Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Bill of Materials and Design Details

Caricato da

kinjalpatel12345Descrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Bill of Materials and Design Details

Caricato da

kinjalpatel12345Copyright:

Formati disponibili

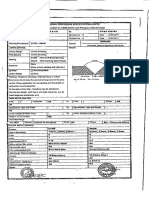

BILL OF MATERIALS

ITEM QTY

50.18

5.92

36.00

18.00

N1

DESCRIPTION

MATERIAL

Pipe - Sch. Std, 12.00 NPS

Head, Pipe Cap - Sch. Std, 12.00 NPS

SA-234 WPB

SA-106B

3

4

5

6

1

1

2

1

Pipe - Sch. 40, 4.00 NPS

Flange, RFSO - 150#, 4.00 NPS

Half Coupling, SW - 3000#, 2.00 NPS

Half Coupling, SW - 3000#, 0.50 NPS

SA-106B

SA-105

SA-105

SA-105

7

8

9

10

2

4

1

1

Plate 0.375" thick

Plate 7.50" x 2.00" x .375"

Code nameplate bracket

Code nameplate

SA-G40.21 38W

SA-G40.21 38W

SA-G40.21 38W

Stainless

NOTES:

8.00

0.125

.38

0.500

2 plc

1.

2.

3.

All dimensions in inches.

All welds shall be neat in appearance, free from slag and other defects.

Vessel to be cleaned of scale, oil,weld spatter and all other foreign material,

prior to hydrostatic test.

4. Remove all sharp edges on nozzles (1/8" minimum radius)

5. All nozzles to support nomial loads only.

6. Grind welds flush under repads.

7. Maximum misalignment of butt joints is limited to .25T (Category A, B, C, D

up to 1/2" thick)

8. Repad to have min. 1/8" telltale hole.

9. All fittings conform to B16.9 standards.

10. All couplings to conform to B16.11 (2011 Add.) standards.

11. All flanges to conform to B16.5 (2009 Add.)/ B16.47 standards.

12. Flange bolt holes to straddle natural centre lines.

1.00

14.38

12.75

N3

N2

12.03

8.81

2

0.250

Typ.

0.250

1

N4

10

0.625 Hole Typ.

2.00

DESIGN DATA

7.00

Design Code:

Seismic Code:

Wind Code:

Design Conditions

MAWP - Int / Ext:

MDMT:

Corrosion Allowance:

Examination

Impact Testing:

Radiography:

PWHT:

Hydro Test:

Service:

Fluid:

Capacity:

Weight - Empty:

Weight - Operating:

Code

11.00

28.00

2.25

31.50

1.25

34.00

REVISIONS

NOZZLE SCHEDULE

NOZZLE

WELDS

Mark Size Qty. Service

Type

41

UW-16.1 (c) with 0.250

inside projection

FLANGES

42

43

Type

0.250

Slip on

SB

F1

F2

4"

Vent

N2

2"

Inlet

UW-16.1(c)

0.313

N3

2"

Outlet

UW-16.1(c)

0.313

0.50"

Drain

UW-16.1(c)

0.250

0.375 0.250 0.375

BOM

ITEM #

N1

SB

F2

F1

Slip On Flange

Outside

Typ. Circ. Seam

41

41

Outside

Shell

UW-16.1 (c)

REVISION HISTORY

DATE

DRW

CHK

Release

3/21/2012

KM

LB

XYZ Vessel Corp.

123 Basic Street

Seatown, Ontario, Canada

X1Y 2Z3

xyz

Nozzle

Typ.

REV.

3,4

43

Nozzle

N4

ASME VIII-1 2007 Ed. 2008 Add.

N/A

N/A

200 / 0 psi @ 300 F

-20 F @ 150 psi

0

None per UG-20(f) 1-5

None

None

260 psi @ Ambient

Air / Water / Steam

6 cu. ft.

250 lbs

450 lbs

Outside

Shell

UW-16.1 (c) with

inside projection

Full

Pen.

Certified by

XYZ Vessel Corp.

(Name of Manufacturer)

psi

at

F

500

150

Max. allowable working pressure (MAWP)

500 F

15

psi

at

Max. allowable external working pressure

at

150 psi

-20 F

Min. Design Metal Temperature (MDMT)

-

To Follow

CRN

Manufacturer's serial number

2012

Year built

Eng

Pressure Vessel Engineering, Ltd.

120 Randall Drive, Suite B

Waterloo, Ontario, Canada

N2V 1C6

www.pveng.com

info@pveng.com

Tel. 519-880-9808

Fax 519-880-9810

Title

Design Calcs Sample

Size

Scale

Job ID

Drawing No.

PVE-5918

1:8

Material

See BOM

Design Calcs Sample

Sheet

Revision:

1 OF 1

This drawing and the information herein is confidential, and must not be reproduced

or used in any way without the written permission of Pressure Vessel Engineering Ltd.

Potrebbero piacerti anche

- Sample2 DrawingDocumento1 paginaSample2 DrawingganeshNessuna valutazione finora

- Pipeline Welding Procedure SpecificationDocumento11 paginePipeline Welding Procedure SpecificationVijo Jose100% (1)

- PVEdwg 6847 0.0 MFG - VesselDocumento1 paginaPVEdwg 6847 0.0 MFG - VesselglazetmNessuna valutazione finora

- Sample8 DrawingDocumento1 paginaSample8 DrawingRam Kumar NNessuna valutazione finora

- Bill of Materials and Engineering DrawingsDocumento1 paginaBill of Materials and Engineering DrawingsFaull JackmanNessuna valutazione finora

- Sample13 DrawingDocumento2 pagineSample13 DrawingSourav HaitNessuna valutazione finora

- 40SS Series: High Pressure Stainless Steel FilterDocumento8 pagine40SS Series: High Pressure Stainless Steel FilterYair Alexis Muñoz RojasNessuna valutazione finora

- 1 1610 110Documento4 pagine1 1610 110MuhammedHafisNessuna valutazione finora

- Protect equipment and processes with a compact line strainerDocumento3 pagineProtect equipment and processes with a compact line strainersanthoshkrishnaNessuna valutazione finora

- HCPL 3120 HCPL J312 HCNW3120 25 Amp Output Current IGBT Gate Drive OptocouplerDocumento24 pagineHCPL 3120 HCPL J312 HCNW3120 25 Amp Output Current IGBT Gate Drive OptocouplerMaikel MenkeNessuna valutazione finora

- AR029022.001 (Filtro - ITEM 616A) HHDocumento1 paginaAR029022.001 (Filtro - ITEM 616A) HHJohan PintoNessuna valutazione finora

- AR029022.001 (Filtro - ITEM 616A) (1) CCDocumento1 paginaAR029022.001 (Filtro - ITEM 616A) (1) CCJohan PintoNessuna valutazione finora

- Sample2 DrawingDocumento1 paginaSample2 DrawingSourav HaitNessuna valutazione finora

- Valcor Scientific Industrial SV75Documento2 pagineValcor Scientific Industrial SV75Carlitos RuizNessuna valutazione finora

- Ultra-miniature Surface Mount DIP SwitchesDocumento3 pagineUltra-miniature Surface Mount DIP SwitchesAAurelianNessuna valutazione finora

- PCB ConnectorsDocumento83 paginePCB ConnectorsMuhammad ZakaNessuna valutazione finora

- SMD FusesDocumento5 pagineSMD FusesatentinNessuna valutazione finora

- Brochure 3Documento12 pagineBrochure 3Gohilakrishnan ThiagarajanNessuna valutazione finora

- Material PropertiesDocumento4 pagineMaterial Propertiesbratkp100% (1)

- AGIP STD - Valves Specification SheetDocumento1 paginaAGIP STD - Valves Specification Sheethalim_kaNessuna valutazione finora

- AGIP STD - Valves Specification SheetDocumento1 paginaAGIP STD - Valves Specification Sheethalim_kaNessuna valutazione finora

- 8 Position Dip SwitchDocumento2 pagine8 Position Dip SwitchChai SilwanusNessuna valutazione finora

- AWACASTpartsDocumento3 pagineAWACASTpartsMario Alfonso Maldonado BahamondeNessuna valutazione finora

- AGIP STD - Valves Specification SheetDocumento1 paginaAGIP STD - Valves Specification Sheethalim_kaNessuna valutazione finora

- Thermocouples and Thermowells SpecificationDocumento26 pagineThermocouples and Thermowells SpecificationJeff Stadnik100% (3)

- Vishay Siliconix: Features Product SummaryDocumento8 pagineVishay Siliconix: Features Product Summaryaldo_suviNessuna valutazione finora

- Data Sheet: HCPL-3120/J312 HCNW3120Documento27 pagineData Sheet: HCPL-3120/J312 HCNW3120onafetsNessuna valutazione finora

- FX96 ECHO FX Circuit Diagram BreakdownDocumento3 pagineFX96 ECHO FX Circuit Diagram Breakdown大石 真義Nessuna valutazione finora

- WPS PQR PDFDocumento23 pagineWPS PQR PDFtomj9104Nessuna valutazione finora

- Valve Description Code PagesDocumento13 pagineValve Description Code PagesAdrian GallegosNessuna valutazione finora

- Si 4368 DyDocumento9 pagineSi 4368 DyChristopher RiceNessuna valutazione finora

- AGIP STD - Valves Specification SheetDocumento1 paginaAGIP STD - Valves Specification Sheethalim_kaNessuna valutazione finora

- Omron Industrial Automation: G9Sa Safety Relay UnitsDocumento90 pagineOmron Industrial Automation: G9Sa Safety Relay UnitsDenyNessuna valutazione finora

- IsometricsDocumento4 pagineIsometricsMuhammedHafisNessuna valutazione finora

- NW FlangeDocumento11 pagineNW FlangeStanley PeterNessuna valutazione finora

- RVBD 10 - 520 P 030520 enDocumento2 pagineRVBD 10 - 520 P 030520 enfeironmaidenNessuna valutazione finora

- Piping Material Specification RatingsDocumento4 paginePiping Material Specification RatingsPrasanta Kumar BeheraNessuna valutazione finora

- AGIP STD - Valves Specification SheetDocumento1 paginaAGIP STD - Valves Specification Sheethalim_kaNessuna valutazione finora

- MK SeriesDocumento13 pagineMK Seriesishak789Nessuna valutazione finora

- Staal 40: Gate ValvesDocumento8 pagineStaal 40: Gate ValvesEric LarrondoNessuna valutazione finora

- 2-01201-N-T-019 R05 Diseño de TuberiasDocumento55 pagine2-01201-N-T-019 R05 Diseño de TuberiasnarufredNessuna valutazione finora

- PCB Connectors: Series 851Documento4 paginePCB Connectors: Series 851Neil Benbin BarteNessuna valutazione finora

- Manual Monitors 2 PDFDocumento17 pagineManual Monitors 2 PDFjulian sanchezNessuna valutazione finora

- Special Purpose Basic SwitchDocumento5 pagineSpecial Purpose Basic Switchng_viet_cuong_groupNessuna valutazione finora

- ITAP Pressure Reducing Valves GuideDocumento41 pagineITAP Pressure Reducing Valves GuidekelvinNessuna valutazione finora

- HCPL J312Documento24 pagineHCPL J312Sergiu BadalutaNessuna valutazione finora

- NTS4101P Power MOSFET: 20 V, 1.37 A, Single P Channel, SC 70Documento5 pagineNTS4101P Power MOSFET: 20 V, 1.37 A, Single P Channel, SC 70Jalil AhmedNessuna valutazione finora

- Vishay Siliconix: Features Product SummaryDocumento8 pagineVishay Siliconix: Features Product SummaryMhd SayutiNessuna valutazione finora

- 60 Series Tube Fitting 150123Documento7 pagine60 Series Tube Fitting 150123Nilesh MistryNessuna valutazione finora

- 1 ATI Stellram U INCIMA DimenzijeDocumento8 pagine1 ATI Stellram U INCIMA DimenzijeBosko LukavicNessuna valutazione finora

- Bom Sr. Sample QtyDocumento3 pagineBom Sr. Sample QtySiddharth GuptaNessuna valutazione finora

- MDMT Calculations For A Pressure Vessel - Abdel Halim GalalaDocumento12 pagineMDMT Calculations For A Pressure Vessel - Abdel Halim Galalabego00Nessuna valutazione finora

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDa EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNessuna valutazione finora

- Design Guidelines for Surface Mount TechnologyDa EverandDesign Guidelines for Surface Mount TechnologyValutazione: 5 su 5 stelle5/5 (1)

- All-in-One Manual of Industrial Piping Practice and MaintenanceDa EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceValutazione: 5 su 5 stelle5/5 (1)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDa EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsValutazione: 4.5 su 5 stelle4.5/5 (10)

- Materials Data for Cyclic Loading: Low-Alloy SteelsDa EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsValutazione: 5 su 5 stelle5/5 (2)

- Flare Types and ComponentsDocumento6 pagineFlare Types and Componentskinjalpatel12345Nessuna valutazione finora

- Outotec - Seismic Design of Elevated Slurry Storage Tanks For As NZS 1170 (Rosart)Documento8 pagineOutotec - Seismic Design of Elevated Slurry Storage Tanks For As NZS 1170 (Rosart)Serguei DobrinNessuna valutazione finora

- Assessing Plans For Inspection and Testing of New Storage TanksDocumento8 pagineAssessing Plans For Inspection and Testing of New Storage TanksKhepa BabaNessuna valutazione finora

- Upstream Oil & Gas: Operational Certainty ConsultingDocumento5 pagineUpstream Oil & Gas: Operational Certainty Consultingkinjalpatel12345Nessuna valutazione finora

- Tanks Lecture 3Documento70 pagineTanks Lecture 3zikzak2011Nessuna valutazione finora

- Contagious DiseaseDocumento2 pagineContagious Diseasekinjalpatel12345Nessuna valutazione finora

- Storage Tank Design Calculations - Seismic Design & Overturning Moment - by Abdel Halim GalalaDocumento10 pagineStorage Tank Design Calculations - Seismic Design & Overturning Moment - by Abdel Halim Galalamarkfgt57% (7)

- Comparative Study of Seismic Performance of Reinforced Concrete Building Designed Accordance With Indian Codes and American CodesDocumento9 pagineComparative Study of Seismic Performance of Reinforced Concrete Building Designed Accordance With Indian Codes and American Codeskinjalpatel12345Nessuna valutazione finora

- Tank DesignDocumento164 pagineTank DesignTarun ChandraNessuna valutazione finora

- IEC 60617-10-1996 ScanDocumento81 pagineIEC 60617-10-1996 Scankinjalpatel12345Nessuna valutazione finora

- Germ Theory: Microorganisms Cause DiseaseDocumento13 pagineGerm Theory: Microorganisms Cause Diseasekinjalpatel12345Nessuna valutazione finora

- 2020 Coronavirus Pandemic in IndiaDocumento32 pagine2020 Coronavirus Pandemic in Indiakinjalpatel12345Nessuna valutazione finora

- Coronavirus Cases:: Watch Full Episodes For FreeDocumento19 pagineCoronavirus Cases:: Watch Full Episodes For Freekinjalpatel12345Nessuna valutazione finora

- World PopulationDocumento3 pagineWorld Populationkinjalpatel12345Nessuna valutazione finora

- IEC 60617-8-1996 Scan PDFDocumento38 pagineIEC 60617-8-1996 Scan PDFkinjalpatel12345Nessuna valutazione finora

- IEC 60617-6-1996 Scan PDFDocumento56 pagineIEC 60617-6-1996 Scan PDFkinjalpatel12345Nessuna valutazione finora

- IEC 60617-9-1996 Scan PDFDocumento45 pagineIEC 60617-9-1996 Scan PDFkinjalpatel12345Nessuna valutazione finora

- Performance of One UnitDocumento1 paginaPerformance of One Unitkinjalpatel12345Nessuna valutazione finora

- IEC 60617-11-1996 ScanDocumento60 pagineIEC 60617-11-1996 Scankinjalpatel12345Nessuna valutazione finora

- Configure SPLM2012 Standalone LaptopDocumento1 paginaConfigure SPLM2012 Standalone Laptopkinjalpatel12345Nessuna valutazione finora

- Student Transfer Application FormDocumento1 paginaStudent Transfer Application Formkinjalpatel12345Nessuna valutazione finora

- Hatha Yoga Pradipika PDFDocumento102 pagineHatha Yoga Pradipika PDFlovablesagi100% (1)

- IDT2016 Malaysia Agenda-Rev20160212Documento1 paginaIDT2016 Malaysia Agenda-Rev20160212kinjalpatel12345Nessuna valutazione finora

- API510 Aug17+TUV&IICS5 5 Ultrsonic Nov17Documento10 pagineAPI510 Aug17+TUV&IICS5 5 Ultrsonic Nov17kinjalpatel12345Nessuna valutazione finora

- T 9 HxspecenglishDocumento1 paginaT 9 Hxspecenglishkinjalpatel12345Nessuna valutazione finora

- Ijiset V1 I6 72 PDFDocumento6 pagineIjiset V1 I6 72 PDFkinjalpatel12345Nessuna valutazione finora

- Tubesheets For U-Tube Heat ExchangersDocumento2 pagineTubesheets For U-Tube Heat Exchangerskinjalpatel12345Nessuna valutazione finora

- Finite Element Analysis Optimizes Tube Sheet ThicknessDocumento11 pagineFinite Element Analysis Optimizes Tube Sheet Thicknesssagar1503Nessuna valutazione finora

- How To Reduce Your Tax PaymentFY 2017-2018 - Businees League 4Documento1 paginaHow To Reduce Your Tax PaymentFY 2017-2018 - Businees League 4kinjalpatel12345Nessuna valutazione finora

- Design of Bolted Flange Joints PD386 Updated November 2010 1Documento1 paginaDesign of Bolted Flange Joints PD386 Updated November 2010 1kinjalpatel12345Nessuna valutazione finora

- Requirements in Executing A Hot Tap - ION PRODocumento25 pagineRequirements in Executing A Hot Tap - ION PROHous BoukadoNessuna valutazione finora

- Simple DistillationDocumento5 pagineSimple DistillationJheian Christian TubleNessuna valutazione finora

- L&L - Sandipan - Inlet Facilities LNG ProjectsDocumento34 pagineL&L - Sandipan - Inlet Facilities LNG ProjectsankitalalwaniNessuna valutazione finora

- Equipamentos E Processos Térmicos (Equipment and Thermal Processes) ERASMUS - Workgroup 2Documento12 pagineEquipamentos E Processos Térmicos (Equipment and Thermal Processes) ERASMUS - Workgroup 2taha akbulatNessuna valutazione finora

- Effect of Lean Amine Temperature on Gas SweeteningDocumento5 pagineEffect of Lean Amine Temperature on Gas SweeteningYorman Zambrano SilvaNessuna valutazione finora

- Module 4 - Part 3Documento76 pagineModule 4 - Part 3916 Maneesh nn ME BNessuna valutazione finora

- Siare Perseo - Service ManualDocumento55 pagineSiare Perseo - Service ManualsolcarwxNessuna valutazione finora

- 9 - Cone NozzleDocumento2 pagine9 - Cone NozzleSinalau ButodNessuna valutazione finora

- Global Warming: Air Is The Name Given To Atmosphere Used inDocumento15 pagineGlobal Warming: Air Is The Name Given To Atmosphere Used insamoooonNessuna valutazione finora

- Piping Inspection and Test PlanDocumento22 paginePiping Inspection and Test PlanHaythem Ben Zid100% (1)

- Empirical DeliverabilityDocumento199 pagineEmpirical Deliverabilitymath62210Nessuna valutazione finora

- Owners Manual-Z Milpro ERB-380 ERB-400Documento27 pagineOwners Manual-Z Milpro ERB-380 ERB-400Andre Vidal N. SNessuna valutazione finora

- Facility Flare ReductionDocumento46 pagineFacility Flare Reductioneng_ahrNessuna valutazione finora

- CH 6 - 2 Differential Analysis of Fluid Flow Part II WebDocumento55 pagineCH 6 - 2 Differential Analysis of Fluid Flow Part II WebasifNessuna valutazione finora

- 4 Sep - hor.ReEntrainment Articulo1Documento10 pagine4 Sep - hor.ReEntrainment Articulo1Humberto Pallares100% (1)

- 61 MC Elvain Cave Durand Bingham Fluids HR ValueDocumento12 pagine61 MC Elvain Cave Durand Bingham Fluids HR Valueharoub_nasNessuna valutazione finora

- pb3-06 510series Broc QX PDFDocumento8 paginepb3-06 510series Broc QX PDFJaime LondoñoNessuna valutazione finora

- SCES3083 Topic 5 FluidDocumento44 pagineSCES3083 Topic 5 Fluid胡佳玲Nessuna valutazione finora

- Catalog Ach OldDocumento25 pagineCatalog Ach Oldprakash1010Nessuna valutazione finora

- Acv 12Documento2 pagineAcv 12Ali BabasidiNessuna valutazione finora

- Pumps Catalog en PDFDocumento36 paginePumps Catalog en PDFHABIB PIRZADANessuna valutazione finora

- PET 332 E Production Engineering & Surface FacilitiesDocumento13 paginePET 332 E Production Engineering & Surface Facilities000Nessuna valutazione finora

- Mandalina Ghosh (Greenhouse Effect)Documento13 pagineMandalina Ghosh (Greenhouse Effect)amrittapadarNessuna valutazione finora

- Gas Laws Worksheet #2 Boyles Charles and CombinedDocumento2 pagineGas Laws Worksheet #2 Boyles Charles and CombinedRaymond Scott100% (1)

- physics reddytubeDocumento4 paginephysics reddytubepp2922192Nessuna valutazione finora

- F3-Flow Through A NozzleDocumento21 pagineF3-Flow Through A NozzleTAN PANG ZORNessuna valutazione finora

- 8.8 Calculation of Fugacity (Liquids) : Example S8.1 Vapor and Liquid Fugacities Using The Virial EquationDocumento1 pagina8.8 Calculation of Fugacity (Liquids) : Example S8.1 Vapor and Liquid Fugacities Using The Virial EquationtruffeloveNessuna valutazione finora

- COP of Refrigerator by Using PH ChartDocumento16 pagineCOP of Refrigerator by Using PH ChartMuhammad MashamNessuna valutazione finora

- Refrigerant Service ToolsDocumento10 pagineRefrigerant Service ToolsHoàngViệtAnhNessuna valutazione finora