Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Machine News Vol. 03 No. 06

Caricato da

SreeharanCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Machine News Vol. 03 No. 06

Caricato da

SreeharanCopyright:

Formati disponibili

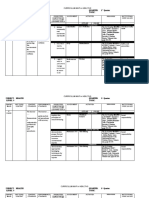

Page |1

December 2015

Machine News

NEWSLETTER

DEPARTMENT OF MECHANICAL ENGINEERING, SVS College of Engineering

Vol. 03

No. 06

Editor: Dr. N. Shanmuga Sundaram

For internal circulation only

st

th

1 November 2015 30 November 2015

Associate Editors: Mr. B. N. Sreeharan, Mr. K. Rajan

In plant Training/Internship

Paper Publications in Journals

Mr. N. Jagadhesan and Mr. P. Sathyaseelan of IV

Mech. B underwent in plant training in Southern

Railways in their Podanur workshop from

16.11.2015 to 20.11.2015.

Mr. T. Ravi, AP/ME and Mr. P. Kanagaraj, AP/ME

published a paper titled " Numerical and Buckling

Analysis of Composite Hybrid Propeller Shaft " in the

"International Journal for Research in Applied Science

and Engineering Technology (IJRASET)", Volume 3

(November 2015), issue XI, Pages 383-387 and

ISSN:2321-9653.

Placement Training

Placement training was conducted for IV Mech. A &

B students as detailed below

In basic maths, logical reasoning, verbal reasoning,

emotional techniques and personal HR by the

maths faculty from S & H department and the

Placement & Training Cell from 17.11.2015 to

21.11.2015.

In engineering drawing by Mr. I. Anbarasan, AP

[SG]/ME and Mr. N. Karthikeyan, AP/ME on

16.11.2015.

On lathe & special machines, strength of materials,

refrigeration & air conditioning, welding, fluid

mechanics and machinery, heat transfer,

CAD/CAM and casting by Mr. N. Prasanna,

AP/ME,

Mr.

N.

Karthikeyan,

AP/ME,

Mr.

M.

Gopalakrishnan,

AP/ME,

Mr. N. Prabhushankar, AP/ME, Mr. S. Karthik,

AP/ME, Mr. S. Binson, AP/ME, Mr. V.

Murugabalaji, AP/ME and Mr. A. Kannan, AP/ME

respectively on 19.11.2015.

In engineering drawing by Mr. P. Kanagaraj,

AP/ME and Mr. R. Midhun, AP/ME and

Mr. S. Karthik AP/ME on 27.11.2015.

Faculty Development Programmes

Mr. B. N. Sreeharan, AP[SG]/ME had been to a seminar

on "Scientific Publication and Evaluation: Writing

Research Papers, Citation Analysis and Plagiarism"

on 27.10.2015 and 28.10.2015 organised by the

Department of Library, CIT, DRDO-INMAS, Delhi &

SALIS.

Mr. N. Nagarajan, AP[SG]/ME and Mr. R. Dinesh,

AP/ME had participated in a workshop on "Design of

Experiments and Optimization for the Researchers

(with Hands-on Training)" conducted by the

Department of Aeronautical and Mechanical

Engineering, Karpagam Institute of Technology,

Coimbatore on 16.11.2015 and 17.11.2015.

Also Mr. I. Anbarasan, AP[SG]/ME attended a

workshop on "TEQIP II Sponsored Foundation Skills

in Integrated Product Development (FSIPD)"

organised by PSG College of Technology, Coimbatore

from 23.11.2015 to 27.11.2015.

Mr. A. Kannan, AP/ME, Mr. V. Murugabalaji, AP/ME,

Mr. M. Prabhu, AP/ME and Mr. S. Settu, AP/ME went

for a workshop from 25.11.2015 to 27.11.2015 on

"Finite Element Applications in Mechanical

Engineering" organised by the Department of

Machine News

December 2015

Mechanical Engineering, Hindusthan College of

Engineering and Technology, Coimbatore.

Research Grant Received/Applied

Mr. N. Nagarajan, AP[SG]/ME, Mr. A. Kannan, AP/ME

and

Mr.

P.

VineethKumar,

AP/ME

and

Mr. N. Karthikeyan, AP/ME applied for a grant for their

projects to Motorola, India. The grant value amounts

to Rs. 75000.

Green Engine

Green engine is the internal combustion engine with

some or major modifications in its parts and design

Construction and Working of Green Engine:Green engine is really evolutionary concept. Its

construction is a lot varied from the conventional

reciprocating engine. Green engine have rotary type

construction. Central shaft is provided with the four

vanes around it. These vanes run on the internal

wall of engine as shaft rotates. Small chambers are

provided at two inlet ports in which various

functions like intake, compression, mixing and finally

combustion is achieved. Then power of expanding

gases is released in expansion chamber and then

flue gases are sent to exhaust.

Intake: - The air arrives to the engine through the

direct air intake port in the absence of an air inlet

pipe, throttle and inlet valves on the air intake

system. A duct is provided on the sides of the vane

and rotor. The duct is so shaped that when the air

moves through, strong swirls generate when it gets

compressed in the chamber. The air pushes the vane

blades which in turn impart a proportionate rotation

in the small rotor which houses the chambers. The

inlet air duct ends with a very narrow opening to the

chamber.

Compression: - The rushing air from the duct is

pushed by the blades into the small chambers in the

rotor. The volume of these chambers is

comparatively

very

small.

Naturally,

the

compression obtained by such a procedure is very

satisfactory. As earlier mentioned, the compressed

air is in a swirling state, ready to be mixed with the

fuel which will be injected into the chamber when it

will be place before the injector by the already

rotating rotor.

Mixing: - As soon as the chamber comes in front of

the fuel injector, the injector sprays fuel into the

Page |2

compressed air. Because of the shape of the

chamber, the fuel mixes well with the compressed

air. The importance of ideal mixing leads to deletion

of CO emission. And also because of the strong

swirling, a centrifugal effect is exerted in the air-fuel

mixture. Moreover, the rotation of the burner,

makes this centrifugal affects all the more effective.

Mixing phase has enough time to produce an ideal

air-fuel mixture as the spark plug is positioned

towards the other end of the rotor or burner.

Combustion: - As the chamber rotates towards the

end of its path, it is positioned before the spark

plug. A spark flies from the plug into the air-fuel

mixture. Because of the mixing phase, the air-fuel

mixture is denser near the spark plug, thereby,

enabling lean-burning of the charge and also a

uniform flame front. As soon as the whole charge is

ignited, the burner rotates to position itself in front

of the narrow exit.

Power: - The expanded gas rushes out of the

chamber through the narrow opening, thereby

pushing the name in the process. The sudden

increase in volume ensures that more power is

released. Or in other words, the thermal energy is

fully utilized.

Exhaust: - As the thermal energy is fully utilized, the

exhaust gases bring along comparatively less heat

energy. This mainly helps in the thermal efficiency of

the engine. It raises the engines thermal efficiency

and also because of the complete burning of the

charge, poisonous gases like CO are absent in the

exhaust emissions.

Technical Feature:- Compared to conventional

piston engines, operated on four phases, the Green

engine is an actual six phase internal combustion

engine with much higher expansion ratio. Thus it has

six independent or separate working processes:

intake, compression, mixing, combustion, power and

exhaust, resulting in the high air charge rate.

Satisfactory air-fuel mixing, complete burning, high

combustion efficiency and full expansion. The most

Machine News

Page |3

December 2015

important characteristic is the expansion ratio being

much bigger than the compression ratio. Also, the

other main features are the revolutionary

innovations of the sequential variable compression

ratio, constant volume combustion and selfadapting sealing system. Therefore, an engine

having extremely high thermal efficiency, near-zero

emissions, quietness, light and small, lower cost with

capability of burning of various fuels has come into

being.

Direct Air Intake:- Direct air intake means that there

is no air inlet pipe, throttle and inlet valves on the

air intake system. Air filter is directly connected to

the intake port of the engine, and together with the

less heating effect of air intake process, benefited

from lower temperature of independent intake

chamber, a highest volumetric efficiency which

makes engine produce a high torque of output on all

speed range is achieved. The pump loss which

consumes the part of engine power is eliminated.

Also fuel measuring facilities are built-in, and parts

are saved.

Sequential Variable Compression Ratio: - This

greatly revolutionary innovation can provide the

most suitable compression ratio for the engine

whatever operation mode it works on with burning

variety of fuels. Therefore, an excellent combustion

performance is attained.

Direct Fuel Injection: - Direct fuel injection can

provide higher output and torque, while at the same

time it also enhances the response for acceleration.

conventional engine whose performances lack of

efficient combustion time, resulting in heavy CO

emission and low fuel usage rate, the Green engine

has a sufficient controllable combustion time to

match any fuels.

Strong Swirling :- As a tangential air duct in between

combustion chamber and compression chamber, a

very swirling which could lost until gas port is

opened, can be formed while air is pumped into the

combustion chamber. Consequently, the air-fuel

mixing and the combustion process can have a

satisfying working condition.

Self-Adapting Sealing System: - This is another

revolutionary innovation applied in the Green

engine: it can eliminate a number of seal plates or

strips to achieve gapless seal and to provide most

efficient and reliable sealing system with less

friction.

Modular Design: - Use of modular design is the best

way for engine mass production. Thus stacking of

rotors easily extends range of available power.

Limited Parts and Small Size: - There is only a few

dozens of parts which can be easily manufactured in

the engine structure when compared with modern

piston engine which comprises of more than a

thousand parts. It suggests that the cost will be very

low. Also, due to the compact structure the package

and the weight of the Green engine will be only 1/5

to 1/10 of the regular engine on the same output.

Advantages:-

Super Air-Fuel Mixing: - Since the independent airfuel mixing phase is having enough time for mixing

air and fuel under strong swirling and hot situation,

the engine is capable to burn any liquid or gas fuels

without modifications. An ideal air-fuel mixture

could delete CO emission. Also centrifugal effect

coming from both strong swirling and rotation of the

burner makes the air-fuel mixture denser near the

spark plug. It benefits to cold starting and managing

lean-burning.

Lowest Surface to Volume Ratio: - The shape of

combustion chamber herein can be designed as

global as possible. Thus, a lowest surface to be

obtained, and the engine is having less heat losses

and high combustion efficiency.

Controllable Combustion Time:- Due to the

independent combustion phase, compared to the

Higher Efficiency.

Lower exhaust temperature.

Emission control.

For low weight and size green engine

delivers much better performance.

Better performance.

Low cost engine.

Less noisy and less vibrations and hence

high efficient.

Conclusion:- The Green engines prototypes have

been recently developed, and also because of the

unique design, limitations have not been

determined to any extent. But even in the face of

limitations if any, the Green engine is sure to serve

the purpose to a large extent.

- Compiled by Mr. K. Rajan, AP/ME

December 2015

Machine News

Vision, Mission and

d Objectives of our

college

Vision

To promote technical education and strive for the

betterment of society

Mission

To impart quality technical education and

training to the students to make them

competent engineers and thereby contribute to

National Development.

To provide an environment to foster research

and innovation.

To groom the learners to emerge as leaders at

various technological platforms.

Objectives

To equip students as skill oriented persons with

sound knowledge of fundamentals to meet the

ever challenging needs of the society.

To provide training to the students to attain

excellence in leadership qualities thereby

making them socially responsible

onsible citizens.

To promote quality education in Engineering

and Technology through research and

innovations.

Facts To Know

Shakespeare invented the word 'assassination'

and 'bump'.

Stewardesses is the longest word typed with

only the left hand.

The ant always falls over on its right side when

intoxicated.

The electric chair was invented by a dentist.

The human heart creates enough pressure when

it pumps out to the body to Squirt blood 30 feet.

Wearing headphones for just an hour will

increase the bacteria

cteria in your ear By 700 times.

Ants don't sleep .

A cow gives nearly 200,000 glasses of milk in her

lifetime.

Dragonflies are one of the fastest insects, flying

50 to 60 mph.

The largest cockroach on record is one

measured at 3.81 inches in length.

Page |4

Thee blood of mammals is red, the blood of

insects is yellow, and the blood of lobsters is

blue.

Before air conditioning was invented, white

cotton slipcovers were put on furniture to keep

the air cool.

A one ounce milk chocolate bar has 6 mg of

caffeine.

Carbon monoxide can kill a person in less than

15 minutes.

The largest ever hailstone weighed over 1kg and

fell in Bangladesh in 1986.

Ants can live up to 16 years.

In Belgium, there is a museum that is just for

strawberries.

The sense of smell of an ant is just as good as a

dog's.

Popped popcorn should be stored in the freezer

or refrigerator as this way it can stay crunchy for

up to three weeks.

The most common name in the world is

Mohammed.

The name of all the continents end with the

same letter thatt they start with.

The strongest muscle in the body is the tongue.

TYPEWRITER is the longest word that can be

made using the letters only on one row ! of the

keyboard.

Women blink nearly twice as much as men!!

You can't kill yourself by holding your breath.

People say "Bless you " when you sneeze

because when you sneeze, your heart stops for a

millisecond.

It is physically impossible for pigs to look up into

the sky.

The "sixth sick sheik's sixth sheep's sick" is said

to be the toughest tongue twister in the English

language.

If you sneeze too hard, you can fracture a rib. If

you try to suppress a sneeze, you can rupture a

blood vessel in your head or neck and die.

A crocodile cannot stick its tongue out.

A snail can sleep for three years.

All polar bears are left handed.

The cigarette lighter was invented before the

match.

Like fingerprints, everyone's tongue print is

different.

- Compiled by Mr. A. Vignesh,

Vignesh Final B. E. Mech. B

Reach us at:

svsmechnewsletter@gmail.com

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Employee Turnover ReportDocumento10 pagineEmployee Turnover ReportDon83% (6)

- Design For AssemblyDocumento34 pagineDesign For AssemblySreeharan100% (1)

- Design For Manufacture, Assembly and EnvironmentDocumento3 pagineDesign For Manufacture, Assembly and EnvironmentSreeharanNessuna valutazione finora

- Relationship Between Geometric Welding Parameters and Optical-Acoustic Emissions From Electric Arc in GMAW-S ProcessDocumento9 pagineRelationship Between Geometric Welding Parameters and Optical-Acoustic Emissions From Electric Arc in GMAW-S ProcessSreeharanNessuna valutazione finora

- Analysis of Weld Bead Characteristics On GMAW by Changing Wire Electrode GeometryDocumento10 pagineAnalysis of Weld Bead Characteristics On GMAW by Changing Wire Electrode GeometrySreeharanNessuna valutazione finora

- Machine News Vol. 03 No. 05Documento4 pagineMachine News Vol. 03 No. 05SreeharanNessuna valutazione finora

- Diploma Examination, 2011: Total No of Pages: Register Number: Name of The Candidate: 3Documento3 pagineDiploma Examination, 2011: Total No of Pages: Register Number: Name of The Candidate: 3SreeharanNessuna valutazione finora

- UrinalysisDocumento10 pagineUrinalysismaximussathishNessuna valutazione finora

- Fluid MechanicsDocumento12 pagineFluid MechanicsSreeharanNessuna valutazione finora

- 1-1FlowCharts For HaccpDocumento3 pagine1-1FlowCharts For HaccpPeter George0% (1)

- QMS - 001 Compliance of RecordsDocumento4 pagineQMS - 001 Compliance of Recordsedgardovrgs3169Nessuna valutazione finora

- EO MNC 10 June 2022Documento4 pagineEO MNC 10 June 2022LeulaDianneCantosNessuna valutazione finora

- Why Is ICS Important For Schools?Documento8 pagineWhy Is ICS Important For Schools?Spit FireNessuna valutazione finora

- SnapNrack 2018 Product CatalogDocumento24 pagineSnapNrack 2018 Product CatalogAloNessuna valutazione finora

- RNA and Protein Synthesis Problem SetDocumento6 pagineRNA and Protein Synthesis Problem Setpalms thatshatterNessuna valutazione finora

- 1st English Lesson 6-7 - CompressedDocumento21 pagine1st English Lesson 6-7 - Compressedharonac588Nessuna valutazione finora

- Predrag Mladenovic CVDocumento3 paginePredrag Mladenovic CVStefan Markovic JagodinacNessuna valutazione finora

- Recipes For Ceviche, Pebre and Pisco SourDocumento4 pagineRecipes For Ceviche, Pebre and Pisco SourJoaquín Rolón CarrerasNessuna valutazione finora

- Motor DeiselShip Latest PDFDocumento154 pagineMotor DeiselShip Latest PDFCadet Prateek SaxenaNessuna valutazione finora

- HC-33 Maximum Moisture Hair Styling Gel PDFDocumento2 pagineHC-33 Maximum Moisture Hair Styling Gel PDFdianaNessuna valutazione finora

- JETIR1904787Documento3 pagineJETIR1904787RONAL SALAS CONTRERASNessuna valutazione finora

- Wastewater Treatment Lab TestDocumento8 pagineWastewater Treatment Lab TesthuyNessuna valutazione finora

- Work Immersion Rubric & Assessment ReportDocumento2 pagineWork Immersion Rubric & Assessment ReportJEE AR CANTERENessuna valutazione finora

- Chapter 2 Body CoordinationDocumento25 pagineChapter 2 Body CoordinationnanarahmannaimNessuna valutazione finora

- Roadshow Advanced 7.2 V3.2 221004 FinalDocumento347 pagineRoadshow Advanced 7.2 V3.2 221004 FinalEddy StoicaNessuna valutazione finora

- Calcium Cyanide: Hydrogen Cyanide. CONSULT THE NEW JERSEYDocumento6 pagineCalcium Cyanide: Hydrogen Cyanide. CONSULT THE NEW JERSEYbacabacabacaNessuna valutazione finora

- How To Conduct A Situation AnalysisDocumento10 pagineHow To Conduct A Situation AnalysisÂmany AymanNessuna valutazione finora

- Program Thành TrungDocumento3 pagineProgram Thành TrungQuốc HuyNessuna valutazione finora

- The Learner The Learner : 1 QuarterDocumento4 pagineThe Learner The Learner : 1 QuarterRode Jane SumambanNessuna valutazione finora

- English The RainDocumento2 pagineEnglish The RainsmitaNessuna valutazione finora

- BFPPPDocumento15 pagineBFPPPFaith JacalanNessuna valutazione finora

- Guía Oficial de La Delegación Argentina de Los Juegos Olímpicos Tokio 2020Documento330 pagineGuía Oficial de La Delegación Argentina de Los Juegos Olímpicos Tokio 2020Leandro BonavidaNessuna valutazione finora

- Manoshe Street Takeaway MenuDocumento9 pagineManoshe Street Takeaway MenuimaddakrNessuna valutazione finora

- Curriculum Guide: Exploratory Course On Household ServicesDocumento5 pagineCurriculum Guide: Exploratory Course On Household ServicesJovanni Mancao PodadorNessuna valutazione finora

- Electron Configurations of The Elements (Data Page) - WikipediaDocumento25 pagineElectron Configurations of The Elements (Data Page) - WikipediaAlex OmungaNessuna valutazione finora

- Scaffolding-Fixed and Mobile: Safety Operating ProceduresDocumento1 paginaScaffolding-Fixed and Mobile: Safety Operating Proceduresmohammed muzammilNessuna valutazione finora

- Pizza Hut and Dominos - A Comparative AnalysisDocumento19 paginePizza Hut and Dominos - A Comparative AnalysisSarvesh Kumar GautamNessuna valutazione finora

- Introduction To Nervous SystemDocumento4 pagineIntroduction To Nervous SystemErnie G. Bautista II, RN, MD100% (1)