Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Is 1838 3 2011 PDF

Caricato da

jaianit89Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Is 1838 3 2011 PDF

Caricato da

jaianit89Copyright:

Formati disponibili

Disclosure to Promote the Right To Information

Whereas the Parliament of India has set out to provide a practical regime of right to

information for citizens to secure access to information under the control of public authorities,

in order to promote transparency and accountability in the working of every public authority,

and whereas the attached publication of the Bureau of Indian Standards is of particular interest

to the public, particularly disadvantaged communities and those engaged in the pursuit of

education and knowledge, the attached public safety standard is made available to promote the

timely dissemination of this information in an accurate manner to the public.

1 +, 1 +

01 ' 5

The Right to Information, The Right to Live

Step Out From the Old to the New

Mazdoor Kisan Shakti Sangathan

Jawaharlal Nehru

IS 1838-3 (2011): Preformed Fillers for Expansion Joints in

Concrete Pavements and Structures(non-extruding and

resilient type) Part 3 Polymer Based [CED 13: Building

Construction Practices including Painting, Varnishing and

Allied Finishing]

! $ ' +-

Satyanarayan Gangaram Pitroda

Invent a New India Using Knowledge

! > 0 B

BharthariNtiatakam

Knowledge is such a treasure which cannot be stolen

IS 1838 (Part 3) : 2011

Hkkjrh; ekud

dahV iVjh o lajpukvksa ukWu ,DlVwfMax o jst+hfy;sUV

dkj dh ds fy, igys ls rS;kj Hkj.k lkexzh fof'kf"V

Hkkx

ikWfyej vkkkfjr

Indian Standard

PREFORMED FILLERS FOR EXPANSION JOINTS IN

CONCRETE PAVEMENTS AND STRUCTURES

(NON-EXTRUDING AND RESILIENT TYPE)

SPECIFICATION

PART 3 POLYMER BASED

ICS 91.100.10

BIS 2011

BUREAU OF INDIAN STANDARDS

MANAK BHAVAN, 9 BAHADUR SHAH ZAFAR MARG

NEW DELHI 110002

December 2011

Price Group 3

Building Construction Practices Sectional Committee, CED 13

FOREWORD

This Indian Standard (Part 3) was adopted by the Bureau of Indian Standards, after the draft finalized by the

Building Construction Practices Sectional Committee had been approved by the Civil Engineering Division

Council.

Joints are required in concrete pavements, roads, runways, floor and roof slabs in buildings to relieve stresses

developed due to temperature shrinkage, creep, relaxation, vibration, etc. To provide an even surface these joints

must be filled and at the same time the materials used for filling should permit expansion and contraction of the

concrete member. The joint filler is a strip of compressible material used to form and fill the expansion joints in

structures. The chief function of the joint filler is to permit the joint to expand without developing stresses. Joint

filler are produced from a variety of materials such as bitumen impregnated fibre, cork strips, sponge or synthetic

rubber, expanded plastics, epoxy, coconut pith and CNSL resin.

To make the joints effective it is also necessary to prevent the ingress of water or grit down the joint. This is

achieved by using a sealing compound over the joint filler. The requirement for sealing compounds and methods

of installation of joints has been covered separately in IS 1834 : 1984 Specification for hot applied sealing

compound for joints in concrete (first revision), IS 3414 : 1968 Code of practice for design and installation of

joints in buildings, IS 6509 : 1985 Code of practice for installation of joints in concrete pavements (first revision),

IS 11433 (Part 1) : 1985 Specification for one-part gun-grade polysulphide-based joints sealants: Part 1 General

requirements and IS 12118 (Part 1) : 1987 Specification for two parts polysulphide based sealants: Part 1

General requirements.

This standard is published in three parts. Other parts are:

Part 1 Bitumen impregnated fibre

Part 2 CNSL aldehyde resin and coconut pith

This standard has been published to cover the requirements for polymer based filler type of expansion joint

fillers.

The composition of the Committee responsible for the formulation of this standard is given at Annex B.

For the purpose of deciding whether a particular requirement of this standard is complied with the final value,

observed or calculated, expressing the results of a test or analysis, shall be rounded off in accordance with

IS 2 : 1960 Rules for rounding off numerical values (revised). The number of significant places retained in the

rounded off value should be the same as that of the specified value in this standard.

IS 1838 (Part 3) : 2011

Indian Standard

PREFORMED FILLERS FOR EXPANSION JOINTS IN

CONCRETE PAVEMENTS AND STRUCTURES

(NON-EXTRUDING AND RESILIENT TYPE)

SPECIFICATION

PART 3 POLYMER BASED

1 SCOPE

Length

Width

Thickness

1.1 This standard (Part 3) specifies the requirements

for polymer based fillers for expansion joints.

1.1.1 The fillers may be used for filling expansion joints

such as in buildings, concrete pavements and other

structures.

: 1 800 mm, 2 200 mm

: 900 mm, 1 100 mm

: 8 mm, Min

: 50 mm, Max

Alternatively, the dimensions of the preformed strips

shall be mutually agreed between the purchaser and

the manufacturer. For dimensional measurements, a

reference may be made to IS 10566.

2 REFERENCES

The following standards contain provisions which

through reference in this text, constitute provisions of

this standard. At the time of publication, the editions

indicated were valid. All standards are subject to

revision and parties to agreement based on this standard

are encouraged to investigate the possibility of applying

the most recent editions of the standards indicated

below:

5.2 Tolerance

The tolerance on the average dimensions shall be as

given below:

On length

: + 5 mm

On width

: + 3 mm

On thickness : + 1.5 mm

IS No.

10566 : 1983

Title

Methods of tests for preformed fillers

for expansion joints in concrete

paving and structural construction

12118 (Part 1) : Specification for two parts poly1987

sulphide based sealants: Part 1

General requirements

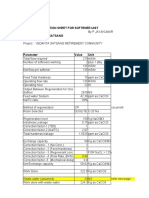

6 PHYSICAL REQUIREMENTS

The physical requirement of the fillers shall conform

to col 3 of Table 1 when tested in accordance with the

method specified in IS 10566.

7 INSTALLATION

For general guidance in installing the preformed fillers,

the provisions in Annex A may be referred.

3 MATERIAL

8 PACKING

The material used shall be pre-moulded cross-linked

polymers that are non-absorbent, non-staining, nondeteriorating, closed-cell and compressible in nature

and may undergo stretching.

The performed joint fillers shall be packed in such a

manner that there shall be no distortion or breakage of

the fillers or deterioration of their properties during

transportation.

4 MANUFACTURE

9 MARKING

The materials shall be suitably polymerized to obtain

fillers for appropriate use conforming to the

requirements laid down in this standard.

9.1 The packages shall be marked with the

manufacturers name or trade-mark, if any, dimensions

and type of filler.

5 DIMENSIONS AND TOLERANCES

5.1 Dimensions

9.2 BIS Certification Marking

Typical dimensions of individual filler member are as

follows:

Each package may also be marked with the Standard

Mark.

1

IS 1838 (Part 3) : 2011

Table 1 Physical Requirements of Fillers

(Clause 6)

9.2.1 The use of the Standard Mark is governed by the

provisions of the Bureau of Indian Standards Act, 1986

and the Rules and Regulations made thereunder. The

details of conditions under which the licence for the

use of the Standard Mark may be granted to

manufacturers or producers may be obtained from the

Bureau of Indian Standards.

The sampling shall be done at random.

10.2 Size of Sample

Each sample shall consist of sufficient material so that

five test pieces measuring 100 mm 100 mm could be

obtained.

10.3 Tests

10 SAMPLING

All the test pieces as selected in 10.2 shall be subjected

to dimensional and physical requirements. The lot shall

be accepted, if all the five test pieces meet the physical

and dimensional requirements; otherwise not.

10.1 Number of Samples

One representative sample shall be selected from each

lot of 100 m2 of the material having same thickness.

ANNEX A

(Clause 7)

TYPICAL LAYING PROCEDURE

A-1.2 When forming expansion joint with the polymer

A-1 LAYING PROCEDURE

based filler in cast-in-situ concrete, joint sealing slots

A-1.1 Expansion joints are full depth joints provided

are to be formed in the following manner:

transversely in concrete pavements and also between

a) Shape of the field moulded sealant is

structural members of a structure like slabs, beams and

important as it is subjected to compression

columns, etc to allow their expansion and contraction

and tension during expansion and contraction

without stressing them. The cross-linked closed cell

phases of concrete members. The sealants

polymer filler may be used as shuttering on one side

which are solid at service temperatures are

of the expansion joint by abutting with the already cast

likely to change in their shape when subjected

RCC member and fixed in proper position by using

to varying temperatures and humidity, but

double sided adhesive tape or synthetic rubber adhesive

their volume will remain same. The shape of

as per manufacturers recommendations. Both open

the sealant is important as strains developed

ends of the polyethylene filler (already fixed on

in them during expansion and contraction

exposed face of structural member) shall be restrained

should not exceed the permissible limit

and kept in position with the normal shuttering

recommended by the manufacturers. In all the

materials as per the manufacturers recommendations.

2

IS 1838 (Part 3) : 2011

cases, width and total depth of expansion joint

is always known but only depth of the sealant

is to be worked out which varies depending

on the location and its environmental

conditions like temperature and humidity etc,

around the place. For further details on

sealants, see IS 12118 (Part 1).

b) For cast-in-situ concrete work in respect of

concrete pavements as well as structures, the

polymer based filler board is used in

expansion joint as one side shuttering for the

entire depth of concrete. To enable application

of sealant in the expansion joint groove, the

filler board has to be cut according to

requirements and removed upto the sealant

depth. In order to achieve this requirement,

the filler board provided for the entire depth,

is cut up-to sealant depth D for the entire

length and further subdivided into two or

more lengths as per site requirements and

convenience, before concreting of the

adjoining panel. This cut top strip is pinned

back on to the bottom strip using nails at twoinch intervals or as per recommendations of

the manufacturers, after ensuring that the slot

is clean and dry. Also install a strip of filler

material on top of the filler, flush with the

finished surface using either a tape/synthetic

rubber based adhesive. This top strip shall

remain in this position till completion of

concreting (including water curing and drying

the concrete surface completely) in adjoining

panel, before application of sealants in the

joint groove. This top strip shall however be

removed at the time application of sealants in

the expansion joint groove (see Fig.1).

A-1.3 The filler material may also be used as shuttering

on one side the expansion joint by abutting with the

already cast member. To hold the two free sides of

shuttering, suitable MS bolts both threaded sides may

be used at every regular interval (say 1 m) and secured

with concrete using appropriate nuts. These bolts shall

be taken out later and the hole grouted with suitable

cement mortar (see Fig. 2)

FIG. 1 TYPICAL INSTALLATION DETAILS Continued

IS 1838 (Part 3) : 2011

Step 3 Complete Expansion Joint Treatment

for Horizontal Surface (Floor)

Step 4 Complete Expansion Joint Treatment

for Vertical Surface (Wall)

FIG. 1 TYPICAL INSTALLATION DETAILS

FIG. 2 TYPICAL LAYOUT

OF

USE

OF

PREFORMED POLYMER B ASED F ILLER

4

AS

SHUTTERING

TO

COLUMN M EMBER

IS 1838 (Part 3) : 2011

ANNEX B

(Foreword)

COMMITTEE COMPOSITION

Building Construction Practices Sectional Committee, CED 13

Organization

Representative(s)

In personal capacity (Flat No. 2061, Engineers Apartments,

Plot No. 11, Sector 18A, Dwarka, New Delhi 110078)

SHRI D. S. SACHDEV (Chairman)

Ahluwalia Contracts (India) Limited, New Delhi

SHRI SHOBHIT UPPAL

SHRI VINAY PAL (Alternate)

Bhabha Atomic Research Centre, Mumbai

SHRI K. SRINIVAS

SHRI H. E. IYER (Alternate)

Building Materials & Technology Promotion Council,

New Delhi

SHRI J. K. P RASAD

SHRI S. K. GUPTA (Alternate)

Central Building Research Institute, Roorkee

SHRI S. G. DAVE

SHRI R. K. GARG (Alternate)

Central Public Works Department, CDO, New Delhi

CHIEF ENGINEER (CDO)

SUPERINTENDING E NGINEER (D) II (Alternate)

Central Public Works Department, CSQ, New Delhi

SHRI VIRENDRA S HARMA

SHRI MaYANK K. TILAK (Alternate)

Confederation of Construction Products and Services,

New Delhi

SHRI DEEPAK GAHLOWT

SHRI SHASHI KANT (Alternate)

Construction Industry Development Council, New Delhi

SHRI P. R. SWARUP

Delhi Development Authority, New Delhi

CHIEF ENGINEER (SWZ)

SUPERINTENDING ENGINEER (P) (SWZ) (Alternate)

Engineers India Limited, New Delhi

SHRI SUDHIR CHATURVEDI

SHRI RAVINDRA KUMAR (Alternate)

Fly Ash Unit, Department of Science & Technology, New Delhi

DR VIMAL KUMAR

Forest Research Institute, Dehra Dun

DR V. S. KISHAN KUMAR

Housing & Urban Development Construction Corporation,

New Delhi

SHRIMATI M ANORAMA DUTTA

SHRIMATI MANJU SAFAYA (Alternate)

Indian Buildings Congress, New Delhi

SHRI S. C. BHATIA

SHRI P. S. CHADHA (Alternate)

Indian Glass Manufacturers Association, New Delhi

SHRI ALOK MODI

SHRI SANJAY LABROO (Alternate)

Indian Plywood Industries Research & Training Institute,

Bangalore

SHRI JAGADISH VENGALA

SHRI AMITAVA SIL (Alternate)

Metallizing Equipment Co Pvt Limited, Jodhpur

SHRI S. C. MODI

SHRI ANKUR MODI (Alternate)

Military Engineering Services, Engineer-in-Chiefs Branch,

New Delhi

SHRI JAGDEV THAKUR

SHRI KUSHAL YADAV (Alternate)

National Buildings Construction Corporation, New Delhi

SHRI AMITABHA BASU

SHRI RAJIV TYAGI (Alternate)

North East Institute of Science and Technology (CSIR), Jorhat

DR S. D. BARUAH

SHRI AMITAVA BISWAS (Alternate)

NTPC Ltd, New Delhi

SHRI R. L. DAS

SHRI ANIL K APOOR (Alternate)

Pest Control (India) Pvt Ltd, Mumbai

SHRI SHANKAR M. GHUGE

SHRI P. N. NOWROJEE (Alternate)

Public Works Department, Government of NCT of Delhi, New Delhi

SHRI A. K. SINHA

SHRI PUNEET KUMAR VATS (Alternate)

Research, Designs and Standards Organization, Ministry of

Railways, Lucknow

SHRI PRABHAT KUMAR

SHRI ASHUTOSH KUMAR (Alternate)

IS 1838 (Part 3) : 2011

Organization

Representative(s)

School of Planning & Architecture, New Delhi

PROF S. K. KHANNA

PROF M. L. BAHRI (Alternate)

Structural Engineering Research Centre (CSIR), Chennai

DR NAGESH R. I YER

SHRI P. SRINIVASAN (Alternate)

The Indian Institute of Architects, Mumbai

SHRI VIJAY GARG

SHRI SHAMIT MANCHANDA (Alternate)

The Institution of Engineers (India), Kolkata

SHRI P. K. ADLAKHA

SHRI DEVENDRA G ILL (Alternate)

In personal capacity (Pratap Nursery Lane, Panditwari,

Dehra Dun 248007)

SHRI K. S. PRUTHI

BIS Directorate General

SHRI A. K. SAINI, Scientist F & Head (Civ Engg)

[Representing Director General (Ex-officio)]

Member Secretary

SHRI S. ARUN KUMAR

Scientist C (Civ Engg), BIS

Bureau of Indian Standards

BIS is a statutory institution established under the Bureau of Indian Standards Act, 1986 to promote

harmonious development of the activities of standardization, marking and quality certification of goods

and attending to connected matters in the country.

Copyright

BIS has the copyright of all its publications. No part of these publications may be reproduced in any form

without the prior permission in writing of BIS. This does not preclude the free use, in the course of

implementing the standard, of necessary details, such as symbols and sizes, type or grade designations.

Enquiries relating to copyright be addressed to the Director (Publications), BIS.

Review of Indian Standards

Amendments are issued to standards as the need arises on the basis of comments. Standards are also reviewed

periodically; a standard along with amendments is reaffirmed when such review indicates that no changes are

needed; if the review indicates that changes are needed, it is taken up for revision. Users of Indian Standards

should ascertain that they are in possession of the latest amendments or edition by referring to the latest issue of

BIS Catalogue and Standards : Monthly Additions.

This Indian Standard has been developed from Doc No.: CED 13 (7733).

Amendments Issued Since Publication

Amend No.

Date of Issue

Text Affected

BUREAU OF INDIAN STANDARDS

Headquarters:

Manak Bhavan, 9 Bahadur Shah Zafar Marg, New Delhi 110 002

Telephones : 2323 0131, 2323 3375, 2323 9402

Website: www.bis.org.in

Regional Offices:

Central

: Manak Bhavan, 9 Bahadur Shah Zafar Marg

NEW DELHI 110002

Eastern

: 1/14 C.I.T. Scheme VII M, V. I. P. Road, Kankurgachi

KOLKATA 700054

Telephones

2323 7617

2323 3841

Northern : SCO 335-336, Sector 34-A, CHANDIGARH 160022

Southern : C.I.T. Campus, IV Cross Road, CHENNAI 600113

Western

Branches:

: Manakalaya, E9 MIDC, Marol, Andheri (East)

MUMBAI 400093

2337 8499, 2337 8561

2337 8626, 2337 9120

60 3843

60 9285

{

{

2254 1216, 2254 1442

2254 2519, 2254 2315

2832 9295, 2832 7858

2832 7891, 2832 7892

AHMEDABAD. BANGALORE. BHOPAL. BHUBANESHWAR. COIMBATORE. DEHRADUN.

FARIDABAD. GHAZIABAD. GUWAHATI. HYDERABAD. JAIPUR. KANPUR. LUCKNOW.

NAGPUR. PARWANOO. PATNA. PUNE. RAJKOT. THIRUVANANTHAPURAM.

VISAKHAPATNAM.

Published by BIS, New Delhi

Potrebbero piacerti anche

- MEP DatabookDocumento668 pagineMEP Databookjaianit8986% (7)

- Material Specifications: Low Carbon Steel, Hot Rolled PlateDocumento6 pagineMaterial Specifications: Low Carbon Steel, Hot Rolled PlatetimNessuna valutazione finora

- Fire Hydrant System Design Installation Commisioning and TestingDocumento5 pagineFire Hydrant System Design Installation Commisioning and Testingjaianit89Nessuna valutazione finora

- AltaLink8090 Family SMDocumento1.817 pagineAltaLink8090 Family SMjannnu_sbNessuna valutazione finora

- Astm C 171 2007Documento2 pagineAstm C 171 2007sabruno100% (3)

- Indian Standard Is 456 2000 COMPILEDDocumento61 pagineIndian Standard Is 456 2000 COMPILEDKalasekar M Swamy79% (14)

- BS 6464 1984 Reinforced Plastics Pipes Fittings and Joints For Process Plants PDFDocumento60 pagineBS 6464 1984 Reinforced Plastics Pipes Fittings and Joints For Process Plants PDFDavid FonsecaNessuna valutazione finora

- Reinforced Concrete Buildings: Behavior and DesignDa EverandReinforced Concrete Buildings: Behavior and DesignValutazione: 5 su 5 stelle5/5 (1)

- Water Softner Design VedantaDocumento5 pagineWater Softner Design Vedantajaianit89Nessuna valutazione finora

- Catalog WiperDocumento24 pagineCatalog WiperRicardo RivasNessuna valutazione finora

- Is 11158 1984 ISO 7083 1983 Proportions and Dimensions of Symbols For Geometrical Tolerancing Used in Technical DrawingsDocumento10 pagineIs 11158 1984 ISO 7083 1983 Proportions and Dimensions of Symbols For Geometrical Tolerancing Used in Technical DrawingsleovenuNessuna valutazione finora

- Specification of ConcreteDocumento64 pagineSpecification of ConcreteMelinda Gordon75% (4)

- Is 1838 3 2011 PDFDocumento12 pagineIs 1838 3 2011 PDFAjit P. SinghNessuna valutazione finora

- Disclosure To Promote The Right To InformationDocumento20 pagineDisclosure To Promote The Right To InformationJGD123Nessuna valutazione finora

- Is 4990 2011 PDFDocumento20 pagineIs 4990 2011 PDFPratik DiyoraNessuna valutazione finora

- Is 10701 2012Documento18 pagineIs 10701 2012JGD123Nessuna valutazione finora

- Is 15466 (2004)Documento16 pagineIs 15466 (2004)slamienkaNessuna valutazione finora

- Revised Draft of Is 4990 Shuttering Ply StandardDocumento28 pagineRevised Draft of Is 4990 Shuttering Ply Standardad2100Nessuna valutazione finora

- Is 2180 1988Documento6 pagineIs 2180 1988Venugopalan ManaladikalamNessuna valutazione finora

- 14862Documento17 pagine14862Amitabha DebNessuna valutazione finora

- BS 1722 Part 4 (Chestnut Pale Fences)Documento16 pagineBS 1722 Part 4 (Chestnut Pale Fences)nandi_scrNessuna valutazione finora

- Disclosure To Promote The Right To InformationDocumento27 pagineDisclosure To Promote The Right To InformationBabin SaseendranNessuna valutazione finora

- ICC-ES Evaluation Report ESR-2218Documento12 pagineICC-ES Evaluation Report ESR-2218Mark J LeingangNessuna valutazione finora

- Wis4 35 01Documento17 pagineWis4 35 01swinousNessuna valutazione finora

- Is 3370 2 2009Documento18 pagineIs 3370 2 2009Manish AhujaNessuna valutazione finora

- BS 1521Documento11 pagineBS 1521Shameel PtNessuna valutazione finora

- Is 4253 2 2008Documento14 pagineIs 4253 2 2008Ashutosh SinghNessuna valutazione finora

- Astm d7682Documento4 pagineAstm d7682Vicki WillifordNessuna valutazione finora

- Indian Standard Is 456 2000 For Print SECTIONS 1 2 3Documento42 pagineIndian Standard Is 456 2000 For Print SECTIONS 1 2 3Kalasekar M SwamyNessuna valutazione finora

- Tarpaulins - Is 7903 - 2011Documento12 pagineTarpaulins - Is 7903 - 2011Jignesh TrivediNessuna valutazione finora

- Is 3115 - 1992 (Lime Based Blocks)Documento8 pagineIs 3115 - 1992 (Lime Based Blocks)satnam1979Nessuna valutazione finora

- IS:2201 (Part1)Documento25 pagineIS:2201 (Part1)greatpic100% (1)

- Is 654 1992 PDFDocumento14 pagineIs 654 1992 PDFmutton moonswamiNessuna valutazione finora

- BS 1881-101-Method of Sampling Fresh Concrete On SiteDocumento11 pagineBS 1881-101-Method of Sampling Fresh Concrete On SiteShazrul Nizam92% (12)

- Is 10262 2009 PDFDocumento21 pagineIs 10262 2009 PDFNatarajan NalanthNessuna valutazione finora

- Is 195 2005Documento8 pagineIs 195 2005Santosh KumarNessuna valutazione finora

- IS - 15466 - Rubber Seals For Hydraulic GatesDocumento13 pagineIS - 15466 - Rubber Seals For Hydraulic GateskiranrauniyarNessuna valutazione finora

- Particular Specifications IlcbDocumento5 pagineParticular Specifications IlcbAaron WilsonNessuna valutazione finora

- Is 15658 2006Documento27 pagineIs 15658 2006Navneet SinghNessuna valutazione finora

- Disclosure To Promote The Right To InformationDocumento22 pagineDisclosure To Promote The Right To InformationVineet SinghNessuna valutazione finora

- Spiral Wound GasketsDocumento7 pagineSpiral Wound GasketsPrem NautiyalNessuna valutazione finora

- Is 15622 2006 PDFDocumento20 pagineIs 15622 2006 PDFPatel SumitNessuna valutazione finora

- Is.1875 1992Documento14 pagineIs.1875 1992Sadashiva sahooNessuna valutazione finora

- Scotchcast Polyolefin Fibers: For Use in Wet-Mix ShotcreteDocumento2 pagineScotchcast Polyolefin Fibers: For Use in Wet-Mix Shotcretejack21abNessuna valutazione finora

- Plain and Reinforced Concrete - Code of Practice (Fourth Revision)Documento107 paginePlain and Reinforced Concrete - Code of Practice (Fourth Revision)nafees92Nessuna valutazione finora

- BS 1881-106Documento16 pagineBS 1881-106Ragu NathanNessuna valutazione finora

- Pavement Quality ConcreteDocumento9 paginePavement Quality ConcreteKG RohillaNessuna valutazione finora

- Disclosure To Promote The Right To Information: IS 9550 (2001) : Bright Steel Bars (MTD 4: Wrought Steel Products)Documento14 pagineDisclosure To Promote The Right To Information: IS 9550 (2001) : Bright Steel Bars (MTD 4: Wrought Steel Products)anand.bharadwajNessuna valutazione finora

- 10646Documento6 pagine10646Richa JainNessuna valutazione finora

- IS 4990.2011 Concrete Shuttering Ply PDFDocumento20 pagineIS 4990.2011 Concrete Shuttering Ply PDFRam BabuNessuna valutazione finora

- Is 1905 1987Documento30 pagineIs 1905 1987Arun Peru100% (1)

- 1.1 A. 1.2 A. B. C. 1.3 A. B. C. D. E. F. G. H. I.: Click HereDocumento5 pagine1.1 A. 1.2 A. B. C. 1.3 A. B. C. D. E. F. G. H. I.: Click HereRiksa AsNessuna valutazione finora

- Disclosure To Promote The Right To InformationDocumento8 pagineDisclosure To Promote The Right To InformationCst WclNessuna valutazione finora

- C1666 1207960-1Documento4 pagineC1666 1207960-1Fabio Teodoro100% (1)

- C11-Icc Er 5558Documento3 pagineC11-Icc Er 5558prufino2Nessuna valutazione finora

- D1751Documento2 pagineD1751grats_singco100% (1)

- NB 15Documento12 pagineNB 15Pinakin PatelNessuna valutazione finora

- BBA Cert For ReCo High Adherence Strip and Panel Lug System For Ret Walls & Bridge Abuts (2003)Documento8 pagineBBA Cert For ReCo High Adherence Strip and Panel Lug System For Ret Walls & Bridge Abuts (2003)sandycastleNessuna valutazione finora

- BBA Cert 12-H182 For RECo Geostrap Reinforcement For Reinforced Soil Retaining WallsDocumento12 pagineBBA Cert 12-H182 For RECo Geostrap Reinforcement For Reinforced Soil Retaining WallssandycastleNessuna valutazione finora

- IS Code.14443.1997Documento26 pagineIS Code.14443.1997selvakumarNessuna valutazione finora

- D 5168 - 03 - RduxnjgDocumento6 pagineD 5168 - 03 - Rduxnjgjamaljamal20Nessuna valutazione finora

- Elastic, Plastic and Yield Design of Reinforced StructuresDa EverandElastic, Plastic and Yield Design of Reinforced StructuresNessuna valutazione finora

- Increasing the Durability of Paint and Varnish Coatings in Building Products and ConstructionDa EverandIncreasing the Durability of Paint and Varnish Coatings in Building Products and ConstructionNessuna valutazione finora

- Polyurethanes: Science, Technology, Markets, and TrendsDa EverandPolyurethanes: Science, Technology, Markets, and TrendsValutazione: 1 su 5 stelle1/5 (1)

- Subject: Bill of Quantities - DG - MAKE OF MATERIALS SL - No Description Makes in Alphabetical OrderDocumento1 paginaSubject: Bill of Quantities - DG - MAKE OF MATERIALS SL - No Description Makes in Alphabetical Orderjaianit89Nessuna valutazione finora

- SEC 15490 Swimming PoolsDocumento8 pagineSEC 15490 Swimming Poolsjaianit89Nessuna valutazione finora

- Sun Sine Smart Solar Power Generator/ Micro Inverter - "SPG 350"Documento2 pagineSun Sine Smart Solar Power Generator/ Micro Inverter - "SPG 350"jaianit89Nessuna valutazione finora

- Pure Sine Wave Inverter: P O P ODocumento2 paginePure Sine Wave Inverter: P O P Ojaianit89Nessuna valutazione finora

- Commercial Bldg-BOQ Without RatesDocumento35 pagineCommercial Bldg-BOQ Without Ratesjaianit89Nessuna valutazione finora

- 9.cipet Boys Hoste-BoqDocumento19 pagine9.cipet Boys Hoste-Boqjaianit89Nessuna valutazione finora

- Syngineering Water MBR Vs SBR PDFDocumento5 pagineSyngineering Water MBR Vs SBR PDFjaianit89Nessuna valutazione finora

- Pie Chart Representing Segment-Wise RevenueDocumento2 paginePie Chart Representing Segment-Wise Revenuejaianit89Nessuna valutazione finora

- Checklist of Layout For Port Blair Planning Area PDFDocumento2 pagineChecklist of Layout For Port Blair Planning Area PDFjaianit89Nessuna valutazione finora

- 20150402522.electrical SLD-Model PDFDocumento1 pagina20150402522.electrical SLD-Model PDFjaianit89Nessuna valutazione finora

- Pie Chart Representing Segment-Wise RevenueDocumento2 paginePie Chart Representing Segment-Wise Revenuejaianit89Nessuna valutazione finora

- Checklist of Building Plan For Port Blair Planning Area PDFDocumento3 pagineChecklist of Building Plan For Port Blair Planning Area PDFjaianit89Nessuna valutazione finora

- TB08104003E Tab 1Documento152 pagineTB08104003E Tab 1priyanka236Nessuna valutazione finora

- Head Calculation For Sewage Transfer Pump - 19.05.2012 FinalDocumento2 pagineHead Calculation For Sewage Transfer Pump - 19.05.2012 Finaljaianit89Nessuna valutazione finora

- Documents Formalities Required For The Issuance of A B C&D Class Contractor CardsDocumento8 pagineDocuments Formalities Required For The Issuance of A B C&D Class Contractor Cardsjaianit89100% (1)

- Is 3414 1968 PDFDocumento30 pagineIs 3414 1968 PDFjaianit89100% (1)

- Time Maintenance - Log Book: RI/OR/MLB/02Documento1 paginaTime Maintenance - Log Book: RI/OR/MLB/02jaianit89Nessuna valutazione finora

- Is 278 2009 PDFDocumento11 pagineIs 278 2009 PDFjaianit89Nessuna valutazione finora

- Is 2751 1979 PDFDocumento41 pagineIs 2751 1979 PDFjaianit89Nessuna valutazione finora

- Tolerancing: Basic GuideDocumento25 pagineTolerancing: Basic GuideJenh FabularNessuna valutazione finora

- Astm B688 (1996)Documento6 pagineAstm B688 (1996)ElmerNessuna valutazione finora

- Design of Dies - Unit 5 PDFDocumento178 pagineDesign of Dies - Unit 5 PDF210 SureshNessuna valutazione finora

- SM 24HS Product Flyer 1Documento3 pagineSM 24HS Product Flyer 1Neuber JuniorNessuna valutazione finora

- Disclosure To Promote The Right To InformationDocumento9 pagineDisclosure To Promote The Right To Informationharpreet singhNessuna valutazione finora

- NewDealSeals Brochure Oil Seals 2019Documento29 pagineNewDealSeals Brochure Oil Seals 2019vamsi patnala100% (1)

- 2003 04 NewsletterDocumento4 pagine2003 04 NewslettergurugoodrichNessuna valutazione finora

- Creating The Layout in ExpressPCBDocumento21 pagineCreating The Layout in ExpressPCBmamatha_bandaruNessuna valutazione finora

- H-1000-0078-02-A Technical Specification CMM Fixtures enDocumento36 pagineH-1000-0078-02-A Technical Specification CMM Fixtures enrubenNessuna valutazione finora

- Is 1726Documento14 pagineIs 1726Santosh MhatreNessuna valutazione finora

- TAPTITEII CONTI RemincDocumento24 pagineTAPTITEII CONTI RemincguruprasadcvNessuna valutazione finora

- Control Techniques Servo MotorsDocumento56 pagineControl Techniques Servo MotorsEduardoSenciaNessuna valutazione finora

- Unc Sidekick User ManualDocumento83 pagineUnc Sidekick User ManualMilicaNessuna valutazione finora

- Scheerer Catalog 2-15Documento64 pagineScheerer Catalog 2-15José Del Orbe GarcíaNessuna valutazione finora

- Catalogo Chumaceras RHP AbleDocumento16 pagineCatalogo Chumaceras RHP AbleOzetoNessuna valutazione finora

- Astm D6297-13Documento3 pagineAstm D6297-13ten100% (3)

- Pen GunDocumento10 paginePen GunКолясиК80% (5)

- ISO 1167 4 2007, ThermoplasticsDocumento12 pagineISO 1167 4 2007, ThermoplasticsAzima Zalfa AuliyakNessuna valutazione finora

- Hot RolledDocumento16 pagineHot Rolledlbo33Nessuna valutazione finora

- SOP - 06 - Visual and Dimensional ProcedureDocumento22 pagineSOP - 06 - Visual and Dimensional ProcedureSuci YatiningtiyasNessuna valutazione finora

- Hyster P2.5-3.0Documento3 pagineHyster P2.5-3.0alkskgNessuna valutazione finora

- Is 1838 3 2011 PDFDocumento12 pagineIs 1838 3 2011 PDFjaianit89Nessuna valutazione finora

- Biréli LagrèneDocumento17 pagineBiréli LagrèneMarcos Faustino0% (1)

- 3 WL 00200-5 Ex. 23-41Documento30 pagine3 WL 00200-5 Ex. 23-41NuM NaNessuna valutazione finora

- MNL 32-2014Documento74 pagineMNL 32-2014Hassan MokhtarNessuna valutazione finora