Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Ia - Machining NC II

Caricato da

Delvin Jan del RosarioTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Ia - Machining NC II

Caricato da

Delvin Jan del RosarioCopyright:

Formati disponibili

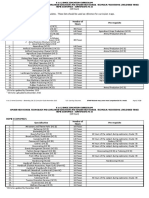

K TO 12 BASIC EDUCATION CURRICULUM

JUNIOR HIGH SCHOOL TECHNOLOGY AND LIVELIHOOD TRACK AND SENIOR HIGH SCHOOL TECHNICAL-VOCATIONAL LIVELIHOOD TRACK

INDUSTRIAL ARTS - MACHINING NC II

(640 hours)

These are the specializations and their pre-requisites. These lists should be used as reference for curriculum maps.

AGRI-FISHERY ARTS

1.

2.

3.

4.

5.

Specialization

Agricultural Crops Production (NC I)

Agricultural Crops Production (NC II)++

Agricultural Crops Production (NC III)

Animal Health Care Management (NC III)

Animal Production (NC II) +

When updated, this CG will become the following:

1. Animal Production (Poultry-Chicken) (NC II);

2. Animal Production (Ruminants) (NC II); and

3. Animal Production (Swine) (NC II)

6.

Aquaculture (NC II)

7.

Artificial Insemination (Ruminants) (NC II)

8.

Artificial Insemination (Swine) (NC II)

9.

Agricultural Crops Production (NC I)

10.

Fish Capture (NC II) ++

11.

Fishing Gear Repair and Maintenance (NC III)

12.

Fish-Products Packaging (NC II)

13.

Fish Wharf Operation (NC I)

14.

Food (Fish) Processing (NC II)

15.

Horticulture (NC II) +

16.

Horticulture (NC III)

17.

Landscape Installation and Maintenance (NC II)

18.

Organic Agriculture (NC II)

19.

Pest Management (NC II)

20.

Rice Machinery Operation (NC II)

21.

Rubber Processing (NC II)

22.

Rubber Production (NC II)

23.

Slaughtering Operation (NC II)

+

CG to be updated by December 2015

++

CG to be uploaded by December 2015

K to 12 Industrial Arts Machining (NC II) Curriculum Guide November 2015

Number of Hours

Pre-requisite

480 hours

640 hours

320 hours

Agricultural Crops Production (NC II)

Animal Production (NC II)

480 hours

640

160

160

320

640

320

320

160

640

640

640

320

320

320

320

320

320

160

hours

hours

hours

hours

hours

hours

hours

hours

hours

hours

hours

hours

hours

hours

hours

hours

hours

hours

*LO-Learning Outcomes

Animal Production (NC II)

Animal Production (NC II)

Horticulture (NC II)

Agricultural Crops Production

Agricultural Crops Production

Agricultural Crops Production

Agricultural Crops Production

(NC

(NC

(NC

(NC

I)

I)

I)

I)

Animal Production (NC II)

STVEP Schools may cover more competencies in a week

Page 1 of 18

K TO 12 BASIC EDUCATION CURRICULUM

JUNIOR HIGH SCHOOL TECHNOLOGY AND LIVELIHOOD TRACK AND SENIOR HIGH SCHOOL TECHNICAL-VOCATIONAL LIVELIHOOD TRACK

INDUSTRIAL ARTS - MACHINING NC II

(640 hours)

HOME ECONOMICS

Specialization

1.

Attractions and Theme Parks (NC II)

2.

Barbering (NC II)

3.

Bartending (NC II)

4.

Beauty/Nail Care (NC II)

5.

Bread and Pastry Production (NC II)

6.

Caregiving (NC II)

7.

Commercial Cooking (NC III)

8.

Cookery (NC II)

9.

Dressmaking (NC II)

10.

Events Management Services (NC III)

11.

Fashion Design (Apparel) (NC III)

12.

Food and Beverage Services (NC II) +

13.

Front Office Services (NC II)

14.

Hairdressing (NC II)

15.

Hairdressing (NC III)

16.

Handicraft (Basketry, Macrame) (Non-NC)

17.

Handicraft (Fashion Accessories, Paper Craft) (Non-NC)

18.

Handicraft (Needlecraft) (Non-NC)

19.

Handicraft (Woodcraft, Leathercraft) (Non-NC)

20.

Housekeeping (NC II) +

21.

Local Guiding Services (NC II)

22.

Tailoring (NC II)

23.

Tourism Promotion Services (NC II)

24.

Travel Services (NC II)

25.

Wellness Massage (NC II)

+

CG to be updated by December 2015

K to 12 Industrial Arts Machining (NC II) Curriculum Guide November 2015

Number of

Hours

160 hours

320 hours

320 hours

160 hours

160 hours

640 hours

320 hours

320 hours

320 hours

320 hours

640 hours

160 hours

160 hours

320 hours

640 hours

160 hours

160 hours

160 hours

160 hours

160 hours

160 hours

320 hours

160 hours

160 hours

160 hours

*LO-Learning Outcomes

Pre-requisite

40 hours of the subject during exploratory Grade 7/8

40 hours of the subject during exploratory Grade 7/8

Cookery (NC II)

40 hours of the subject during exploratory Grade 7/8

40 hours of the subject during exploratory Grade 7/8

Dressmaking (NC II) or Tailoring (NC II)

40 hours of the subject during exploratory Grade 7/8

Hairdressing (NC II)

40 hours of the subject during exploratory Grade 7/8

STVEP Schools may cover more competencies in a week

Page 2 of 18

K TO 12 BASIC EDUCATION CURRICULUM

JUNIOR HIGH SCHOOL TECHNOLOGY AND LIVELIHOOD TRACK AND SENIOR HIGH SCHOOL TECHNICAL-VOCATIONAL LIVELIHOOD TRACK

INDUSTRIAL ARTS - MACHINING NC II

(640 hours)

INDUSTRIAL ARTS

Specialization

Number of Hours

Automotive Servicing (NC I) +

Automotive Servicing (NC II)

Carpentry (NC II)

Carpentry (NC III)

Construction Painting (NC II)

Consumer Electronics Servicing (NC II) +

Domestic Refrigeration and Airconditioning (DOMRAC) Servicing (NC II)

Driving (NC II)

Electrical Installation and Maintenance (NC II)

Electric Power Distribution Line Construction (NC II)

Electronic Products Assembly and Servicing (NC II) ++

640

640

640

320

160

640

640

160

640

320

Furniture Making (Finishing) (NC II) +

Instrumentation and Control Servicing (NC II)

Gas Metal Arc Welding (GMAW) (NC II)

Gas Tungsten Arc Welding (GTAW) (NC II)

Machining (NC I) ++

Machining (NC II)

Masonry (NC II)

Mechatronics Servicing (NC II)

Motorcycle/Small Engine Servicing (NC II)

Plumbing (NC I)

Plumbing (NC II)

Refrigeration and Air-Conditioning (Packaged Air-Conditioning Unit

[PACU]/Commercial Refrigeration Equipment [CRE]) Servicing (NC III)

24.

Shielded Metal Arc Welding (NC I)

25.

Shielded Metal Arc Welding (NC II)

26.

Tile Setting (NC II)

27.

Transmission Line Installation and Maintenance (NC II)

+

CG to be updated by December 2015

++

CG to be uploaded by December 2015

480

320

320

320

640

640

320

320

320

320

320

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

(CG under construction based on Consumer Electronics Servicing

(NC II) CG)

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

K to 12 Industrial Arts Machining (NC II) Curriculum Guide November 2015

hours

hours

hours

hours

hours

hours

hours

hours

hours

hours

Pre-requisite

Automotive Servicing (NC I)

Carpentry (NC II)

Electrical Installation and Maintenance (NC II)

640 hours

hours

hours

hours

hours

hours

hours

hours

hours

hours

hours

hours

640 hours

320

320

320

640

*LO-Learning Outcomes

hours

hours

hours

hours

Electronic Products Assembly and Servicing (EPAS) (NC II)

Shielded Metal Arc Welding (SMAW) (NC II)

Shielded Metal Arc Welding (GMAW) (NC II)

Machining (NC I)

Consumer Electronics Servicing (NC II)

Plumbing (NC I)

Domestic Refrigeration and Airconditioning (DOMRAC)

Servicing (NC II)

Shielded Metal Arc Welding (NC I)

Electrical Installation and Maintenance (NC II)

STVEP Schools may cover more competencies in a week

Page 3 of 18

K TO 12 BASIC EDUCATION CURRICULUM

JUNIOR HIGH SCHOOL TECHNOLOGY AND LIVELIHOOD TRACK AND SENIOR HIGH SCHOOL TECHNICAL-VOCATIONAL LIVELIHOOD TRACK

INDUSTRIAL ARTS - MACHINING NC II

(640 hours)

INFORMATION, COMMUNICATIONS AND TECHNOLOGY (ICT)

Number of

Hours

320 hours

Specialization

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

+

Animation (NC II)

Broadband Installation (Fixed Wireless Systems) (NC II)

160 hours

Computer Hardware Servicing (NC II) +

Computer Programming (NC IV) +

320 hours

When updated, this CG will become the following:

1. Programming (.net Technology) (NC II)++

2. Programming (Java) (NC II)++

3. Programming (Oracle Database) (NC II)++

Pre-requisite

1. Telecom OSP and Subscriber Line Installation

(Copper Cable/POTS and DSL) (NC II)

2. Telecom OSP Installation (Fiber Optic Cable) (NC

II)

320 hours

Computer System Servicing (NC II) ++

(CG under construction based on Computer Hardware Servicing

(NC II) CG)

Contact Center Services (NC II)

Illustration (NC II)

Medical Transcription (NC II)

Technical Drafting (NC II)

Telecom OSP and Subscriber Line Installation

(Copper Cable/POTS and DSL) (NC II)

Telecom OSP Installation (Fiber Optic Cable) (NC II)

320 hours

320

320

320

320

hours

hours

hours

hours

320 hours

Computer Hardware Servicing (NC II)

160 hours

Telecom OSP and Subscriber Line Installation

(Copper Cable/POTS and DSL) (NC II)

CG to be updated by December 2015

CG to be uploaded by December 2015

++

K to 12 Industrial Arts Machining (NC II) Curriculum Guide November 2015

*LO-Learning Outcomes

STVEP Schools may cover more competencies in a week

Page 4 of 18

K TO 12 BASIC EDUCATION CURRICULUM

JUNIOR HIGH SCHOOL TECHNOLOGY AND LIVELIHOOD TRACK AND SENIOR HIGH SCHOOL TECHNICAL-VOCATIONAL LIVELIHOOD TRACK

INDUSTRIAL ARTS - MACHINING NC II

(640 hours)

Prerequisite: Machining NC I

Course Description:

This course is designed to enhance the knowledge, desirable attitudes and skills of a machinist in accordance with industry standards. It covers the following core

competencies: performing bench work operation (basic and complex), turning work piece (basic and intermediate), milling work piece (basic and intermediate), and grinding

work piece (basic and complex).

CONTENT

Introduction

1. Basic concepts in Machining

2. Relevance of the course

3. Career opportunities

CONTENT STANDARD

The learner demonstrates

an understanding of the

basic concepts, and

underlying theories in

Machining

PERFORMANCE STANDARD

The learner independently

demonstrates the common

competencies in Machining as

prescribed by TESDA Training

Regulations.

LEARNING COMPETENCIES

CODE

1. Explain basic concepts in Machining.

2. Discuss the relevance of the course.

3. Explore career opportunities in Machining.

PERSONAL ENTREPRENEURIAL COMPETENCIES AND SKILLS (PECS)

1. Assessment of Personal

Entrepreneurial Competencies

and Skills (PECS) vis--vis a

practicing

entrepreneur/employee

1.1 Characteristics

1.2 Attributes

1.3 Lifestyle

1.4 Skills

1.5 Traits

2. Analysis of ones PECS

The learner demonstrates

an understanding of ones

Personal Entrepreneurial

Competencies and Skills

(PECS).

The learner recognizes his/her

Personal Entrepreneurial

Competencies and Skills (PECS)

and prepares a list of PECS of a

practitioner/entrepreneur in

SMAW.

LO 1. Recognize Personal Entrepreneurial

Competencies and Skills (PECS) needed in

Machining.

1.1 Assess ones PECS: characteristics,

attributes, lifestyle, skills, and traits.

1.2 Assess practitioners characteristics,

attributes, lifestyle, skills, and traits.

1.3 Compare ones PECS with that of a

practitioner /entrepreneur.

TLE_PECS9-1200-1

The learner demonstrates

an understanding of the

concepts environment and

market that relate to a

career choice in

Machining.

The learner independently

generates a business idea based

on the analyses of the

environment and market in

Machining

LO 1. Generate a business idea that relates

with a career choice in Machining.

1.1 Conduct SWOT analysis.

1.2 Identify the different products/services

available in the market.

1.3 Compare different products/services in

Machining business.

TLE_EM9-1200-1

*LO-Learning Outcomes

STVEP Schools may cover more competencies in a week

Page 5 of 18

ENVIRONMENT AND MARKET (EM)

1. Key concepts of Environment

and Market

2. Products & services available in

the market

3. Differentiation of products and

services

4. Customers and their buying

K to 12 Industrial Arts Machining (NC II) Curriculum Guide November 2015

K TO 12 BASIC EDUCATION CURRICULUM

JUNIOR HIGH SCHOOL TECHNOLOGY AND LIVELIHOOD TRACK AND SENIOR HIGH SCHOOL TECHNICAL-VOCATIONAL LIVELIHOOD TRACK

INDUSTRIAL ARTS - MACHINING NC II

(640 hours)

CONTENT

CONTENT STANDARD

PERFORMANCE STANDARD

habits

5. Competition in the market

6. SWOT Analysis

LEARNING COMPETENCIES

CODE

1.4 Determine the profile potential customers.

1.5 Determine the profile potential competitors.

1.6 Generate potential business idea based on

the SWOT analysis.

LESSON 1: PERFORMING BENCH WORK BASIC (PBW)

Identification of layout tools

Preparation of layout tools

Procedures in laying out work

piece

Safety measure in laying out

The learner demonstrates

an understanding of the

basic concepts and

underlying theories in

layout and mark

dimensions on a work

piece.

Types of cutting tools

Preparation of materials to be cut

Methods of cutting flat,

rectangular and round blocks

Kinds of chipping tools

Preparation of materials to be

chipped

Procedures in chipping flat

rectangular and round blocks

Types of files

Selection of appropriate files

Preparation of materials for filing

Methods of filing

Application of safety measures in

cutting chipping and filing

The learner demonstrates,

an understanding of the

basic concepts and

underlying theories in

cutting, chipping and filing

flat, rectangular or round

blocks.

K to 12 Industrial Arts Machining (NC II) Curriculum Guide November 2015

The learner independently

performs bench work operation

based on industry standard.

*LO-Learning Outcomes

LO 1. Layout, mark dimensions/features

on work piece.

1.1 Identify layout tools.

1.2 Select layout tools in accordance with the

working drawing.

1.3 Perform layout procedures according to

industry standard.

1.4 Follow safety standards in layout.

TLE_IAMAC912PBW-Ia-e-1

LO 2. Cut, chip, and file flat, rectangular or

round blocks.

2.1 Cut material within specified tolerance.

2.2 Select appropriate chipping tools for the job.

2.3 Prepare materials for chipping according to

requirements.

2.4 Perform chipping rectangular and round

block according to standard procedure.

2.5 Apply method of chipping according to

working drawing.

2.6 Select appropriate types of files to polish

flat, rectangular or round blocks.

2.7 Prepare materials for filing according to

requirements.

2.8 Apply methods of cutting chipping and filing

according to working drawing.

2.9 Apply safety measures in cutting, chipping

and filing.

TLE_IAMAC912PBW-If-j-2

STVEP Schools may cover more competencies in a week

Page 6 of 18

K TO 12 BASIC EDUCATION CURRICULUM

JUNIOR HIGH SCHOOL TECHNOLOGY AND LIVELIHOOD TRACK AND SENIOR HIGH SCHOOL TECHNICAL-VOCATIONAL LIVELIHOOD TRACK

INDUSTRIAL ARTS - MACHINING NC II

(640 hours)

CONTENT

CONTENT STANDARD

Identification of drilling machine

Selection of drill bit according to

working drawing

Selection of required rpm

according to the working drawing

Drilling of hole according to

industry standard

Kinds of reamer

Selection of required reamer

according to specification

Procedure in reaming

Safety practices in drilling and

reaming

The learner demonstrates

an understanding of the

basic concepts and

underlying theories in

drilling, reaming and

lapping the hole.

PERFORMANCE STANDARD

LEARNING COMPETENCIES

CODE

LO 3. Drill, ream and lap hole

Identify drilling machine.

3.1 Select speed and feed appropriate for the

drill size and kind of materials.

3.2 Drill work piece according to specification.

3.3 Prepare tools and materials based on

operation to be performed specified on

working drawing.

3.4 Select reamers according to the industry

standard.

3.5 Ream the hole in accordance with the

working drawing specification.

3.6 Follow safety practices in drilling and

reaming.

3.7 Wear personal protective equipment.

TLE_IAMAC912PBW-IIa-e-3

LO 1. Determine job requirements.

1.1 Interpret plans/ drawings or blueprint.

1.2 Determine sequence of operation to

produce component of specification.

1.3 Select holding devices according to the

requirements.

1.4 Inspect tools according to manufacturers

specification.

1.5 Check machine guards, coolant and dust

extraction devices according to

manufacturers manual.

TLE_IAMAC912TWP-IIf-j-4

LO 2. Set up work piece.

2.1 Mount a work piece in chuck into required

level of accuracy using tools and equipment

in accordance with work site procedure.

TLE_IAMAC912TWP-IIIa-h5

LESSON 2: TURNING WORK PIECE BASIC (TWP)

Plans/drawing

interpretation

Lathe work holding

devices

Cutting tools accessories

and their uses

Safety in handling tools

and equipment

Checking procedure of

machine guards, coolant

and dust extraction

devices

The learners demonstrates

an understanding of the

basic concepts and underlying theories in

determining job

requirements.

Tools and equipment used

in mounting a work piece

Setting up procedures of a

The learner demonstrates

an understanding of the

basic concepts and

underlying theories in

K to 12 Industrial Arts Machining (NC II) Curriculum Guide November 2015

The learners independently

perform turning work piece

(basic) based on industry

standard.

*LO-Learning Outcomes

STVEP Schools may cover more competencies in a week

Page 7 of 18

K TO 12 BASIC EDUCATION CURRICULUM

JUNIOR HIGH SCHOOL TECHNOLOGY AND LIVELIHOOD TRACK AND SENIOR HIGH SCHOOL TECHNICAL-VOCATIONAL LIVELIHOOD TRACK

INDUSTRIAL ARTS - MACHINING NC II

(640 hours)

CONTENT

CONTENT STANDARD

PERFORMANCE STANDARD

LEARNING COMPETENCIES

CODE

work piece

Instrument and equipment

used in setting up a work

piece

Setting-up operations and

safety procedures in

handling of tools,

instrument and equipment

setting up a work piece.

2.2 Set up a work piece to required level of

accuracy using instrument/ equipment

according to work site procedures.

2.3 Perform set-up operations applying

knowledge in safety procedures and using

personal protective devices.

Formulas in solving speed

and feed in turning

operations.

Lathe accessories and

their uses.

Procedures of the different

lathe operations

Procedures and

techniques in measuring a

work piece

Safety procedure in lathe

operations

The learner demonstrates

an understanding of the

basic concepts and

underlying theories in

performing turning

operation, checking and

measuring a work piece.

LO 3. Perform turning operations.

3.1 Calculate speed and feeds using appropriate

mathematical techniques and reference

materials.

3.2 Use lathe accessories appropriate to the

requirements of the operations.

3.3 Perform lathe operations to produce

component of specifications in the working

drawing.

3.4 Check work piece conforming to

specifications using appropriate techniques,

measuring tools and equipment.

3.5 Apply knowledge in safety procedures and

use personal protective devices.

TLE_IAMAC912TWP-IIIh-jIV-6

LO 1. Set up a work piece.

1.1 Interpret plans/ drawing to produce

component of specification.

1.2 Determine sequence of operation to

produce component of specification.

1.3 Select cutting tools and work holding

devices according to job requirement.

1.4 Set up a work piece to the required level of

accuracy using instrument/equipment

according to work site procedure.

TLE_IAMAC912MWP-Ia-h-7

LESSON 3: MILLING WORK PIECE BASIC (MWP)

Plans/ drawing

interpretation

Process planning

Kinds and uses of cutting

tools and work holding

devices

Safety practices

Instrument and equipment

used in setting up a work

The learner demonstrates

an understanding of the

basic concepts and

underlying theories in

setting up a work piece.

K to 12 Industrial Arts Machining (NC II) Curriculum Guide November 2015

*LO-Learning Outcomes

STVEP Schools may cover more competencies in a week

Page 8 of 18

K TO 12 BASIC EDUCATION CURRICULUM

JUNIOR HIGH SCHOOL TECHNOLOGY AND LIVELIHOOD TRACK AND SENIOR HIGH SCHOOL TECHNICAL-VOCATIONAL LIVELIHOOD TRACK

INDUSTRIAL ARTS - MACHINING NC II

(640 hours)

CONTENT

CONTENT STANDARD

PERFORMANCE STANDARD

CODE

1.5 Perform set-up operation applying

knowledge in safety procedures and using

personal protective devices.

piece

Setting-up operations and

safety procedures in

handling of tools,

instrument and equipment

Formulas for speeds and

feeds

Milling machine

accessories and their uses

Milling machine operations

Safety in operating a

milling machine

Procedure and techniques

in measuring a work piece

LEARNING COMPETENCIES

The learner demonstrates

an understanding of the

basic concepts and

underlying theories in

performing milling

operations and checking

/measuring a work piece.

LO 2. Perform milling operation.

2.1 Set speeds and feeds appropriate to the job.

2.2 Use milling machine accessories appropriate

to the requirements of the operation.

2.3 Perform milling operations to produce

component to specifications in the blue

print.

2.4 Apply milling operations with safety

procedures and use personal protective

devices.

2.5 Check work piece measurement for

conformity in specification using appropriate

techniques, measuring tools and equipment.

TLE_IAMAC912MWP-Ih-j-IIIIIa-e-8

The learner independently

performs grinding a work piece

(basic) based on industry

standard.

LO 1. Set up work piece and machine

accessories

1.1 Determine parts and functions of a grinding

machine.

1.2 Select grinding wheels in accordance with

work requirement.

1.3 Select grinder accessories appropriate to the

requirements of an operation.

1.4 Check machine guards, coolant and dust

extractor device according to work site

procedure.

TLE_IAMAC912GWP-IIIf-j-9

*LO-Learning Outcomes

STVEP Schools may cover more competencies in a week

LESSON 4: GRINDING WORKPIECE BASIC (GWP)

Parts and function of a

grinding machine and

accessories

Kinds of work holding

devices in grinding

Types and grades of

grinding wheels.

Checking procedure of

machine guards, coolant

and dust extraction

devices

Safety practices

The learner demonstrates

an understanding of the

basic concepts and

underlying theories in

setting up a work piece

and machine accessories.

K to 12 Industrial Arts Machining (NC II) Curriculum Guide November 2015

Page 9 of 18

K TO 12 BASIC EDUCATION CURRICULUM

JUNIOR HIGH SCHOOL TECHNOLOGY AND LIVELIHOOD TRACK AND SENIOR HIGH SCHOOL TECHNICAL-VOCATIONAL LIVELIHOOD TRACK

INDUSTRIAL ARTS - MACHINING NC II

(640 hours)

CONTENT

Setting-up procedure in

grinding flat, square,

parallel, angle, radii,

groove and profiles

Procedure in grinding flat,

parallel and square

surfaces

Procedure in grinding

angled surfaces

Procedure in grinding radii

Procedure in grinding

grooves and profiles

Work holding devices

appropriate for grinding

Safety practices in grinding

Procedures and

techniques in measuring a

work a piece

CONTENT STANDARD

PERFORMANCE STANDARD

The learner demonstrates

an understanding of the

basic concepts and

underlying theories in

performing grinding

operations and measuring

a work piece

LEARNING COMPETENCIES

CODE

LO 2. Perform grinding operation

2.1 Set-up grinding machine in accordance with

the work specification.

2.2 Clamp a work piece to avoid damage.

2.3 Perform grinding operations safely to

produce component to specification.

2.4 Measure a work piece using appropriate

techniques, measuring tool and equipment.

TLE_IAMAC912GWP-IV-10

LO 1. Hone, scrape surface.

1.1 Perform honing operation in accordance

with procedure.

1.2 Perform scraping according to procedure.

1.3 Perform honing and scraping operations

applying knowledge in safety and using

personal protective devices.

TLE_IAMAC912PBC-Ia-h-11

LESSON 5: PERFORMING BENCHWORK COMPLEX (PBC)

Types of Honing tools Scrapers

Procedure in: Honing Scraping

Safety practices

Set of screw extractors

Procedure in removing

worn- out bolt in a

The learner demonstrates

an understanding of the

basic concepts and

underlying theories in

honing and scraping a

surface

The learner independently

performs a bench work

operation (Complex) based on

industry standard.

The learner demonstrates

an understanding of the

basic concepts and

K to 12 Industrial Arts Machining (NC II) Curriculum Guide November 2015

*LO-Learning Outcomes

LO 2. Remove damaged bolt in threaded

hole.

2.1 Determine screw extractors according to job

requirements.

TLE_IAMAC912PBC-Ih-jIIa-e-12

STVEP Schools may cover more competencies in a week

Page 10 of 18

K TO 12 BASIC EDUCATION CURRICULUM

JUNIOR HIGH SCHOOL TECHNOLOGY AND LIVELIHOOD TRACK AND SENIOR HIGH SCHOOL TECHNICAL-VOCATIONAL LIVELIHOOD TRACK

INDUSTRIAL ARTS - MACHINING NC II

(640 hours)

CONTENT

threaded hole

Procedure in repairing

damaged threads

Safety practices

CONTENT STANDARD

PERFORMANCE STANDARD

underlying theories in

removing damaged bolt in

the threaded hole.

LEARNING COMPETENCIES

CODE

2.2 Remove damaged bolt according to

procedure

2.3 Perform removal of damaged bolt in a

threaded hole and repair damaged thread

applying knowledge in safety and using

personal protective devices.

2.4 Repair damaged thread according to

procedure.

LESSON 6: TURNING WORK PIECE INTERMEDIATE (TWI)

Kinds of cutting tools

Uses of work holding devices

Centering tools and device

Procedure in setting up a work

piece

Safety practices for setting up a

work piece

The learner demonstrates

an understanding of the

basic concepts and

underlying theories in

setting up a work piece.

Speeds, feeds and

machining time

calculations

Machine accessories and

their uses.

Kinds of cutting tools

Uses of work holding

devices

Centering tools and

devices

Lathe operations

procedures

Lathe safety practices

The learner demonstrates

an understanding of the

basic concepts and

underlying theories in

performing turning

operations.

K to 12 Industrial Arts Machining (NC II) Curriculum Guide November 2015

The learner independently

performs grinding a work piece

(intermediate) based on

industry standards.

LO 1. Set up a work piece.

1.1 Select cutting tools and work holding

devices.

1.2 Center a work piece in accordance with

work requirements.

1.3 Set up a work piece on chuck to the

required level of accuracy using tools and

equipment in accordance with work site

procedure.

1.4 Perform set-up operations in accordance

with approved safety procedures and

practices.

LO 2. Perform turning operations

2.1 Calculate speeds, feeds and machining time

in accordance with job requirements

2.2 Use lathe accessories appropriate to the

requirements of the operation.

2.3 Perform lathe operations to produce part

according to specifications.

2.4 Apply knowledge in safety procedures and

using personal protective devices.

2.5 Check work piece measurement as per

specification.

*LO-Learning Outcomes

STVEP Schools may cover more competencies in a week

TLE_IAMAC912TWI-IIf-jIIIa-c-13

TLE_IAMAC912TWI-IIIc-jIV-14

Page 11 of 18

K TO 12 BASIC EDUCATION CURRICULUM

JUNIOR HIGH SCHOOL TECHNOLOGY AND LIVELIHOOD TRACK AND SENIOR HIGH SCHOOL TECHNICAL-VOCATIONAL LIVELIHOOD TRACK

INDUSTRIAL ARTS - MACHINING NC II

(640 hours)

CONTENT

CONTENT STANDARD

PERFORMANCE STANDARD

LEARNING COMPETENCIES

CODE

Procedure in setting up a

work piece

Procedure and

techniques in measuring

work piece

LESSON 7: MILLING WORK PIECE INTERMEDIATE (MWI)

Interpretation working

drawing

Procedure in setting up a

work piece

Speeds and feeds

calculation

Milling machine

accessories and their uses

Kinds of cutting tools

Uses of work holding

devices

Safety practices

The learner demonstrates

an understanding of the

basic concepts and

underlying theories in

setting up work piece.

Formulas for speeds and

feeds

Milling machine

accessories and their uses

Milling machine operations

Safety procedures in

milling operation

Procedure and techniques

in measuring a work piece

The learner demonstrates

an understanding of the

basic concepts and

underlying theories in

performing milling

operations and checking

work piece measurement.

The learner independently

performs milling work piece

(intermediate) based on

industry standards.

LO 1. Set up work piece.

1.1 Interpret plans/drawing to produce

component of specification.

1.2 Select cutting tools and work holding

devices according to job requirement.

1.3 Perform set up operation in accordance with

safety procedures and practices.

LO 2. Perform milling operations and check

work piece.

2.1 Set speeds and feeds according to job

requirement.

2.2 Use milling machine accessories according

to job requirements.

2.3 Perform milling operations according to

established procedure.

2.4 Check work piece measurement as per

specification.

TLE_IAMAC912MWI-Ia-h-15

TLE_IAMAC912MWI-Ih-j-IIIIIa-e-16

LESSON 8: GRINDING WORKPIECE - COMPLEX OPERATION (GWC)

Working drawing

interpretation

The learner demonstrates

K to 12 Industrial Arts Machining (NC II) Curriculum Guide November 2015

The learner independently

*LO-Learning Outcomes

LO 1. Select wheels and accessories

1.1 Interpret working drawing to produce

STVEP Schools may cover more competencies in a week

TLE_IAMAC9Page 12 of 18

K TO 12 BASIC EDUCATION CURRICULUM

JUNIOR HIGH SCHOOL TECHNOLOGY AND LIVELIHOOD TRACK AND SENIOR HIGH SCHOOL TECHNICAL-VOCATIONAL LIVELIHOOD TRACK

INDUSTRIAL ARTS - MACHINING NC II

(640 hours)

CONTENT

CONTENT STANDARD

Selection of grinding

operations

Selection of holding

devices

Selection of wheels

Selection of accessories

Safe handling of tool,

equipment and materials

Inspect grinding wheel

Checking procedure of

machine guards, coolant

and dust extraction

devices

Shop safety practices

an understanding of the

basic concepts and

underlying theories in

selecting wheels and

accessories.

Adjusting grinding machine

set up

Grinding operations of

external and internal

tapers

The learner demonstrates

an understanding of the

basic concepts and

underlying theories in

performing grinding

operations.

PERFORMANCE STANDARD

performs grinding a work piece

(complex) based on industry

standard.

internal radii

internal recess

remove warp

Proper use of:

- holding devices

- wheels and accessories

- materials

- coolant

procedures and techniques in

measuring work piece

Shop safety practices

Safe handling of tool, equipment

and

K to 12 Industrial Arts Machining (NC II) Curriculum Guide November 2015

component according to specifications

1.2 Select work holding device according to

operation requirements.

1.3 Inspect grinding wheel to the required

shape and size.

1.4 Select accessories according to job

requirement.

1.5 Check machine guards, coolant and dust

extractor according to work site procedure.

LO 2. Perform grinding operations.

2.1 Adjust grinding machine set up in

accordance with the work site procedure

2.2 Clamp or hold the work piece to avoid

damage

2.3 Perform grinding operations with safety to

produce component to specification

2.4 Measure the work piece for conformity in

specification using appropriate techniques,

measuring tool and equipment.

LEARNING COMPETENCIES

*LO-Learning Outcomes

STVEP Schools may cover more competencies in a week

CODE

12GWC-IIIf-jIVa-b-17

TLE_IAMAC912GWC-IVb-j18

Page 13 of 18

K TO 12 BASIC EDUCATION CURRICULUM

JUNIOR HIGH SCHOOL TECHNOLOGY AND LIVELIHOOD TRACK AND SENIOR HIGH SCHOOL TECHNICAL-VOCATIONAL LIVELIHOOD TRACK

INDUSTRIAL ARTS - MACHINING NC II

(640 hours)

RESOURCES

TOOLS AND EQUIPMENT

Hand hack saw

Power hack saw

Metal band saw

Lathe machine

- Lathe accessories

- 3-jaw chuck

- 4-jaw chuck

- Collect chuck

- Face plate

- Drill chuck

- Lathe center

- Steady rest

- Follower rest

- Cutting tools

Drill press

Electric hand drill

Milling machine

Shaper machine

Surface grinder

Bench Grinder

Angle disc grinder

Veeblock with clamp

Surface plate

Sine bar

Dial indicator

Universal bevel protractor

Drill press

Bevel protractor

Hermaphrodite

Prick punch

Hammer

Steel rule

SUPPLIES AND MATERIALS

K to 12 Industrial Arts Machining (NC II) Curriculum Guide November 2015

LEARNING MATERIALS

Paper

Pencil

Triangles

Pencil & paper

Drawing table

Protractor

Brush

Light oil

Oil can

Dust pan

Grease gun

Clean rags

Calculator

Measuring instrument

Work piece (mild steel plate, rectangular and

round block)

Layout tools

Small hole gauge

Drill bit

Go-no-go gauge

Telescopic gauge

Vernier caliper

Micrometer caliper

Reamer holder

Working bench w/ vise

Paint brush

Grinding coolant

Tool bit gauge

V-block

Brass shim

Apron

Gloves

*LO-Learning Outcomes

References (books)

Manuals

Mathematics books

Formulas of speed and feed

Table for speed and feed

Maintenance chart

Working drawing

STVEP Schools may cover more competencies in a week

Page 14 of 18

K TO 12 BASIC EDUCATION CURRICULUM

JUNIOR HIGH SCHOOL TECHNOLOGY AND LIVELIHOOD TRACK AND SENIOR HIGH SCHOOL TECHNICAL-VOCATIONAL LIVELIHOOD TRACK

INDUSTRIAL ARTS - MACHINING NC II

(640 hours)

RESOURCES

TOOLS AND EQUIPMENT

Scriber

Divider

Tool blank

Milling cutters

Lecture

Reportiorial

Group discussion

Interaction

Demonstration

Film viewing

Self-paced learning

Plant visitation

SUPPLIES AND MATERIALS

K to 12 Industrial Arts Machining (NC II) Curriculum Guide November 2015

LEARNING MATERIALS

Safety glass

Spanner wrench

Combination square

Height gauge

Angular plate

Square block

Interview

Written

Practical exercise

Direct observation

*LO-Learning Outcomes

STVEP Schools may cover more competencies in a week

Page 15 of 18

K TO 12 BASIC EDUCATION CURRICULUM

JUNIOR HIGH SCHOOL TECHNOLOGY AND LIVELIHOOD TRACK AND SENIOR HIGH SCHOOL TECHNICAL-VOCATIONAL LIVELIHOOD TRACK

INDUSTRIAL ARTS - MACHINING NC II

(640 hours)

GLOSSARY

1.

2.

3.

4.

5.

6.

7.

8.

9.

Lathe Machine

Faceplate and lathe dog

Bed

Head stock

Danger

Emergency

Hazard

Injury

Safety measure

is a machine where the work piece rotates against the tool bit.

are work-holding devices used in turning between centers.

the foundation or base on which the other parts of the lathe are fitted.

it contains the spindle to which the various work-holding attachments are fitted

something that may cause injury

a dangerous happening or situation

a risk of harm or danger.

an instance of harm or damage

taking measure to prevent accident

K to 12 Industrial Arts Machining (NC II) Curriculum Guide November 2015

*LO-Learning Outcomes

STVEP Schools may cover more competencies in a week

Page 16 of 18

K TO 12 BASIC EDUCATION CURRICULUM

JUNIOR HIGH SCHOOL TECHNOLOGY AND LIVELIHOOD TRACK AND SENIOR HIGH SCHOOL TECHNICAL-VOCATIONAL LIVELIHOOD TRACK

INDUSTRIAL ARTS - MACHINING NC II

(640 hours)

CODE BOOK LEGEND

Sample: TLE_IA-MAC11-PBW-Ia-c-1

LEGEND

First Entry

Uppercase

Letter/s

SAMPLE

Learning Area and

Strand/ Subject or

Specialization

Grade Level

Domain/ Content/

Component/ Topic

DOMAIN / COMPONENT

Technology and Livelihood

Education_

Industrial Arts

Machining NC II

9/10/11/12

TLE_IA

MAC

9-12

Performing Bench Work - Basic

PBW

-

Roman Numeral

*Zero if no specific

Quarter

Quarter

First Quarter

Week

Week one to five

a-e

Performing Bench Work Basic

Turning Work Piece - Basic

Milling Work Piece - Basic

Grinding Work Piece - Basic

Performing Bench Work - Complex

Turning Work Piece - Intermediate

Milling Work Piece - Intermediate

Grinding Work Piece - Complex Operation

CODE

PBW

TWP

MWP

GWP

PBC

TWI

MWI

GWC

Lower case

letter/s

*Put an en-dash (-)

in between letters

to indicate more

than a specific week

Arabic Number

Competency

Layout, mark dimensions/ features

on work piece

Technology-Livelihood Education and Technical-Vocational Track specializations may be taken between Grades 9 to 12.

Schools may offer specializations from the four strands as long as the minimum number of hours for each specialization is met.

Please refer to the sample Curriculum Map on the next page for the number of semesters per Industrial Arts specialization and those that have pre-requisites. Curriculum

Maps may be modified according to specializations offered by a school.

K to 12 Industrial Arts Machining (NC II) Curriculum Guide November 2015

*LO-Learning Outcomes

STVEP Schools may cover more competencies in a week

Page 17 of 18

K TO 12 BASIC EDUCATION CURRICULUM

JUNIOR HIGH SCHOOL TECHNOLOGY AND LIVELIHOOD TRACK AND SENIOR HIGH SCHOOL TECHNICAL-VOCATIONAL LIVELIHOOD TRACK

INDUSTRIAL ARTS - MACHINING NC II

(640 hours)

Please note that these subjects have pre-requisites mentioned in the CG.

Other specializations with no pre-requisites may be taken up during these semesters.

Pre-requisites of the subjects to the right should be taken up during these semesters.

K to 12 Industrial Arts Machining (NC II) Curriculum Guide November 2015

CG to be updated by December 2015

++ CG to be uploaded by December 2015

**This is just a sample. Schools make their own curriculum maps considering the

specializations to be offered. Subjects may be taken up at any point during Grades 9-12.

*LO-Learning Outcomes

STVEP Schools may cover more competencies in a week

Page 18 of 18

Potrebbero piacerti anche

- Engineering Applications: A Project Resource BookDa EverandEngineering Applications: A Project Resource BookValutazione: 2.5 su 5 stelle2.5/5 (1)

- He - Bartending NC IIDocumento32 pagineHe - Bartending NC IISofia Tulabing100% (3)

- Ia - Gas Metal Arc Welding (Gmaw) NC IIDocumento17 pagineIa - Gas Metal Arc Welding (Gmaw) NC IIAngel AlarasNessuna valutazione finora

- HE - Tailoring NC II 20151119Documento21 pagineHE - Tailoring NC II 20151119Jo De Ann50% (6)

- HE - Attractions and Theme Parks NC II 20151119Documento32 pagineHE - Attractions and Theme Parks NC II 20151119Angel AlarasNessuna valutazione finora

- Ict - Broadband Installation (Fixed Wireless Systems) NC IIDocumento16 pagineIct - Broadband Installation (Fixed Wireless Systems) NC IIAngel Alaras50% (2)

- K to 12 ICT Curriculum Guide for Telecom OSP InstallationDocumento15 pagineK to 12 ICT Curriculum Guide for Telecom OSP InstallationAngel AlarasNessuna valutazione finora

- HE - Food and Beverages NC II 20151119Documento17 pagineHE - Food and Beverages NC II 20151119Sofia TulabingNessuna valutazione finora

- AF - Aquaculture NC II 20151119Documento28 pagineAF - Aquaculture NC II 20151119Michael ParejaNessuna valutazione finora

- IA - Electrical Installation and Maintenance NC II 20151119Documento25 pagineIA - Electrical Installation and Maintenance NC II 20151119Jo De Ann100% (1)

- AF - Horticulture NC II 20151119Documento35 pagineAF - Horticulture NC II 20151119Rosalie Tilos Orito100% (1)

- Animation NC II CGDocumento18 pagineAnimation NC II CGErick EsplanaNessuna valutazione finora

- ICT - Medical Transcription NC II 20151119Documento19 pagineICT - Medical Transcription NC II 20151119Angel AlarasNessuna valutazione finora

- AF - Agri-Crop Production NC II 20151119 PDFDocumento26 pagineAF - Agri-Crop Production NC II 20151119 PDFFidel B. Diopita100% (7)

- Electrical Installation and Maintenance NC II CGDocumento23 pagineElectrical Installation and Maintenance NC II CGRusshel Jon Llamas Macalisang83% (12)

- K-12 Agri-Fishery Guide Fishport Wharf OperationDocumento11 pagineK-12 Agri-Fishery Guide Fishport Wharf OperationAngel AlarasNessuna valutazione finora

- HE - Wellness Massage NC II 20151119Documento12 pagineHE - Wellness Massage NC II 20151119Angel AlarasNessuna valutazione finora

- ICT - Technical Drafting NC II 20151119Documento26 pagineICT - Technical Drafting NC II 20151119Danz TagNessuna valutazione finora

- Programming Java NC III CGDocumento32 pagineProgramming Java NC III CGHersey Badulis Hernandez100% (2)

- Automotive Servicing NC II CGDocumento36 pagineAutomotive Servicing NC II CGChristine Grace Espallardo JungcoNessuna valutazione finora

- Housekeeping NC II CG PDFDocumento19 pagineHousekeeping NC II CG PDFRics Jayden100% (2)

- K to 12 Animation Curriculum GuideDocumento18 pagineK to 12 Animation Curriculum GuideChristine Mercede33% (3)

- ICT - Computer Hardware Servicing NC II 20151119Documento21 pagineICT - Computer Hardware Servicing NC II 20151119Florie Capales-PelinNessuna valutazione finora

- Computer Systems Servicing NC II Curriculum GuideDocumento32 pagineComputer Systems Servicing NC II Curriculum GuideMacly Umali91% (11)

- ICT - Computer Programming NC IV 20151119Documento20 pagineICT - Computer Programming NC IV 20151119Danz Tag0% (1)

- K to 12 Food and Beverage Services Curriculum GuideDocumento25 pagineK to 12 Food and Beverage Services Curriculum GuideRhylyahnaraRhon Palla Peralta100% (2)

- Programming Oracle Database NC III CG PDFDocumento32 pagineProgramming Oracle Database NC III CG PDFHersey Badulis HernandezNessuna valutazione finora

- K to 12 Contact Center Services Curriculum GuideDocumento24 pagineK to 12 Contact Center Services Curriculum GuideJamee ThompsonNessuna valutazione finora

- AF - Fish Processing NC II 20151119Documento43 pagineAF - Fish Processing NC II 20151119Lai Serrano100% (1)

- Programming .Net Technology NC III CGDocumento33 pagineProgramming .Net Technology NC III CGHersey Badulis Hernandez100% (1)

- Telecom OSP Installation (Fiber Optic Cable) NC II CGDocumento16 pagineTelecom OSP Installation (Fiber Optic Cable) NC II CGjoetaps100% (1)

- Carpentry NC II CGDocumento26 pagineCarpentry NC II CGRickyJeciel100% (2)

- Automotive Servicing NC I CG - Spideylab - Com - 2017Documento45 pagineAutomotive Servicing NC I CG - Spideylab - Com - 2017Cristy Pearl S. GarciaNessuna valutazione finora

- Animation NC II CG (Word Version)Documento24 pagineAnimation NC II CG (Word Version)Marc RiomalosNessuna valutazione finora

- Strengthened Technical-Vocational Education ProgramDocumento11 pagineStrengthened Technical-Vocational Education ProgramP'tit Ger100% (6)

- ICT Computer Programming CGDocumento19 pagineICT Computer Programming CGJohn HeilNessuna valutazione finora

- Cookery SHS Cur Guide G11 WordDocumento49 pagineCookery SHS Cur Guide G11 WordRowena Lalongisip De Leon100% (5)

- An Overview To Industrial Arts ModuleDocumento44 pagineAn Overview To Industrial Arts ModuleEla Sofia ArnaizNessuna valutazione finora

- Computer Programming CGDocumento20 pagineComputer Programming CGRonald Allan BalderosaNessuna valutazione finora

- ICT Animation CGDocumento15 pagineICT Animation CGDominicSavio0% (1)

- Curriculum For Animation NC IIDocumento16 pagineCurriculum For Animation NC IIRonz de Borja100% (1)

- Definition of Industrial ArtsDocumento4 pagineDefinition of Industrial ArtsJoshua CondeNessuna valutazione finora

- Tesda Offered Courses Are Disseminated in Different Fields of SpecializationDocumento6 pagineTesda Offered Courses Are Disseminated in Different Fields of SpecializationMylene Robles GupitNessuna valutazione finora

- ICT Computer Hardware Servicing CGDocumento19 pagineICT Computer Hardware Servicing CGGerry SantosNessuna valutazione finora

- Osh Induction Program in Enhancing Safety Awareness Amongst Fabrication Workers in Brooke Dockyard, Kuching, SarawakDa EverandOsh Induction Program in Enhancing Safety Awareness Amongst Fabrication Workers in Brooke Dockyard, Kuching, SarawakValutazione: 5 su 5 stelle5/5 (1)

- Technical and Vocational Education and Training in the Philippines in the Age of Industry 4.0Da EverandTechnical and Vocational Education and Training in the Philippines in the Age of Industry 4.0Nessuna valutazione finora

- Practical Telecommunications and Wireless Communications: For Business and IndustryDa EverandPractical Telecommunications and Wireless Communications: For Business and IndustryNessuna valutazione finora

- Electrical Distribution System of a Skyscraper in the United StatesDa EverandElectrical Distribution System of a Skyscraper in the United StatesNessuna valutazione finora

- Rapid Thermal Processing: Science and TechnologyDa EverandRapid Thermal Processing: Science and TechnologyRichard B. FairNessuna valutazione finora

- Training Facility Norms and Standard Equipment Lists: Volume 2---Mechatronics TechnologyDa EverandTraining Facility Norms and Standard Equipment Lists: Volume 2---Mechatronics TechnologyNessuna valutazione finora

- Practical Industrial Data Communications: Best Practice TechniquesDa EverandPractical Industrial Data Communications: Best Practice TechniquesValutazione: 5 su 5 stelle5/5 (2)

- The Smart Card ReportDa EverandThe Smart Card ReportWendy AtkinsValutazione: 4 su 5 stelle4/5 (4)

- Gallium Arsenide IC Applications HandbookDa EverandGallium Arsenide IC Applications HandbookNessuna valutazione finora

- Engineering Service Revenues World Summary: Market Values & Financials by CountryDa EverandEngineering Service Revenues World Summary: Market Values & Financials by CountryNessuna valutazione finora

- 2nd Week EIM DailyDocumento5 pagine2nd Week EIM DailyDelvin Jan del RosarioNessuna valutazione finora

- 03 - General Shop Safety Lesson PointsDocumento1 pagina03 - General Shop Safety Lesson PointsDelvin Jan del RosarioNessuna valutazione finora

- 2002teched1112 MetalfabricmachinDocumento116 pagine2002teched1112 MetalfabricmachinDelvin Jan del RosarioNessuna valutazione finora

- Intent Letter UEDocumento1 paginaIntent Letter UEDelvin Jan del RosarioNessuna valutazione finora

- Intent Letter UEDocumento1 paginaIntent Letter UEDelvin Jan del RosarioNessuna valutazione finora

- Accomplishment ReportDocumento2 pagineAccomplishment ReportDelvin Jan del RosarioNessuna valutazione finora

- Mis 001 & Mis 002 Ma'Am Anna 2016Documento4.237 pagineMis 001 & Mis 002 Ma'Am Anna 2016Delvin Jan del RosarioNessuna valutazione finora

- Colour Pocoyo 54 PDFDocumento1 paginaColour Pocoyo 54 PDFDelvin Jan del RosarioNessuna valutazione finora

- Evaluation SolaireDocumento4 pagineEvaluation SolaireDelvin Jan del RosarioNessuna valutazione finora

- ScheduleDocumento1 paginaScheduleDelvin Jan del RosarioNessuna valutazione finora

- Database Management SystemDocumento15 pagineDatabase Management SystemDelvin Jan del RosarioNessuna valutazione finora

- School of Hospitality and Tourism Management: Arellano University Jose Abad Santos Campus 3058 Taft Avenue, Pasay CityDocumento2 pagineSchool of Hospitality and Tourism Management: Arellano University Jose Abad Santos Campus 3058 Taft Avenue, Pasay CityDelvin Jan del RosarioNessuna valutazione finora

- Delvin ThesisDocumento34 pagineDelvin ThesisDelvin Jan del RosarioNessuna valutazione finora

- Delvin de Asis GamingDocumento8 pagineDelvin de Asis GamingDelvin Jan del RosarioNessuna valutazione finora

- Virus Bacteria Fungi Parasite Cell Diameter Nucleic Acid Type of Nucleus Ribosome Mitochondria Nature of Outer Surface Motility ReplicationDocumento11 pagineVirus Bacteria Fungi Parasite Cell Diameter Nucleic Acid Type of Nucleus Ribosome Mitochondria Nature of Outer Surface Motility ReplicationDelvin Jan del RosarioNessuna valutazione finora

- Virus Bacteria Fungi Parasite Cell Diameter Nucleic Acid Type of Nucleus Ribosome Mitochondria Nature of Outer Surface Motility ReplicationDocumento11 pagineVirus Bacteria Fungi Parasite Cell Diameter Nucleic Acid Type of Nucleus Ribosome Mitochondria Nature of Outer Surface Motility ReplicationDelvin Jan del RosarioNessuna valutazione finora

- ZDocumento1 paginaZDelvin Jan del RosarioNessuna valutazione finora

- Iguico, Maria SofiaDocumento4 pagineIguico, Maria SofiaDelvin Jan del RosarioNessuna valutazione finora

- AnalysisDocumento6 pagineAnalysisDelvin Jan del RosarioNessuna valutazione finora

- Case AnalysisDocumento3 pagineCase AnalysisGeleine Curutan - OniaNessuna valutazione finora

- Example Case Analysis: Western Chain SawDocumento16 pagineExample Case Analysis: Western Chain SawDelvin Jan del RosarioNessuna valutazione finora

- Effective Classroom Management StrategiesDocumento3 pagineEffective Classroom Management StrategiesSherif ElkadyNessuna valutazione finora

- School of Hospitality and Tourism Management: Arellano University Jose Abad Santos Campus 3058 Taft Avenue, Pasay CityDocumento1 paginaSchool of Hospitality and Tourism Management: Arellano University Jose Abad Santos Campus 3058 Taft Avenue, Pasay CityDelvin Jan del RosarioNessuna valutazione finora

- Effective Classroom Management StrategiesDocumento3 pagineEffective Classroom Management StrategiesSherif ElkadyNessuna valutazione finora

- AnalysisDocumento6 pagineAnalysisDelvin Jan del RosarioNessuna valutazione finora

- Role of Microfinance Instutions ProjectDocumento81 pagineRole of Microfinance Instutions ProjectKirti PrajapatiNessuna valutazione finora

- 4thsem ModelQuestions On ED Stimulation Support Sustainability PJ 10apr2020Documento3 pagine4thsem ModelQuestions On ED Stimulation Support Sustainability PJ 10apr2020Adarsh JaiswalNessuna valutazione finora

- ENTP Chap 3Documento12 pagineENTP Chap 3MarenightNessuna valutazione finora

- EDM Minor 2 Notes PDFDocumento42 pagineEDM Minor 2 Notes PDFहर्ष वर्धन गुप्ताNessuna valutazione finora

- Effective Communication EssentialsDocumento128 pagineEffective Communication EssentialsKalema Saidi100% (1)

- Tesfaye TegegneDocumento85 pagineTesfaye TegegneCanlor Lopes100% (1)

- BrandingDocumento2 pagineBrandingSheila Mae MalesidoNessuna valutazione finora

- Growth Gauntlet: 2022 Survey ResultsDocumento26 pagineGrowth Gauntlet: 2022 Survey ResultsSSM PartnersNessuna valutazione finora

- TCBE 4104 Construction MGTDocumento114 pagineTCBE 4104 Construction MGTRichard Simon KisituNessuna valutazione finora

- INSPIRA JOURNAL OF COMMERCEECONOMICS COMPUTER SCIENCEJCECS Vol 03 N0 03 July Sept 2017 Pages 35 To 43Documento9 pagineINSPIRA JOURNAL OF COMMERCEECONOMICS COMPUTER SCIENCEJCECS Vol 03 N0 03 July Sept 2017 Pages 35 To 43Nirmalandu DasNessuna valutazione finora

- 221-14 McCasland - Responsive Information For ReleaseDocumento142 pagine221-14 McCasland - Responsive Information For ReleaseLouis McCaslandNessuna valutazione finora

- Lesson 2 - Evaluate Problems and OpportunitiesDocumento16 pagineLesson 2 - Evaluate Problems and OpportunitiesRomen CenizaNessuna valutazione finora

- 14 Chapter-4 Competency PDFDocumento32 pagine14 Chapter-4 Competency PDFJasy HazarikaNessuna valutazione finora

- China Innovation Eco-SystemDocumento47 pagineChina Innovation Eco-SystemDRAGON-STAR PlusNessuna valutazione finora

- Technology Innovation ManagementDocumento104 pagineTechnology Innovation ManagementDoina IsakNessuna valutazione finora

- Engaged Board Accomplished GoalsDocumento20 pagineEngaged Board Accomplished GoalsatlasnetworkNessuna valutazione finora

- Entrepreneurship: Famous EntrepreneursDocumento3 pagineEntrepreneurship: Famous EntrepreneursClarence CardonaNessuna valutazione finora

- Ls4 Elem Las21 To-Las50-MergedDocumento31 pagineLs4 Elem Las21 To-Las50-MergedJaypee Aturo100% (2)

- Value Creation Through Novel Resource ConfigurationDocumento15 pagineValue Creation Through Novel Resource ConfigurationAsyrafinafilah HasanawiNessuna valutazione finora

- Syllabus DBA840DDocumento3 pagineSyllabus DBA840DLakanPHNessuna valutazione finora

- Qualities of Entrepreneurs: 1. DisciplinedDocumento2 pagineQualities of Entrepreneurs: 1. DisciplinedCindyHan DreamVlogNessuna valutazione finora

- EM - Module 3 - Identification of Business Opportunity (AU) For ClassDocumento22 pagineEM - Module 3 - Identification of Business Opportunity (AU) For ClassRokeshuvaraj0% (1)

- Entrepren IDocumento57 pagineEntrepren IArun SinghNessuna valutazione finora

- SHTT Case StudiesDocumento81 pagineSHTT Case StudiesDespicable TrangNessuna valutazione finora

- Buboy AssigmentDocumento6 pagineBuboy AssigmentCrisCate0% (1)

- Evolution and Revolution of EntrepreneurshipDocumento10 pagineEvolution and Revolution of Entrepreneurshipnagendra_6391Nessuna valutazione finora

- Science & Tech Capacity Building ProgramDocumento7 pagineScience & Tech Capacity Building ProgramVadivel N P PillaiNessuna valutazione finora

- Drivers and Challenges For Internationalization: A Study With Born Global FirmsDocumento14 pagineDrivers and Challenges For Internationalization: A Study With Born Global FirmsMai Ngô Võ NgọcNessuna valutazione finora

- Entrepreneurship Skills for Growth-Orientated SMEsDocumento23 pagineEntrepreneurship Skills for Growth-Orientated SMEsSurya PrasannaNessuna valutazione finora

- Cambridge-international-as-a-level-economics-study-revision-guide-sample-pages (2)Documento23 pagineCambridge-international-as-a-level-economics-study-revision-guide-sample-pages (2)S.V. CREATIONSNessuna valutazione finora