Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Do - 278 - s2003 Drainage Steel Grating Specifications

Caricato da

rubydelacruzTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Do - 278 - s2003 Drainage Steel Grating Specifications

Caricato da

rubydelacruzCopyright:

Formati disponibili

,'p

~1 U .pt'eO If~

REPUBLIC OF THE PHIUPPINES

II-Io-OJ

DEPARTMENT OF PUBLIC WORKS AND HIGHWAYS

OFFICE OF THE SECRETARY

MANILA

DEPARTMENT ORDER)

278

No.

Series of 2003 ~

SUBJECT

DPWH Standard

Specifications for Drainage

Steel Grating with Frame

11-10-'"

-x-x-x-x-x-x-x-x-x-x-x-x-xFor the guidance and compliance of all concerned, the standard specifications for

Drainage Steel Grating with Frame are hereby prescribed which shall form part of the

DPWH Standard Specifications, Volume II- Highways, Bridges and Airports.

This supersedes all existing specifications and related issuances issued contrary

hereto.

This Order shall take effect immediately.

DO

IIv8 p; 2

Item 511 - Specification for Drainage Steel Grating with Frame

511.1 Description

This item shall consist of furnishing all materiaJst toolst and equipment including

labor required in Wldertaking the proper application of steel grating with frame as shown

on the plans and in accordance with this specification.

511.2 Classes and Uses of Road Grates and Frames

Classes of grates that are commonly use in drainage work are sumPt trench and

box.

Sump grates shall be used to create a trafficable groWld level ently area for

surface rainwater to flow into the WldergroWld stonnwater drainage system. Sump grates

shall be used in paved or grassed areas that are graded to direct the swface water to a

single pit or to a series of pits. Sump grates shall be plain or hinged.

Trench grates shall be used to collect surface rainwater run off from areas that

cannot be graded to direct flow into a single pit.

Box grates or road drainage shall be used to transfer road swface stonn water into

an undergroWld drainage system. Nonnally used in conjWlction with kerb entry, the

addition of the grate significantly increases the hydraulic capacity of the inlet,

particularly on steep slopes.

511.3 Strength Classifications

grates

and the loading conditions for Sump, Trench and Box

Class A - Test Load 10kN

For locations trafficked only by pedestrianst wheelchairs and cyclists inaccessible to motor vehicles by virtue of barriers, narrow passages or stepped or

Wlpaved approaches.

Class B - Test Load 80kN

For locations normally trafficked by pedestrians and slow moving passenger cars

or light agricultural tractors.

These locations include areas accessible to

infrequent slow moving heavy trucks.

Typical locations include footpaths,

groWld level and multistoried car parks, suburban driveways and back yards.

Class C - Test Load 150kN

For locations trafficked by slow moving fully laden trucks such as pedestrians,

malls and industrial or commercial areas.

Do!l'Z78 p~3

Class D - Test Load 210kN

For locations trafficked by fast moving fully laden trucks and forklifts with wheel

loads to S.OT. This includes all public roads from residential to freeway.

Class E, F or G - Test Load 400kN, 600kN or 900kN

For locations subject to vehicles such as large forklifts, earthmoving or container

handling equipment and aircraft. Typical locations include wharves, container

storage areas, heavy industIy or construction sites and domestic or international

airports.

All loading conditions specified above are applicable to the three classes of grates

depending on their specific uses and locations.

511.4

Materials Requirement

511.4.1 Steel Grating

The steel grating shall be made of fabricated mild steel provided with hot dip

galvanized in accordance with ASlM A1S3/AASIITO M 232 for superior corrosion

protection. Steel grating shall be machine-made grating comprised of steel flat bars

standing on edge equispaced from each other. To prevent them from falling over and to

provide restraint in buckling, a twisted cross rod (6mm) is forge-welded'" into the top of

the flat bars.

511.4.2 Steel Frame

The steel frame clear openings of drainage grates shall be 15mm larger than

nominal sizes of industIy standard sized pits. These pits increase in size in increments of

15Omm. This shall be done to allow frames to be placed over standard panel formwork

and cast in while pouring the pit walls, to speeds up installation and ensure the frame is

fully embedded in the concrete.

511.4.3 Drainage Grate Sizes

The drainage grates shall be identified by their internal clear opening dimensions

of the frame. For square and rectangular grates, the normal convention shall be the width

x length. Metal units shall conform to the approved plan dimensions and specifications

requirement for the designated materials.

"'Forge-welding

is a process of metal fusion using a combination

of high temperature and high pressure.

D0/I278 p.4

Grates shall consist of 25mm to 65mm x 3mm, 4.5mm or 5mm thick flat bars

with length of not more than 6.1m spaced at 30mm O.c. with 6mm twisted rod spaced at

100mm o.c .. Angular frame (L 75mm x 75mm x 9mm thick) shall be coated with hot

dipped galvanized for superior corrosion protection finish and extended life. If required,

I-Beam support shall be provided in the grates in accordance with the approved plan. It

shall also conform to the requirements of ASlM A 153 or its equivalents AASHTO M

232.

511.4.4

The metal unit shall conform to ASlM A 36 / AASHTO M 183.

Dimension Tolerances:

Thickness

Width

Length

Straightness

511.4.5

=

=

=

+/- 0.2Omm

+/- 0.8Omm

+ 50mm/Nll., mm

6mm in each 1.5m length

Joint Mortar

Unless otherwise indicated on the Plans, joint mortar shall be composed of one

part Portland Cement and two parts fine aggregate by volume to which hydrated lime has

been added in an amount equal to 10 percent of the cement by weight. All materials for

mortar shall meet the requirements of Item 405, Structural Concrete. Structural concrete

used shall attain a minimum 28-day compressive strength of 20.682 MPa (3000 psi).

511.5

Construction

Requirements

Concrete construction shall conform to the requirements for Item 405, Structural

Concrete.

Metal

be assembled

readily in the

machining, if

one pm.

gratings which are to rest on frames shall bear on them evenly. They shall

before shipment and so marked that the same pieces may be reassembled

same position when installed. Inaccuracy of bearings shan be corrected by

necessaty. The steel grating and its corresponding frame shall constitute

When grade adjustment or existing drainage grates is specified, the frames and

steel gratings shan be removed and the walls shall be reconstructed as required. The

cleaned frames shall be reset at the required elevation. Upon completion, each drainage

grates shall be cleaned of any accumulations of silt, debris, or foreign matter of any kind

and shall be kept clear of such accumulation until final acceptance of the work.

Excavation and backfill shall be done in accordance with Item 102, Excavation.

DO:278 p.5

511.6 Acceptance Requirement

A sufficient number of cylinders for concrete construction shall be cast from the

concrete for each unit for compression tests at 7, 14 and 28 days, and to anow for at least

3 cylinders for each test. If the strength requirement is met at 7 or 14 days, the units shan

be certified for use 14 days from the date of casting. If the strength is not met at 28 days,

an units made from that batch or load will be rejected.

The steel grating plants will be inspected periodically for compliance with

specified manufacturing and fabricating methods and bars samples will be obtained for

laboratory testing for compliance with material quality requirements.

All draining grates materials shan be subjected to inspection for acceptance as to

condition at the latest practicable time the Engineer has the opportunity to check for

compliance prior to or during incotpOration of materials into the work.

511.7 Method of Measurement

The quantity to be measured and paid for will be the number of pairs of metal

frames and gratings completed and accepted. Concrete and reinforcing steel (AASHTO

M 31) will be measured and paid for under Item 405, Structural Concrete and Item 404,

Reinforcing Stee~ respectively.

Excavation and backfill will be measured and paid for as provided in Item 102,

Excavation.

511.8Basis of Payment

The accepted quantities, determined as provided in Section 511.7, Method of

Measurement of the Pay Items in the Bill of Quantities will be paid for at the contract

unit prices, which shan constitute full compensation for furnishing and placing an

materials and for an labor, equipment, tools and incidentals necessary to complete the

item.

Pay Item No.

511

Description

Metal frames and grating

Unit of Measurement

Pair

DO#Z78 p.

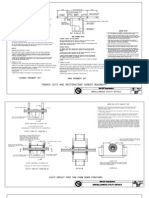

Steel grating with provisions of slots on corners and sides I()r holding do\vn

bolts.

Doll

278 p~ 7

Frames shall be placed over standard panel torm\vork and cast in while

pouring the pit walls. This meth\)d of installation ensures the frame to be

flill:v embedded in the concrete.

Doll

Z78 p. 8

Steel g.rating. shall be titted in its frame by providing

made of stalnlcss.;ted

or sput \vcldcd on corners

resistance to unautlF'ri?ed (1pcning.

holding dow1l bolts

and sicks lu pr'o'ide

DO~I: 718 p. 9

Installed steel grating (Trench) at Quiapo-Quezon Bh'd, Underrass.

Sput \vclding methud was

llsed In tillS particular project.

DO#Z78 p. 10

.

~:

Project:

Product:

DPWH - Quezon Blvd. underpass

Webdrain Trench Grates - WA655/1/P/G

Consists of FB 65 x 5 mm thk spaced @ 30mm o.c.

With 6mm twisted rod spaced @ 100 mm o.c.

With angular frame (L75 x 75 x 9mm thk)

Hot Dipped Galvanized with BS EN ISO 1461

Bell

2:78 p.11

'.,~s

~~:tJijp

Project:

Product:

DPWH - Blumentritt

Webdrain Sump Grates - WA655/1/P/G

Consists of FB 65 x 5 mm thk spaced @ 30mm o.c.

With 6mm twisted rod spaced @ 100 mm o.c.

With angular frame (L75 x 75 x 9mm thk) & with I-Beam Support

Hot Dipped Galvanized with BS EN ISO 1461

r'"

DO;!!VB p. 12

Project:

Product:

to.

f

i.

~

DPWH - Espana Corner Morayta

Webdrain Sump Grates - WA655/1/P/G

Consists of FB 65 x 5 mm thk spaced @ 30mm o.c.

With 6mm twisted rod spaced @ 100 mm o.c.

With angular frame (L75 x 75 x 9mm thk) & with I-Beam Support

Hot Dipped Galvanized with BS EN ISO 1461

DOl!278 p.13

Project:

Product:

DPWH - Espana

\Nebdrain Sump Grates - WA655/1/PiG

Consists of FB 65 x 5 mm thk spaced @ 30mm o.c.

With 6mm twisted rod spaced @ 100 mm o.c.

With angular frame (L75 x 75 x 9mm thk) & with I-Beam Support

Hot Dipped Galvanized with BS EN ISO 1461

Potrebbero piacerti anche

- Method Statement On Bore Piling Work & Contiguous Bore Piling WorkDocumento43 pagineMethod Statement On Bore Piling Work & Contiguous Bore Piling Workjasekan.dc100% (1)

- Bored Cast in Situ Method LogyDocumento77 pagineBored Cast in Situ Method LogySujan RajkumarNessuna valutazione finora

- Annexure 2A - Prestressing - VOLUME 5-69-84Documento16 pagineAnnexure 2A - Prestressing - VOLUME 5-69-84ManukantShrotriyaNessuna valutazione finora

- Section 6 - Manholes, Frames, Covers and Cleanouts 6-01. General RequirementsDocumento3 pagineSection 6 - Manholes, Frames, Covers and Cleanouts 6-01. General RequirementsThupten Gedun Kelvin Ong100% (1)

- DPWH Geotextile StandardsDocumento12 pagineDPWH Geotextile StandardsFatima Jade Castillo Ang100% (1)

- PillingDocumento21 paginePillingHadiyan RosyidiNessuna valutazione finora

- Is 785 1998 Reinforced Concrete Poles For Overhead Power and Telecommunication Lines - SpecificationDocumento10 pagineIs 785 1998 Reinforced Concrete Poles For Overhead Power and Telecommunication Lines - SpecificationDebajani DekabaruahNessuna valutazione finora

- P'R 1 Dp"Jt-I : Republic of The PhilippinesDocumento5 pagineP'R 1 Dp"Jt-I : Republic of The PhilippinesjrsiaseNessuna valutazione finora

- Pipe Supports IP 4-2-2: ScopeDocumento3 paginePipe Supports IP 4-2-2: ScopeSixto Gerardo Oña AnaguanoNessuna valutazione finora

- Retaining Walls - Soldier Pile (LRFD)Documento11 pagineRetaining Walls - Soldier Pile (LRFD)rashi1717Nessuna valutazione finora

- Clarifier Tank Part 1 - GeneralDocumento4 pagineClarifier Tank Part 1 - Generalfiddy_ftNessuna valutazione finora

- MS For BoredDocumento18 pagineMS For BoredsinlekmNessuna valutazione finora

- Techinical Specifications Welcome To NescoDocumento54 pagineTechinical Specifications Welcome To NescotejzabNessuna valutazione finora

- Prestressing Works SpecsDocumento30 paginePrestressing Works SpecsVladimir Simeunovic100% (1)

- Chain Link Fences and Gates Part 1 - General 1.1 DescriptionDocumento5 pagineChain Link Fences and Gates Part 1 - General 1.1 Descriptionm_a_nada67% (3)

- 31 62 16 Steel Sheet PilesDocumento6 pagine31 62 16 Steel Sheet PilesFadredskyNessuna valutazione finora

- DO 028 s2018Documento8 pagineDO 028 s2018Anthony TangNessuna valutazione finora

- Tieback Anchors - 1.24.11Documento7 pagineTieback Anchors - 1.24.11xcvNessuna valutazione finora

- Memo 097.7 - 103019 - Item 455 Steel RibsDocumento5 pagineMemo 097.7 - 103019 - Item 455 Steel RibsBai Alleha MusaNessuna valutazione finora

- 1814 3) Design Criteria For Steel Structural WorksDocumento18 pagine1814 3) Design Criteria For Steel Structural WorksPrasadarao TalluriNessuna valutazione finora

- 8/17/2021 /conversion/tmp/activity - Task - Scratch/537054108Documento8 pagine8/17/2021 /conversion/tmp/activity - Task - Scratch/537054108Christian GarciaNessuna valutazione finora

- Neral Specification For Skid Mounting Assemblyt - 03-GTS-02 REV. 1Documento10 pagineNeral Specification For Skid Mounting Assemblyt - 03-GTS-02 REV. 1Ashok Kumar100% (1)

- Bridge Technical NoteDocumento5 pagineBridge Technical Noteপ্রিয়দীপ প্রিয়মNessuna valutazione finora

- Checklist For 33kV Bus Duct Structure Design & DrawingDocumento4 pagineChecklist For 33kV Bus Duct Structure Design & DrawingRupesh KhandekarNessuna valutazione finora

- Reinforced Concrete Poles For Overhead Power and Telecommunication Lines - SpecificationDocumento10 pagineReinforced Concrete Poles For Overhead Power and Telecommunication Lines - SpecificationKumar AtrayNessuna valutazione finora

- Do 050 S2007-Mse SpecsDocumento12 pagineDo 050 S2007-Mse SpecsCarol SantosNessuna valutazione finora

- Disclosure To Promote The Right To InformationDocumento13 pagineDisclosure To Promote The Right To InformationHeather CarterNessuna valutazione finora

- GRATINGS Rev.1Documento7 pagineGRATINGS Rev.1mohdNessuna valutazione finora

- Solution Manual Prestressed Concrete A Fundamental Approach 5th Edition Edward G. NawyDocumento64 pagineSolution Manual Prestressed Concrete A Fundamental Approach 5th Edition Edward G. Nawykrakatua100% (1)

- Part 6 - Sec 6.08.2.1 RC Pipe CulvertsDocumento2 paginePart 6 - Sec 6.08.2.1 RC Pipe CulvertsAbdul Wahab JamilNessuna valutazione finora

- Sec 683Documento15 pagineSec 683asdsdssdNessuna valutazione finora

- Special Specification 5202 Pipe CasingDocumento6 pagineSpecial Specification 5202 Pipe Casingresp-ectNessuna valutazione finora

- Section 705 Prestressed Concrete Members For BridgesDocumento12 pagineSection 705 Prestressed Concrete Members For BridgesCarlos SYNessuna valutazione finora

- 2010 SJI Composite Joist COSP Final 25mar111Documento15 pagine2010 SJI Composite Joist COSP Final 25mar111Samir DjezzarNessuna valutazione finora

- C 1063 - 03 QzewnjmDocumento9 pagineC 1063 - 03 QzewnjmGarcia ManuelNessuna valutazione finora

- Compliance On Qcs SpecsDocumento16 pagineCompliance On Qcs Specsvhin84Nessuna valutazione finora

- Post Tension SpecificationDocumento7 paginePost Tension SpecificationsweetlaicheeNessuna valutazione finora

- Checklist For 33kV HG Fuse Structure Design & DrawingDocumento4 pagineChecklist For 33kV HG Fuse Structure Design & DrawingRupesh KhandekarNessuna valutazione finora

- SPC Occ 221423 MeDocumento4 pagineSPC Occ 221423 Metarekhisham1234Nessuna valutazione finora

- Standard Specification For Corrugated Steel Structural Plate, Zinc-Coated, For Field-Bolted Pipe, Pipe-Arches, and ArchesDocumento17 pagineStandard Specification For Corrugated Steel Structural Plate, Zinc-Coated, For Field-Bolted Pipe, Pipe-Arches, and Archesjun floresNessuna valutazione finora

- Project Standards and Specifications Metallic Expansion Joint Rev01Documento4 pagineProject Standards and Specifications Metallic Expansion Joint Rev01hiyeonNessuna valutazione finora

- Do 051 S2006Documento17 pagineDo 051 S2006MANOLO C. LUCENECIONessuna valutazione finora

- 4514 Power FastDocumento11 pagine4514 Power Fastgreg_mercurio_1Nessuna valutazione finora

- Raymond Pile BrochureDocumento16 pagineRaymond Pile Brochuremoyarek100% (4)

- Sarcheshmeh Flash Smelting Furnace Project: Specification For Fabrication and Erection of SteelworkDocumento36 pagineSarcheshmeh Flash Smelting Furnace Project: Specification For Fabrication and Erection of Steelworkmobin1978Nessuna valutazione finora

- Checklist For 33kV DP Structure Design & DrawingDocumento4 pagineChecklist For 33kV DP Structure Design & DrawingRupesh KhandekarNessuna valutazione finora

- Is 13349Documento20 pagineIs 13349raji357100% (1)

- Supply and Installation of Driven PilesDocumento7 pagineSupply and Installation of Driven PilesTAHER AMMARNessuna valutazione finora

- 3B ManholesDocumento5 pagine3B ManholesRony BaloyiNessuna valutazione finora

- MS For Slot Drain Installation-1-8Documento8 pagineMS For Slot Drain Installation-1-8Jonel TorresNessuna valutazione finora

- VicRoads Bridge Design Technical NotesDocumento111 pagineVicRoads Bridge Design Technical NotesJunnoKaiserNessuna valutazione finora

- Checklist For Isolator With or Without One or Two Earth Switch Structure Design & DrawingDocumento4 pagineChecklist For Isolator With or Without One or Two Earth Switch Structure Design & DrawingRupesh KhandekarNessuna valutazione finora

- Behaviour of Precast Reinforced Concrete Pile CapsDocumento6 pagineBehaviour of Precast Reinforced Concrete Pile CapsgaddargaddarNessuna valutazione finora

- Reinforced Concrete Buildings: Behavior and DesignDa EverandReinforced Concrete Buildings: Behavior and DesignValutazione: 5 su 5 stelle5/5 (1)

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyDa EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNessuna valutazione finora

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDa EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsValutazione: 4.5 su 5 stelle4.5/5 (10)

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesDa EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesValutazione: 4.5 su 5 stelle4.5/5 (16)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsDa Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsValutazione: 4 su 5 stelle4/5 (1)

- Spot Welding Interview Success: An Introduction to Spot WeldingDa EverandSpot Welding Interview Success: An Introduction to Spot WeldingNessuna valutazione finora

- Coa C2015-008Documento18 pagineCoa C2015-008Robelle Rizon100% (1)

- BP 344 - DPWHDocumento11 pagineBP 344 - DPWHJabriellaSanMiguelNessuna valutazione finora

- GPPB Resolution No. 07-2019 Liquidated Damages RevisionDocumento7 pagineGPPB Resolution No. 07-2019 Liquidated Damages RevisionrubydelacruzNessuna valutazione finora

- LocalGovUnitsProcManual PDFDocumento282 pagineLocalGovUnitsProcManual PDFmarwinjsNessuna valutazione finora

- DPWH Procedure ManualDocumento182 pagineDPWH Procedure ManualrubydelacruzNessuna valutazione finora

- TSO Policy 12% VATDocumento3 pagineTSO Policy 12% VATrubydelacruzNessuna valutazione finora

- Distress Manual 2014Documento146 pagineDistress Manual 2014Alfonso ReyesNessuna valutazione finora

- DPWH Inertial ProfileDocumento4 pagineDPWH Inertial ProfilerubydelacruzNessuna valutazione finora

- Commonwealth Avenue, Quezon CityDocumento3 pagineCommonwealth Avenue, Quezon CityAngeli Lou Joven VillanuevaNessuna valutazione finora

- Building ConstructionDocumento26 pagineBuilding Constructionsile15Nessuna valutazione finora

- CSHP Checklist 2011-1Documento2 pagineCSHP Checklist 2011-1Yssem Esor Ragiaba SelafarNessuna valutazione finora

- NEDA ICC Project Evaluation Procedures and Guidelines As of 24 June 2004Documento26 pagineNEDA ICC Project Evaluation Procedures and Guidelines As of 24 June 2004rubydelacruz0% (1)

- DO 005 s2017Documento195 pagineDO 005 s2017Isiah Ojoy100% (1)

- Rocond SlideDocumento29 pagineRocond SliderubydelacruzNessuna valutazione finora

- c82-122-b Signature of CafDocumento5 paginec82-122-b Signature of CafrubydelacruzNessuna valutazione finora

- PGBCode User Guide ManualDocumento204 paginePGBCode User Guide ManualrubydelacruzNessuna valutazione finora

- So - 092 - s2005 Analysis of Road Construction ManagementDocumento13 pagineSo - 092 - s2005 Analysis of Road Construction ManagementrubydelacruzNessuna valutazione finora

- DO 016 s2018 Geotagged PhotosDocumento2 pagineDO 016 s2018 Geotagged PhotosrubydelacruzNessuna valutazione finora

- DO - 079 - s2017 (Geotagging)Documento56 pagineDO - 079 - s2017 (Geotagging)Drew B Mrtnz100% (1)

- Philippine Green Building Code - ProcessDocumento67 paginePhilippine Green Building Code - ProcessrubydelacruzNessuna valutazione finora

- DO 009 S2011.PDF Procurement ProcessDocumento5 pagineDO 009 S2011.PDF Procurement ProcessrubydelacruzNessuna valutazione finora

- CB AnalysisDocumento15 pagineCB AnalysisTushar SharmaNessuna valutazione finora

- Economic and Financial AnalysiDocumento7 pagineEconomic and Financial AnalysirubydelacruzNessuna valutazione finora

- Philippine Green Buildings Spreadsheet 2017-04-27Documento3 paginePhilippine Green Buildings Spreadsheet 2017-04-27Teodoro QuintanaNessuna valutazione finora

- DO - 011 - s2017 Inclusion of Minimum Test PDFDocumento14 pagineDO - 011 - s2017 Inclusion of Minimum Test PDFrubydelacruzNessuna valutazione finora

- RevisedIRR RA9184Documento299 pagineRevisedIRR RA9184Francis Jr CastroNessuna valutazione finora

- GPPB Resolution 29-2014 Pcab LicenseDocumento5 pagineGPPB Resolution 29-2014 Pcab LicenserubydelacruzNessuna valutazione finora

- DO - 014 - s2017 Determination of Major and Similar Categories PDFDocumento23 pagineDO - 014 - s2017 Determination of Major and Similar Categories PDFrubydelacruzNessuna valutazione finora

- PBD For Goods - 5theditionDocumento113 paginePBD For Goods - 5theditionjosephNessuna valutazione finora

- DO - 011 - s2017 Inclusion of Minimum Test PDFDocumento14 pagineDO - 011 - s2017 Inclusion of Minimum Test PDFrubydelacruzNessuna valutazione finora

- 3 Overview Concrete Admixtures in JordanDocumento5 pagine3 Overview Concrete Admixtures in Jordanmalak hindiNessuna valutazione finora

- Trench Cuts and Restorations Across Roadways: Flexible Pavement Cut Rigid Pavement CutDocumento3 pagineTrench Cuts and Restorations Across Roadways: Flexible Pavement Cut Rigid Pavement CutIqueline JacqelineNessuna valutazione finora

- SOR Civil 2010Documento26 pagineSOR Civil 2010Zool HilmiNessuna valutazione finora

- IS 1893 (Part-4) 2015Documento31 pagineIS 1893 (Part-4) 2015jacs12770% (10)

- Purigo 5SDocumento2 paginePurigo 5SLW85Nessuna valutazione finora

- 1st UnitDocumento11 pagine1st UnitManish ShashikantNessuna valutazione finora

- Contractor'S Statement of Work Accomplished: Environmental Management Bureau 10Documento3 pagineContractor'S Statement of Work Accomplished: Environmental Management Bureau 10Razul DaranginaNessuna valutazione finora

- Astm C33Documento8 pagineAstm C33Rafael100% (1)

- Construction ScheduleDocumento3 pagineConstruction Schedulegroup2sd1314100% (1)

- 04 Kemcure WDocumento2 pagine04 Kemcure WMohamed Osama AshmawyNessuna valutazione finora

- 11kV Power Evacuation Arrangement - Tender BOQDocumento3 pagine11kV Power Evacuation Arrangement - Tender BOQVamsi PavuluriNessuna valutazione finora

- Test ProcedureDocumento27 pagineTest ProcedureAjayNessuna valutazione finora

- Report Floating Concrete...Documento5 pagineReport Floating Concrete...AnkitNessuna valutazione finora

- Earth For Homes 1955Documento80 pagineEarth For Homes 1955est_nu100% (1)

- Conplast CNDocumento2 pagineConplast CNMoatz HamedNessuna valutazione finora

- Boundarywall - Guidelines.jestha 2072Documento25 pagineBoundarywall - Guidelines.jestha 2072Dipendra MaharjanNessuna valutazione finora

- 701 Clavex (Lanko)Documento2 pagine701 Clavex (Lanko)wwcengNessuna valutazione finora

- RCC Compound Wall Manufacturer - Devbapa GroupDocumento16 pagineRCC Compound Wall Manufacturer - Devbapa GroupdevbapagroupNessuna valutazione finora

- Brochure-Bonna-Pipe - En-092021 RCC PIPEDocumento36 pagineBrochure-Bonna-Pipe - En-092021 RCC PIPENaing Win AungNessuna valutazione finora

- IRC Ammendments 2018Documento31 pagineIRC Ammendments 2018ਸੁਖਬੀਰ ਸਿੰਘ ਮਾਂਗਟ100% (1)

- Recommended Labour Output Constants For Building WorksDocumento2 pagineRecommended Labour Output Constants For Building Worksniraj rai100% (1)

- List of Modules Offered in Academic Year 2013/2014: Department of Civil & Environmental EngineeringDocumento22 pagineList of Modules Offered in Academic Year 2013/2014: Department of Civil & Environmental EngineeringLinus TanNessuna valutazione finora

- Internal and External ExplotionDocumento13 pagineInternal and External ExplotionG Chan KimNessuna valutazione finora

- Concrete Segmental Bridges: Design and Construction ofDocumento8 pagineConcrete Segmental Bridges: Design and Construction ofMinh LinhTinhNessuna valutazione finora

- Yield Line Analysis Analysis of Slab (Handout)Documento5 pagineYield Line Analysis Analysis of Slab (Handout)Gabriel JamesNessuna valutazione finora

- Ehsani Yeganeh, AliDocumento108 pagineEhsani Yeganeh, Alinsm98473Nessuna valutazione finora

- WRN STD 002aDocumento1 paginaWRN STD 002ahenryLYDNessuna valutazione finora

- Concrete Mix Design Calculation For M20, M25, M30 Concrete With Procedure & ExampleDocumento8 pagineConcrete Mix Design Calculation For M20, M25, M30 Concrete With Procedure & ExampleLokeNessuna valutazione finora

- BrickDocumento13 pagineBrickyohannessharew55Nessuna valutazione finora

- Analyze Time-Cost Required For Conventional and Prefabricated Building ComponentsDocumento9 pagineAnalyze Time-Cost Required For Conventional and Prefabricated Building ComponentsAnonymous kw8Yrp0R5rNessuna valutazione finora