Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Exergetic Analysis by George Tsatsaronis

Caricato da

Edson BenitesDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Exergetic Analysis by George Tsatsaronis

Caricato da

Edson BenitesCopyright:

Formati disponibili

15

Exergoeconomics and

Exergoenvironmental Analysis

George Tsatsaronis

15.1 Introduction

The objective evaluation and the improvement of an energy-conversion system from

the viewpoints of thermodynamics, economics, and environmental impact require a

deep understanding of

1. the real thermodynamic inefficiencies and the processes that caused them,

2. the costs associated with equipment and thermodynamic inefficiencies as well

as the connection between these two important factors, and

3. possible measures that would improve the efficiency and the cost effectiveness

and would reduce the environmental impact of the system being studied.

Exergoeconomics and exergoenvironmental evaluation provide methods for obtaining this information. Because an exergoenvironmental analysis and evaluation are

conducted in complete analogy to the exergoeconomic ones, in the following sections more emphasis is placed on exergoeconomics, which has been significantly

developed. Exergoeconomics consists of an exergy analysis, an economic analysis,

and an exergoeconomic evaluation.

The term exergoeconomics was coined by the author in 1984 [1] to clearly characterize a combination of exergy analysis with economic analysis, when in this combination the exergy-costing principle (Subsection 15.4.1) is used. In this way, a distinction

can be made between exergoeconomic methods and applications on one side and

other numerous applications on the other side, in which results from a thermodynamic analysis (sometimes including an exergy analysis) and an economic analysis

are presented (under the term thermoeconomic analysis) but without applying the

exergy-costing principle. The case in which the exergy-costing principle is not used

is in general of less interest to scientists and engineers and belongs to the broader

field of thermoeconomics, which is defined as any possible combination or coexistence of a thermodynamic analysis with an economic one, and thus also includes

exergoeconomics. It should be mentioned that, before 1984, all authors were using

the term thermoeconomics to indicate what we call today exergoeconomics. Even

after 1984, and still today, some authors continue to use the term thermoeconomics

(even when the exergy-costing principle is used) instead of the more precise term,

exergoeconomics. This practice, however, contributes to some confusion in the field.

377

378

Exergoeconomics and Exergoenvironmental Analysis

The term exergoenvironmental analysis was coined in 2006 by L. Meyer and the

author to characterize the new approach and to avoid confusion with other already

existing terms and approaches.

15.2 Exergetic Analysis

An energy-based analysis identifies only the energy transfers to the environment

as thermodynamic inefficiencies, fails to identify any inefficiency in an adiabatic

process, and misleads the analyst by considering as an inefficiency the heat rejection

to the environment dictated by the second law of thermodynamics. The additional

concept that corrects these misconceptions is the exergy concept.

Exergy is the maximum theoretical useful work (shaft work or electrical work)

obtainable from an energy-conversion system as this is brought into thermodynamic

equilibrium with the thermodynamic environment while interacting only with this

environment [2, 3]. Alternatively, exergy is the minimum theoretical work (shaft

work or electrical work) required for forming a quantity of matter from substances

present in the thermodynamic environment and for bringing the matter to a specified

state. Thus exergy is a measure of the deviation of the state of the system from the

state of this environment.

The thermodynamic environment in exergy analysis (also called reference environment) is a large thermodynamic system in equilibrium, in which the state variables (T0 , p0 ) and the chemical potentials of the chemical components contained

in it remain constant when, in a thermodynamic process, heat and materials are

exchanged between another system and this environment. It is important to note

that no chemical reactions can take place between chemical components contained

in this environment because the latter is not in equilibrium. The thermodynamic

environment is free of irreversibilities and its exergy is equal to zero. The thermodynamic environment, for which we need to use a model, should be as close as

possible to, but is not identical with, the physical environment. The thermodynamic

environment is part of the surroundings of any energy-conversion system. In the

following discussion, the term environment refers to the thermodynamic environment when exergetic considerations are made, and to the physical environment when

environmental impact is studied.

In the absence of nuclear, magnetic, electrical, and surface-tension effects, the

PH

,

total exergy of a system Esys consists of four components: physical exergy Esys

CH

KN

PT

chemical exergy E , kinetic exergy E , and potential exergy E [3]:

PH

Esys = Esys

+ ECH + EKN + EPT

(15.1a)

PH

Esys = m esys

+ eCH + eKN + ePT .

(15.1b)

or

In the preceding equation, m is the mass of the system and e refers to the mass

specific exergy.

PH

The rate of physical exergy E j associated with the jth material stream is

PH

E j = me

PH

j h0 ) T0 (s j s0 )].

j = m[(h

(15.2)

15.2 Exergetic Analysis

379

Here m

is the mass flow rate and e, h, and s denote the specific exergy, enthalpy,

and entropy, respectively, of the material stream. The subscript 0 refers to the

property values of the same mass flow rate at temperature T0 and pressure p0 of the

environment.

The physical exergy of a working fluid can be further split into its thermal (e T )

and mechanical (e M ) exergy components. This splitting may improve the accuracy

of calculations and facilitates an exergoeconomic optimization:

ePH

j = [(h j h j,X) T0 (s j s j,X)] p=const + [(h j,X h j,0 ) T0 (s j,X s j,0 )]T0 =const .

|

{z

} |

{z

}

eT

eM

(15.3)

In the preceding equation, the point X is defined at the given pressure p and the

temperature T0 of the environment.

The chemical exergy is defined as the maximum useful work obtainable as the

system, being at temperature T0 and pressure p0 , is brought into chemical equilibrium with the environment. Thus, for calculating the chemical exergy, not only the

temperature and pressure but also the chemical composition of the environment has

to be specified. Because our natural environment is not in equilibrium, there is a

need to model an exergy-reference environment [35]. The use of tabulated standard

chemical exergy values for substances contained in the environment at standard conditions (Tref = 298.15 K, pref = 1.013 bar) facilitates the calculation of exergy values.

The effect of small variations in the values of T0 and p0 on the chemical exergy of

reference substances might be neglected in practical applications.

The chemical exergy of an ideal mixture of N ideal gases is

e CH

mixture

ideal gases

N

X

0

xl e lCH + RT

l=1

N

X

xl ln (xl ) .

(15.4)

l=1

Here e lCH is the standard molar chemical exergy of the lth substance, and xl is

the mole fraction of the lth substance in the system at T0 .

For solutions of liquids, the chemical exergy can be obtained with the aid of the

activity coefficients l :

CH

=

e solution

N

X

l=1

0

xl e lCH + RT

N

X

xl ln(l xl ).

(15.5)

l=1

The standard chemical exergy of a substance not present in the environment

can be calculated by considering a reversible reaction of the substance with other

substances for which the values of standard chemical exergy are known [3].

The change in total exergy of a closed system undergoing a change from state 1

to state 2 (E2 E1 ) is caused through transfers of energy in the form of work and

heat between the system and its surroundings and is given by

E2 E1 = EQ12 + EW12 ED.

(15.6)

The exergy transfer EQ12 is associated with heat transfer Q12 , and the exergy

transfer EW12 is associated with the transfer of energy by work W12 .

380

Exergoeconomics and Exergoenvironmental Analysis

A part of the exergy supplied to a real energy-conversion system is destroyed

because of irreversibilities within the system. Contrary to mass and energy, the

exergy is not conserved in real systems. The exergy-destruction rate is equal to

ED,k = T0 Sgen,k = T0 mksgen,k.

(15.7)

Hence exergy destruction can be calculated either from the entropy generation

[Eq. (15.7)] by use of an entropy balance or directly from an exergy balance [Eq.

(15.6)]. The term ED,k is equal to zero only in ideal processes.

Thermodynamic processes are governed by the laws of conservation of mass

and energy. These conservation laws state that the total mass and total energy can

be neither created nor destroyed in a process. However, exergy is not generally

conserved but is destroyed by irreversibilities within a system. Furthermore, exergy

is lost when the energy associated with a material or energy stream is rejected to the

environment.

An exergy balance for the kth component at steady-state conditions can be

written as

E F,k = E P,k + E D,k,

(15.8)

where E P,k is the exergy of product (the desired result, expressed in exergy terms,

achieved by the kth component), and E F,k is the exergy of fuel (the exergetic

resources expended in the kth component to generate the exergy of product).

Here it is assumed that the system boundaries used for all exergy balances are

at the temperature T0 of the environment and therefore there are no exergy losses

associated with a component [6]. Exergy losses ( E L) appear only at the level of the

overall system (subscript tot), for which the exergy balance becomes

E F,tot = E P,tot +

n

X

E D,k + E L,tot .

(15.9)

k=1

The following two dimensionless variables are used for the conventional exergetic evaluation of the kth component of a system [3, 6]:

r Exergetic efficiency,

k =

E P,k

E D,k

=1

;

E F,k

E F,k

(15.10)

E D,k

.

E F,tot

(15.11)

r exergy-destruction ratio,

yk =

The exergetic efficiency of the overall system is

tot =

n

X

E P,tot

E L,tot

=1

yk

.

E F,tot

E F,tot

k=1

(15.12)

For the distinction between productive components, for which an exergetic efficiency is calculated, and dissipative components, for which no meaningful efficiency

can be defined, see [7].

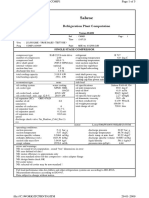

15.3 A Compression Refrigeration Machine as an Example

381

TCD

condenser

Figure 15.1. Schematic of a compression

refrigeration machine.

throttling

valve

secondary

working fluid

secondary

working fluid

9

4

evaporator

TEV

compressor

The exergy concept complements and enhances an energetic analysis by calculating

1. the true thermodynamic value of an energy carrier,

2. the real thermodynamic inefficiencies in a system, and

3. variables that unambiguously characterize the performance of a system (kth

component or overall system) from the thermodynamic viewpoint.

The real thermodynamic inefficiencies in an energy-conversion system are

related to exergy destruction and exergy loss. All real processes are irreversible

because of effects such as chemical reaction, heat transfer through a finite temperature difference, mixing of matter at different compositions, temperatures and

pressure, unrestrained expansion, and friction. An exergy analysis identifies the system components with the highest thermodynamic inefficiencies and the processes

that cause them.

15.3 A Compression Refrigeration Machine as an Example

The simple vapor-compression refrigeration machine shown in Fig. 15.1 is used here

as an example for demonstrating the application of the methods discussed in this

chapter. This machine consists of a compressor and motor, (CM), a condenser (CD),

a throttling valve (TV), and an evaporator (EV). Ammonia is the primary working

fluid for the refrigeration machine, whereas water is used as the secondary working

fluid in the condenser, and air is the secondary working fluid in the evaporator.

The product from the overall system is the cold rate Q cold = 50 kW, the exergy rate

of which is kept constant in the analysis: E P,tot = E 9 E 8 = const. The isentropic

efficiency of the compressor is assumed to be CM = 0.85. For simplicity, pressure

drops are neglected in all heat exchangers.

Table 15.1 shows the material, mass flow rate, temperature, pressure, specific

enthalpy, specific entropy, and specific physical exergy of all streams of matter shown

in Fig. 15.1. The exergy destruction within each component of the refrigeration

machine is calculated with Eq. (15.8):

CM ( E 2 E 1 ), E D,CD = ( E 2 E 3 ) ( E 7 E 6 )

E D,CM = W

E D,EV = ( E 4 E 1 ) ( E 9 E 8 ),

M

M

T

T

E D,TV = ( E 3 E 4 ) ( E 4 E 3 ) = E 3 E 4 .

382

Exergoeconomics and Exergoenvironmental Analysis

Table 15.1. Thermodynamic data for the vapor-compression refrigeration machine under real

operating conditions

Stream

1

2

3

4

W

0a

6 = 0a

7

8

9

0a

a

Material

stream

(kg/s)

T

( C)

p

(bars)

h

(kJ/kg)

s

(kJ/kg K)

ePH

(kJ/kg)

Ammonia

Ammonia

Ammonia

Ammonia

0.0454

0.0454

0.0454

0.0454

15

115

30

15

2.36

11.67

11.67

2.36

1444

1716

341.6

341.6

5.827

5.934

1.488

1.557

126.3

366.8

296.1

275.8

Ammonia

Water

Water

Air

Air

Air

2.98

2.98

9.94

9.94

1536

83.93

104.8

273.3

268.3

293.4

6.572

0.296

0.367

6.776

6.757

6.847

20

20

25

0

5

20

1

1

1

1

1

1

0

0

0.176

0.719

1.138

0

cPH

(/GJ)

66.69

66.43

66.30

71.35

27.78

0

580.6

0

84.73

0 is the reference point for calculating the exergy value of each material stream.

Table 15.2 shows the exergy rates associated with fuel, product, and exergydestruction as well as the exergetic efficiency and the exergy-destruction ratio for

each component and for the overall refrigeration machine. The results in Table 15.2

indicate that the condenser and the evaporator have the highest exergy-destruction

ratios and the lowest exergetic efficiencies. According to these results, the efforts to

improve the thermodynamic efficiency of the refrigeration machine should focus on

these two components.

15.4 Economic Analysis

The cost of the final products is one of the most important factors affecting the

selection of an option for the design or operation of an energy-conversion system.

The cost of a product is the amount of money paid to acquire or produce it. The

market price of a product is, in general, affected not only by the production cost of

the product and the desired profit but also by other factors, such as demand, supply,

competition, regulation, and subsidies. Exergoeconomics deals with costs.

The annual total revenue requirement (total product cost) for a system is the

revenue that must be collected in a given year through the sale of all products generated by this system to compensate the system operating company for all expenditures

Table 15.2. Conventional exergetic analysis for the vapor-compression

refrigeration machine

Component

E F,k (kW)

E P,k (kW)

E D,k (kW)

k (%)

yk (%)

CM

CD

TV

EV

Overall system

12.340

3.206

7.953

6.778

12.340

10.912

0.525

7.028

4.158

4.158

1.428

2.681

0.925

2.620

7.653

88.43

16.39

88.37

61.35

33.70

11.57

21.73

7.50

21.24

62.0

Potrebbero piacerti anche

- Presentation 1Documento8 paginePresentation 1chandrima das100% (1)

- Thermosyphon Oil Cooling Demonstration Projec1Documento1 paginaThermosyphon Oil Cooling Demonstration Projec1Raúl RiveraNessuna valutazione finora

- Baath Arab Socialist Party - Constitution (Approved in 1947)Documento9 pagineBaath Arab Socialist Party - Constitution (Approved in 1947)Antonio de OdilonNessuna valutazione finora

- Technical Papers: 34th Annual Meeting International Institute of Ammonia RefrigerationDocumento40 pagineTechnical Papers: 34th Annual Meeting International Institute of Ammonia Refrigerationrohitkb09Nessuna valutazione finora

- Vapour Absorption Machine Basics PresentationDocumento16 pagineVapour Absorption Machine Basics PresentationAyub GNNessuna valutazione finora

- Ammonia Application, Thermosyphon Cooling & Other Refrigeration Developments - PHDocumento10 pagineAmmonia Application, Thermosyphon Cooling & Other Refrigeration Developments - PHVee SundarNessuna valutazione finora

- IIAR Ammonia Refrigeration Piping HandbookDocumento5 pagineIIAR Ammonia Refrigeration Piping HandbookALFONSO THAWENessuna valutazione finora

- HR Recruiter Interview Question & AnswerDocumento6 pagineHR Recruiter Interview Question & AnswerGurukrushna PatnaikNessuna valutazione finora

- Accounting TheoryDocumento192 pagineAccounting TheoryABDULLAH MOHAMMEDNessuna valutazione finora

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationDa EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationNessuna valutazione finora

- Ammonia Incident Profile in BrazilDocumento20 pagineAmmonia Incident Profile in BrazilAUTHERMIC HVAC&R Climatização e RefrigeraçãoNessuna valutazione finora

- Overall Heat Transfer Coefficient and Pipe Length CalculationDocumento2 pagineOverall Heat Transfer Coefficient and Pipe Length CalculationCaleb FalcoteloNessuna valutazione finora

- Danfoss Co2 dRZ0ZR102Documento16 pagineDanfoss Co2 dRZ0ZR102Denis Alfafrio GotNessuna valutazione finora

- Liquid Recirculation System-2Documento7 pagineLiquid Recirculation System-2Behnam AshouriNessuna valutazione finora

- Hydrocarbons As Refrigerants in Small Heat Pump and RefrigerationDocumento12 pagineHydrocarbons As Refrigerants in Small Heat Pump and RefrigerationGiovanniCuocoNessuna valutazione finora

- NHsoft VPDocumento5 pagineNHsoft VPBASEM NOMAN ALI MOHAMMEDNessuna valutazione finora

- BAC Evaporative CondensersDocumento12 pagineBAC Evaporative CondensersKONARASKI1982Nessuna valutazione finora

- Optimizing Hot Gas DefrostDocumento9 pagineOptimizing Hot Gas DefrostHoàngViệtAnhNessuna valutazione finora

- Non-Electrical Auto-Purger (NEAP) : Operator Installation & Instruction ManualDocumento8 pagineNon-Electrical Auto-Purger (NEAP) : Operator Installation & Instruction ManualfriguzNessuna valutazione finora

- Pur-15-02 - Air Purger Type PurDocumento4 paginePur-15-02 - Air Purger Type PurAnderson Giovanny Herrera DelgadoNessuna valutazione finora

- Performance Analysis of Plate Heat Exchangers Used As Refrigerant EvaporatorsDocumento295 paginePerformance Analysis of Plate Heat Exchangers Used As Refrigerant EvaporatorskarthikeyanNessuna valutazione finora

- Air Purger (CPA-10) - Cool PartnersDocumento3 pagineAir Purger (CPA-10) - Cool PartnersMohammad AmerNessuna valutazione finora

- Honeywell CS10XE Evaporative Air Cooler English - Instructions - ManualDocumento21 pagineHoneywell CS10XE Evaporative Air Cooler English - Instructions - Manualaljh71100% (2)

- Boiler SelectionDocumento7 pagineBoiler SelectionOndRechTacLetMovNessuna valutazione finora

- Hetland Lynum Santen GarveriDocumento16 pagineHetland Lynum Santen GarveriMarco Bruto HorseshoeNessuna valutazione finora

- Effect of Flash Gas Bypass On Performance of VCR SystemDocumento4 pagineEffect of Flash Gas Bypass On Performance of VCR SystemesatjournalsNessuna valutazione finora

- A Review of Absorption RefrigerationDocumento30 pagineA Review of Absorption RefrigerationSoni Rodríguez Castellanos100% (1)

- Condensers Control and Reclaim VOCsDocumento3 pagineCondensers Control and Reclaim VOCsgpcshfNessuna valutazione finora

- The Definitive Guide To Cryogenic EngineeringDocumento21 pagineThe Definitive Guide To Cryogenic EngineeringSamanthaPereraNessuna valutazione finora

- 070.450-IOM XJF 2013-11 Rev 2022-03Documento38 pagine070.450-IOM XJF 2013-11 Rev 2022-03Mohamed HeshamNessuna valutazione finora

- Τιμοκαταλογοσ Price ListDocumento108 pagineΤιμοκαταλογοσ Price ListBambas FrostNessuna valutazione finora

- Refrigeration and Air Conditioning: Lab ManualDocumento48 pagineRefrigeration and Air Conditioning: Lab ManualcaxxvadgvadgfsNessuna valutazione finora

- 5 Condensers & EvaporatorDocumento6 pagine5 Condensers & EvaporatorMohammedSafuvanKazhungilNessuna valutazione finora

- Installation and Use GuideDocumento17 pagineInstallation and Use GuideNc NikNessuna valutazione finora

- Technical Information: C S ™ D S R CDocumento17 pagineTechnical Information: C S ™ D S R Cfrigoremont100% (1)

- Head Pressure RefrigerationDocumento6 pagineHead Pressure RefrigerationGeorge MavromatidisNessuna valutazione finora

- Parker Oil Cross ReferenceDocumento3 pagineParker Oil Cross ReferenceWarwick HolthamNessuna valutazione finora

- Selection of Capillary Tube For Refrigeration SystemDocumento4 pagineSelection of Capillary Tube For Refrigeration SystemInternational Journal of Engineering Inventions (IJEI)100% (2)

- 1.0 Chiller UnitDocumento12 pagine1.0 Chiller UnitfebousNessuna valutazione finora

- Thermodynamic Analysis of Vapor Absorption Refrigeration System and Calculation of COPDocumento8 pagineThermodynamic Analysis of Vapor Absorption Refrigeration System and Calculation of COPEver Ospino MeloNessuna valutazione finora

- Carnot Refrigeration CycleDocumento11 pagineCarnot Refrigeration CycleZaimNessuna valutazione finora

- ScrewCompressors XRV204 SpecSheet DigitalDocumento1 paginaScrewCompressors XRV204 SpecSheet DigitalBarros Arias EnriqueNessuna valutazione finora

- Implementation of Hot Gas Bypass For RefrigerationDocumento5 pagineImplementation of Hot Gas Bypass For RefrigerationhurshawNessuna valutazione finora

- Khan 2000Documento18 pagineKhan 2000HIMANSHU YADAVNessuna valutazione finora

- Distillation Dynamics and Control Workbook 2006 PDFDocumento18 pagineDistillation Dynamics and Control Workbook 2006 PDFEr Mayur PatilNessuna valutazione finora

- S 3 Lab VentilationDocumento5 pagineS 3 Lab VentilationElena JavierNessuna valutazione finora

- NH3 Guidance EPADocumento27 pagineNH3 Guidance EPAtfbennett100% (1)

- Air Purger & Ammonia PurifierDocumento22 pagineAir Purger & Ammonia PurifierJulius Wahyu AgungNessuna valutazione finora

- API Standard 520 - Sizing, Selection, & Installation of Pressure Relieving Devices Part I, Sizing & SelectionDocumento5 pagineAPI Standard 520 - Sizing, Selection, & Installation of Pressure Relieving Devices Part I, Sizing & SelectionEmilia CarazzoNessuna valutazione finora

- Trane ENL Ice Storage DesignDocumento75 pagineTrane ENL Ice Storage DesignblindjaxxNessuna valutazione finora

- 52-57 - Engineer's Notebook - Nall PDFDocumento5 pagine52-57 - Engineer's Notebook - Nall PDFAnonymous 9pKSMxb8Nessuna valutazione finora

- Sab87 Sab81 2stage Nh3Documento2 pagineSab87 Sab81 2stage Nh3Yutt WattNessuna valutazione finora

- Refrigeration LoadDocumento33 pagineRefrigeration LoadMelody Ermita RayosoNessuna valutazione finora

- Refrigeration Liquid Recirculation SystemsDocumento7 pagineRefrigeration Liquid Recirculation Systemsgoodspeed_phNessuna valutazione finora

- Cascade Refrigeration System "For Blood Storage"Documento4 pagineCascade Refrigeration System "For Blood Storage"International Journal of Innovative Science and Research TechnologyNessuna valutazione finora

- 3089.045 / Set C - Overhaul Set - SAB 283 S/L: Part No Designation Qty. Pos No. Item ImageDocumento3 pagine3089.045 / Set C - Overhaul Set - SAB 283 S/L: Part No Designation Qty. Pos No. Item ImageKevin ViaudNessuna valutazione finora

- Progress in Refrigeration Science and Technology: Proceedings of the XIth International Congress of Refrigeration, Munich, 1963Da EverandProgress in Refrigeration Science and Technology: Proceedings of the XIth International Congress of Refrigeration, Munich, 1963Nessuna valutazione finora

- Statistics for Process Control Engineers: A Practical ApproachDa EverandStatistics for Process Control Engineers: A Practical ApproachNessuna valutazione finora

- Chemical Reactor Design, Optimization, and ScaleupDa EverandChemical Reactor Design, Optimization, and ScaleupNessuna valutazione finora

- Determination of Toxic Organic Chemicals In Natural Waters, Sediments and Soils: Determination and AnalysisDa EverandDetermination of Toxic Organic Chemicals In Natural Waters, Sediments and Soils: Determination and AnalysisValutazione: 3 su 5 stelle3/5 (1)

- Dynamic Programming in Chemical Engineering and Process Control by Sanford M RobertsDa EverandDynamic Programming in Chemical Engineering and Process Control by Sanford M RobertsNessuna valutazione finora

- Lolita Enrico Vs Heirs of Spouses Eulogio Medinaceli and Trinidad MedinaceliDocumento3 pagineLolita Enrico Vs Heirs of Spouses Eulogio Medinaceli and Trinidad Medinacelichatmche-06Nessuna valutazione finora

- CH 2 & CH 3 John R. Schermerhorn - Management-Wiley (2020)Documento9 pagineCH 2 & CH 3 John R. Schermerhorn - Management-Wiley (2020)Muhammad Fariz IbrahimNessuna valutazione finora

- Week 4 CasesDocumento38 pagineWeek 4 CasesJANNNessuna valutazione finora

- NB-CPD IR 4r1 - Guidance For SGs On Their Role and Working MethodsDocumento19 pagineNB-CPD IR 4r1 - Guidance For SGs On Their Role and Working MethodsmingulNessuna valutazione finora

- Social Contract Theory - Internet Encyclopedia of PhilosophyDocumento28 pagineSocial Contract Theory - Internet Encyclopedia of Philosophywolf1804100% (1)

- Introduction To Biostatistics KMPK 2023Documento46 pagineIntroduction To Biostatistics KMPK 2023ciciNessuna valutazione finora

- Post-Stroke Rehabilitation: Kazan State Medical UniversityDocumento11 paginePost-Stroke Rehabilitation: Kazan State Medical UniversityAigulNessuna valutazione finora

- Classroom Management PaperDocumento7 pagineClassroom Management PaperdessyutamiNessuna valutazione finora

- Roman Catholic of Aklan Vs Mun of Aklan FULL TEXTDocumento33 pagineRoman Catholic of Aklan Vs Mun of Aklan FULL TEXTDessa Ruth ReyesNessuna valutazione finora

- English Preparation Guide DAF 202306Documento12 pagineEnglish Preparation Guide DAF 202306TIexamesNessuna valutazione finora

- Timing Light Schematic or DiagramDocumento2 pagineTiming Light Schematic or Diagramprihharmanto antokNessuna valutazione finora

- Deception With GraphsDocumento7 pagineDeception With GraphsTanmay MaityNessuna valutazione finora

- 7A Detailed Lesson Plan in Health 7 I. Content Standard: Teacher's Activity Students' ActivityDocumento10 pagine7A Detailed Lesson Plan in Health 7 I. Content Standard: Teacher's Activity Students' ActivityLeizel C. LeonidoNessuna valutazione finora

- Sample Opposition To Motion To Alter or Amend Judgment in United States District CourtDocumento3 pagineSample Opposition To Motion To Alter or Amend Judgment in United States District CourtStan BurmanNessuna valutazione finora

- Kepimpinan BerwawasanDocumento18 pagineKepimpinan BerwawasanandrewanumNessuna valutazione finora

- Diplomatic Quarter New Marriott Hotel & Executive ApartmentsDocumento1 paginaDiplomatic Quarter New Marriott Hotel & Executive Apartmentsconsultnadeem70Nessuna valutazione finora

- A Week in My CountryDocumento2 pagineA Week in My CountryAQhuewulland Youngprincess HokageNarutoNessuna valutazione finora

- Electronic Check ProcessingDocumento1 paginaElectronic Check Processingaaes2Nessuna valutazione finora

- Superscope, Inc. v. Brookline Corp., Etc., Robert E. Lockwood, 715 F.2d 701, 1st Cir. (1983)Documento3 pagineSuperscope, Inc. v. Brookline Corp., Etc., Robert E. Lockwood, 715 F.2d 701, 1st Cir. (1983)Scribd Government DocsNessuna valutazione finora

- Ant Colony AlgorithmDocumento11 pagineAnt Colony Algorithmjaved765Nessuna valutazione finora

- Oscar Characterization TemplateDocumento3 pagineOscar Characterization Templatemqs786Nessuna valutazione finora

- Eco - Module 1 - Unit 3Documento8 pagineEco - Module 1 - Unit 3Kartik PuranikNessuna valutazione finora

- Satya Prakash Tucker Chief Secretary To GovernmentDocumento1 paginaSatya Prakash Tucker Chief Secretary To Governmentmass1984Nessuna valutazione finora

- Reflection (The We Entrepreneur)Documento2 pagineReflection (The We Entrepreneur)Marklein DumangengNessuna valutazione finora

- Iml601 Week 4 AbsDocumento69 pagineIml601 Week 4 AbsNur Nazurah NordinNessuna valutazione finora

- Design and Implementation of Computerized Hospital Database MNT SystemDocumento13 pagineDesign and Implementation of Computerized Hospital Database MNT SystemOgidiolu Temitope EbenezerNessuna valutazione finora