAM Imachining Getting StartedrhutchcroftNessuna valutazione finora

- The Complete Guide to Simple OEE MeasurementDocumento26 pagineThe Complete Guide to Simple OEE MeasurementWan Sek Choon100% (2)

- North South University: Course Code: BUS650 Section 01 Fall 2018Documento18 pagineNorth South University: Course Code: BUS650 Section 01 Fall 2018Khandkar Sahil Ridwan100% (1)

- Winning at New ProductsDocumento24 pagineWinning at New Products劉緯文100% (1)

- Production and Cost AnalysisDocumento60 pagineProduction and Cost AnalysisKhushwant AryaNessuna valutazione finora

- TUV India online training programs June-July 2021Documento12 pagineTUV India online training programs June-July 2021Ashutosh ChauhanNessuna valutazione finora

- Cornell Notes MRP & ERPDocumento2 pagineCornell Notes MRP & ERPSamuel SNessuna valutazione finora

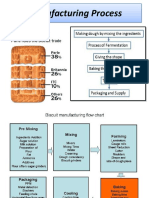

- Manufacturing ProcessDocumento12 pagineManufacturing ProcessmehrezNessuna valutazione finora

- Computer-Aided Process PlanningDocumento3 pagineComputer-Aided Process PlanningAbdul-wahab RiyadhNessuna valutazione finora

- Efficient Facility Layout DesignDocumento78 pagineEfficient Facility Layout DesignPrakhar RastogiNessuna valutazione finora

- Lean Software DevelopmentDocumento49 pagineLean Software Developmentabbasamir2998Nessuna valutazione finora

- Test Bank For Managerial Accounting, 3rd Edition WildDocumento158 pagineTest Bank For Managerial Accounting, 3rd Edition WildPhuong Pham BichNessuna valutazione finora

- 5.2 Production MethodsDocumento3 pagine5.2 Production MethodsGonzalo PastorNessuna valutazione finora

- CMM Levels Guide Software Process ImprovementDocumento2 pagineCMM Levels Guide Software Process ImprovementImranNessuna valutazione finora

- Workholders Work Piece ControlDocumento16 pagineWorkholders Work Piece ControlRam WaingankarNessuna valutazione finora

- Total Quality Management Practices in Manufacturing and Service Industries: A Comparative StudyDocumento23 pagineTotal Quality Management Practices in Manufacturing and Service Industries: A Comparative StudysharjeelNessuna valutazione finora

- GOOD VIEW Equipment List 20100906Documento1 paginaGOOD VIEW Equipment List 20100906TIEBUSA DESIGNNessuna valutazione finora

- Quality Management - KreznerQMDocumento36 pagineQuality Management - KreznerQMHenry Zegarra RodriguezNessuna valutazione finora

- What Is PQCDSM in TPM Concept - Yahoo AnswersDocumento2 pagineWhat Is PQCDSM in TPM Concept - Yahoo Answersgetashishvaid67% (3)

- Ws DC Motor enDocumento8 pagineWs DC Motor enebriculzNessuna valutazione finora

- Acct 303 Chapter 20Documento26 pagineAcct 303 Chapter 20adarshdk1Nessuna valutazione finora