Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

LNG Technolog Selection

Caricato da

maheshlavandCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

LNG Technolog Selection

Caricato da

maheshlavandCopyright:

Formati disponibili

81-84

12/15/04

2:01pm

Page 81

n recent years, process selection studies for baseload

LNG production have grown in scope and have increasingly considered multiple cycle options. The reasons

are varied and include interest in larger train capacities, a

desire to minimise CO2 emissions, different compressor

driver arrangements, plus specialised applications such

as floating production storage and offloading (FPSO)

plants, LNG peak shaving and associated gas liquefaction. This article describes the work process used in aiding the LNG plant owner to select the optimal process

technology, along with some specific examples of applications.

Work process

Typically, a process selection study will start with a design

basis prepared by the plant owner or his representative

that defines many of the design parameters to be used in

the study, such as ambient conditions; feed composition

and conditions; process equipment design assumptions

such as pressure drop and heat exchanger approach

temperatures; fuel balance requirements; possible driver

configurations and desired production of LNG and LPGs.

The owner will also give some information on the criteria

to be optimised in the design, for example, maximise production, minimise power, or minimise CO2 emissions.

Preferably, the owner will provide the basis for a cost

function that can incorporate several parameters. This

allows the process licensor to optimally trade off capital

investment for efficiency. By receiving as much information as possible from the plant owner on the criteria that it

will be used for the evaluation, the process licensor can

provide an optimised design that will best meet the

owners objectives.

The first step after the design basis is established is to

perform process simulations. Even when the licensor is

provided with a highly detailed design basis, there are

several unspecified equipment performance parameters

that need to be defined for the process simulation. In particular, parameters that define the performance and

capacity of the compressors and the main cryogenic heat

exchanger (MCHE) are crucial to assessing the performance of a cycle. Ideally, such parameters are calculated

with a model that is embedded in the process simulation

rather than being calculated in another software application. This approach can save time and result in a more

optimal design, particularly if numerical optimisation techniques are used.

For several years Air Products has been using proprietary sequential quadratic programming based techniques to optimise process designs. Several (typically

20 - 50) flowsheet parameters are varied to optimise performance relative to an objective function, while incorporating multiple constraints. The objective function used in

the optimisation can be simply to maximise production or

minimise power at fixed production; or a more sophisticated cost based objective function can be used that considers both capital and operating costs. The method is

superior to older design optimisation methods such as

parametric studies. This is particularly true for optimising

flowsheets that have a large number of variables that are

not linearly independent, like for LNG plants. Air Products

has found that the use of these numerical techniques not

only allows the process engineer to produce significantly

better designs, but perhaps just as important, they also

serve as a check against any unconscious biases the

process designer may have.

To assess compressor performance, Air Products

utilises an in-house compressor efficiency correlation

HYDROCARBON ENGINEERING MAY 2004

Technology

selection

Mark J. Roberts, Dr Yu-Nan Liu, James C.

Bronfenbrenner and James Solomon,Air

Products and Chemicals, Inc., USA,

describe the work process used in

aiding the LNG plant owner to select

the optimal process technology.

81

81-84

12/15/04

2:01pm

Page 82

Applications of

process

technology

Baseload LNG plants

Figure 1. Air Products AP-X process.

Figure 2. AP-X LNG process layout.

(ICEC). ICEC is a program that accurately predicts

inline compressor efficiency and impeller size. The program calculates performance as a function of impeller

size, stage shape characteristics, and Mach number

related effects. ICEC predicts compressor efficiency

within 2 percentage points accuracy, and can be adjusted

to reflect known differences between manufacturers.

Air Products has integrated ICEC into the process

simulation models so that constraints on parameters such

as inlet flow coefficient, peripheral Mach number and

impeller diameters can be met in the converged and optimised simulation. The optimisation routine considers the

effect of the flowsheet variables (pressures, compositions

etc) and the compressor speed on the compression

equipment efficiency and design. Compressor design

constraints are periodically updated to reflect the latest

proven technology available from the compressor suppliers. The use of ICEC eliminates time consuming iterations

with the suppliers, and assures a feasible and near-optimal

design on the first pass. The information from ICEC can

then be translated into known manufacturers frame sizes.

After the final process selection is made, compressor performance parameter specifications are sent to the vendors

to verify both the aerodynamic and mechanical considerations, and to validate the calculated design.

82

The propane pre-cooled, mixed refrigerant LNG process (C3MR) has been

the workhorse of the LNG industry for

more than 30 years. It has been applied

in LNG plants producing from 1 - 5 million tpy of LNG per train, using steam

and gas turbine drivers, sea water and

air cooling, rich and lean feeds containing varying levels of nitrogen, with and

without LPG extraction. The process

has proven to be efficient, flexible, reliable and cost competitive.

For many cases, the C3MR process

remains the optimal solution. In some

cases however, depending on the

design basis and owner preference,

other solutions should be considered.

For example, with very cold ambient

conditions a dual MR process can offer

advantages over C3MR.

In recent years, interest has grown

in ever larger train capacities so that

economies of scale can significantly

reduce the unit cost for LNG. To meet

this requirement, Air Products has

developed and patented the AP-X

LNG process1.

The AP-X LNG process will

increase single train capacities to

7 - 10 million tpy. By producing warmer

LNG at pressure, todays C3MR or dual

MR process capacity can produce up to

80% more LNG with the same proven

equipment in use today. In the AP-X

process, the warmer LNG is then subcooled to storage temperature by a

gaseous nitrogen refrigerant in the

same compression/expansion cycle that has been used for

years to liquefy oxygen, nitrogen, and for peak-shaver natural gas liquefiers. The efficiency of this process is as high as

any in the industry, while the capital cost of the liquefier per

unit of LNG is reduced significantly.

The C3MR version of the AP-X process cycle is

depicted in Figure 1. Similar to the traditional C3MR process,

propane is used to provide cooling to a temperature of

approximately -30 C. The feed is then cooled and liquefied

by mixed refrigerant, exiting the MCHE at a temperature of

approximately -120 C. Final subcooling of the LNG is performed using cold gaseous nitrogen from the nitrogen

expander. Figure 2 shows the equipment layout for the liquefaction and subcooling sections of an AP-X LNG train.

Coil wound heat exchangers are used to liquefy and subcool

the LNG, while the nitrogen economiser uses brazed aluminum plate fin heat exchangers.

The power split between C3, MR, and N2 is flexible, and

can be manipulated by changing the temperature range of

the three refrigerant loops. This feature, and the use of the

Split-MR machinery configuration2, allows considerable

flexibility in matching compressor driver sets, whether Frame

7s, Frame 9s, electric motors or combinations of the above.

The use of electric motors as compressor drivers is gaining increasing interest in the LNG industry. Electricity can be

HYDROCARBON ENGINEERING MAY 2004

81-84

12/15/04

2:01pm

Page 83

generated in a combined cycle power plant to

greatly reduce the CO2 emitted per unit LNG produced. Electric motors are also a very flexible drive

system for the baseload LNG production. Single

train liquefaction capacities from 7 - 10 million tpy

can be easily achieved using electric motors with

the AP-X process, with the specific arrangement

depending upon the desired capacity and the maximum motor size considered proven by the LNG

owner. Systems may also be considered, which

use combinations of electric motor and gas turbine

drive for the refrigeration compressors. With the

use of variable frequency devices, the speed of

each compressor can be optimised not only to

achieve maximum compressor aerodynamic efficiency at a design point, but also across the range

of ambient temperature extremes to maximise

annualised production.

Figure 3. Air Products DMR2 cycle.

FPSO Plants

There is continued interest in a Floating Production

Storage and Offloading (FPSO) facility for baseload LNG service. The design of such a facility presents significant technical challenges, not the least

of which is the selection of the liquefaction cycle.

Developing and selecting a liquefaction cycle suitable for a FPSO facility presents unique challenges to the process licensor. Safety and compactness are particularly important criteria for

FPSO service. Due to the very limited space available aboard a FPSO vessel, there is increased

emphasis on compactness. The heightened concern with safety is related to the geographical isolation and compact nature of a FPSO plant.

Inevitably, operating personnel will be located

closer to the plant equipment than on a land based

plant, and evacuation on a floating plant facility is

problematic.

Figure 4. Air Products DMR2 process plant layout.

In addition to the special emphasis on compactness and safety, the typical issues guiding the

selection of a liquefaction cycle for a land based

plant such as flexibility, efficiency and operability

apply to FPSO facilities as well. The cycle

selected should have the operating flexibility to

handle varying feed compositions and ambient

temperatures, high efficiency in order to maximise

production for a given driver configuration, and

simplicity and operability to enable operating personnel to maximise production and avoid downtime.

To some extent the above considerations can

be competing objectives. For example, more efficient cycles often require more pieces of equipment, which can lead to a less compact design. To

further complicate issues, FPSO facilities have

been proposed to handle a wide variety of feed

compositions and capacities. Air Products has

received inquiries for facilities to handle feed compositions from rich to lean and at design capacities

from 1 - 5 million tpy LNG production. For these

reasons, it is not possible to select a single cycle

as the preferred one for all FPSO opportunities.

The cycle selected for a particular opportunity will

depend on the train capacity, driver selection (gas Figure 5. Peak shaver LNG cycle.

turbine or electric drive), project economics (capital versus power) and owner preference.

mise between the competing objectives at a size range of

The Air Products DMR2 cycle2 is a recently developed

approximately 2 - 4.5 million tpy. A simplified schematic of

dual mixed refrigerant cycle. It represents a good comproHYDROCARBON ENGINEERING MAY 2004

83

81-84

12/15/04

2:01pm

Page 84

this cycle is shown in Figure 3. The condensation of liquids

between compression stages of the warm (pre-cooling)

mixed refrigerant allows this cycle to achieve very close alignment of cooling curves in the warm heat exchanger (HX1),

resulting in a high thermodynamic efficiency.

This cycle offers safety advantages over the propane precooled mixed refrigerant cycle (C3MR) or cascade cycles.

The primary reason is the use of a mixed refrigerant rather

than propane for pre-cooling. In the C3MR and cascade

cycles, there is a significant inventory of propane refrigerant

in multiple vessels and interconnecting piping runs, with the

potential (however remote) for leakage. The Piper Alpha offshore gas processing platform disaster of 1988 provides

much of the basis for this concern. In that incident, an explosion occurred after dense propane gas accumulated at a low

point on the platform4.

The use of a single vapourising pressure for the pre-cooling mixed refrigerant leads to a more compact design compared with other dual mixed refrigerant cycles that use multiple vapourising pressures in the pre-cooling circuit. This

allows the use of a single wound coil heat exchanger for precooling, saving space compared with multiple pressure

designs with multiple pre-cooling exchangers and interconnecting piping. Figure 4 shows the equipment layout for the

liquefaction and subcooling sections of a DMR2 train.

Peak shaving LNG plants

Small LNG plants producing 5 - 20 MMSCFD of LNG are

common in industrialised countries. Typically, these plants

are used for peak shaving in that they produce LNG from

pipeline gas during warm months to be re-vapourised and

consumed during peak demand winter months.

Figure 5 shows a process flowsheet for a typical peak

shaving plant. A closed-loop nitrogen expander cycle provides refrigeration for making LNG. Advances in compressor

84

loaded expander, or compander technology over the last 15

- 20 years have made this type of cycle particularly attractive

for small plants. State-of-the-art high efficiency compander

designs allow this type of cycle to be competitive in efficiency

for small plants. The use of pure nitrogen as a refrigerant

also saves significant cost over a mixed refrigerant cycle,

since there is no need to procure or store hydrocarbon refrigerant components. The use of nitrogen also saves cost in the

refrigerant recycle compressor. Efficient, relatively inexpensive integral gear compressors that are typically used in the

air separation industry can be used for peak shaver LNG

plants using nitrogen recycle technology.

Conclusion

The selection of the optimal LNG liquefaction technology in

the early phases of a project can have a large impact on the

overall profitability. To provide the best possible solution, it is

important that the process licensor has not only a complete

and detailed design basis, but also as much information as

possible on the objective criteria used by the LNG owner to

evaluate proposed solutions. There are several different

cycle and equipment options that can be considered

depending on the project specifics. Air Products objective as

a process licensor is to provide proven process and equipment technology that maximises return on investment to the

LNG owner.

References

1.

2.

3.

4.

ROBERTS, M.J., and AGRAWAL, R., Hybrid Cycle for the Production

of Liquefied Natural Gas, US Patent 6,308,521.

LIU, Y.N., LUCAS, C.E., BOWER, R.W., and BRONFENBRENNER,

J.C., Reducing LNG Costs by better Capital Utilization, LNG 13, May

2001, Seoul, Korea.

ROBERTS, M.J., and AGRAWAL, R., Dual Mixed Refrigerant Cycle for

Gas Liquefaction US Patent 6,119,479.

LEES, F.P., Loss Prevention in the Process Industries, Volume 3, Piper

Alpha, Appendix 19/11, 1996.

HYDROCARBON ENGINEERING MAY 2004

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- 0930-AlexaaDocumento30 pagine0930-AlexaaRuth Pauline HutapeaNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Tight OilDocumento5 pagineTight OilmaheshlavandNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- 1.LTPF 2014 Chapter 05 Pipelines Final Proof Sept 2014Documento19 pagine1.LTPF 2014 Chapter 05 Pipelines Final Proof Sept 2014maheshlavandNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- Flare Pilot System SafetyDocumento5 pagineFlare Pilot System SafetyBehnam HosseinzadehNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Ge LNGDocumento28 pagineGe LNGRoozbeh P100% (1)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Wartsila LNG SystemsDocumento8 pagineWartsila LNG SystemsPandhuNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- IHP Enrollment FormDocumento2 pagineIHP Enrollment FormmaheshlavandNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- SRV NoiseDocumento7 pagineSRV NoisebbmokshNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- List of Funds Offered by DBSDocumento3 pagineList of Funds Offered by DBSmaheshlavandNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- Piping Vibration AnalysisDocumento16 paginePiping Vibration AnalysissimonlubisNessuna valutazione finora

- Flare Pilot System SafetyDocumento5 pagineFlare Pilot System SafetyBehnam HosseinzadehNessuna valutazione finora

- Tight OilDocumento5 pagineTight OilmaheshlavandNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Verification SchemeDocumento22 pagineVerification Schememaheshlavand100% (1)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Hsg253 The Safe Isolation of Plant and EquipmentDocumento81 pagineHsg253 The Safe Isolation of Plant and EquipmentRichard HollidayNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Curve Fitting Excel GuideDocumento14 pagineCurve Fitting Excel GuideFirdaus AzizanNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Hsg253 The Safe Isolation of Plant and EquipmentDocumento81 pagineHsg253 The Safe Isolation of Plant and EquipmentRichard HollidayNessuna valutazione finora

- Curve Fitting Excel GuideDocumento14 pagineCurve Fitting Excel GuideFirdaus AzizanNessuna valutazione finora

- Gulfpub HP 201401Documento103 pagineGulfpub HP 201401maheshlavandNessuna valutazione finora

- Carbon Capture and StorageDocumento7 pagineCarbon Capture and StoragePriyam RamsokulNessuna valutazione finora

- BP 2012 2030 Energy Outlook BookletDocumento88 pagineBP 2012 2030 Energy Outlook BookletRizwan Khan TaoNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Western Area LIC Housing Loan AddressDocumento3 pagineWestern Area LIC Housing Loan AddressmaheshlavandNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- BP 2012 2030 Energy Outlook BookletDocumento88 pagineBP 2012 2030 Energy Outlook BookletRizwan Khan TaoNessuna valutazione finora

- Caterpiller Engine InfoDocumento8 pagineCaterpiller Engine InfomaheshlavandNessuna valutazione finora

- Quantum Mechanics 1Documento88 pagineQuantum Mechanics 1Mehul GuptaNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- JCM Hybrid Controller User ManualDocumento13 pagineJCM Hybrid Controller User ManualMtvc LbNessuna valutazione finora

- Model AR Ellipse® Annular Flow Meter PDFDocumento2 pagineModel AR Ellipse® Annular Flow Meter PDFjhorlanNessuna valutazione finora

- ST Series Servo Motor: Beijing KND CNC Technique Co.,Ltd. 01.2012Documento21 pagineST Series Servo Motor: Beijing KND CNC Technique Co.,Ltd. 01.2012Dinos ArhNessuna valutazione finora

- Proposed Rule: Airworthiness Directives: Cubcrafters, Inc., Model PC18&ndash 160Documento2 pagineProposed Rule: Airworthiness Directives: Cubcrafters, Inc., Model PC18&ndash 160Justia.comNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Hydrographic SurveyDocumento24 pagineHydrographic SurveyKamal Veer100% (1)

- Atmospheric Water Generator DesignDocumento9 pagineAtmospheric Water Generator Designscribd2Nessuna valutazione finora

- Design and Generating Energy As A Car Alternator TDocumento7 pagineDesign and Generating Energy As A Car Alternator TJohnny TestNessuna valutazione finora

- 39CQ Iom 06302014Documento20 pagine39CQ Iom 06302014Non Etabas GadnatamNessuna valutazione finora

- Solutions To ExercisesDocumento47 pagineSolutions To ExercisesNathan D. Gutzmann60% (5)

- EMT2-hw4 - SolDocumento6 pagineEMT2-hw4 - SolSuper SpecialNessuna valutazione finora

- Elective 4 Module1Documento27 pagineElective 4 Module1kentong compraNessuna valutazione finora

- MVDC-Connected Offshore Wind Power Hybrid Resonant ConverterDocumento4 pagineMVDC-Connected Offshore Wind Power Hybrid Resonant ConverterBrightworld ProjectsNessuna valutazione finora

- Cylinder Cutout Cylinder CutoutDocumento12 pagineCylinder Cutout Cylinder CutoutIsrael Miranda ZamarcaNessuna valutazione finora

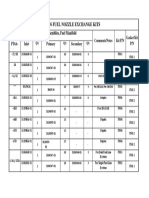

- Pt6 Fuel Nozzle Exchange Kits: Adapter Assemblies, Fuel ManifoldDocumento1 paginaPt6 Fuel Nozzle Exchange Kits: Adapter Assemblies, Fuel ManifoldBerchNessuna valutazione finora

- Futuro Continuo Afirmativo y NegativoDocumento4 pagineFuturo Continuo Afirmativo y NegativoSkoNessuna valutazione finora

- Euler-Ship Mast LocationDocumento61 pagineEuler-Ship Mast LocationzeldaikNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- RAIS PDA AppDocumento8 pagineRAIS PDA Appzaw lin ooNessuna valutazione finora

- SGP Chapter-1Documento81 pagineSGP Chapter-1Shashank ReddyNessuna valutazione finora

- Spe 21970 MSDocumento13 pagineSpe 21970 MSasu jaranNessuna valutazione finora

- Mechatronics Handbook - 02 - Mechatronic Design Approach PDFDocumento16 pagineMechatronics Handbook - 02 - Mechatronic Design Approach PDFJosé Fernando TerronesNessuna valutazione finora

- New Holland Engine F4ge Backhoe en Service ManualDocumento10 pagineNew Holland Engine F4ge Backhoe en Service Manualenrique100% (47)

- JIMMA UNIVERSITY INTERNS' MANUFACTURING EXPERIENCEDocumento41 pagineJIMMA UNIVERSITY INTERNS' MANUFACTURING EXPERIENCEAmanuelNessuna valutazione finora

- (Geoffrey Lawrence, Kristen Lyons, Tabatha Walling (BookFi) PDFDocumento321 pagine(Geoffrey Lawrence, Kristen Lyons, Tabatha Walling (BookFi) PDFIManNessuna valutazione finora

- Kaplan Turbine Working As A Propeller CFD InvestigDocumento11 pagineKaplan Turbine Working As A Propeller CFD InvestigclaudehackerNessuna valutazione finora

- Sungris BrochureDocumento8 pagineSungris Brochurechemasi123Nessuna valutazione finora

- 1004 Saiesh 1005 Brembley 1006 Russell 1007 MukeshDocumento65 pagine1004 Saiesh 1005 Brembley 1006 Russell 1007 MukeshbenonNessuna valutazione finora

- Budget of Lesson Science 9Documento14 pagineBudget of Lesson Science 9Hezl Valerie ArzadonNessuna valutazione finora

- U3 Oxidation and Reduction PPT WatermarkDocumento45 pagineU3 Oxidation and Reduction PPT Watermarkapi-125934329Nessuna valutazione finora

- Dpu96 Sitras PDFDocumento214 pagineDpu96 Sitras PDFConrad Ziebold VanakenNessuna valutazione finora

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsDa EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNessuna valutazione finora

- Guidelines for Chemical Process Quantitative Risk AnalysisDa EverandGuidelines for Chemical Process Quantitative Risk AnalysisValutazione: 5 su 5 stelle5/5 (1)

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksDa EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksValutazione: 5 su 5 stelle5/5 (1)

- Guidelines for the Management of Change for Process SafetyDa EverandGuidelines for the Management of Change for Process SafetyNessuna valutazione finora